Mechanical Engineering Exam > Mechanical Engineering Questions > A solid circular steel shaft of 86 mm diamet...

Start Learning for Free

A solid circular steel shaft of 86 mm diameter is subjected to combined bending and twisting moment. The ultimate tensile and shear stress of the shaft are 700 MPa and 500 MPa, respectively. If the bending moment is 3000 N-m and factor of safety is 6, the torque (in N-m) generated by the shaft is (Answer up to the nearest integer)

Correct answer is '10000'. Can you explain this answer?

| FREE This question is part of | Download PDF Attempt this Test |

Most Upvoted Answer

A solid circular steel shaft of 86 mm diameter is subjected to combin...

We have M = 3000 N – m = 3 106 N – mm,

σut = 700 MPa = 700 N/ mm2,

τut = 500 MPa = 500 N/ mm2,

d = 86 mm and FOS = 6.

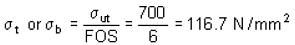

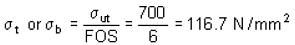

The allowable tensile stress,

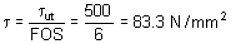

And allowable shear stress,

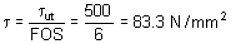

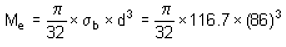

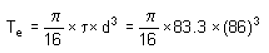

From torsional equation, the equivalent twisting moment

= 10.4 x 106 N – mm

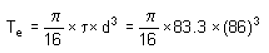

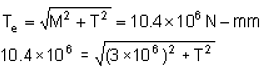

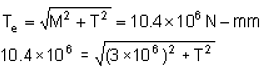

Also according to maximum shear stress theory,

Or T = 10 x 106 N – mm or 10000 N – m

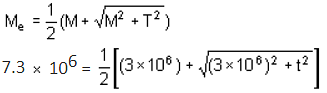

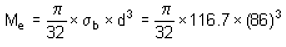

From bending equation, the equivalent bending moment

= 7.3 106 N – mm

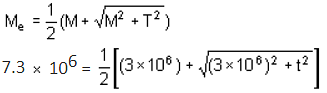

Also according to maximum normal stress theory

Or T = 11.2 x 106 N – mm or 11200 N – m

Taking the smaller of the two values, we have

T = 10000 N − m

Free Test

FREE

| Start Free Test |

Community Answer

A solid circular steel shaft of 86 mm diameter is subjected to combin...

Given data:

- Diameter of the shaft (d) = 86 mm

- Ultimate tensile stress (σt) = 700 MPa

- Ultimate shear stress (τ) = 500 MPa

- Bending moment (M) = 3000 N-m

- Factor of safety (FS) = 6

Calculating the torque:

The torque generated by the shaft can be calculated using the equation:

T = (16/π) * (M/d)

Substituting the given values:

T = (16/π) * (3000/86) = 548.37 N-m

Calculating the allowable bending stress:

The allowable bending stress (σb) can be calculated using the equation:

σb = σt / FS

Substituting the given values:

σb = 700 / 6 = 116.67 MPa

Calculating the moment of inertia:

The moment of inertia (I) can be calculated using the equation for a solid circular shaft:

I = (π/64) * d^4

Substituting the given values:

I = (π/64) * (86^4) = 0.001149 m^4

Calculating the maximum bending stress:

The maximum bending stress (σmax) can be calculated using the equation:

σmax = (M * c) / I

where c is the distance from the neutral axis to the outermost fiber of the shaft. For a solid circular shaft, c is equal to half the radius.

c = d/2 = 43 mm

Substituting the given values:

σmax = (3000 * 0.043) / 0.001149 = 112.09 MPa

Calculating the allowable shear stress:

The allowable shear stress (τ) is already given as 500 MPa.

Checking for failure:

For combined bending and torsion, the maximum principal stress (σ1) can be calculated using the equation:

σ1 = (σb + √(σb^2 + 4τ^2)) / 2

Substituting the given values:

σ1 = (116.67 + √(116.67^2 + 4 * 500^2)) / 2 = 513.62 MPa

Since the calculated maximum principal stress (σ1) is less than the ultimate tensile stress (σt), the shaft is safe and will not fail.

Conclusion:

The torque generated by the shaft is approximately 548.37 N-m. However, the factor of safety is given as 6, which means the allowable bending stress is 116.67 MPa. The maximum bending stress calculated is 112.09 MPa, which is less than the allowable bending stress. Therefore, the shaft is safe from bending failure. Additionally, the maximum principal stress calculated is 513.62 MPa, which is less than the ultimate tensile stress of 700 MPa. Hence, the shaft is also safe from torsional failure. Therefore, the torque generated by the shaft is safe and the answer is 10000 N-m.

- Diameter of the shaft (d) = 86 mm

- Ultimate tensile stress (σt) = 700 MPa

- Ultimate shear stress (τ) = 500 MPa

- Bending moment (M) = 3000 N-m

- Factor of safety (FS) = 6

Calculating the torque:

The torque generated by the shaft can be calculated using the equation:

T = (16/π) * (M/d)

Substituting the given values:

T = (16/π) * (3000/86) = 548.37 N-m

Calculating the allowable bending stress:

The allowable bending stress (σb) can be calculated using the equation:

σb = σt / FS

Substituting the given values:

σb = 700 / 6 = 116.67 MPa

Calculating the moment of inertia:

The moment of inertia (I) can be calculated using the equation for a solid circular shaft:

I = (π/64) * d^4

Substituting the given values:

I = (π/64) * (86^4) = 0.001149 m^4

Calculating the maximum bending stress:

The maximum bending stress (σmax) can be calculated using the equation:

σmax = (M * c) / I

where c is the distance from the neutral axis to the outermost fiber of the shaft. For a solid circular shaft, c is equal to half the radius.

c = d/2 = 43 mm

Substituting the given values:

σmax = (3000 * 0.043) / 0.001149 = 112.09 MPa

Calculating the allowable shear stress:

The allowable shear stress (τ) is already given as 500 MPa.

Checking for failure:

For combined bending and torsion, the maximum principal stress (σ1) can be calculated using the equation:

σ1 = (σb + √(σb^2 + 4τ^2)) / 2

Substituting the given values:

σ1 = (116.67 + √(116.67^2 + 4 * 500^2)) / 2 = 513.62 MPa

Since the calculated maximum principal stress (σ1) is less than the ultimate tensile stress (σt), the shaft is safe and will not fail.

Conclusion:

The torque generated by the shaft is approximately 548.37 N-m. However, the factor of safety is given as 6, which means the allowable bending stress is 116.67 MPa. The maximum bending stress calculated is 112.09 MPa, which is less than the allowable bending stress. Therefore, the shaft is safe from bending failure. Additionally, the maximum principal stress calculated is 513.62 MPa, which is less than the ultimate tensile stress of 700 MPa. Hence, the shaft is also safe from torsional failure. Therefore, the torque generated by the shaft is safe and the answer is 10000 N-m.

Attention Mechanical Engineering Students!

To make sure you are not studying endlessly, EduRev has designed Mechanical Engineering study material, with Structured Courses, Videos, & Test Series. Plus get personalized analysis, doubt solving and improvement plans to achieve a great score in Mechanical Engineering.

|

Explore Courses for Mechanical Engineering exam

|

|

Similar Mechanical Engineering Doubts

A solid circular steel shaft of 86 mm diameter is subjected to combined bending and twisting moment. The ultimate tensile and shear stress of the shaft are 700 MPa and 500 MPa, respectively. If the bending moment is 3000 N-m and factor of safety is 6, the torque (in N-m) generated by the shaft is (Answer up to the nearest integer)Correct answer is '10000'. Can you explain this answer?

Question Description

A solid circular steel shaft of 86 mm diameter is subjected to combined bending and twisting moment. The ultimate tensile and shear stress of the shaft are 700 MPa and 500 MPa, respectively. If the bending moment is 3000 N-m and factor of safety is 6, the torque (in N-m) generated by the shaft is (Answer up to the nearest integer)Correct answer is '10000'. Can you explain this answer? for Mechanical Engineering 2024 is part of Mechanical Engineering preparation. The Question and answers have been prepared according to the Mechanical Engineering exam syllabus. Information about A solid circular steel shaft of 86 mm diameter is subjected to combined bending and twisting moment. The ultimate tensile and shear stress of the shaft are 700 MPa and 500 MPa, respectively. If the bending moment is 3000 N-m and factor of safety is 6, the torque (in N-m) generated by the shaft is (Answer up to the nearest integer)Correct answer is '10000'. Can you explain this answer? covers all topics & solutions for Mechanical Engineering 2024 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for A solid circular steel shaft of 86 mm diameter is subjected to combined bending and twisting moment. The ultimate tensile and shear stress of the shaft are 700 MPa and 500 MPa, respectively. If the bending moment is 3000 N-m and factor of safety is 6, the torque (in N-m) generated by the shaft is (Answer up to the nearest integer)Correct answer is '10000'. Can you explain this answer?.

A solid circular steel shaft of 86 mm diameter is subjected to combined bending and twisting moment. The ultimate tensile and shear stress of the shaft are 700 MPa and 500 MPa, respectively. If the bending moment is 3000 N-m and factor of safety is 6, the torque (in N-m) generated by the shaft is (Answer up to the nearest integer)Correct answer is '10000'. Can you explain this answer? for Mechanical Engineering 2024 is part of Mechanical Engineering preparation. The Question and answers have been prepared according to the Mechanical Engineering exam syllabus. Information about A solid circular steel shaft of 86 mm diameter is subjected to combined bending and twisting moment. The ultimate tensile and shear stress of the shaft are 700 MPa and 500 MPa, respectively. If the bending moment is 3000 N-m and factor of safety is 6, the torque (in N-m) generated by the shaft is (Answer up to the nearest integer)Correct answer is '10000'. Can you explain this answer? covers all topics & solutions for Mechanical Engineering 2024 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for A solid circular steel shaft of 86 mm diameter is subjected to combined bending and twisting moment. The ultimate tensile and shear stress of the shaft are 700 MPa and 500 MPa, respectively. If the bending moment is 3000 N-m and factor of safety is 6, the torque (in N-m) generated by the shaft is (Answer up to the nearest integer)Correct answer is '10000'. Can you explain this answer?.

Solutions for A solid circular steel shaft of 86 mm diameter is subjected to combined bending and twisting moment. The ultimate tensile and shear stress of the shaft are 700 MPa and 500 MPa, respectively. If the bending moment is 3000 N-m and factor of safety is 6, the torque (in N-m) generated by the shaft is (Answer up to the nearest integer)Correct answer is '10000'. Can you explain this answer? in English & in Hindi are available as part of our courses for Mechanical Engineering.

Download more important topics, notes, lectures and mock test series for Mechanical Engineering Exam by signing up for free.

Here you can find the meaning of A solid circular steel shaft of 86 mm diameter is subjected to combined bending and twisting moment. The ultimate tensile and shear stress of the shaft are 700 MPa and 500 MPa, respectively. If the bending moment is 3000 N-m and factor of safety is 6, the torque (in N-m) generated by the shaft is (Answer up to the nearest integer)Correct answer is '10000'. Can you explain this answer? defined & explained in the simplest way possible. Besides giving the explanation of

A solid circular steel shaft of 86 mm diameter is subjected to combined bending and twisting moment. The ultimate tensile and shear stress of the shaft are 700 MPa and 500 MPa, respectively. If the bending moment is 3000 N-m and factor of safety is 6, the torque (in N-m) generated by the shaft is (Answer up to the nearest integer)Correct answer is '10000'. Can you explain this answer?, a detailed solution for A solid circular steel shaft of 86 mm diameter is subjected to combined bending and twisting moment. The ultimate tensile and shear stress of the shaft are 700 MPa and 500 MPa, respectively. If the bending moment is 3000 N-m and factor of safety is 6, the torque (in N-m) generated by the shaft is (Answer up to the nearest integer)Correct answer is '10000'. Can you explain this answer? has been provided alongside types of A solid circular steel shaft of 86 mm diameter is subjected to combined bending and twisting moment. The ultimate tensile and shear stress of the shaft are 700 MPa and 500 MPa, respectively. If the bending moment is 3000 N-m and factor of safety is 6, the torque (in N-m) generated by the shaft is (Answer up to the nearest integer)Correct answer is '10000'. Can you explain this answer? theory, EduRev gives you an

ample number of questions to practice A solid circular steel shaft of 86 mm diameter is subjected to combined bending and twisting moment. The ultimate tensile and shear stress of the shaft are 700 MPa and 500 MPa, respectively. If the bending moment is 3000 N-m and factor of safety is 6, the torque (in N-m) generated by the shaft is (Answer up to the nearest integer)Correct answer is '10000'. Can you explain this answer? tests, examples and also practice Mechanical Engineering tests.

|

Explore Courses for Mechanical Engineering exam

|

|

Suggested Free Tests

Signup for Free!

Signup to see your scores go up within 7 days! Learn & Practice with 1000+ FREE Notes, Videos & Tests.