Special Casting Processes | Manufacturing Engineering - Mechanical Engineering PDF Download

Special Casting Processes

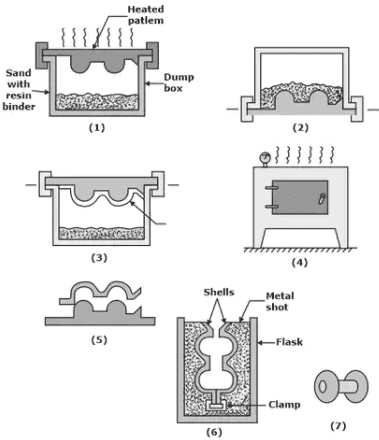

Shell moulding

Shell moulding is a casting process in which the mould is a thin shell (typically 9 mm) made of sand held together by a thermosetting resin binder.

The thickness of the shell can be determined accurately by controlling the time that the pattern is in contact with the mould.

Steps in Shell-Moulding

Vacuum Moulding

It uses a sand mould held together by vacuum pressure rather than by a chemical binder.

Accordingly, the term vacuum in this process refers to the making of the mould rather than the casting operation itself.

Investment casting

(i) In investment casting, a pattern made of wax is coated with a refractory material to make the mould, after which the wax is melted away prior to pouring the molten metal.

(ii) The term Investment comes from one of the less familiar definitions of the word Invest, which is "to cover completely," this referring to the coating of the refractory material around the wax pattern.

Advantages of investment casting

Parts of great complexity and intricacy can be cast

Close dimensional control—tolerances of ± 0.075 mm, are possible.

Good surface finish is possible.

Disadvantage of investment casting

Because many steps are involved in this casting operation, it is a relatively expensive process.

Investment castings are normally small in size, although parts with complex geometries weighing up to 75 lb have been successfully cast.

Applications of investment casting

All types of metals. including steels, stainless steels, and other high-temperature alloys, can be investment cast.

Examples of parts include complex machinery parts, blades. and other components for turbine engines, jewellery, and dental fixtures.

Permanent-Mould Casting Processes

In this section. permanent-mould casting is treated as the basic process in the group of casting processes that all use reusable metal moulds.

Other members of the group include die casting and centrifugal casting.

Variations of permanent-mould casting

Several casting processes are quite like the basic permanent-mould method.

These include:

Slush casting.

Low-pressure casting

Vacuum permanent-mould casting.

- Slush casting

Slush Casting Slush casting is a permanent mould process in which a hollow casting is formed by inverting the mould after partial freezing at the surface to drain out the liquid metal in the center. - Low-Pressure Casting

In low-pressure casting, the liquid metal is forced into the cavity under low pressure— approximately 0.1 MPa from beneath so that the flow is upward - Vacuum Permanent-Mould Casting

The general configuration or the vacuum permanent-mould casting process is like the low-pressure casting operation. The difference is that reduced air pressure from the vacuum in the mould is used to draw the liquid metal into the cavity, rather than forcing it by positive air pressure from below.

Die casting

Die casting is a permanent-mould casting process in which the molten metal is injected into the mould cavity under high pressure. Typical pressures are 7 to 350 MPa.

There are two main types of die-casting machines:

- Hot chamber die casting

- Cold chamber die casting

- Hot chamber die casting

(i) In hot-chamber machines, the metal is melted in a container attached to the machine, and a piston is used to inject the liquid metal under high pressure into the die. Typical injection pressures are 7 to 35 MPa.

(ii) The process is therefore limited in its applications to low-melting-point metals that do not chemically attack the plunger and other mechanical components. The metals include zinc, tin, lead, and sometimes magnesium. - Cold chamber die casting

(i) In cold-chamber die-casting machines, molten metal is poured into an unheated chamber from an external melting container, and a piston is used to inject the metal under high pressure into the die cavity.

(ii) Cold-chamber machines are typically used for casting aluminum, brass, and magnesium alloys. Low-melting-point alloys (zinc, tin, lead) can also be cast on cold-chamber machines, but the advantages of the hot-chamber process usually favor its use on these metals.

Advantages of die casting:

- High production rates possible.

- Economical for large production quantities.

- Close tolerances possible, on the order of ±0.076 mm for small parts.

- Good surface finish.

Limitation of die casting:

- In addition to the metals cast, is the shape restriction. The part geometry must allow for removal from the die cavity.

Centrifugal casting

Centrifugal casting refers to several casting methods in which the mould is rotated at high speed so that centrifugal force distributes the molten metal to the outer regions of the die cavity. The group includes:

- True centrifugal casting

- Semi centrifugal casting

- Centrifuge casting

- Centrifuge Casting

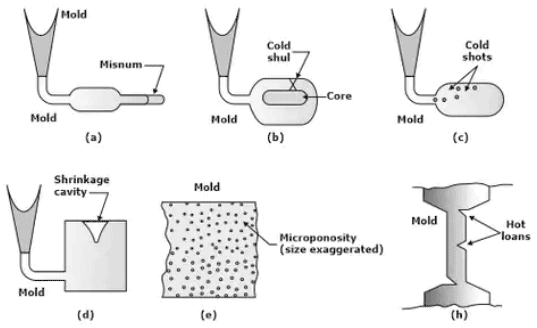

In centrifuge casting, the mould is designed with part cavities located away from the axis of rotation, so that the molten metal poured into the mould is distributed to these cavities by centrifugal force. - Casting Defects

Some common defects in castings

Some common defects in castings

(i) Misruns

(ii) Cold Shuts

(iii) Shrinkage cavity

(iv) Microporosity

(v) Hot tearing

(vi) Sand blow

(vii) Pinholes

(viii) Sand wash

(ix) Scabs

(x) Penetration

(xi) Mould shift

(xii) Core shift

(xiii) Mould crack

Advantages of the Special Casting process:

- Greater dimensional accuracy.

- Higher metallurgical quality.

- Lower production cost (in certain cases).

- Ability to cast extremely thin sections.

- High production rates.

- Better surface finishes on the castings; therefore low labour and finishing costs.

- Minimum need for further machining of castings.

- Castings may possess a denser and finer grain structure.

- Castings are slightly stronger and more ductile than solid mould castings.

|

56 videos|80 docs|29 tests

|

FAQs on Special Casting Processes - Manufacturing Engineering - Mechanical Engineering

| 1. What are the different types of special casting processes? |  |

| 2. How does investment casting differ from other casting processes? |  |

| 3. What is the purpose of shell molding in casting processes? |  |

| 4. How does vacuum casting work? |  |

| 5. What are the advantages of continuous casting over other casting methods? |  |