Railways Exam > Railways Questions > For a given level of safety stock and EOQ or...

Start Learning for Free

For a given level of safety stock and EOQ ordering

- a)The Reorder point depends only on the rate of consumption

- b)The Reorder point is independent of the rate of consumption

- c)The Reorder point depends only on the lead time

- d)The Reorder point depends upon the rate of consumption and lead time

Correct answer is option 'D'. Can you explain this answer?

| FREE This question is part of | Download PDF Attempt this Test |

Verified Answer

For a given level of safety stock and EOQ orderinga)The Reorder point...

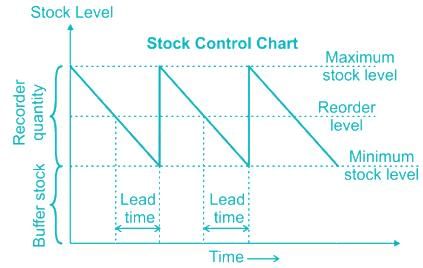

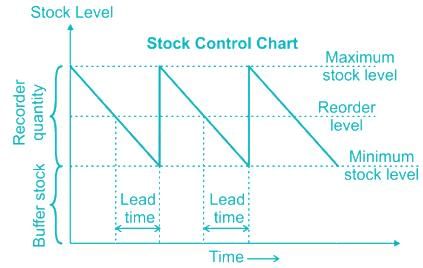

The inventory level at which the order is placed is called the reorder point.

View all questions of this test

Lead time (L) is the time between placing and receiving an order

Reorder point = daily demand × lead time + safety stock

Important Points

- Safety stock is the buffer and is defined as the difference between the reorder level and the lead time demand. It is the buffer that we have to make sure that demand that exceeds the lead time demand is met during lead time.

- The safety stock or buffer stock function concerns short range variation in either demand or replacement. A great deal of inventory planning is devoted to determining the size of safety stocks. Safety stock provides protection against two types of uncertainty with sales in excess of forecast during the replenishment period. The second type of uncertainty concerns delays in replenishment.

- The reorder point is the inventory level at which a new order is placed. The order must be placed while there is enough stock in place to cover demand during lead time.

- The inventory level might be depleted at a slower or faster rate during lead time. When demand is uncertain, safety stock is added as a hedge against stock-out

Most Upvoted Answer

For a given level of safety stock and EOQ orderinga)The Reorder point...

Explanation:

Reorder point is the level of inventory at which an order should be placed for replenishment. It is a critical factor in inventory management as it ensures that the stock is always available to meet the demand. The reorder point is determined by the safety stock, the rate of consumption, and the lead time.

a) The Reorder point depends only on the rate of consumption:

This statement is incorrect because the reorder point is not solely dependent on the rate of consumption. While the rate of consumption is a crucial factor in determining the reorder point, other factors like safety stock and lead time also play a crucial role.

b) The Reorder point is independent of the rate of consumption:

This statement is incorrect because the reorder point is dependent on the rate of consumption. The higher the rate of consumption, the faster the inventory will be depleted, and the earlier the reorder point will be reached.

c) The Reorder point depends only on the lead time:

This statement is incorrect because the reorder point is not solely dependent on the lead time. While lead time is an essential factor in determining the reorder point, other factors like safety stock and the rate of consumption also play a crucial role.

d) The Reorder point depends upon the rate of consumption and lead time:

This statement is correct. The reorder point is determined by the safety stock, the rate of consumption, and the lead time. The safety stock is the buffer stock maintained to meet unexpected demand or delays in the supply chain. The rate of consumption determines how fast the inventory will be depleted, while the lead time is the time taken for the supplier to deliver the order. The reorder point is calculated as:

Reorder Point = (Rate of Consumption * Lead Time) + Safety Stock

Therefore, the reorder point is dependent on both the rate of consumption and lead time.

Reorder point is the level of inventory at which an order should be placed for replenishment. It is a critical factor in inventory management as it ensures that the stock is always available to meet the demand. The reorder point is determined by the safety stock, the rate of consumption, and the lead time.

a) The Reorder point depends only on the rate of consumption:

This statement is incorrect because the reorder point is not solely dependent on the rate of consumption. While the rate of consumption is a crucial factor in determining the reorder point, other factors like safety stock and lead time also play a crucial role.

b) The Reorder point is independent of the rate of consumption:

This statement is incorrect because the reorder point is dependent on the rate of consumption. The higher the rate of consumption, the faster the inventory will be depleted, and the earlier the reorder point will be reached.

c) The Reorder point depends only on the lead time:

This statement is incorrect because the reorder point is not solely dependent on the lead time. While lead time is an essential factor in determining the reorder point, other factors like safety stock and the rate of consumption also play a crucial role.

d) The Reorder point depends upon the rate of consumption and lead time:

This statement is correct. The reorder point is determined by the safety stock, the rate of consumption, and the lead time. The safety stock is the buffer stock maintained to meet unexpected demand or delays in the supply chain. The rate of consumption determines how fast the inventory will be depleted, while the lead time is the time taken for the supplier to deliver the order. The reorder point is calculated as:

Reorder Point = (Rate of Consumption * Lead Time) + Safety Stock

Therefore, the reorder point is dependent on both the rate of consumption and lead time.

Attention Railways Students!

To make sure you are not studying endlessly, EduRev has designed Railways study material, with Structured Courses, Videos, & Test Series. Plus get personalized analysis, doubt solving and improvement plans to achieve a great score in Railways.

|

Explore Courses for Railways exam

|

|

Similar Railways Doubts

For a given level of safety stock and EOQ orderinga)The Reorder point depends only on the rate of consumptionb)The Reorder point is independent of the rate of consumptionc)The Reorder point depends only on the lead timed)The Reorder point depends upon the rate of consumption and lead timeCorrect answer is option 'D'. Can you explain this answer?

Question Description

For a given level of safety stock and EOQ orderinga)The Reorder point depends only on the rate of consumptionb)The Reorder point is independent of the rate of consumptionc)The Reorder point depends only on the lead timed)The Reorder point depends upon the rate of consumption and lead timeCorrect answer is option 'D'. Can you explain this answer? for Railways 2024 is part of Railways preparation. The Question and answers have been prepared according to the Railways exam syllabus. Information about For a given level of safety stock and EOQ orderinga)The Reorder point depends only on the rate of consumptionb)The Reorder point is independent of the rate of consumptionc)The Reorder point depends only on the lead timed)The Reorder point depends upon the rate of consumption and lead timeCorrect answer is option 'D'. Can you explain this answer? covers all topics & solutions for Railways 2024 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for For a given level of safety stock and EOQ orderinga)The Reorder point depends only on the rate of consumptionb)The Reorder point is independent of the rate of consumptionc)The Reorder point depends only on the lead timed)The Reorder point depends upon the rate of consumption and lead timeCorrect answer is option 'D'. Can you explain this answer?.

For a given level of safety stock and EOQ orderinga)The Reorder point depends only on the rate of consumptionb)The Reorder point is independent of the rate of consumptionc)The Reorder point depends only on the lead timed)The Reorder point depends upon the rate of consumption and lead timeCorrect answer is option 'D'. Can you explain this answer? for Railways 2024 is part of Railways preparation. The Question and answers have been prepared according to the Railways exam syllabus. Information about For a given level of safety stock and EOQ orderinga)The Reorder point depends only on the rate of consumptionb)The Reorder point is independent of the rate of consumptionc)The Reorder point depends only on the lead timed)The Reorder point depends upon the rate of consumption and lead timeCorrect answer is option 'D'. Can you explain this answer? covers all topics & solutions for Railways 2024 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for For a given level of safety stock and EOQ orderinga)The Reorder point depends only on the rate of consumptionb)The Reorder point is independent of the rate of consumptionc)The Reorder point depends only on the lead timed)The Reorder point depends upon the rate of consumption and lead timeCorrect answer is option 'D'. Can you explain this answer?.

Solutions for For a given level of safety stock and EOQ orderinga)The Reorder point depends only on the rate of consumptionb)The Reorder point is independent of the rate of consumptionc)The Reorder point depends only on the lead timed)The Reorder point depends upon the rate of consumption and lead timeCorrect answer is option 'D'. Can you explain this answer? in English & in Hindi are available as part of our courses for Railways.

Download more important topics, notes, lectures and mock test series for Railways Exam by signing up for free.

Here you can find the meaning of For a given level of safety stock and EOQ orderinga)The Reorder point depends only on the rate of consumptionb)The Reorder point is independent of the rate of consumptionc)The Reorder point depends only on the lead timed)The Reorder point depends upon the rate of consumption and lead timeCorrect answer is option 'D'. Can you explain this answer? defined & explained in the simplest way possible. Besides giving the explanation of

For a given level of safety stock and EOQ orderinga)The Reorder point depends only on the rate of consumptionb)The Reorder point is independent of the rate of consumptionc)The Reorder point depends only on the lead timed)The Reorder point depends upon the rate of consumption and lead timeCorrect answer is option 'D'. Can you explain this answer?, a detailed solution for For a given level of safety stock and EOQ orderinga)The Reorder point depends only on the rate of consumptionb)The Reorder point is independent of the rate of consumptionc)The Reorder point depends only on the lead timed)The Reorder point depends upon the rate of consumption and lead timeCorrect answer is option 'D'. Can you explain this answer? has been provided alongside types of For a given level of safety stock and EOQ orderinga)The Reorder point depends only on the rate of consumptionb)The Reorder point is independent of the rate of consumptionc)The Reorder point depends only on the lead timed)The Reorder point depends upon the rate of consumption and lead timeCorrect answer is option 'D'. Can you explain this answer? theory, EduRev gives you an

ample number of questions to practice For a given level of safety stock and EOQ orderinga)The Reorder point depends only on the rate of consumptionb)The Reorder point is independent of the rate of consumptionc)The Reorder point depends only on the lead timed)The Reorder point depends upon the rate of consumption and lead timeCorrect answer is option 'D'. Can you explain this answer? tests, examples and also practice Railways tests.

|

Explore Courses for Railways exam

|

|

Suggested Free Tests

Signup for Free!

Signup to see your scores go up within 7 days! Learn & Practice with 1000+ FREE Notes, Videos & Tests.