Civil Engineering (CE) Exam > Civil Engineering (CE) Questions > To produce a high head multi-stage centrifuga...

Start Learning for Free

To produce a high head multi-stage centrifugal pumps, the impellers are connected :

- a)in parallel

- b)in series

- c)in parallel and in series both

- d)none of the above

Correct answer is option 'B'. Can you explain this answer?

Most Upvoted Answer

To produce a high head multi-stage centrifugal pumps, the impellers ar...

Explanation:

Introduction:

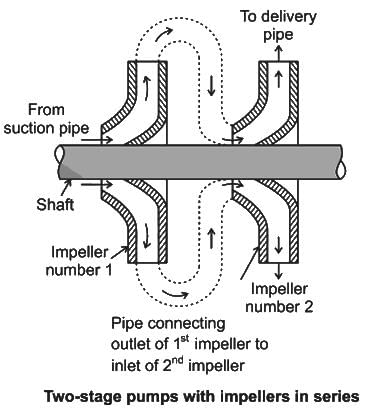

Multi-stage centrifugal pumps are used to generate high head or pressure in various applications, such as water supply, irrigation, oil and gas industry, and power plants. These pumps consist of multiple impellers that are arranged in a specific configuration to achieve the desired head.

Impeller Connection:

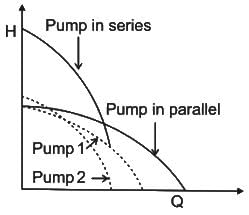

The impellers in a multi-stage centrifugal pump are connected in series. This means that the discharge of one impeller is connected to the suction of the next impeller, and so on. In this configuration, the fluid passes through each impeller in a sequential manner, with the pressure increasing at each stage.

Reasons for Series Connection:

1.Increased Head: Connecting the impellers in series allows the pump to generate a higher head compared to a single-stage pump. Each impeller adds to the total head by increasing the pressure of the fluid. Thus, the total head is the sum of the heads produced by each impeller.

2. Efficiency: Series connection of impellers allows for better efficiency in high head applications. Each impeller operates at a lower head, reducing the load on individual impellers and improving overall efficiency. This is because the power required to generate a high head in a single-stage impeller would be significantly higher, resulting in lower efficiency.

3. Compact Design: Series connection of impellers allows for a more compact pump design compared to parallel connection. This is because the series connection requires a single shaft to connect all the impellers, whereas parallel connection would require multiple shafts and bearings.

4. Balancing: Series connection allows for better hydraulic balancing of the impellers. As the fluid passes through each impeller, it imparts some axial thrust. In a series connection, the axial thrusts of all the impellers are balanced, resulting in smoother operation and reduced wear on bearings.

Conclusion:

In summary, multi-stage centrifugal pumps for high head applications have their impellers connected in series. This configuration allows for increased head, better efficiency, compact design, and improved hydraulic balancing.

Introduction:

Multi-stage centrifugal pumps are used to generate high head or pressure in various applications, such as water supply, irrigation, oil and gas industry, and power plants. These pumps consist of multiple impellers that are arranged in a specific configuration to achieve the desired head.

Impeller Connection:

The impellers in a multi-stage centrifugal pump are connected in series. This means that the discharge of one impeller is connected to the suction of the next impeller, and so on. In this configuration, the fluid passes through each impeller in a sequential manner, with the pressure increasing at each stage.

Reasons for Series Connection:

1.Increased Head: Connecting the impellers in series allows the pump to generate a higher head compared to a single-stage pump. Each impeller adds to the total head by increasing the pressure of the fluid. Thus, the total head is the sum of the heads produced by each impeller.

2. Efficiency: Series connection of impellers allows for better efficiency in high head applications. Each impeller operates at a lower head, reducing the load on individual impellers and improving overall efficiency. This is because the power required to generate a high head in a single-stage impeller would be significantly higher, resulting in lower efficiency.

3. Compact Design: Series connection of impellers allows for a more compact pump design compared to parallel connection. This is because the series connection requires a single shaft to connect all the impellers, whereas parallel connection would require multiple shafts and bearings.

4. Balancing: Series connection allows for better hydraulic balancing of the impellers. As the fluid passes through each impeller, it imparts some axial thrust. In a series connection, the axial thrusts of all the impellers are balanced, resulting in smoother operation and reduced wear on bearings.

Conclusion:

In summary, multi-stage centrifugal pumps for high head applications have their impellers connected in series. This configuration allows for increased head, better efficiency, compact design, and improved hydraulic balancing.

Free Test

FREE

| Start Free Test |

Community Answer

To produce a high head multi-stage centrifugal pumps, the impellers ar...

If a centrifugal pump consists of two or more impellers, the pump is called a multistage centrifugal pump. The impeller may be mounted on the same shaft or on different shafts.

A multistage pump is having the following functions:

To produce high heads:

A multistage pump is having the following functions:

To produce high heads:

- For developing a high head, a number of impellers are mounted in series or on the same shaft.

N = Number of identical impellers mounted on the same shaft

Hm = Head developed by each impeller

Total head developed = N × Hm

The discharge passing through each impeller is the same.

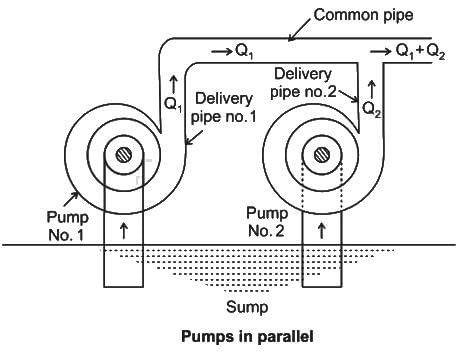

To discharge a large quantity of liquid:

- For obtaining a high discharge, the pumps should be connected in parallel.

N = Number of identical pumps arranged in parallel

Q = Discharge from one pump

Total discharge = N × Q

Each of the pumps is working against the same head.

|

Explore Courses for Civil Engineering (CE) exam

|

|

Question Description

To produce a high head multi-stage centrifugal pumps, the impellers are connected :a)in parallelb)in seriesc)in parallel and in series bothd)none of the aboveCorrect answer is option 'B'. Can you explain this answer? for Civil Engineering (CE) 2025 is part of Civil Engineering (CE) preparation. The Question and answers have been prepared according to the Civil Engineering (CE) exam syllabus. Information about To produce a high head multi-stage centrifugal pumps, the impellers are connected :a)in parallelb)in seriesc)in parallel and in series bothd)none of the aboveCorrect answer is option 'B'. Can you explain this answer? covers all topics & solutions for Civil Engineering (CE) 2025 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for To produce a high head multi-stage centrifugal pumps, the impellers are connected :a)in parallelb)in seriesc)in parallel and in series bothd)none of the aboveCorrect answer is option 'B'. Can you explain this answer?.

To produce a high head multi-stage centrifugal pumps, the impellers are connected :a)in parallelb)in seriesc)in parallel and in series bothd)none of the aboveCorrect answer is option 'B'. Can you explain this answer? for Civil Engineering (CE) 2025 is part of Civil Engineering (CE) preparation. The Question and answers have been prepared according to the Civil Engineering (CE) exam syllabus. Information about To produce a high head multi-stage centrifugal pumps, the impellers are connected :a)in parallelb)in seriesc)in parallel and in series bothd)none of the aboveCorrect answer is option 'B'. Can you explain this answer? covers all topics & solutions for Civil Engineering (CE) 2025 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for To produce a high head multi-stage centrifugal pumps, the impellers are connected :a)in parallelb)in seriesc)in parallel and in series bothd)none of the aboveCorrect answer is option 'B'. Can you explain this answer?.

Solutions for To produce a high head multi-stage centrifugal pumps, the impellers are connected :a)in parallelb)in seriesc)in parallel and in series bothd)none of the aboveCorrect answer is option 'B'. Can you explain this answer? in English & in Hindi are available as part of our courses for Civil Engineering (CE).

Download more important topics, notes, lectures and mock test series for Civil Engineering (CE) Exam by signing up for free.

Here you can find the meaning of To produce a high head multi-stage centrifugal pumps, the impellers are connected :a)in parallelb)in seriesc)in parallel and in series bothd)none of the aboveCorrect answer is option 'B'. Can you explain this answer? defined & explained in the simplest way possible. Besides giving the explanation of

To produce a high head multi-stage centrifugal pumps, the impellers are connected :a)in parallelb)in seriesc)in parallel and in series bothd)none of the aboveCorrect answer is option 'B'. Can you explain this answer?, a detailed solution for To produce a high head multi-stage centrifugal pumps, the impellers are connected :a)in parallelb)in seriesc)in parallel and in series bothd)none of the aboveCorrect answer is option 'B'. Can you explain this answer? has been provided alongside types of To produce a high head multi-stage centrifugal pumps, the impellers are connected :a)in parallelb)in seriesc)in parallel and in series bothd)none of the aboveCorrect answer is option 'B'. Can you explain this answer? theory, EduRev gives you an

ample number of questions to practice To produce a high head multi-stage centrifugal pumps, the impellers are connected :a)in parallelb)in seriesc)in parallel and in series bothd)none of the aboveCorrect answer is option 'B'. Can you explain this answer? tests, examples and also practice Civil Engineering (CE) tests.

|

Explore Courses for Civil Engineering (CE) exam

|

|

Signup for Free!

Signup to see your scores go up within 7 days! Learn & Practice with 1000+ FREE Notes, Videos & Tests.