Mulching and Composting, Biomass Management for Fodder & Energy | Biomass Management for Fodder & Energy - Agricultural Engineering PDF Download

Introduction

Paddy residue management is also important as machines are being increasingly used for harvesting of grains, and this mechanical harvesting leaves huge amount of residues in the field. There are several options for management of rice residues. In this chapter we shall study mulching and composting of rice straw.

14.2. Mulching

The practice of spreading plant residue or any other material like straw on the soil surface to reduce water evaporation losses is called mulching. Appropriate tillage and mulch practices are used to conserve soil moisture and increase the yield of crops. Mulches are designed to protect exposed soil or freshly seeded areas from erosion by eliminating direct impact of precipitation and slowing overland flows and to foster the growth of vegetation by increasing available moisture and act as shade. Mulches can increase the infiltration rate of the soil, reduce soil moisture loss by evaporation, prevent crusting and sealing of the soil surface, modify soil temperatures and provide a suitable microclimate for seed germination leading to better root growth and higher grain yields.

14.3. Types of Mulches

14.3.1. Organic Mulches

- Straw: The mulch most commonly used in conjunction with seeding. The straw should come from rice, wheat or oats (free of troublesome weed seeds) and may be spread by hand or machine. Straw can be windblown and must be anchored down by an acceptable method.

- Hay: May be used in lieu of straw where volunteers will not present a problem, and may be spread by hand or machine. Hay can be windblown and must also be anchored or tacked down.

- Corn Stalks: These should be shredded into 100 to 150 mm (4 to 6 inch) lengths. Stalks decompose slowly and are resistant to displacement.

- Wood Chips: Suitable for areas that will not be closely mowed, and around ornamental plantings. Chips decompose slowly and do not require tacking. They must be treated with 6 kg of nitrogen per tonnes of chips to prevent nutrient deficiency in plants; however, can be a very inexpensive mulch if chips are obtained from trees cleared on the site.

- Bark Chips and Shredded Bark: These are by-products of timber processing which are used in landscaped plantings. Bark is also a suitable mulch for areas planted to grasses and not closely mowed. It may be applied by hand or mechanically and is not usually toxic to grasses or legumes; additional nitrogen fertilizer is not required.

14.3.2. Fiber Mulches

Fiber mulches are used in hydroseeding operations and applied as part of the slurry. It creates the best seed-soil contact when applied over top of newly seeded areas. These fibers do not require tacking, although tacking agents or binders are sometimes used in conjunction with the application of fiber mulch. This form of mulch does not provide sufficient protection to highly erodible soils. Additionally, fiber mulch will not be considered adequate mulch when used during the dry summer months or when used for late fall mulch cover. Use straw mulch during these periods. Fiber mulch may be used to tack straw mulch. This treatment is well suited for steep slopes, critical areas, and areas susceptible to displacement.

14.3.3. Chemical Mulches and Soil Binders

Chemical Mulches and Soil Binders make excellent mulches but are only use of these materials can reduce costs, a wide range of synthetic, spray-on materials are marketed to stabilize and protect the soil surface. These are emulsions or dispersions of vinyl compounds, rubber or other substances which are mixed with water and applied to the soil. They may be used alone in some cases as temporary stabilizers or in conjunction with fiber mulches or straw. When used alone, chemical mulches do not have the capability to insulate the soil or retain soil moisture that organic mulches have. This soil protection is also easily damaged by tratic. Application of these mulches is usually more expensive than organic mulching, and the mulches decompose in 60-90 days.

The type of mulch selected and the application rate will depend on conditions at the site, such as slope, erodibility, soil temperatures, moisture, wind, the potential for weed infestations, and the potential that wild animals might cause damage. The amount of mulch added to the soil should not suppress the growth of most plants. General mulch recommendations to protect disturbed soils from raindrop splash and sheet flow include: straw applied at 2-2.5 tons/acre, wood fiber or wood cellulose applied at 0.5-1 ton/acre and wood chips applied at 5-6 tons/acre. Early mulching proved advantageous, since the structure of soil improves progressively after the mulch is applied. Mulches increase soil moisture because they improve infiltration of rainfall and slow down evaporation from coil surface.

14.4. Paddy straw mulching

Previously a waste item, paddy straw helps to reduce weeds and increase soil moisture when used on its own or as a base layer for mulch. Rice straw is lightweight, so it is best used in a place that will not get heavy winds when used without heavier mulch as a top layer. The quality of mulch depends of the quality of the straw. Clean straw without any dampness or mold and free from weed seeds is to be used for effective mulching. Seedling establishment has been high with straw mulch. Straw decomposes within 1 to 3 years. Usually, about 2 – 2.5 tons of straw is applied per acre providing about 66 to 100 percent cover. For seedlings to germinate and become established soil needs to show through the straw. A heavier application of straw will help suppress weeds and keep the soil cooler.

14.5. Composting

Composting is an aerobic process in which microorganisms convert a mixed organic substrate into carbon dioxide, water, minerals and stabilized organic matter under controlled condition, particularly of moisture and aeration are required to yield temperatures conductive to the microorganisms involved in the composting process. The stabilized compost produced should benefit the plant growth and be suitable for agricultural applications. Compost is a mixture of decayed organic materials decomposed by microorganisms in a warm, moist and aerobic environment, releasing nutrients into readily available forms for plant use.

The technology used in composting facilities range from very simple windrow and mattress composting facilities to highly advanced composting in closed reactors with automated control of process parameters. Composting facilities typically consist of three stages; primary treatment, composting, and final treatment. The primary treatment usually involves some sort of separation and screening to remove unwanted materials and ensure a proper particle size. Primary treatment can also include mixing with structure materials or adjustment of the C/N ratio pH, or water content. The composting can take place in one process for instance in a reactor or in open windrows. The process may also be a combination of primary composting in a reactor for a short period (1 – 3 days) followed by composting in windrows for several months. The purpose of the final treatment is to make the compost ready for marketing or storage. This typically involves screening to 10-15 mm particle size, hygeinization and in certain cases mixing of different types of compost to adjust the nutrient (N, P, K) contents of the finished product.

14.6. Composting process

The composting process can be divided into four phases.

The initial phase is the first period after initiation of the compost process where the temperature rises to about 50oC over a period of a few days. During this phase the population of especially bacteria increases rapidly and compounds that are easily degradable, such as sugars, starch, proteins and fats are degraded. Due to the rapid rate of degradation and oxygen consumption it is often difficult to provide enough oxygen for the biological processes and the compost will have a tendency to develop anaerobic pockets. Modest decreases in pH may be observed due to the production of organic acids by anaerobic organisms. The organisms active during the initial phase are mesophilic (optimal temperature 35-45 oC) and thermophilic (optimal temperature (55 – 60 oC) bacteria.

If the conditions in the composting material are well maintained the composting material are well maintained the composting process will normally enter the thermophilic phase next. This phase involves especially thermophilic bacteria and also certain thermophilic actinomycetes and fungi. During this phase the temperature can exceed 70oC and temperatures as high as 80-85 oC have been observed during composting o sewage sludge. The pH usually increases to about 7.5 due to the destruction of the organic acids. Near the end of the thermophilic phase when the readily degradable organic material has been removed by the microorganisms only organic materials such as hemicellulose, lignin, chitin, and similar compounds that are more difficult to degrade remain. The microbial activity especially concerning the bacteria begins to decrease and the temperature in the compost begins to fall. At this point the composting process is not yet finished and the compost is sometimes called raw compost.

Upon completion of the thermophilic phase the temperature decreases to levels where the mesophilic organisms have their optimum and the composting process enters the mesophilic phase. During this phase where the temperature ranges between 35 and 45 oC the more difficult to-degrade components such as cellulose and lignin are decomposed. During the mesophilic phase several types of bacteria are still very active but it is especially the actinomycetes and fungi that are important during this phase. Actinomycetes and fungi are better adapted to utilize the more difficult degradable compounds compared to most of the bacteria. Some fungi can even produce penicillin that will kill some of the bacteria. The mesophilic phase can take up to several weeks to complete. At the end of the mesophilic phase the compost is often called finished compost.

The final phase of the composting process is termed the cooling phase, during this phase the temperature slowly decreases to near ambient levels during a time span of several weeks, the microbial degradation of the organic material will be almost completed when entering the cooling phase and the rate of degradation will approach that of a natural soil. The organic matter remaining consists of very complex compounds with humus like structures that are difficult to degrade. The pH during this phase will normally stay relatively constant at about 8. Towards the end of the cooling phase higher organisms such as worms and insects will often colonize the compost. The compost is now termed mature compost and the structure of the organic matter in the compost will closely resemble that of humus.

14.7. Process parameters

14.7.1. Temperature:

The temperature controls the microbial activity and thus the rate of the composting process. The degradation rate usually increases strongly with temperature up to about 70-80 oC. Above this temperature most microorganisms will either be killed or form spores, which is a resting stage. This prevents further increases in degradation rte and temperature of the compost. It is often important to maintain a high temperature as long as possible to ensure rapid degradation and effective use of the compost facility.

14.7.2. Water content

The water content controls both the microbial activity and the oxygen transportation in the compost material. At low water contents oxygen will be transported faster and easier because a greater amount of the pores are filled with air. This makes it easier to ensure a high oxygen concentration in the compost. Low water contents, however, are inhibitory to microorganisms whose activity will cease at gravimetric water contents below 8-12 %. The optimal water content also depends on the structure of material being composted. Materials that are structurally strong can have higher permissible gravimetric water contents (70-80% for wood chips, straw, hay, etc.) because the structure of the materials ensure that there will be a sufficient amount of air-filled pores.

14.7.3. pH

Composting may proceed effectively over a range of pHs without seriously limiting the process. The optimum pH for microorganisms involved in composting lies between 6.5 and 7.5.

14.7.4. C/N ratio

A good C/N ratio to ensure efficient decomposition in 30 parts carbon to 1 part nitrogen by weight. When too little nitrogen is present, decomposition will occur more slowly; if too much nitrogen exists, it can be lost to atmosphere as ammonia gas.

14.7.5. Oxygen concentration

Oxygen concentration is the limiting factor for biological degradation especially in the early stages of the composting process. If the oxygen concentration is too low, the process will proceed at a much slower rate resulting in lower temperatures in the compost. Also low oxygen concentrations are usually the cause of foul odors originating from organic acids that are produced as a result of anaerobic conditions. Proper oxygen concentrations can be maintained by turning the compost more frequently. Frequent turning or high aeration rates can, however, lead to increased evaporation of water and decreased compost temperatures.

14.8. Composting methods

14.8.1. Turned windrow composting

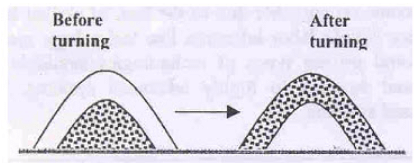

The organic material that is to be composted is formed into piles that are roughly triangular or trapezoidal in cross section. If manual construction is used the piles should be about 2.5m wide, in case of mechanical turning they can be as wide as 3-4m. The piles are often 20-50m long depending on the amount of input to the facility. The piles are normally turned 7-10 times over a period of about 15 weeks to ensure aeration and to expose all material to the high temperatures in the center of the pile. Turning of the piles can be done either manual or mechanical to make proper exposure to high temperature. The course of the composting process is typically controlled based on temperature and moisture content. If the temperature decreases due to low moisture contents, the piles are watered. If temperature decreases due to lack of oxygen, the piles are turned more frequently to increase oxygen concentration and microbial turnover. After the active composting period, the compost is stored in piles for 2-3 months without turning to ensure proper stability, i.e., that the microbial activity in the compost material has reached a level corresponding to natural soils.

Fig. Process of turning windrows to ensure proper exposure to high temperatures Static pile composting

14.8.2. Static pile composting

The static pile composting process is closely related to turned windrow composting in that both technologies uses open piles during composting. In the static pile process oxygen supply is provided by means of forced aeration rather than natural convection. Perforated aeration pipes are installed under the piles and air is sucked in through the piles toward the pipes and is subsequently pumped to a bio filter where odor-causing compounds produced during the composting process are adsorbed and subsequently degraded. The filter can be made very simple from finished compost. Air may alternatively be pushed from the perforated pipe out through the compost pile. This approach has the advantage that moisture and dust will not accumulate in the piping system.

The static piles are usually not quite static, however, they are turned less frequently than the basic turned windrows usually 3-5 times during the first 15 weeks. Aerationequirements for static pile composting varies with the type of material being composted but is typically on the order of 20-30 m3air per ton of compost per hour.

14.8.3. Mattress composting

Mattress composting is a very simple technology that is especially suitable for yard and park waste, i.e., plant residues and tree branches etc. the mattress composting process usually takes significantly longer than both turned and static windrow composting due to the construction and operation of the mattress. The height of the mattress can be varied depending on the space available but a height of 2 to 6 m has been used widely. Phase 1, i.e., the mattress construction and pre-composting at 50oC can take from 3 months up to approximately one year.

At the beginning of phase 2 the mattress is usually rebuilt using a tractor or bulldozer to ensure homogeneity of the materials. The mattress may actually be “turned” several times during the composting phase. During this phase the temperature can rise to approximately 70oC. The phase 2 composting takes from 8 to 12 months typically. When the composting phase is nearing its end, the microbial activity and temperature will start to decrease and the temperature will reach about 40oC.At this point the composted material is typically screened (phase 3) and perhaps mixed with other types of compost to adjust nitrogen and phosphorous content and then stored for later marketing.

14.9. Rice Straw Composting

Rice straw is rich in carbon and poor in nitrogen, which limits the composting process. Microorganisms need carbon for cell structure formation and nitrogen for cellular protein synthesis. It was found that C:N ratio of 25 to 30:1 for raw material was desirable for efficient composting. Organic materials poor in nitrogen content (wide C:N ratio) decompose slowly, take more time and result in lower amount of compost formation. Under the situation, the biological activity diminishes and several successions of organisms may be required to degrade the carbonaceous materials. So, C:N ratio of organic materials poor in nitrogen should be made narrow by adding organic raw materials including farm yard manure and poultry droppings or nitrogen in the form of any nitrogenous fertilizer for better decomposition.

14.9.1. IBS Rapid Rice Straw Composting

Rapid composting requires carbon-rich materials such as rice straw, nitrogen-rich materials like animal manure and the activator Trichoderma harzianum. If animal manure is difficult to obtain, it may be replaced with leguminous plants such as azolla and sesbania. At harvest time, rice straw is heaped to one side of the paddy. It saves labor later to have one compost pile for each paddy instead of one central pile. The process steps are as below.

- Rice straw is soaked overnight in irrigation water or in the rain until saturated.

- A simple platform is made in the middle of the paddy (size is relative to the size of the paddy).

- A layer of saturated rice straw 10-15 cm thick is loosely piled on the platform.

- On top of the layer, one or two handfuls of the activator, Trichoderma harzianum is broadcast (25 kg /ha).

- Straw is alternately layered with the activator until all the straw has been used.

- Manure and nitrogenous plants are put on top of the straw layers. The nitrogen substrate is 15-25% of total composition.

- The compost is covered (with plastic, banana leaves, or coconut fronds) and heats up within 25 hours.

- The compost must be moistened frequently to compensate for evaporation.

- The compost is left unturned and matures within one month. It is ready for use when the pile has cooled and is 30% of its original size.

14.9.2. Vermicomposting using paddy straw

The term “vermicomposting” had recently been coined to mean the use of earthworms for composting organic residues. Vermicomposting is an appropriate technique for efficient recycling of animal wastes, crop residues and agro-industrial wastes. Paddy straw is a wide C:N (80:1) organic material, low in nitrogen and phosphorus but fairly rich in potassium. Superphosphate is generally added to fortify the phosphorous content of the compost. It also checks the volatilization loss of NH3 from the decomposable mass during the process of compost formation.

In conventional method of composting, paddy straw takes 6-8 months for decomposition resulting in a poor quality of compost. The process of conversion of organic materials into manure is chiefly microbiological and greatly influenced by the proportion of carbonaceous and nitrogenous materials present in organic wastes.

Earthworm activities are important in aiding faster decomposition process mainly done by microbial actions. It grinds the organic waste materials in the gizzard and the actions of bacteria therein hasten the decomposition process. The number of bacteria and actinomycetes increased 1000 fold during passage of substrate through the gut.

Besides, aeration, mixing and turning over the materials are essential in decomposition process which are also done by earthworms. Jena et al, (2002) conducted an experiment in Orissa taking red earthworm (Eisenia foetida) for the decomposition of paddy straw in presence of fertilizer sources to add N and P. Dried and chopped (3-4 cm) paddy straw, after thorough mixing with fresh cowdung slurry was introduced into pots. Nitrogen in the form of Calcium Ammonium Nitrate (CAN) was applied to raise the N level of the straw to 2 per cent N and phosphorus as Single Super Phosphate (SSP) to raise the total P2O5 content to 0.2 per cent. In control, no such additional fertilizer N or P was added. Watering was done to pots to maintain the moisture content to 40-50 per cent.

After two week of preliminary decomposition, red earthworms were released at 10 adults per pot. The pots were covered with gunny bag to maintain moisture and temperature under shed. This prevents worms from crawling outside the waste material and also to prevent entry of other insects. Ten weeks after the initiation of the composting process, the compost masses were collected. The experimental results showed neutral reaction of the compost masses indicating their suitability for soil application. The straw decomposition was (91 per cent by vermiculture in presence of fertilizer N & P which was greater than the control. The C:N ratio decreased to 10:1 due to earthworm activity alone and further decreased to 8:1 when inoculated in presence of Nitrogen and Phosphorous, showing better influence for the decomposition of a wide C:N ratio material like paddy straw. The earthworm population was increased by 16-20 times.

14.10. Benefits of compost

- Improves the soil structure, porosity and density, thus creating a better plant root environment.

- Increases moisture infiltration and permeability of heavy soils, thus reducing erosion and runoff.

- Improves water-holding capacity, thus reducing water loss and leaching in sandy soils.

- Supplies beneficial micro-organisms to soils, a variety of macro and micronutrients in addition to significant quantities of organic matter.

- May control or suppress certain soil-borne plant pathogens.

- Improves Cation Exchange Capacity (CEC) of soils and growing media, thus improving their ability to hold nutrients for plant use.

- Improves and stabilizes soil pH.

- On practical agricultural level, the compost is an easy process; it saves money on disposal costs, in addition that reduces the need of the farmer for chemical fertilizers.

- On environmental level, the compost reduces the volume of garbage.

Composting of rice-straw into a value added product is thus highly promising alternative to its burning and can potentially increase the agricultural productivity and reduce the problem of environmental pollution.