Mechanical Engineering Exam > Mechanical Engineering Questions > Consider the following parameters: Grindin...

Start Learning for Free

Consider the following parameters:

Grinding wheel diameter

Regulating wheel diameter

Speed of grinding wheel

Speed of regulating wheel

Which of the above parameters will influence the axial feed rate in centre-less grinding?

- a)2 and 4

- b)2 and 3

- c)1 and 3

- d)1 and 4

Correct answer is option 'A'. Can you explain this answer?

| FREE This question is part of | Download PDF Attempt this Test |

Most Upvoted Answer

Consider the following parameters: Grinding wheel diameter Regulat...

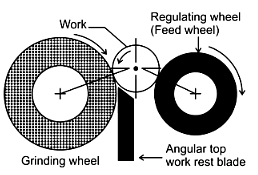

In different from other cylindrical processes, where the work piece is held in the grinding machine, while grinding between centers, the workpiece is not mechanically constrained during centreless grinding. Therefore the parts to be ground on a centreless grinder do not need center holes, drivers or workhead fixtures at the ends

Axial feed rate in centreless grinding is,

f = πDNsinα

Where, N is speed of regulating wheel and

D is diameter of regulating wheel

α is angle between the axes of grinding and regulating wheels

Free Test

FREE

| Start Free Test |

Community Answer

Consider the following parameters: Grinding wheel diameter Regulat...

Introduction:

Centreless grinding is a machining process that uses abrasive cutting to remove material from a workpiece. It differs from centered grinding operations in that no spindle or fixture is used to locate and secure the workpiece. Instead, the workpiece is supported between two wheels - the grinding wheel and the regulating wheel. The axial feed rate is an important parameter in centreless grinding, as it determines the rate at which material is removed from the workpiece.

Factors influencing the axial feed rate:

1. Grinding wheel diameter:

The grinding wheel diameter plays a significant role in determining the axial feed rate. A larger grinding wheel diameter will result in a higher feed rate, as there is a larger contact area between the grinding wheel and the workpiece. This increased contact area allows for more material to be removed per revolution of the grinding wheel.

2. Regulating wheel diameter:

The regulating wheel diameter also affects the axial feed rate. A larger regulating wheel diameter will result in a higher feed rate, as it increases the speed at which the workpiece is fed through the grinding zone. This is because a larger regulating wheel diameter increases the peripheral speed of the workpiece, leading to a higher feed rate.

3. Speed of grinding wheel:

The speed of the grinding wheel is another parameter that influences the axial feed rate. A higher speed of the grinding wheel will result in a higher feed rate, as it increases the rate at which material is removed from the workpiece. This is because a higher speed of the grinding wheel leads to a higher cutting velocity, resulting in a higher feed rate.

4. Speed of regulating wheel:

Similarly, the speed of the regulating wheel also affects the axial feed rate. A higher speed of the regulating wheel will result in a higher feed rate, as it increases the rate at which the workpiece is fed through the grinding zone. This is because a higher speed of the regulating wheel leads to a higher peripheral speed of the workpiece, resulting in a higher feed rate.

Conclusion:

In summary, the parameters that influence the axial feed rate in centreless grinding are the grinding wheel diameter and the speed of the regulating wheel. A larger grinding wheel diameter and a higher speed of the regulating wheel will result in a higher feed rate. These parameters should be carefully considered and optimized to achieve the desired material removal rate and surface finish in centreless grinding operations.

Centreless grinding is a machining process that uses abrasive cutting to remove material from a workpiece. It differs from centered grinding operations in that no spindle or fixture is used to locate and secure the workpiece. Instead, the workpiece is supported between two wheels - the grinding wheel and the regulating wheel. The axial feed rate is an important parameter in centreless grinding, as it determines the rate at which material is removed from the workpiece.

Factors influencing the axial feed rate:

1. Grinding wheel diameter:

The grinding wheel diameter plays a significant role in determining the axial feed rate. A larger grinding wheel diameter will result in a higher feed rate, as there is a larger contact area between the grinding wheel and the workpiece. This increased contact area allows for more material to be removed per revolution of the grinding wheel.

2. Regulating wheel diameter:

The regulating wheel diameter also affects the axial feed rate. A larger regulating wheel diameter will result in a higher feed rate, as it increases the speed at which the workpiece is fed through the grinding zone. This is because a larger regulating wheel diameter increases the peripheral speed of the workpiece, leading to a higher feed rate.

3. Speed of grinding wheel:

The speed of the grinding wheel is another parameter that influences the axial feed rate. A higher speed of the grinding wheel will result in a higher feed rate, as it increases the rate at which material is removed from the workpiece. This is because a higher speed of the grinding wheel leads to a higher cutting velocity, resulting in a higher feed rate.

4. Speed of regulating wheel:

Similarly, the speed of the regulating wheel also affects the axial feed rate. A higher speed of the regulating wheel will result in a higher feed rate, as it increases the rate at which the workpiece is fed through the grinding zone. This is because a higher speed of the regulating wheel leads to a higher peripheral speed of the workpiece, resulting in a higher feed rate.

Conclusion:

In summary, the parameters that influence the axial feed rate in centreless grinding are the grinding wheel diameter and the speed of the regulating wheel. A larger grinding wheel diameter and a higher speed of the regulating wheel will result in a higher feed rate. These parameters should be carefully considered and optimized to achieve the desired material removal rate and surface finish in centreless grinding operations.

Attention Mechanical Engineering Students!

To make sure you are not studying endlessly, EduRev has designed Mechanical Engineering study material, with Structured Courses, Videos, & Test Series. Plus get personalized analysis, doubt solving and improvement plans to achieve a great score in Mechanical Engineering.

|

Explore Courses for Mechanical Engineering exam

|

|

Consider the following parameters: Grinding wheel diameter Regulating wheel diameter Speed of grinding wheel Speed of regulating wheel Which of the above parameters will influence the axial feed rate in centre-less grinding?a)2 and 4b)2 and 3c)1 and 3d)1 and 4Correct answer is option 'A'. Can you explain this answer?

Question Description

Consider the following parameters: Grinding wheel diameter Regulating wheel diameter Speed of grinding wheel Speed of regulating wheel Which of the above parameters will influence the axial feed rate in centre-less grinding?a)2 and 4b)2 and 3c)1 and 3d)1 and 4Correct answer is option 'A'. Can you explain this answer? for Mechanical Engineering 2024 is part of Mechanical Engineering preparation. The Question and answers have been prepared according to the Mechanical Engineering exam syllabus. Information about Consider the following parameters: Grinding wheel diameter Regulating wheel diameter Speed of grinding wheel Speed of regulating wheel Which of the above parameters will influence the axial feed rate in centre-less grinding?a)2 and 4b)2 and 3c)1 and 3d)1 and 4Correct answer is option 'A'. Can you explain this answer? covers all topics & solutions for Mechanical Engineering 2024 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for Consider the following parameters: Grinding wheel diameter Regulating wheel diameter Speed of grinding wheel Speed of regulating wheel Which of the above parameters will influence the axial feed rate in centre-less grinding?a)2 and 4b)2 and 3c)1 and 3d)1 and 4Correct answer is option 'A'. Can you explain this answer?.

Consider the following parameters: Grinding wheel diameter Regulating wheel diameter Speed of grinding wheel Speed of regulating wheel Which of the above parameters will influence the axial feed rate in centre-less grinding?a)2 and 4b)2 and 3c)1 and 3d)1 and 4Correct answer is option 'A'. Can you explain this answer? for Mechanical Engineering 2024 is part of Mechanical Engineering preparation. The Question and answers have been prepared according to the Mechanical Engineering exam syllabus. Information about Consider the following parameters: Grinding wheel diameter Regulating wheel diameter Speed of grinding wheel Speed of regulating wheel Which of the above parameters will influence the axial feed rate in centre-less grinding?a)2 and 4b)2 and 3c)1 and 3d)1 and 4Correct answer is option 'A'. Can you explain this answer? covers all topics & solutions for Mechanical Engineering 2024 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for Consider the following parameters: Grinding wheel diameter Regulating wheel diameter Speed of grinding wheel Speed of regulating wheel Which of the above parameters will influence the axial feed rate in centre-less grinding?a)2 and 4b)2 and 3c)1 and 3d)1 and 4Correct answer is option 'A'. Can you explain this answer?.

Solutions for Consider the following parameters: Grinding wheel diameter Regulating wheel diameter Speed of grinding wheel Speed of regulating wheel Which of the above parameters will influence the axial feed rate in centre-less grinding?a)2 and 4b)2 and 3c)1 and 3d)1 and 4Correct answer is option 'A'. Can you explain this answer? in English & in Hindi are available as part of our courses for Mechanical Engineering.

Download more important topics, notes, lectures and mock test series for Mechanical Engineering Exam by signing up for free.

Here you can find the meaning of Consider the following parameters: Grinding wheel diameter Regulating wheel diameter Speed of grinding wheel Speed of regulating wheel Which of the above parameters will influence the axial feed rate in centre-less grinding?a)2 and 4b)2 and 3c)1 and 3d)1 and 4Correct answer is option 'A'. Can you explain this answer? defined & explained in the simplest way possible. Besides giving the explanation of

Consider the following parameters: Grinding wheel diameter Regulating wheel diameter Speed of grinding wheel Speed of regulating wheel Which of the above parameters will influence the axial feed rate in centre-less grinding?a)2 and 4b)2 and 3c)1 and 3d)1 and 4Correct answer is option 'A'. Can you explain this answer?, a detailed solution for Consider the following parameters: Grinding wheel diameter Regulating wheel diameter Speed of grinding wheel Speed of regulating wheel Which of the above parameters will influence the axial feed rate in centre-less grinding?a)2 and 4b)2 and 3c)1 and 3d)1 and 4Correct answer is option 'A'. Can you explain this answer? has been provided alongside types of Consider the following parameters: Grinding wheel diameter Regulating wheel diameter Speed of grinding wheel Speed of regulating wheel Which of the above parameters will influence the axial feed rate in centre-less grinding?a)2 and 4b)2 and 3c)1 and 3d)1 and 4Correct answer is option 'A'. Can you explain this answer? theory, EduRev gives you an

ample number of questions to practice Consider the following parameters: Grinding wheel diameter Regulating wheel diameter Speed of grinding wheel Speed of regulating wheel Which of the above parameters will influence the axial feed rate in centre-less grinding?a)2 and 4b)2 and 3c)1 and 3d)1 and 4Correct answer is option 'A'. Can you explain this answer? tests, examples and also practice Mechanical Engineering tests.

|

Explore Courses for Mechanical Engineering exam

|

|

Suggested Free Tests

Signup for Free!

Signup to see your scores go up within 7 days! Learn & Practice with 1000+ FREE Notes, Videos & Tests.