Retaining Walls

2.5. Retaining walls are structures used to retain earth or water or other materials such as coal, ore, etc; where conditions do not permit the mass to assume its natural slope. The retaining material is usually termed as backfill. The main function of retaining walls is to stabilize hillsides and control erosion. When roadway construction is necessary over rugged terrain with steep slopes, retaining walls can help to reduce the grades of roads and the land alongside the road. Some road projects lack available land beside the travel way, requiring construction right along the toe of a slope. In these cases extensive grading may not be possible and retaining walls become necessary to allow for safe construction and acceptable slope conditions for adjacent land uses. Where soils are unstable, slopes are quite steep, or heavy runoff is present, retaining walls help to stem erosion. Excessive runoff can undermine roadways and structures, and controlling sediment runoff is a major environmental and water quality consideration in road and bridge projects. In these situations, building retaining walls, rather than grading excessively, reduces vegetation removal and reduces erosion caused by runoff. In turn, the vegetation serves to stabilize the soil and filter out sediments and pollutants before they enter the water source, thus improving water quality.

In this section you will learn the following

Gravity walls

Semi Gravity Retaining Wall

Flexible walls

Special type of retaining walls

Different Types of Retaining Structures On the basis of attaining stability, the retaining structures are classified into following:

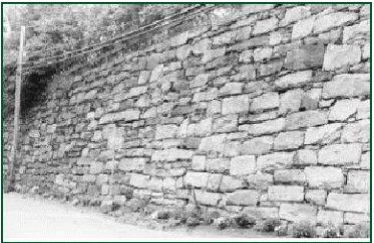

1. Gravity walls : Gravity walls are stabilized by their mass. They are constructed of dense, heavy materials such as concrete and stone masonry and are usually reinforced.Some gravity walls do use mortar, relying solely on their weight to stay in place, as in the case of dry stone walls. They are economical for only small heights

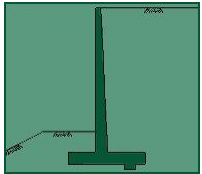

Semi Gravity Retaining Wall

These walls generally are trapezoidal in section. This type of wall is constructed in concrete and derives its stability from its weight. A small amount of reinforcement is provided for reducing the mass of the concrete.This can be classified into two: 1. Cantilever retaining wall 2. Counter fort retaining wall

Fig 6.3.Semi Gravity Retaining Wall

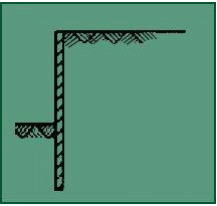

Cantilever retaining wall

This is a reinforced concrete wall which utilises cantilever action to retain the backfill. This type is suitable for retaining backfill to moderate heights(4m-7m). In cross section most cantilevered walls look like "L" s or inverted "T" s. To ensure stability, they are built on solid foundations with the base tied to the vertical portion of the wall with reinforcement rods. The base is then backfilled to counteract forward pressure on the vertical portion of the wall. The cantilevered base is reinforced and is designed to prevent uplifting at the heel of the base, making the wall strong and stable. Local building codes, frost penetration levels and soil qualities determine the foundation and structural requirements of taller cantilevered walls. Reinforced concrete cantilevered walls sometimes have a batter. They can be faced with stone, brick, or simulated veneers. Their front faces can also be surfaced with a variety of textures. Reinforced Concrete Cantilevered Walls are built using forms. When the use of forms is not desired, Reinforced Concrete Block Cantilevered Walls are another option. Where foundation soils are poor, Earth Tieback Retaining Walls are another choice. These walls are counterbalanced not only by a large base but also by a series of horizontal bars or strips extending out perpendicularly from the vertical surface into the slope. The bars or strips, sometimes called "deadmen" are made of wood, metal, or synthetic materials such as geotextiles. Once an earth tieback retaining wall is backfilled, the weight and friction of the fill against the horizontal members anchors the structure.

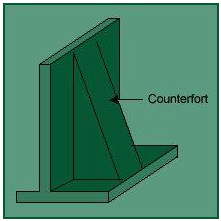

Counterfort retaining wall

When the height of the cantilever retaining wall is more than about 7m, it is economical to provide vertical bracing system known as counter forts. In this case, both base slab and face of wall span horizontally between the counter forts.

Fig. 6.5 Counter fort retaining wall

3. Flexible walls: there are two classes of flexible walls.

A. Sheet pile walls and

B. Diaphragm wall

A.Sheet Pile Walls Sheet piles are generally made of steel or timber. The use of timber piles is generally limited to temporary sdtructures in which the depth of driving does not exceed 3m. for permanent structures and for depth of driving greater than 3m, steel piles are most suitable. Moreover, steel iles are relatively water tight and can be extracted if required and reused. However, the cost of sheet steel piles is generally more than that of timber piles. Reinforced cement concrete piles are generally used when these are to be jetted into fine sand or driven in very soft soils, such as peat. For tougher soils , the concrete piles generally break off. Based on its structural form and loading system, sheet pile walls can be classified into 2 types:(i)Cantilever Sheet Piles and(ii)Anchored Sheet Piles 1. Cantilever sheet pile walls:

Fig. 6.6.Cantilever sheet pile wallFig. 6.6.Cantilever sheet pile wall

Cantilever sheet piles are further divide into two types: Free cantilever sheet pile It is a sheet pile subjected to a concentrated horizontal load at its top. There is no back fill above the dredge level. The free cantilever sheet pile derives its stability entirely from the lateral passive resistance of the soil below the dredge level into which it is driven. Cantilever Sheet Pile Wall with Backfill

A cantilever sheet pile retains backfill at a higher level on one side. The stability is entirely from the lateral passive resistance of the soil into which the sheet pile is driven, like that of a free cantilever sheet pile.

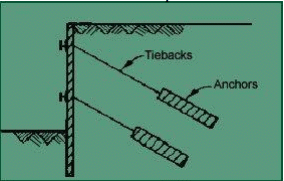

2. Anchored sheet pile walls Anchored shet pile walls are held above the driven depth by anchors provided ata suitable level. The anchors provided for the stability of the sheet ile , in addition tomthe lateral passive resistance of the soil into which the shet piles are driven. The anchored sheet piles are also of two types.

Fig. 6.7.Anchored sheet pile wall

Free earth support piles.

An anchored pile is said to have free earth support when the depth of embedment is small and the pile rotates at its bottom tip. Thus there is a point of contraflexure in the pile. Fixed earth support piles. An anchored sheet pile has fixed earth support when the depth of embedment is large. The bottom tip of the pile is fixed against rotations. There is a change in the curvature of the pile, and hence, an inflection point occurs.

Diaphragm Walls Diaphragm walls are commonly used in congested areas for retention systems and permanent foundation walls. They can be installed in close proximity to existing structures, with minimal loss of support to existing foundations. In addition, construction dewatering is not required, so there is no associated subsidence. Diaphragm walls have also been used as deep groundwater barriers through and under dams.

Diaphragm walls are constructed by the slurry trench technique which was developed in Europe, and has been used in the United States since the l940's. The technique involves excavating a narrow trench that is kept full of an engineered fluid or slurry. The slurry exerts hydraulic pressure against the trench walls and acts as shoring to prevent collapse. Slurry trench excavations can be performed in all types of soil, even below the ground water table. Cast in place; diaphragm walls are usually excavated under bentonite slurry. The construction sequence usually begins with the excavation of discontinuous primary panels. Stop-end pipes are placed vertically in each end of the primary panels, to form joints for adjacent secondary panels. Panels are usually 8 to 20 feet long, with widths varying from 2 to 5 feet. Once the excavation of a panel is complete, a steel reinforcement cage is placed in the center of the panel. Concrete is then poured in one continuous operation, through one or several tremie pipes that extend to the bottom of the trench. The tremie pipes are extracted as the concrete raises in the trench, however the discharge of the tremie pipe always remains embedded in the fresh concrete. The slurry, which is displaced by the concrete, is saved and reused for subsequent panel excavations. When the concrete sets, the end pipes are withdrawn. Similarly, secondary panels are constructed between the primary panels, and the process continues to create a continuous wall. The finished walls may cantilever or require anchors or props for lateral support.

Fig. 6.8. Construction Stages of a Diaphragm Wall using Slurry Trench Technique.

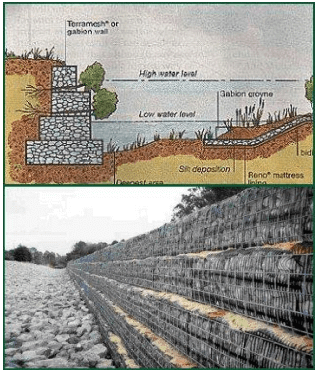

4. Special type of retaining walls Gabion walls Gabion walls are constructed by stacking and tying wire cages filled with trap rock or native stone on top of one another. They can have a continuous batter (gently sloping) or be stepped back (terraced) with each successively higher course.

This is a good application where the retaining wall needs to allow high amounts of water to pass through it, as in the case of riverbank stabilization. It is important to use a filter fabric with the gabion to keep adjacent soil from flowing into or through the cages along with the water. As relatively flexible structures, they are useful in situations where movement might be anticipated. Vegetation can be reestablished around the gabions and can soften the visible edges allowing them to blend into the surrounding landscape. For local roads, they are a preferred low-cost retaining structure.

Fig. 6.9 (i) Gabion Wall

Fig.6.9 (ii) Gabion Wall