Mechanical Engineering Exam > Mechanical Engineering Notes > Mechanical Engineering SSC JE (Technical) > Torsional & Bending Stresses in Machine Parts

Torsional & Bending Stresses in Machine Parts | Mechanical Engineering SSC JE (Technical) PDF Download

TORSIONAL AND BENDING STRESS IN MACHINE PARTS

Torsional Stress

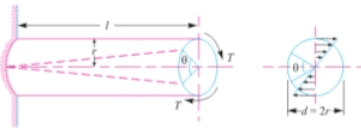

- When a machine member is subjected to two equal and opposite couples acting in parallel plane, then the machine member is said to be subjected to torsion. The stress set up by torsion is known as torsional shear stress.

- It is zero at the centroidal axis and maximum at the outer surface.

where,

ζ = Torsional shear stress induced at the outer surface of the shaft.

r = Radius of the shaft.

T = Torque or twisting moment.

J = Second moment of area of the section about its polar axis.

C = Modulus of rigidity.

l = length of the shaft.

θ = Angle of twist in radians on a length

Power transmitted by a shaft (in watts)

N = Speed in rpm

w = Angular speed in rad/s

Bending Stress

- When a beam subjected to the bending moment, in sagging (upward bending) the fibres of the upper side of the beam will be shortened due to compression and those on the lower side will be elongated due to tension, somewhere between top and bottom fibres, there is a surface at which the fibres are neither shortened nor elongated. Such a surface is called neutral plane.

where,

M = Bending moment acting at the given section

s = Bending stress

I = Moment of inertia of the cross-section about neutral axis

y = distance from the neutral axis to extreme fibre

R = Radius of curvature of beam.

is known as section modulus.

- In case of symmetrical sections such as circular, square or rectangular, the neutral axis passes through its geometrical centre.

- In case of unsymmetrical sections such as L-section or T-section the neutral axis does not pass through its geometrical centre. In such cases, all the centroid of the section is calculated and then the distance of the extreme fibres for both lower and upper side of the section is obtained. Out of these two values, the bigger value is used in bending equation.

- Principal stress,

- Maximum shear stress,

- When the shaft is subjected to an axial load (P) in addition to bending and twisting moments as in the propeller shafts of ship and shafts for driving worm gears, then the resultant tensile stress or compressive stress depend upon the type of axial load.

The document Torsional & Bending Stresses in Machine Parts | Mechanical Engineering SSC JE (Technical) is a part of the Mechanical Engineering Course Mechanical Engineering SSC JE (Technical).

All you need of Mechanical Engineering at this link: Mechanical Engineering

|

5 videos|103 docs|59 tests

|

FAQs on Torsional & Bending Stresses in Machine Parts - Mechanical Engineering SSC JE (Technical)

| 1. What are torsional and bending stresses in machine parts? |  |

| 2. How do torsional and bending stresses affect machine parts? |  |

Ans. Torsional and bending stresses can significantly impact the performance and durability of machine parts. Excessive torsional stress can lead to shearing or failure of shafts or axles, while excessive bending stress can cause deformation, cracking, or even fracture in components such as beams or supports. Understanding and properly managing these stresses are crucial for ensuring the reliability and safety of machine parts.

| 3. What factors contribute to torsional and bending stresses in machine parts? |  |

Ans. Several factors contribute to the development of torsional and bending stresses in machine parts. These include the magnitude and direction of applied loads, the material properties of the component, the geometry and dimensions of the part, as well as the boundary conditions and supports. Analyzing these factors through mathematical models or finite element analysis helps engineers determine the maximum stress levels and design parts accordingly.

| 4. How can torsional and bending stresses be reduced in machine parts? |  |

Ans. There are several strategies to reduce torsional and bending stresses in machine parts. These include optimizing the design by using appropriate geometry, such as increasing the diameter of shafts or adding reinforcing ribs to beams. Choosing materials with higher strength or stiffness properties can also help minimize stress levels. Additionally, applying surface treatments or using stress-relieving techniques during manufacturing can improve the resistance of machine parts to torsional and bending stresses.

| 5. What are the failure criteria for torsional and bending stresses in machine parts? |  |

Ans. The failure criteria for torsional and bending stresses depend on the material properties of the machine part. For ductile materials, failure is typically assessed based on yielding or plastic deformation. On the other hand, for brittle materials, failure is determined by the onset of crack propagation or fracture. Design standards and guidelines provide specific limits and safety factors to ensure that machine parts can withstand the expected torsional and bending stresses without failure.

Related Searches