Railways Exam > Railways Questions > Too low welding current in arc welding would...

Start Learning for Free

Too low welding current in arc welding would result in

- a)Excessive piling up of weld metal, poor penetration, wasted electrodes

- b)Excessive spatter, under cutting along edges, irregular deposits, wasted electrodes

- c)Too small bead, weak weld, and wasted electrodes

- d)None of the above

Correct answer is option 'A'. Can you explain this answer?

| FREE This question is part of | Download PDF Attempt this Test |

Verified Answer

Too low welding current in arc welding would result ina)Excessive pil...

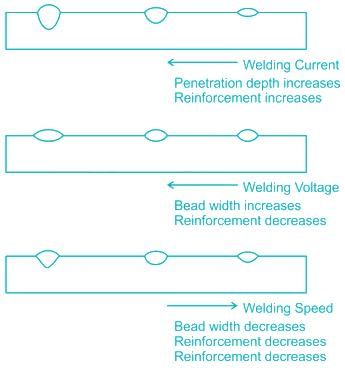

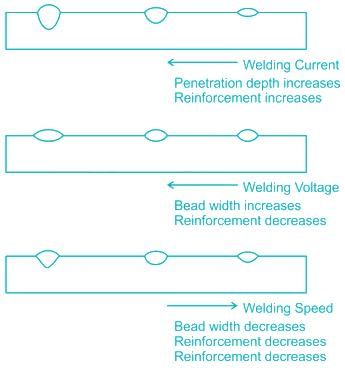

Electrode wire size, welding voltage, current and speed are the four most important welding variables apart from flux.

View all questions of this test

Welding current is the most influential variable as it controls electrode melting rate, depth of penetration and the amount of base metal fused. However, very high current shall lead to too much penetration resulting in burn through in the metal being joined, excessive reinforcement and increased weld shrinkage and, therefore, a large amount of distortion. On the other hand, low current shall lead to insufficient penetration, lack of fusion and unstable arc.

If the welding speed is increased, power or heat input per unit length of the weld is decreased, less welding material is applied per unit length of the weld, and consequently less weld reinforcement results and penetration decreases. Travel speed is used primarily to control bead size and penetration. It is interdependent with the current.

Excessive high travel speed decreases wetting action, increases the tendency for undercut, arc blow, porosity and uneven bead shapes while slower travel speed reduces the tendency to porosity and slag inclusion.

- Too low welding current in arc welding would result in excessive piling up of weld metal

- Too high welding current in arc welding would result in excessive spatter

- Too fast welding speed in arc welding would result in the too small bead

Most Upvoted Answer

Too low welding current in arc welding would result ina)Excessive pil...

Explanation:

Arc welding is a process that uses an electric arc to join metal parts. The welding current is one of the key parameters in the arc welding process. If the welding current is too low, it can cause several problems, including:

Excessive piling up of weld metal: When the welding current is too low, the weld pool may not be hot enough to melt the base metal properly. This can result in the deposition of excess weld metal, which can cause problems like poor penetration, lack of fusion, and porosity.

Poor penetration: Low welding current can cause poor penetration because the weld pool may not be hot enough to melt the base metal properly. This can result in a weak weld joint that is susceptible to failure.

Wasted electrodes: Low welding current can cause excessive electrode consumption because the electrode may not be able to maintain a stable arc. This can result in frequent electrode changes, which can increase the cost of the welding process.

Therefore, it is important to maintain the correct welding current to ensure a high-quality weld joint.

Arc welding is a process that uses an electric arc to join metal parts. The welding current is one of the key parameters in the arc welding process. If the welding current is too low, it can cause several problems, including:

Excessive piling up of weld metal: When the welding current is too low, the weld pool may not be hot enough to melt the base metal properly. This can result in the deposition of excess weld metal, which can cause problems like poor penetration, lack of fusion, and porosity.

Poor penetration: Low welding current can cause poor penetration because the weld pool may not be hot enough to melt the base metal properly. This can result in a weak weld joint that is susceptible to failure.

Wasted electrodes: Low welding current can cause excessive electrode consumption because the electrode may not be able to maintain a stable arc. This can result in frequent electrode changes, which can increase the cost of the welding process.

Therefore, it is important to maintain the correct welding current to ensure a high-quality weld joint.

Attention Railways Students!

To make sure you are not studying endlessly, EduRev has designed Railways study material, with Structured Courses, Videos, & Test Series. Plus get personalized analysis, doubt solving and improvement plans to achieve a great score in Railways.

|

Explore Courses for Railways exam

|

|

Similar Railways Doubts

Too low welding current in arc welding would result ina)Excessive piling up of weld metal, poor penetration, wasted electrodesb)Excessive spatter, under cutting along edges, irregular deposits, wasted electrodesc)Too small bead, weak weld, and wasted electrodesd)None of the aboveCorrect answer is option 'A'. Can you explain this answer?

Question Description

Too low welding current in arc welding would result ina)Excessive piling up of weld metal, poor penetration, wasted electrodesb)Excessive spatter, under cutting along edges, irregular deposits, wasted electrodesc)Too small bead, weak weld, and wasted electrodesd)None of the aboveCorrect answer is option 'A'. Can you explain this answer? for Railways 2024 is part of Railways preparation. The Question and answers have been prepared according to the Railways exam syllabus. Information about Too low welding current in arc welding would result ina)Excessive piling up of weld metal, poor penetration, wasted electrodesb)Excessive spatter, under cutting along edges, irregular deposits, wasted electrodesc)Too small bead, weak weld, and wasted electrodesd)None of the aboveCorrect answer is option 'A'. Can you explain this answer? covers all topics & solutions for Railways 2024 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for Too low welding current in arc welding would result ina)Excessive piling up of weld metal, poor penetration, wasted electrodesb)Excessive spatter, under cutting along edges, irregular deposits, wasted electrodesc)Too small bead, weak weld, and wasted electrodesd)None of the aboveCorrect answer is option 'A'. Can you explain this answer?.

Too low welding current in arc welding would result ina)Excessive piling up of weld metal, poor penetration, wasted electrodesb)Excessive spatter, under cutting along edges, irregular deposits, wasted electrodesc)Too small bead, weak weld, and wasted electrodesd)None of the aboveCorrect answer is option 'A'. Can you explain this answer? for Railways 2024 is part of Railways preparation. The Question and answers have been prepared according to the Railways exam syllabus. Information about Too low welding current in arc welding would result ina)Excessive piling up of weld metal, poor penetration, wasted electrodesb)Excessive spatter, under cutting along edges, irregular deposits, wasted electrodesc)Too small bead, weak weld, and wasted electrodesd)None of the aboveCorrect answer is option 'A'. Can you explain this answer? covers all topics & solutions for Railways 2024 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for Too low welding current in arc welding would result ina)Excessive piling up of weld metal, poor penetration, wasted electrodesb)Excessive spatter, under cutting along edges, irregular deposits, wasted electrodesc)Too small bead, weak weld, and wasted electrodesd)None of the aboveCorrect answer is option 'A'. Can you explain this answer?.

Solutions for Too low welding current in arc welding would result ina)Excessive piling up of weld metal, poor penetration, wasted electrodesb)Excessive spatter, under cutting along edges, irregular deposits, wasted electrodesc)Too small bead, weak weld, and wasted electrodesd)None of the aboveCorrect answer is option 'A'. Can you explain this answer? in English & in Hindi are available as part of our courses for Railways.

Download more important topics, notes, lectures and mock test series for Railways Exam by signing up for free.

Here you can find the meaning of Too low welding current in arc welding would result ina)Excessive piling up of weld metal, poor penetration, wasted electrodesb)Excessive spatter, under cutting along edges, irregular deposits, wasted electrodesc)Too small bead, weak weld, and wasted electrodesd)None of the aboveCorrect answer is option 'A'. Can you explain this answer? defined & explained in the simplest way possible. Besides giving the explanation of

Too low welding current in arc welding would result ina)Excessive piling up of weld metal, poor penetration, wasted electrodesb)Excessive spatter, under cutting along edges, irregular deposits, wasted electrodesc)Too small bead, weak weld, and wasted electrodesd)None of the aboveCorrect answer is option 'A'. Can you explain this answer?, a detailed solution for Too low welding current in arc welding would result ina)Excessive piling up of weld metal, poor penetration, wasted electrodesb)Excessive spatter, under cutting along edges, irregular deposits, wasted electrodesc)Too small bead, weak weld, and wasted electrodesd)None of the aboveCorrect answer is option 'A'. Can you explain this answer? has been provided alongside types of Too low welding current in arc welding would result ina)Excessive piling up of weld metal, poor penetration, wasted electrodesb)Excessive spatter, under cutting along edges, irregular deposits, wasted electrodesc)Too small bead, weak weld, and wasted electrodesd)None of the aboveCorrect answer is option 'A'. Can you explain this answer? theory, EduRev gives you an

ample number of questions to practice Too low welding current in arc welding would result ina)Excessive piling up of weld metal, poor penetration, wasted electrodesb)Excessive spatter, under cutting along edges, irregular deposits, wasted electrodesc)Too small bead, weak weld, and wasted electrodesd)None of the aboveCorrect answer is option 'A'. Can you explain this answer? tests, examples and also practice Railways tests.

|

Explore Courses for Railways exam

|

|

Suggested Free Tests

Signup for Free!

Signup to see your scores go up within 7 days! Learn & Practice with 1000+ FREE Notes, Videos & Tests.