Flexibility and Agility in Manufacturing Systems | Management Optional Notes for UPSC PDF Download

Introduction

- Flexibility encompasses the ability to produce competitively priced, customized products of superior quality that can be swiftly delivered to customers. In manufacturing systems, flexibility refers to the capacity to produce various parts without significant retooling, and it gauges how rapidly a company can transition its processes from producing one product line to another. This trait also pertains to the capability to adjust production schedules, switch parts, or handle multiple parts concurrently. Flexible manufacturing systems, which integrate computer technology with numerical control machine tools, have been hailed as solutions to the challenges faced by manufacturing industries on a global scale.

- Reviewing past literature reveals extensive exploration of the concept of flexibility in manufacturing systems over time. The emergence of flexible manufacturing systems dates back to the 1960s with the introduction of robots, programmable controllers, and computerized numerical controls, bringing automation to the factory floor through numerically-controlled and direct-numerically-controlled machines. Initially defined as a manufacturing system's ability to adapt to changes in customer requirements without significant cost, time, effort, or performance penalties, flexibility has been recognized as a crucial element for managing internal and external disturbances. It serves as a metric for the range of product variants a manufacturing system can accommodate, albeit assessed relative to its capabilities rather than on an absolute scale.

- The primary objective of a flexible manufacturing system is to provide the agility required to respond quickly to market conditions while maintaining high quality standards.

- Studies on flexibility have primarily focused on production environments and interorganizational aspects such as product mix, volume, and production routes. Scholars like Sharifi and Zhang (1999) have argued that flexibility alone may not be adequate to address the challenges posed by intense competitive environments. They have proposed theoretical models linking flexible manufacturing capabilities with volume flexibility, mix flexibility, and customer satisfaction.

Defining Flexibility in Manufacturing Systems

- Browne et al. (1984) define flexibility in manufacturing systems as an integrated computer-controlled system equipped with automated material handling devices and CNC machine-tools capable of simultaneously processing a medium-sized volume of various parts.

- Chan et al. (2007) conducted a simulation study using Taguchi's method to analyze physical and operational parameters of flexible manufacturing systems and their impact on flexibility. Their approach aimed to assess how variations in these parameters influence system performance and identify optimal flexibility levels.

Classification of Manufacturing Flexibility

Sarker et al. (1994) provided a comprehensive classification of manufacturing-related flexibility, including routing flexibility, machine flexibility, process flexibility, expansion flexibility, job flexibility, design flexibility, material handling flexibility, setup time flexibility, and volume flexibility. Flexibility has been recognized by Bolwijn and Kumpe (1990) and De Meyer et al. (1989) as a focal point in the competitive landscape.

Perspectives on Flexibility

- Gupta and Buzacott (1989) emphasized that flexibility does not solely arise from machine capabilities but is the result of a combination of factors such as physical attributes, operational decisions, information integration, and management practices. Bennett et al. (1992) identified critical factors for developing efficient flexible production systems, including effective subsystem integration, appropriate controls and performance measures, alignment of production system design with organizational structure, and the need for clear objectives at the design stage.

- Kumar et al. (2003) employed an ant colony optimization approach to schedule flexibility in manufacturing systems, while Wang and Yen (2001) evaluated transportation times in automated material handling systems for dispatching rule performance in simulation studies.

Challenges and Obstacles

- Gerwin (1993) highlighted the confusion surrounding the concept of manufacturing flexibility, stating that a lack of clarity inhibits progress in utilizing flexibility concepts in industry.

- Gunasekaran et al. (1993) and Gerwin (1993) identified the measurement of flexibility and performance as significant obstacles to fully understanding flexible manufacturing system behavior.

Theoretical Studies on Manufacturing Flexibility

- A wealth of theoretical research has focused on flexibility in manufacturing systems, defining them as systems capable of rapid configuration to produce various products.

- Control theorists and engineers have extensively studied the modeling and analysis of flexibility in manufacturing systems over the past few decades, viewing them as production systems where a discrete number of raw parts are processed and assembled using controlled machines, computers, and/or robots (Ruiz et al., 2009).

Manufacturing System Flexibility:

- Recognition and categorization of incoming part or product styles.

- Ability to distinguish among various incoming styles processed by the system.

Quick Changeover Abilities:

- Rapid adjustment of operating instructions.

- Swift reconfiguration of physical setup.

Flexible Manufacturing System Organization:

Established by Browne et al. (1984), forming the basis for subsequent research on measuring manufacturing flexibility.

Levels of Manufacturing Flexibility

Basic Flexibilities:

- Machine Flexibility: Various operations the machine can perform without extensive switching effort.

- Material Handling Flexibility: Ease of transporting and positioning different part types.

- Operation Flexibility: Ease of using alternative operation sequences for processing a part.

System Flexibilities:

- Volume Flexibility: Profitable operation at different production volumes.

- Expansion Flexibility: Incremental system building and capacity expansion.

- Routing Flexibility: Variation in part paths through the system for a given process plan.

- Process Flexibility: Production of different products without significant setup delay.

- Product Flexibility: Manufacturing various part types with minor setup changes.

Aggregate Flexibilities:

- Program Flexibility: System's ability to run autonomously for extended periods.

- Production Flexibility: Production of various part types without major equipment investment.

- Market Flexibility: Efficient adaptation to changing market conditions.

Categories of Manufacturing Flexibility

Machine Flexibility:

- The ability to adjust a machine or workstation within the system to perform a wide range of production operations and accommodate various part styles.

- Setup or changeover time, ease of machine reprogramming.

Production Flexibility:

- The range of part styles producible within the system.

- Machine flexibility of individual stations, range of machine flexibilities across all stations.

Mix Flexibility:

- The capability to alter product mixes while maintaining the same total production quantity.

- Similarity of parts in the mix, relative work content times of parts produced.

Product Flexibility:

- The ease with which design changes and new products can be accommodated.

- Similarity of new part design to existing part family, offline part program preparation.

Routing Flexibility:

- The capacity to produce parts through alternative workstation sequences in response to interruptions.

- Similarity of parts in the mix, duplications of workstations, cross-training of material workers.

Volume Flexibility:

- The ability to economically produce parts in varying total quantities.

- Level of manual labor, amount invested in capital investment.

Expansion Flexibility:

- The ease with which the system can be expanded to increase total production quantities.

- Expense of adding workstations, ease of layout expansion, type of part handling system.

|

Download the notes

Flexibility and Agility in Manufacturing Systems

|

Download as PDF |

Characteristics of Agile Manufacturing for Change Management

- Recognition: The initial step in managing change is to recognize its occurrence and proactively engage in change management. Conducting a comprehensive company-wide knowledge audit facilitates this process.

- Customer Focus: Companies must prioritize enhancing the customer experience rather than allowing change to dictate business operations. Customers seek solutions that encompass both products and services, offering flexibility, variability, and prompt responses to pricing and support inquiries.

- Resource Leveraging: Agile enterprises excel in effectively utilizing resources and sharing knowledge. Part of change management involves identifying underutilized, unused, or non-existent resources and maximizing their potential or incorporating them into operations.

- Cooperation for Competition: Agile manufacturers alter their interactions with business partners to compete more effectively through collaboration. They understand that they do not dictate market demands but instead listen to customers, identify core competencies, establish partnerships, and share knowledge as needed to deliver solutions to customers.

Agile Manufacturing System

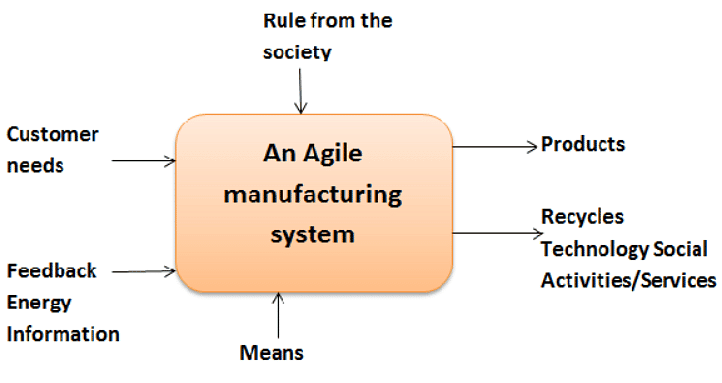

Agile manufacturing is a burgeoning concept in industries striving for manufacturing flexibility and responsiveness to changing market needs. It can be conceptualized as an integrated system of complex interactive subsystems, all working towards common goals. Modeling these subsystems using conventional analytical and mathematical approaches has proven challenging due to the inherent complexities associated with modern manufacturing systems. At its core, an Agile manufacturing system is a multi-objective-seeking system that incorporates customer needs, feedback, and societal energy information to efficiently produce outputs.

Empowering Adaptability and Innovation

Enablers of agile manufacturing encompass a spectrum of tools, methodologies, and concepts that facilitate the adaptability, responsiveness, and efficiency of manufacturing processes. These enablers are instrumental in navigating the complexities of dynamic customer demands, rapid product innovation, and evolving market landscapes. Key enablers include:

- Virtual Enterprise: Leveraging digital technologies to establish flexible, networked organizations capable of collaborating seamlessly across geographical boundaries.

- Formation Tools/Metrics: Utilizing tools and metrics to facilitate the swift formation of partnerships, alliances, and supply chain networks, enabling agile responses to market demands.

- Physically Distributed Teams and Manufacturing: Harnessing distributed teams and manufacturing facilities to enhance responsiveness and scalability while optimizing resource utilization.

- Rapid Partnership Formation Tools/Metrics: Implementing tools and metrics to expedite the formation of partnerships and collaborations, enabling agile adaptation to changing market conditions.

- Concurrent Engineering: Integrating cross-functional teams and processes to enable simultaneous development, design, and production, reducing time-to-market and enhancing product quality.

- Integrated Product/Production/Business Information Systems: Implementing comprehensive information systems that integrate product design, production planning, and business operations, fostering real-time visibility and decision-making.

- Rapid Prototyping Tools: Employing advanced prototyping technologies to accelerate product development cycles, enabling rapid iteration and validation of design concepts.

- Electronic Commerce: Embracing digital platforms and e-commerce channels to streamline procurement, distribution, and sales processes, facilitating agile responses to customer demands and market trends.

These enablers collectively empower organizations to navigate the challenges of agile manufacturing, fostering resilience, innovation, and competitiveness in dynamic business environments.

Conclusion

Agile manufacturing systems have emerged as a response to the challenges posed by fluctuating and dynamic customer demands, coupled with a growing need for extensive product customization. The concept of agility gained prominence in 1991 when industry experts recognized that traditional manufacturing models were struggling to keep pace with the rapidly evolving business landscape. Agile manufacturing integrates organizational structures, human resources, and technological systems into a cohesive and synchronized framework. It describes an approach wherein an organization develops processes, tools, and training to swiftly adapt to changing customer requirements and market dynamics, while still maintaining cost-efficiency and product quality. Many enterprises are embracing this approach to capitalize on new market opportunities. Numerous studies have been conducted to elucidate the processes and benefits associated with agile manufacturing.

FAQs on Flexibility and Agility in Manufacturing Systems - Management Optional Notes for UPSC

| 1. What is the definition of flexibility in manufacturing systems? |  |

| 2. How can manufacturing flexibility be classified? |  |

| 3. What are the levels of manufacturing flexibility? |  |

| 4. What are the categories of manufacturing flexibility? |  |

| 5. What are the characteristics of agile manufacturing for change management? |  |