Fibre to Fabric Class 7 Notes Science

| Table of contents |

|

| WOOL |

|

| WOOL PRODUCTION |

|

| HEALTH HAZARDS IN THE WOOL INDUSTRY |

|

| SILK |

|

| SERICULTURE |

|

| HEALTH HAZARDS IN SERICULTURE |

|

| Key Words |

|

| Activity |

|

Some may say fashion, some colours, some would say designers, some tailors. Those who say fibres are not wrong either. Fibres are, after all, the basic materials that are used to make clothes. Some fibres are obtained from plants and animals; some are made by humans.

Write P for Plant, A for Animal and M for Man-made (or Synthetic) fibres that would be most suited to make the following.

Clothing material or fabric is woven from yarns and yarns are spun from fibres. Different types of fabrics are used for making dresses, curtains, sofa covers, carpets, etc. In this chapter, we will learn about some animal fibres, their sources, and how they are used to make fabrics.

WOOL

Wool is an animal fibre. It is present as a thick coat of hair on the body of certain animals to body heat to escape (you will learn more about this in later chapters). That is why we wear keep them warm. Air gets trapped in the spaces between the hair and does not allow the woollens in winter.

Wool from Sheep

A sheep's hairy coat has two types of fibres: the coarse beard hair and the soft under-hair, found close to the skin. It is the soft under-hair that is used to make wool. Scientists have developed certain breeds of sheep that only have the soft under-hair.

The wool from different varieties of sheep differs in fineness, shine, length, and strength. The finest wool is obtained from the Merino, a breed of sheep originally from Spain. Their wool is very soft and light, and is therefore, used in making the finest woollen clothes.

The wool from different varieties of sheep differs in fineness, shine, length, and strength. The finest wool is obtained from the Merino, a breed of sheep originally from Spain. Their wool is very soft and light, and is therefore, used in making the finest woollen clothes.Rearing of Sheep

Sheep are herbivores and eat mainly grass and leaves. They are sometimes also fed a mixture of pulses, corn, jowar, etc.

In India, sheep are reared in the hilly regions of Jammu and Kashmir, Himachal Pradesh, Uttarakhand, Arunachal Pradesh, Sikkim, Punjab, Haryana, Rajasthan, and Gujarat. Gives a list of some Indian breeds of sheep and examples of products made from the wool obtained from these sheep.

Around the world, sheep are reared in countries ranging from the hot desert regions of Australia, Asia, and the Middle East to the cold regions of Northern Europe, Russia, Iceland, and southern South America.

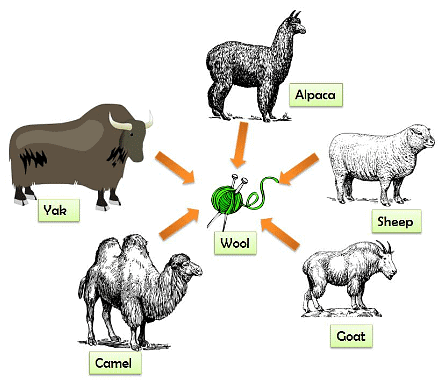

Wool from Other Animals

Although the main source of wool is sheep, wool is also obtained from animals of the camel family, goat, and even rabbits.

Camel hair is obtained from the very soft and fine fur of the undercoat of the camel. The Bactrian camels (two- humped camels found in Siberia, Mongolia, and China) give the best quality camel wool. The alpaca and llama also belong to the camel family. They are found in South America. Their undercoat hair is very soft and lustrous, and the fibres are light-weight.

The Cashmere goat is found in the high plateaus of Asia. The Cashmere fibre, very soft and warm, is obtained from this goat. The Angora goat originally belongs to the Angora (former name of Ankara, the present day capital of Turkey) region in Turkey. The fur of Angora goat provides a type of fibre called mohair. Mohair is very similar to wool in chemical composition but has a much smoother surface. It is durable, light, and warm, and is especially preferred for making soft sweaters and soft coverings for furniture.The Angora rabbit is originally from the Angora (Ankara) region of Turkey. The wool obtained from the Angora rabbit is known as Angora wool.

The Angora goat originally belongs to the Angora (former name of Ankara, the present day capital of Turkey) region in Turkey. The fur of Angora goat provides a type of fibre called mohair. Mohair is very similar to wool in chemical composition but has a much smoother surface. It is durable, light, and warm, and is especially preferred for making soft sweaters and soft coverings for furniture.The Angora rabbit is originally from the Angora (Ankara) region of Turkey. The wool obtained from the Angora rabbit is known as Angora wool.

WOOL PRODUCTION

The different processes involved in wool production are shearing, scouring, grading or sorting, dyeing, drying, and the making of yarn.

Shearing

The process of removal of the fleece from an animal is called shearing.Sheep are usually shorn annually in the spring/summer months. Shearing is done with a manual razor and blade, or with special clippers. Just as a haircut does not hurt us, shearing does not hurt the sheep-it actually helps them by removing the heavy woollen coat that they do not require in summer.

Scouring

The sheared hair is washed properly to remove dirt, dust, and grease. The process of removing dirt, dust, and grease from the sheared hair is called scouring. It is done with the help of machines.

Grading or Sorting

In this process, the wool is sorted on the basis of length, colour, texture, and the ease with which it can be dyed (coloured).

Dyeing

As the natural colour of fleece is white, brown, or black, the sheared wool is dyed in different colours.

Drying

In this process, containers of wool are put through rollers to squeeze out as much water as possible. Then the wool is weighed and packed into bales. The bales are transported to the mills where they are processed further.

Making of Yarn

Explains how the fleece is woven into yarn.

HEALTH HAZARDS IN THE WOOL INDUSTRY

In earlier days, the workers who sorted wool were often infected by bacteria that cause a fatal disease called anthrax, also known as sorter's disease. The bacteria are found in the wool of contaminated sheep and can enter the human body through inhaled air. Nowadays, this disease occurs rarely because of the use of vaccines for prevention.

SILK

Silk is an animal fibre produced by the silkworm. Silk fibres are soft and lustrous.

Life Cycle of a Silk Moth

The female silk moth lays about 300 to 400 eggs at a time. The eggs hatch and the caterpillars, or silkworms, emerge. This is called the larval stage. The silkworm feeds on mulberry leaves.

The silkworm secretes fine filaments from two glands on its head. The filaments are made of a protein that hardens to form silk fibres when exposed to air. The silkworm deposits filaments in layers around its body, through figure-of-eight movements of the head, forming a structure called the cocoon. The silkworm takes three to seven days to prepare the cocoon, formed by about 20-39 concentric layers of a single thread. Inside the cocoon, the silkworm enters the second stage of its life (called the pupa) and then the third and final stage to become an adult moth. Silk threads are obtained from the cocoon of the silkworm.

SERICULTURE

Rearing of silkworms for silk production is called sericulture.

The healthiest moths are chosen for breeding and laying eggs. The first step involves washing the silkworm eggs that had been stored; the eggs hatch only once a year in spring.

After the eggs hatch, the larvae are spread out on trays to grow. They are usually fed chopped mulberry leaves for 20-35 days. Racks or twigs are placed on the trays where the worms spin the cocoons. Spinning may take about 3-7 days, after which the cocoons are put in hot water, this kills the worms and loosens the filaments. The filaments are taken out from the cocoons by a process called reeling or filature. Filaments from several cocoons are twisted together to make a strong thread, which is wound on a reel. The threads are then dyed and woven into silk fabric.

There are different varieties of silk math, which feed on different plants. They produce silk of different quality and texture, eg, tassar, moogo, and kosa silk.

Sometimes, artificial silk is sold as natural silk. The difference between the two can be found out by burning a small piece of the fabric. Artificial silk when burnt either smells like a burning paper (If it is made using a plant fibre) or melts and forms a bead (if it has synthetic fibre in it). Natural silk when burnt, smells like burning hair.

HEALTH HAZARDS IN SERICULTURE

Some of the health hazards associated with sericulture are:

- Handling of dead worms with bare hands contributes to infection and illness. Workers generally need to dip their bare hands into the hot water, and judge by touch whether the fine threads of silk have loosened enough to be wound. This causes blisters and open wounds/ injuries, leading to infection.

- Standing almost continuously for about 12-16 hours a day, reeling the fine silk threads, may lead to health disorders like backaches, spine and vision-related problems.

- Vapours from boiling cocoons and diesel fumes from machines may lead to respiratory diseases such as asthma and bronchitis.

- Continuous exposure to the noise made by spinning and winding machines and looms, where the fabric is woven, may result in hearing disorders.

Key Words

Activity

Aim: To observe the difference between animal fibre and man-made fibre (when brought near a flame)

Materials needed: A candle, a matchbox, a pair of forceps, and swatches of silk, woollen and nylon fabrics)

Method:

1. Light the candle.

2. Cut a small piece of silk fabric. Hold it with the help of forceps and bring it near the flame of the candle.

3. Notice how it burns. Blow off the fire and smell the smoke of the fabric.

4. Repeat the above steps with woollen and nylon fabrics.

Observation: Silk and wool burn with the smell of burning hair, while nylon melts and forms a bead.

|

139 videos|151 docs|18 tests

|