Nuclear Waste Management & Safety Protocols | Science & Technology for UPSC CSE PDF Download

Introduction

Nuclear waste is radioactive material produced during nuclear fission, fuel reprocessing, or other nuclear activities. It poses health and environmental risks due to its long-lived radioactivity, requiring careful management. Safety protocols govern reactor operations, waste handling, and emergency responses to prevent accidents like Chernobyl (1986) or Fukushima (2011). India’s nuclear programme, led by the DAE, BARC, and Nuclear Power Corporation of India Limited (NPCIL), integrates waste management and safety to support its energy goals, including thorium-based reactors (e.g., Advanced Heavy Water Reactor, AHWR). Global trends, like Small Modular Reactors (SMRs) and international cooperation (e.g., India-France LoI, 2025), shape India’s strategies.

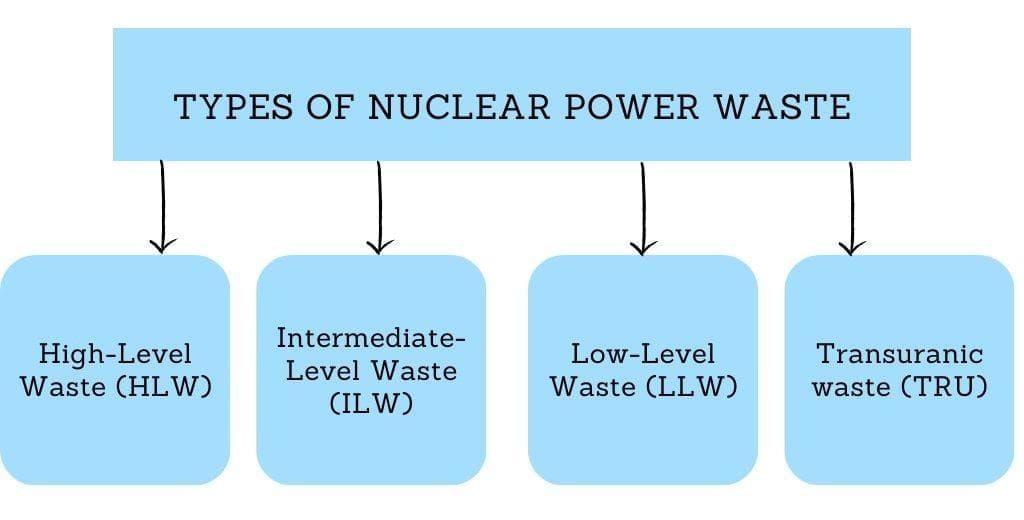

Types of Nuclear Waste

Nuclear waste is classified by radioactivity level and duration, guiding management strategies:

Low-Level Waste (LLW): Includes contaminated materials like clothing, tools, and medical waste. Low radioactivity, short half-life (days to years). ~90% of waste volume, <1% of total radioactivity.

Intermediate-Level Waste (ILW): Includes resins, chemical sludge, and reactor components. Moderate radioactivity, requires shielding and longer storage.

High-Level Waste (HLW): Spent fuel and reprocessing byproducts. Highly radioactive, long half-life (thousands to millions of years). <3% of volume, ~95% of radioactivity.

Thorium-based Waste: Thorium reactors (e.g., AHWR) produce less long-lived waste (half-life ~35 years vs. millennia for uranium), but isotopes like cesium-137 require careful handling.

India’s Context: India generates ~4 tonnes of HLW per GW-year from its Pressurized Heavy Water Reactors (PHWRs). Thorium-based reactors, planned for Stage 3, aim to reduce HLW volume and longevity.

Nuclear Waste Management Processes

Nuclear waste management follows a “reduce, reuse, recycle” approach, with disposal as the final step. India’s closed fuel cycle reprocesses spent fuel to maximize resource use and minimize waste.

1. Waste Generation and Segregation

Sources: Reactors (spent fuel), reprocessing plants (liquid waste), medical facilities (radioisotopes), and research labs.

Segregation: Waste is sorted at source by radioactivity level (LLW, ILW, HLW) to optimize treatment and storage. BARC’s facilities at Tarapur, Trombay, and Kalpakkam handle this.

2. Treatment and Conditioning

LLW and ILW: Compacted, incinerated, or cemented to reduce volume and stabilize for storage. India uses concrete trenches for LLW disposal.

HLW: Vitrified (converted into stable glass) to immobilize radioactivity. India’s vitrification plants at Tarapur (WIP, 1980s) and Kalpakkam (2024) use borosilicate glass.

Thorium Waste: Produces less actinide waste; India researches tailored vitrification for thorium-based HLW.

3. Storage

Interim Storage: HLW stored in cooled pools or dry casks for decades to reduce heat and radioactivity. India’s Away-From-Reactor (AFR) facilities at Tarapur and Kalpakkam store spent fuel.

Long-Term Storage: India plans deep geological repositories (DGRs) for HLW, with site selection ongoing in granite formations (e.g., Karnataka, Rajasthan).

4. Reprocessing

Closed Fuel Cycle: India reprocesses spent fuel to recover plutonium and uranium for Fast Breeder Reactors (FBRs). The Fast Reactor Fuel Cycle Facility (FRFCF) at Kalpakkam, commissioned in 2024, supports this.

Thorium Cycle: Reprocessing thorium fuel to extract uranium-233 for Stage 3 reactors (AHWRs). BARC leads research to optimize this process.

5. Disposal

Near-Surface Disposal: LLW and ILW disposed in engineered trenches or vaults at sites like Tarapur and Kalpakkam.

Deep Geological Repositories (DGRs): Planned for HLW to isolate waste 500–1,000 meters underground. India’s DGR programme is in the site characterization phase, learning from global models (e.g., Finland’s Onkalo).

Thorium Advantage: Shorter-lived waste reduces DGR requirements, lowering long-term costs.

Recent Developments

FRFCF Commissioning (2024): Supports reprocessing for FBRs, reducing HLW volume.

Vitrification Advances: Kalpakkam’s new plant (2024) enhances HLW immobilization, aligning with thorium reactor plans.

Budget 2025-26: ₹20,000 crore allocated for Nuclear Energy Mission, including waste management infrastructure for SMRs and thorium reactors.

International Learning: India studies global DGRs (e.g., Sweden, France) to design its own, with trials planned by 2030.

Safety Protocols in India’s Nuclear Programme

Safety protocols ensure reactor operations, waste handling, and emergency responses minimize risks. India’s Atomic Energy Regulatory Board (AERB) oversees compliance, aligning with IAEA standards.

1. Reactor Safety

Design Features:

PHWRs: Use natural uranium, heavy water, and passive cooling to reduce meltdown risks.

AHWRs: Thorium-based, with passive safety systems (e.g., gravity-driven cooling) to prevent accidents.

SMRs: Planned for 2033, designed with inherent safety (lower core damage frequency).

Redundancy: Multiple safety systems (e.g., backup cooling, containment domes) ensure fail-safe operations.

Stress Tests: Post-Fukushima (2011), India stress-tested all reactors, upgrading cooling and emergency systems.

2. Waste Handling Safety

Radiation Protection: Workers use shielding, remote handling tools, and dosimeters to limit exposure (AERB limit: 20 mSv/year).

Transport: Spent fuel moved in Type-B casks (tested for fire, impact) to AFR facilities or reprocessing plants.

Storage Safety: AFR pools and dry casks monitored for leaks; seismic-resistant designs at Kalpakkam and Tarapur.

3. Emergency Preparedness

On-Site Plans: Each reactor has emergency protocols, including evacuation drills and backup power (e.g., diesel generators).

Off-Site Plans: NDMA coordinates with NPCIL for public safety in a 16-km radius around plants. Example: Kudankulam has regular mock drills.

Post-Fukushima Upgrades: India added mobile power units and flood barriers to coastal plants (e.g., Kalpakkam).

4. Regulatory Framework

AERB: Independent regulator under DAE, enforces safety codes (e.g., AERB/SC/G for governance). Reviews reactor designs, waste facilities, and decommissioning.

IAEA Compliance: India adheres to IAEA’s Safety Standards (e.g., GSR Part 7 for emergencies). Joined Convention on Nuclear Safety (CNS) in 2005.

Recent Reforms: AERB’s autonomy strengthened in 2025 budget, with plans for a new Nuclear Safety Regulatory Authority by 2027.

Recent Developments

Safety Upgrades: Post-2024 PFBR core loading, AERB mandated enhanced monitoring for FBR safety.

International Cooperation: India-France LoI (February 2025) includes safety protocols for SMRs, learning from France’s waste management expertise.

Training: BARC’s 2025 workshops trained 500+ personnel on thorium waste handling and safety.

Public Awareness: NPCIL launched campaigns in 2024 to address public fears about nuclear safety, especially near new reactor sites.

India’s Role and Global Context

India’s Role

Closed Fuel Cycle: Reprocessing spent fuel reduces HLW volume, unlike open-cycle countries (e.g., US). FRFCF (2024) enhances this capability.

Thorium Advantage: Thorium reactors produce less long-lived waste, positioning India as a leader in sustainable nuclear tech.

Global Leadership: India shares waste management expertise with Global South via IAEA forums. BARC’s vitrification tech is a model for developing nations.

Capacity Goals: Waste management supports India’s 100 GW nuclear target by 2047, with thorium reducing disposal needs.

Global Context

Models: Finland’s Onkalo DGR (operational 2024) and France’s CIGEO project guide India’s DGR plans. US stores HLW on-site, lacking a permanent repository.

IAEA Standards: GSR Part 5 (Waste Management) and SSR-5 (Disposal) guide global practices. India aligns through AERB codes.

Challenges: Public opposition (e.g., Kudankulam protests) and high DGR costs (~₹50,000 crore) are universal issues.

Trends (2025): Global focus on SMR waste (smaller volumes) and advanced reprocessing (e.g., pyroprocessing). China’s thorium MSR (2025) reduces waste, challenging India to accelerate.

Challenges, Future Prospects, and Significance

Challenges

Public Perception: Fears of radiation and accidents hinder new reactor approvals (e.g., Jaitapur protests).

DGR Delays: Site selection for India’s DGR lags due to geological and political complexities.

Cost: Waste management facilities (e.g., vitrification plants) require high investment, straining budgets.

Global Competition: China’s thorium waste solutions (2025) outpace India’s experimental stage.

Future Prospects

DGR Development: India aims for a DGR by 2035, with pilot trials in granite formations by 2030.

Thorium Scale-Up: AHWR deployment by 2030s will reduce HLW, easing disposal needs.

Private Sector: Amendments to Atomic Energy Act (2025) will involve private firms in waste tech, boosting innovation.

International Ties: Collaboration with France, US, and IAEA will enhance safety and waste tech, supporting SMRs.

Significance for India

Energy Security: Robust waste management supports India’s 22,480 MW target by 2032, ensuring sustainable nuclear growth.

Environmental Protection: Closed fuel cycles and thorium reduce ecological impact, aligning with SDG 13 (Climate Action).

Global Standing: India’s waste management expertise strengthens its nuclear diplomacy, especially in NSG and IAEA forums.

Nuclear waste management and safety protocols are integral to India’s nuclear ambitions, enabling sustainable energy production while protecting health and the environment. India’s closed fuel cycle, thorium focus, and advanced facilities like FRFCF and vitrification plants position it as a leader in innovative waste solutions. Safety measures, regulated by AERB and aligned with IAEA standards, ensure operational integrity. Recent developments, like the 2025 budget and international collaborations, signal progress toward a robust nuclear ecosystem.

|

90 videos|490 docs|209 tests

|

FAQs on Nuclear Waste Management & Safety Protocols - Science & Technology for UPSC CSE

| 1. What are the main types of nuclear waste and how are they categorized? |  |

| 2. What processes are involved in nuclear waste management? |  |

| 3. What safety protocols are implemented in India’s nuclear program for waste management? |  |

| 4. How does India contribute to global nuclear waste management efforts? |  |

| 5. What challenges does India face in nuclear waste management, and what are the future prospects? |  |