Railways Exam > Railways Questions > Welding process in which two pieces to be jo...

Start Learning for Free

Welding process in which two pieces to be joined are overlapped and placed between two electrodes is known as

- a)percussion welding

- b)projection welding

- c)seam welding

- d)spot welding

Correct answer is option 'D'. Can you explain this answer?

| FREE This question is part of | Download PDF Attempt this Test |

Verified Answer

Welding process in which two pieces to be joined are overlapped and p...

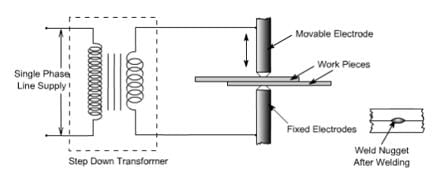

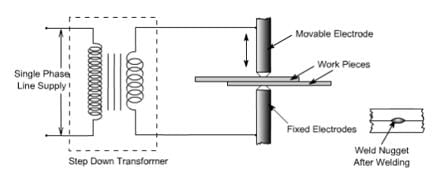

In resistance spot welding, two or more sheets of metal are held between electrodes through which welding current is supplied for a definite time and also force is exerted on work pieces.

View all questions of this test

Most Upvoted Answer

Welding process in which two pieces to be joined are overlapped and p...

Spot welding is a welding process in which two pieces to be joined are overlapped and placed between two electrodes. The correct answer to the given question is option 'D', spot welding.

Spot welding is widely used in various industries, including automotive, aerospace, and construction, due to its efficiency and effectiveness in joining metal components. It is a type of resistance welding, where heat is generated by the resistance to electric current flow at the point of contact between the two pieces being joined.

Below are the key points explaining spot welding in detail:

1. Spot welding process:

- In spot welding, two metal pieces are overlapped and placed between two electrodes, typically made of copper alloy.

- The electrodes apply pressure to hold the pieces together firmly.

- An electric current is then passed through the electrodes, creating resistance heating at the contact points.

- The heat generated by resistance causes the metal to melt, and when the current is stopped, the molten metal solidifies, forming a weld nugget.

2. Advantages of spot welding:

- High production speed: Spot welding is a fast process, making it suitable for high-volume production lines.

- Cost-effective: Spot welding requires minimal equipment and consumables, resulting in lower production costs.

- Strong and durable joints: Spot welding creates welds with high strength and integrity, ensuring the durability of the joined components.

- No additional materials: Spot welding does not require additional filler materials, as the heat generated by resistance melts the metal at the joint.

3. Applications of spot welding:

- Automotive industry: Spot welding is extensively used in the automotive industry to join sheet metal components, such as body panels, frames, and exhaust systems.

- Electrical industry: Spot welding is used to join electrical contacts, connectors, and components in appliances and electronic devices.

- Aerospace industry: Spot welding is utilized in the assembly of aircraft structures, fuel tanks, and engine components.

- Construction industry: Spot welding is employed in the fabrication of steel structures, such as bridges, buildings, and pipelines.

In conclusion, spot welding is a welding process in which two pieces to be joined are overlapped and placed between two electrodes. It is widely used in various industries due to its efficiency, speed, and strong weld joints.

Spot welding is widely used in various industries, including automotive, aerospace, and construction, due to its efficiency and effectiveness in joining metal components. It is a type of resistance welding, where heat is generated by the resistance to electric current flow at the point of contact between the two pieces being joined.

Below are the key points explaining spot welding in detail:

1. Spot welding process:

- In spot welding, two metal pieces are overlapped and placed between two electrodes, typically made of copper alloy.

- The electrodes apply pressure to hold the pieces together firmly.

- An electric current is then passed through the electrodes, creating resistance heating at the contact points.

- The heat generated by resistance causes the metal to melt, and when the current is stopped, the molten metal solidifies, forming a weld nugget.

2. Advantages of spot welding:

- High production speed: Spot welding is a fast process, making it suitable for high-volume production lines.

- Cost-effective: Spot welding requires minimal equipment and consumables, resulting in lower production costs.

- Strong and durable joints: Spot welding creates welds with high strength and integrity, ensuring the durability of the joined components.

- No additional materials: Spot welding does not require additional filler materials, as the heat generated by resistance melts the metal at the joint.

3. Applications of spot welding:

- Automotive industry: Spot welding is extensively used in the automotive industry to join sheet metal components, such as body panels, frames, and exhaust systems.

- Electrical industry: Spot welding is used to join electrical contacts, connectors, and components in appliances and electronic devices.

- Aerospace industry: Spot welding is utilized in the assembly of aircraft structures, fuel tanks, and engine components.

- Construction industry: Spot welding is employed in the fabrication of steel structures, such as bridges, buildings, and pipelines.

In conclusion, spot welding is a welding process in which two pieces to be joined are overlapped and placed between two electrodes. It is widely used in various industries due to its efficiency, speed, and strong weld joints.

Attention Railways Students!

To make sure you are not studying endlessly, EduRev has designed Railways study material, with Structured Courses, Videos, & Test Series. Plus get personalized analysis, doubt solving and improvement plans to achieve a great score in Railways.

|

Explore Courses for Railways exam

|

|

Similar Railways Doubts

Welding process in which two pieces to be joined are overlapped and placed between two electrodes is known asa)percussion weldingb)projection weldingc)seam weldingd)spot weldingCorrect answer is option 'D'. Can you explain this answer?

Question Description

Welding process in which two pieces to be joined are overlapped and placed between two electrodes is known asa)percussion weldingb)projection weldingc)seam weldingd)spot weldingCorrect answer is option 'D'. Can you explain this answer? for Railways 2024 is part of Railways preparation. The Question and answers have been prepared according to the Railways exam syllabus. Information about Welding process in which two pieces to be joined are overlapped and placed between two electrodes is known asa)percussion weldingb)projection weldingc)seam weldingd)spot weldingCorrect answer is option 'D'. Can you explain this answer? covers all topics & solutions for Railways 2024 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for Welding process in which two pieces to be joined are overlapped and placed between two electrodes is known asa)percussion weldingb)projection weldingc)seam weldingd)spot weldingCorrect answer is option 'D'. Can you explain this answer?.

Welding process in which two pieces to be joined are overlapped and placed between two electrodes is known asa)percussion weldingb)projection weldingc)seam weldingd)spot weldingCorrect answer is option 'D'. Can you explain this answer? for Railways 2024 is part of Railways preparation. The Question and answers have been prepared according to the Railways exam syllabus. Information about Welding process in which two pieces to be joined are overlapped and placed between two electrodes is known asa)percussion weldingb)projection weldingc)seam weldingd)spot weldingCorrect answer is option 'D'. Can you explain this answer? covers all topics & solutions for Railways 2024 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for Welding process in which two pieces to be joined are overlapped and placed between two electrodes is known asa)percussion weldingb)projection weldingc)seam weldingd)spot weldingCorrect answer is option 'D'. Can you explain this answer?.

Solutions for Welding process in which two pieces to be joined are overlapped and placed between two electrodes is known asa)percussion weldingb)projection weldingc)seam weldingd)spot weldingCorrect answer is option 'D'. Can you explain this answer? in English & in Hindi are available as part of our courses for Railways.

Download more important topics, notes, lectures and mock test series for Railways Exam by signing up for free.

Here you can find the meaning of Welding process in which two pieces to be joined are overlapped and placed between two electrodes is known asa)percussion weldingb)projection weldingc)seam weldingd)spot weldingCorrect answer is option 'D'. Can you explain this answer? defined & explained in the simplest way possible. Besides giving the explanation of

Welding process in which two pieces to be joined are overlapped and placed between two electrodes is known asa)percussion weldingb)projection weldingc)seam weldingd)spot weldingCorrect answer is option 'D'. Can you explain this answer?, a detailed solution for Welding process in which two pieces to be joined are overlapped and placed between two electrodes is known asa)percussion weldingb)projection weldingc)seam weldingd)spot weldingCorrect answer is option 'D'. Can you explain this answer? has been provided alongside types of Welding process in which two pieces to be joined are overlapped and placed between two electrodes is known asa)percussion weldingb)projection weldingc)seam weldingd)spot weldingCorrect answer is option 'D'. Can you explain this answer? theory, EduRev gives you an

ample number of questions to practice Welding process in which two pieces to be joined are overlapped and placed between two electrodes is known asa)percussion weldingb)projection weldingc)seam weldingd)spot weldingCorrect answer is option 'D'. Can you explain this answer? tests, examples and also practice Railways tests.

|

Explore Courses for Railways exam

|

|

Suggested Free Tests

Signup for Free!

Signup to see your scores go up within 7 days! Learn & Practice with 1000+ FREE Notes, Videos & Tests.