Civil Engineering (CE) Exam > Civil Engineering (CE) Notes > Design of Steel Structures > Tension Member

Tension Member | Design of Steel Structures - Civil Engineering (CE) PDF Download

Introduction

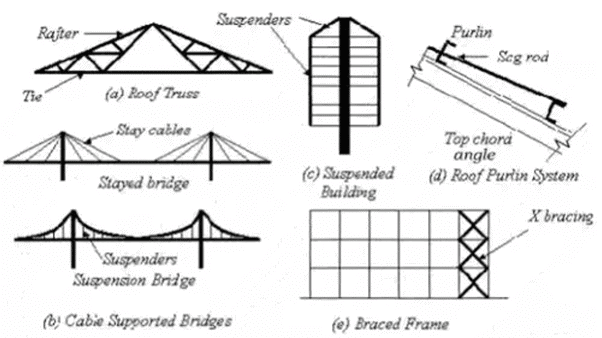

Tension members are linear members in which axial forces act to elongate (stretch) the member. A rope, for example, is a tension member. Tension members carry loads most efficiently since the entire cross-section is subjected to uniform stress. Unlike compression members, they do not fail by buckling. Ties of trusses, suspenders of cable-stayed and suspension bridges, suspenders of buildings systems hung from a central core (such buildings are used in earthquake-prone zones to minimise inertia forces on the structure), and sag rods of roof purlins are other examples of tension members.

Tension Members in Structures

Tension Members in Structures

Tension Members in Structures

Tension Members in Structures

- Tension member has no stability problem.

- In tension member net section will be effective, whereas in compression member gross section is effective.

Net Sectional Area

- For plate

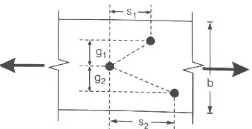

Net area = (b x t) – nd't +

where s1 = Distance between two consecutive rivets in the direction of load, also called pitch.

g1 = Distance between two consecutive rivets perpendicular to the direction of load, also called gauge.

b = Width of the plate

n = Number rivets at the section

T = Thickness of the plate

d' = Gross diameter of the rivet

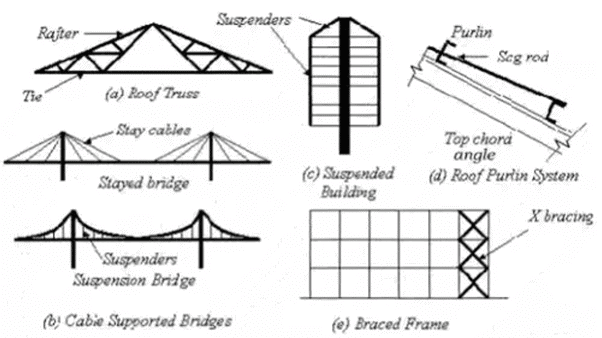

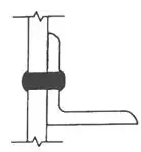

- Single angle connected by one leg only.

(a) Anet = A1 + kA2 where, A1 = Net cross-section of area of the connected leg.

where, A1 = Net cross-section of area of the connected leg.

A2 = Gross cross-sectional area of unconnected leg. (out stand)

(b)

(c)

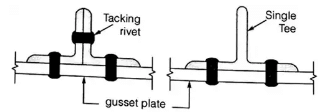

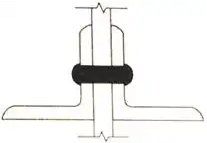

(d) Anet = (I1 + I2 - t)t - For pair of angle placed back to back (or a signal tee) connected by only one leg of each angle (or by the flange of a tee) to the same side of a gusset plate: or if the two angles are tagged along a-a.

(a) Anet = A1 + kA2

(a) Anet = A1 + kA2

(b) k = 5A1 / 5A1 + A2

where, A1 = Area of connected leg

A2 = Area of outstand (unconnected leg)

(c) The area of a web of tee = Thickness of web x (depth – thickness of flange)

(d) The outstand legs of the pair of angles should be tacked by rivets of a pitch not exceeding 1 m. - If two angles are places back to back and connected to both sides of the gusset plate. Then

Anet = A1 + A2(k = 1) when tack riveted.

Anet = A1 + A2(k = 1) when tack riveted.

If not tack riveted then both will be considered separately and case (ii) will be followed

k = 3A1 / 3A1 + A2

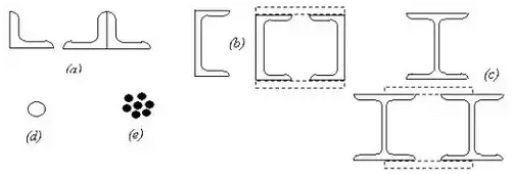

Permissible Stress in Design

- The direct stress in axial tension on the effective net area should not exceed σat

where σat = 0.6fy and fy = minimum yield stress of steel in MPa

Lug Angle

- The lug angle is a short length of an angle section used at a joint to connect the outstanding leg of a member, thereby reducing the length of the joint. When lug angle is used k = 1

The document Tension Member | Design of Steel Structures - Civil Engineering (CE) is a part of the Civil Engineering (CE) Course Design of Steel Structures.

All you need of Civil Engineering (CE) at this link: Civil Engineering (CE)

|

10 videos|41 docs|17 tests

|

FAQs on Tension Member - Design of Steel Structures - Civil Engineering (CE)

| 1. What is a tension member in civil engineering? |  |

A tension member in civil engineering is a structural element that is designed to carry tensile loads. It is typically used in structures such as bridges, roofs, and buildings to resist forces that pull the member apart.

| 2. How is the strength of a tension member determined? |  |

The strength of a tension member is determined by its cross-sectional area and the material's ultimate tensile strength. The cross-sectional area is multiplied by the ultimate tensile strength to calculate the ultimate tensile capacity of the member. The design strength is usually a fraction of the ultimate capacity to account for safety factors.

| 3. What are some common materials used for tension members in civil engineering? |  |

Some common materials used for tension members in civil engineering include steel, aluminum, and reinforced concrete. These materials have high tensile strength and are able to withstand the tension forces exerted on the member.

| 4. How are tension members connected to other structural elements? |  |

Tension members are typically connected to other structural elements using various types of fasteners such as bolts, welds, or connectors. The connection design must ensure that it can transfer the tensile forces from the tension member to the connected elements without compromising the overall structural integrity.

| 5. What are some common failure modes for tension members? |  |

Some common failure modes for tension members include yielding, fracture, and pull-out. Yielding occurs when the material reaches its yield strength and undergoes permanent deformation. Fracture happens when the material fails completely due to excessive tensile stress. Pull-out refers to the failure of the connection between the tension member and the connected elements, resulting in the loss of load transfer capability.

Related Searches