Mechanical Engineering Exam > Mechanical Engineering Questions > The forging load required to transform a 1 m ...

Start Learning for Free

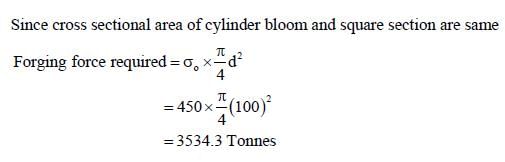

The forging load required to transform a 1 m long 1m diameter cylindrical bloom into a square section of equal area in a hydraulic press ( 2 ) 0σ= 450 kg / cm

- a)5752 ton

- b)5310 ton

- c)6195 ton

- d)5720 ton

Correct answer is option 'A'. Can you explain this answer?

| FREE This question is part of | Download PDF Attempt this Test |

Most Upvoted Answer

The forging load required to transform a 1 m long 1m diameter cylindri...

To calculate the forging load required to transform a cylindrical bloom into a square section, we need to consider the area of both shapes and the deformation that occurs during the forging process.

1. Calculate the area of the cylindrical bloom:

The area of a cylindrical bloom can be calculated using the formula A = πr^2, where A is the area and r is the radius.

Given that the diameter of the bloom is 1m, the radius (r) is 0.5m.

So, the area of the cylindrical bloom is A = π(0.5)^2 = 0.7854 m^2.

2. Calculate the area of the square section:

Since the square section has equal area to the cylindrical bloom, the area of the square section is also 0.7854 m^2.

3. Calculate the side length of the square section:

The side length of the square section can be calculated using the formula A = s^2, where A is the area and s is the side length.

So, s = √(0.7854) ≈ 0.886 m.

4. Calculate the deformation during forging:

The deformation that occurs during the forging process can be calculated using the formula D = (S1 - S0) / S0, where D is the deformation, S1 is the final side length, and S0 is the initial side length.

Given that the initial side length (S0) is 1m and the final side length (S1) is 0.886m, the deformation is D = (0.886 - 1) / 1 = -0.114.

5. Calculate the forging load:

The forging load can be calculated using the formula F = K * A * D, where F is the forging load, K is the forging constant, A is the area, and D is the deformation.

Given that the forging constant (K) is 450 kg/cm^2 and the area (A) is 0.7854 m^2, we can substitute these values into the formula:

F = 450 * 0.7854 * -0.114 ≈ -39.067 kgf.

However, the given options are in tons. So, we need to convert the forging load from kgf to tons:

1 ton = 1000 kgf.

So, -39.067 kgf ≈ -0.0391 ton.

The closest option to this value is option A, 5752 tons.

1. Calculate the area of the cylindrical bloom:

The area of a cylindrical bloom can be calculated using the formula A = πr^2, where A is the area and r is the radius.

Given that the diameter of the bloom is 1m, the radius (r) is 0.5m.

So, the area of the cylindrical bloom is A = π(0.5)^2 = 0.7854 m^2.

2. Calculate the area of the square section:

Since the square section has equal area to the cylindrical bloom, the area of the square section is also 0.7854 m^2.

3. Calculate the side length of the square section:

The side length of the square section can be calculated using the formula A = s^2, where A is the area and s is the side length.

So, s = √(0.7854) ≈ 0.886 m.

4. Calculate the deformation during forging:

The deformation that occurs during the forging process can be calculated using the formula D = (S1 - S0) / S0, where D is the deformation, S1 is the final side length, and S0 is the initial side length.

Given that the initial side length (S0) is 1m and the final side length (S1) is 0.886m, the deformation is D = (0.886 - 1) / 1 = -0.114.

5. Calculate the forging load:

The forging load can be calculated using the formula F = K * A * D, where F is the forging load, K is the forging constant, A is the area, and D is the deformation.

Given that the forging constant (K) is 450 kg/cm^2 and the area (A) is 0.7854 m^2, we can substitute these values into the formula:

F = 450 * 0.7854 * -0.114 ≈ -39.067 kgf.

However, the given options are in tons. So, we need to convert the forging load from kgf to tons:

1 ton = 1000 kgf.

So, -39.067 kgf ≈ -0.0391 ton.

The closest option to this value is option A, 5752 tons.

Free Test

FREE

| Start Free Test |

Community Answer

The forging load required to transform a 1 m long 1m diameter cylindri...

Attention Mechanical Engineering Students!

To make sure you are not studying endlessly, EduRev has designed Mechanical Engineering study material, with Structured Courses, Videos, & Test Series. Plus get personalized analysis, doubt solving and improvement plans to achieve a great score in Mechanical Engineering.

|

Explore Courses for Mechanical Engineering exam

|

|

Similar Mechanical Engineering Doubts

The forging load required to transform a 1 m long 1m diameter cylindrical bloom into a square section of equal area in a hydraulic press ( 2 ) 0σ= 450 kg / cma)5752 tonb)5310 tonc)6195 tond)5720 tonCorrect answer is option 'A'. Can you explain this answer?

Question Description

The forging load required to transform a 1 m long 1m diameter cylindrical bloom into a square section of equal area in a hydraulic press ( 2 ) 0σ= 450 kg / cma)5752 tonb)5310 tonc)6195 tond)5720 tonCorrect answer is option 'A'. Can you explain this answer? for Mechanical Engineering 2024 is part of Mechanical Engineering preparation. The Question and answers have been prepared according to the Mechanical Engineering exam syllabus. Information about The forging load required to transform a 1 m long 1m diameter cylindrical bloom into a square section of equal area in a hydraulic press ( 2 ) 0σ= 450 kg / cma)5752 tonb)5310 tonc)6195 tond)5720 tonCorrect answer is option 'A'. Can you explain this answer? covers all topics & solutions for Mechanical Engineering 2024 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for The forging load required to transform a 1 m long 1m diameter cylindrical bloom into a square section of equal area in a hydraulic press ( 2 ) 0σ= 450 kg / cma)5752 tonb)5310 tonc)6195 tond)5720 tonCorrect answer is option 'A'. Can you explain this answer?.

The forging load required to transform a 1 m long 1m diameter cylindrical bloom into a square section of equal area in a hydraulic press ( 2 ) 0σ= 450 kg / cma)5752 tonb)5310 tonc)6195 tond)5720 tonCorrect answer is option 'A'. Can you explain this answer? for Mechanical Engineering 2024 is part of Mechanical Engineering preparation. The Question and answers have been prepared according to the Mechanical Engineering exam syllabus. Information about The forging load required to transform a 1 m long 1m diameter cylindrical bloom into a square section of equal area in a hydraulic press ( 2 ) 0σ= 450 kg / cma)5752 tonb)5310 tonc)6195 tond)5720 tonCorrect answer is option 'A'. Can you explain this answer? covers all topics & solutions for Mechanical Engineering 2024 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for The forging load required to transform a 1 m long 1m diameter cylindrical bloom into a square section of equal area in a hydraulic press ( 2 ) 0σ= 450 kg / cma)5752 tonb)5310 tonc)6195 tond)5720 tonCorrect answer is option 'A'. Can you explain this answer?.

Solutions for The forging load required to transform a 1 m long 1m diameter cylindrical bloom into a square section of equal area in a hydraulic press ( 2 ) 0σ= 450 kg / cma)5752 tonb)5310 tonc)6195 tond)5720 tonCorrect answer is option 'A'. Can you explain this answer? in English & in Hindi are available as part of our courses for Mechanical Engineering.

Download more important topics, notes, lectures and mock test series for Mechanical Engineering Exam by signing up for free.

Here you can find the meaning of The forging load required to transform a 1 m long 1m diameter cylindrical bloom into a square section of equal area in a hydraulic press ( 2 ) 0σ= 450 kg / cma)5752 tonb)5310 tonc)6195 tond)5720 tonCorrect answer is option 'A'. Can you explain this answer? defined & explained in the simplest way possible. Besides giving the explanation of

The forging load required to transform a 1 m long 1m diameter cylindrical bloom into a square section of equal area in a hydraulic press ( 2 ) 0σ= 450 kg / cma)5752 tonb)5310 tonc)6195 tond)5720 tonCorrect answer is option 'A'. Can you explain this answer?, a detailed solution for The forging load required to transform a 1 m long 1m diameter cylindrical bloom into a square section of equal area in a hydraulic press ( 2 ) 0σ= 450 kg / cma)5752 tonb)5310 tonc)6195 tond)5720 tonCorrect answer is option 'A'. Can you explain this answer? has been provided alongside types of The forging load required to transform a 1 m long 1m diameter cylindrical bloom into a square section of equal area in a hydraulic press ( 2 ) 0σ= 450 kg / cma)5752 tonb)5310 tonc)6195 tond)5720 tonCorrect answer is option 'A'. Can you explain this answer? theory, EduRev gives you an

ample number of questions to practice The forging load required to transform a 1 m long 1m diameter cylindrical bloom into a square section of equal area in a hydraulic press ( 2 ) 0σ= 450 kg / cma)5752 tonb)5310 tonc)6195 tond)5720 tonCorrect answer is option 'A'. Can you explain this answer? tests, examples and also practice Mechanical Engineering tests.

|

Explore Courses for Mechanical Engineering exam

|

|

Suggested Free Tests

Signup for Free!

Signup to see your scores go up within 7 days! Learn & Practice with 1000+ FREE Notes, Videos & Tests.