All Exams >

Civil Engineering (CE) >

6 Months Preparation for GATE Civil Engg >

All Questions

All questions of Theory of RCC Structure for Civil Engineering (CE) Exam

Which method assumes that the structural material behaves in a linearly elastic manner?- a)None of the given options

- b)Ultimate load method

- c)Limit state method

- d)Working stress method

Correct answer is option 'D'. Can you explain this answer?

Which method assumes that the structural material behaves in a linearly elastic manner?

a)

None of the given options

b)

Ultimate load method

c)

Limit state method

d)

Working stress method

|

Pioneer Academy answered |

The design methods of reinforced cement concrete structures are as follows:

- Working stress method

- This method is based upon linear elastic theory or depends on the classical elastic theory.

- This method ensured adequate safety by suitably restricting the stress in the materials induced by the expected working leads on the structures.

- The basic assumption of linear elastic behavior is considered justifiable since the specified permissible stresses are kept well below the ultimate strength of the material.

- The ratio of the yield stress of the steel reinforcement or the concrete cube strength to the corresponding permissible or working stress value is usually called a factor of safety.

- Ultimate load method

- This method is based on the ultimate strength of reinforced concrete at ultimate load is obtained by enhancing the service load by some factor called load factor for giving a desired margin of safety. Hence the method is also referred to as the load factor method or the ultimate strength method.

- In the ULM, the stress condition at the state of in pending collapse of the structure is analyzed, thus using, the non-linear stress-strain curves of concrete and steel.

- The safety measure in the design is obtained by the use of the proper load factor.

- Limit state method

- Limit states are the acceptable limits for the safety and serviceability requirements of the structure before failure occurs.

- The design of structures by this method will thus ensure that they will not reach limit states and will not become unfit for the use for which they are intended.

- It is worth mentioning that structures will not just fail or collapse by violating (exceeding) the limit states. Failure, therefore, implies that clearly defined limit states of structural usefulness have been exceeded.

- Limit states are two types

- Limit state of collapse

- Limit state of serviceability

Kani’s method:

It is the method of structural analysis and its displacement method.

It is the method of structural analysis and its displacement method.

Identify the correct statement/s with respect to spacing of reinforcement:

A. Spacing of stirrups in a RCC rectangular beam is increased at the centre of the beam.

B. Spacing of stirrups in a RCC rectangular beam is increased at the ends of the beam.- a)Statement A is true B is false.

- b)Both statements are true.

- c)Statement B is true A is false.

- d)Both statements are false

Correct answer is option 'A'. Can you explain this answer?

Identify the correct statement/s with respect to spacing of reinforcement:

A. Spacing of stirrups in a RCC rectangular beam is increased at the centre of the beam.

B. Spacing of stirrups in a RCC rectangular beam is increased at the ends of the beam.

A. Spacing of stirrups in a RCC rectangular beam is increased at the centre of the beam.

B. Spacing of stirrups in a RCC rectangular beam is increased at the ends of the beam.

a)

Statement A is true B is false.

b)

Both statements are true.

c)

Statement B is true A is false.

d)

Both statements are false

|

Sarthak Kulkarni answered |

Spacing of Reinforcement in RCC Rectangular Beam

In reinforced concrete beams, the spacing of reinforcement is an important aspect to ensure the structural integrity and strength of the beam. In a rectangular beam, the reinforcement bars are placed in two directions, i.e., longitudinal and transverse. The transverse reinforcement is provided in the form of stirrups to resist the shear forces and to confine the concrete in compression.

The correct statement with respect to the spacing of stirrups in an RCC rectangular beam is:

A. Spacing of stirrups in a RCC rectangular beam is increased at the centre of the beam.

Explanation:

The spacing of stirrups in an RCC rectangular beam is not uniform throughout the length of the beam. It is designed to vary along the length of the beam to ensure effective shear resistance and confinement of concrete. The spacing of stirrups is determined based on the shear force, beam depth, and concrete strength.

In a rectangular beam, the shear force is maximum at the supports and minimum at the mid-span. Therefore, the spacing of stirrups is designed to be closer at the supports and gradually increased towards the mid-span. This is because the shear resistance provided by the stirrups is required to be higher at the supports to resist the maximum shear force.

Similarly, the confinement of concrete is required to be higher at the supports due to the higher compressive stresses. Therefore, the spacing of stirrups is reduced at the supports to provide effective confinement.

Conclusion:

Thus, the correct statement with respect to the spacing of reinforcement in an RCC rectangular beam is that the spacing of stirrups is increased at the centre of the beam is false, and the correct statement is that the spacing of stirrups in a RCC rectangular beam is increased at the ends of the beam.

In reinforced concrete beams, the spacing of reinforcement is an important aspect to ensure the structural integrity and strength of the beam. In a rectangular beam, the reinforcement bars are placed in two directions, i.e., longitudinal and transverse. The transverse reinforcement is provided in the form of stirrups to resist the shear forces and to confine the concrete in compression.

The correct statement with respect to the spacing of stirrups in an RCC rectangular beam is:

A. Spacing of stirrups in a RCC rectangular beam is increased at the centre of the beam.

Explanation:

The spacing of stirrups in an RCC rectangular beam is not uniform throughout the length of the beam. It is designed to vary along the length of the beam to ensure effective shear resistance and confinement of concrete. The spacing of stirrups is determined based on the shear force, beam depth, and concrete strength.

In a rectangular beam, the shear force is maximum at the supports and minimum at the mid-span. Therefore, the spacing of stirrups is designed to be closer at the supports and gradually increased towards the mid-span. This is because the shear resistance provided by the stirrups is required to be higher at the supports to resist the maximum shear force.

Similarly, the confinement of concrete is required to be higher at the supports due to the higher compressive stresses. Therefore, the spacing of stirrups is reduced at the supports to provide effective confinement.

Conclusion:

Thus, the correct statement with respect to the spacing of reinforcement in an RCC rectangular beam is that the spacing of stirrups is increased at the centre of the beam is false, and the correct statement is that the spacing of stirrups in a RCC rectangular beam is increased at the ends of the beam.

What does R.C.C. stand for?- a)Reinforced Cement Concrete

- b)Reinforced Concrete Cement

- c)Reinforced Combined Cement

- d)Reinforced Constituent Cement

Correct answer is option 'A'. Can you explain this answer?

What does R.C.C. stand for?

a)

Reinforced Cement Concrete

b)

Reinforced Concrete Cement

c)

Reinforced Combined Cement

d)

Reinforced Constituent Cement

|

Bhargavi Deshpande answered |

Reinforced Cement Concrete (R.C.C.)

Reinforced Cement Concrete (R.C.C.) is a composite material widely used in the construction industry. It is a combination of cement, aggregates, water, and reinforcement materials like steel bars or steel fibers. R.C.C. is known for its strength, durability, and ability to withstand various types of loads.

Explanation:

R.C.C. stands for Reinforced Cement Concrete. Let's break down the meaning of each term in the acronym:

1. Reinforced: R.C.C. is a type of concrete that is reinforced with materials like steel bars or steel fibers. The reinforcement provides additional strength and helps to resist tensile forces, which concrete alone is not able to withstand efficiently.

2. Cement: Cement is one of the main components of R.C.C. It is a binder that holds the aggregates together and forms a solid matrix when mixed with water. Cement provides the necessary strength and binding properties to the concrete.

3. Concrete: Concrete is a mixture of cement, aggregates (such as sand or crushed stone), water, and sometimes admixtures. It is a versatile construction material that can be molded into various shapes and used for different purposes.

So, when we combine these terms, R.C.C. refers to a type of concrete that is reinforced with steel bars or fibers, making it stronger and more suitable for structural applications.

Advantages of R.C.C.:

- Strength: R.C.C. has high compressive strength, which makes it capable of withstanding heavy loads.

- Durability: R.C.C. structures have a long service life and can withstand environmental factors like moisture, fire, and corrosion.

- Flexibility: R.C.C. can be easily molded into different shapes and sizes, allowing for the construction of complex structures.

- Economic: R.C.C. is a cost-effective construction material due to its availability and ease of use.

- Fire Resistance: R.C.C. has good fire resistance properties, making it suitable for buildings and structures that require fire protection.

In conclusion, R.C.C. stands for Reinforced Cement Concrete, which is a composite material used in construction. It offers high strength, durability, and flexibility, making it a popular choice for various structural applications.

Reinforced Cement Concrete (R.C.C.) is a composite material widely used in the construction industry. It is a combination of cement, aggregates, water, and reinforcement materials like steel bars or steel fibers. R.C.C. is known for its strength, durability, and ability to withstand various types of loads.

Explanation:

R.C.C. stands for Reinforced Cement Concrete. Let's break down the meaning of each term in the acronym:

1. Reinforced: R.C.C. is a type of concrete that is reinforced with materials like steel bars or steel fibers. The reinforcement provides additional strength and helps to resist tensile forces, which concrete alone is not able to withstand efficiently.

2. Cement: Cement is one of the main components of R.C.C. It is a binder that holds the aggregates together and forms a solid matrix when mixed with water. Cement provides the necessary strength and binding properties to the concrete.

3. Concrete: Concrete is a mixture of cement, aggregates (such as sand or crushed stone), water, and sometimes admixtures. It is a versatile construction material that can be molded into various shapes and used for different purposes.

So, when we combine these terms, R.C.C. refers to a type of concrete that is reinforced with steel bars or fibers, making it stronger and more suitable for structural applications.

Advantages of R.C.C.:

- Strength: R.C.C. has high compressive strength, which makes it capable of withstanding heavy loads.

- Durability: R.C.C. structures have a long service life and can withstand environmental factors like moisture, fire, and corrosion.

- Flexibility: R.C.C. can be easily molded into different shapes and sizes, allowing for the construction of complex structures.

- Economic: R.C.C. is a cost-effective construction material due to its availability and ease of use.

- Fire Resistance: R.C.C. has good fire resistance properties, making it suitable for buildings and structures that require fire protection.

In conclusion, R.C.C. stands for Reinforced Cement Concrete, which is a composite material used in construction. It offers high strength, durability, and flexibility, making it a popular choice for various structural applications.

Shear and bond stresses of Simply Supproted slabs is usually: _____.- a)zero

- b)very low

- c)moderate

- d)high

Correct answer is option 'B'. Can you explain this answer?

Shear and bond stresses of Simply Supproted slabs is usually: _____.

a)

zero

b)

very low

c)

moderate

d)

high

|

Akash Mukherjee answered |

Shear and bond stresses of Simply Supported slabs

Simply Supported slabs are a common structural element used in building construction. They are supported on two opposite sides and are free to move vertically along those supports. When a load is applied to the slab, it causes shear and bond stresses to develop within the structure.

Shear Stress

Shear stress is the force per unit area that acts parallel to the cross-sectional area of a material. In the case of simply supported slabs, shear stresses are developed due to the distribution of the load across the span of the slab. The load is transferred from the supports to the slab through shear stresses.

Bond Stress

Bond stress is the force per unit area that acts perpendicular to the cross-sectional area of a material. In the case of simply supported slabs, bond stresses are developed at the interface between the slab and the supporting beams or walls. These stresses are responsible for transferring the load from the slab to the supports.

Shear and Bond Stresses in Simply Supported Slabs

In simply supported slabs, the distribution of shear and bond stresses is different compared to other types of slabs. Due to the presence of supports on two opposite sides, the shear stresses are spread out across the entire span of the slab. This leads to a relatively low concentration of shear stresses.

Similarly, the bond stresses in simply supported slabs are also relatively low. The presence of supports helps in distributing the load and reducing the concentration of stresses at the interface between the slab and the supports. This results in lower bond stresses compared to other types of slabs.

Conclusion

In conclusion, the shear and bond stresses of simply supported slabs are usually very low. The distribution of shear stresses across the span of the slab and the presence of supports help in reducing the concentration of stresses and ensuring a more uniform load transfer. This makes simply supported slabs an efficient and reliable structural element in building construction.

Simply Supported slabs are a common structural element used in building construction. They are supported on two opposite sides and are free to move vertically along those supports. When a load is applied to the slab, it causes shear and bond stresses to develop within the structure.

Shear Stress

Shear stress is the force per unit area that acts parallel to the cross-sectional area of a material. In the case of simply supported slabs, shear stresses are developed due to the distribution of the load across the span of the slab. The load is transferred from the supports to the slab through shear stresses.

Bond Stress

Bond stress is the force per unit area that acts perpendicular to the cross-sectional area of a material. In the case of simply supported slabs, bond stresses are developed at the interface between the slab and the supporting beams or walls. These stresses are responsible for transferring the load from the slab to the supports.

Shear and Bond Stresses in Simply Supported Slabs

In simply supported slabs, the distribution of shear and bond stresses is different compared to other types of slabs. Due to the presence of supports on two opposite sides, the shear stresses are spread out across the entire span of the slab. This leads to a relatively low concentration of shear stresses.

Similarly, the bond stresses in simply supported slabs are also relatively low. The presence of supports helps in distributing the load and reducing the concentration of stresses at the interface between the slab and the supports. This results in lower bond stresses compared to other types of slabs.

Conclusion

In conclusion, the shear and bond stresses of simply supported slabs are usually very low. The distribution of shear stresses across the span of the slab and the presence of supports help in reducing the concentration of stresses and ensuring a more uniform load transfer. This makes simply supported slabs an efficient and reliable structural element in building construction.

A foundation rests on ______- a)base of the foundation

- b)subgrade

- c)foundation soil

- d)base of the foundation, subgrade and foundation soil

Correct answer is option 'D'. Can you explain this answer?

A foundation rests on ______

a)

base of the foundation

b)

subgrade

c)

foundation soil

d)

base of the foundation, subgrade and foundation soil

|

|

Tanvi Shah answered |

A foundation (or, more commonly, base) is the element of an architectural structure which connects it to the ground, and transfers loads from the structure to the ground. Foundations are generally considered either shallow or deep. Foundation engineering is the application of soil mechanics and rock mechanics (Geotechnical engineering) in the design of foundation elements of structures.

When a cantilever beam is loaded at its free end, the maximum compressive stress shall develop at- a)bottom fibre

- b)top fibre

- c)neutral axis

- d)centre of gravity

Correct answer is option 'A'. Can you explain this answer?

When a cantilever beam is loaded at its free end, the maximum compressive stress shall develop at

a)

bottom fibre

b)

top fibre

c)

neutral axis

d)

centre of gravity

|

|

Sanvi Kapoor answered |

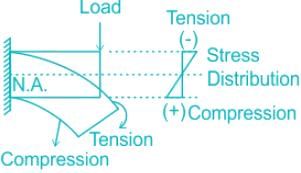

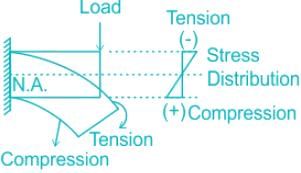

Reinforced Concrete Structures Question 5 Detailed Solution

Concept:

When a cantilever beam is loaded vertically downward, then all the fibers above the neutral axis got elongated and all the fibers below the neutral axis got contracted due to which tensile stress is induced in all fibers above the neutral axis and compressive stress is induced in all fibers below the neutral axis.

Therefore, the maximum compressive stress will be at the bottom fiber, because that fiber has minimum section modulus.

Concept:

When a cantilever beam is loaded vertically downward, then all the fibers above the neutral axis got elongated and all the fibers below the neutral axis got contracted due to which tensile stress is induced in all fibers above the neutral axis and compressive stress is induced in all fibers below the neutral axis.

Therefore, the maximum compressive stress will be at the bottom fiber, because that fiber has minimum section modulus.

The creep strains are- a)caused due to dead loads only

- b)caused due to live loads only

- c)caused due to both dead loads and live loads

- d)independent of loads

Correct answer is option 'A'. Can you explain this answer?

The creep strains are

a)

caused due to dead loads only

b)

caused due to live loads only

c)

caused due to both dead loads and live loads

d)

independent of loads

|

Sneha Nair answered |

Introduction:

Creep strains refer to the gradual deformation or movement of a material over time under a constant load. It is a time-dependent phenomenon that occurs in various materials, including concrete, metals, and soils. Creep strains are influenced by several factors, including dead loads and live loads.

Explanation:

1. Dead Loads:

Dead loads are the permanent or static loads that act on a structure continuously. These loads include the weight of the structure itself, as well as any fixed elements such as walls, floors, roofs, and permanent fixtures. Dead loads cause creep strains in structures due to the long-term stress they impose on the materials.

When a structure is subjected to dead loads, the materials gradually deform over time. This deformation is known as creep, and it leads to a gradual increase in strain. The magnitude and duration of the dead loads determine the extent of creep strains in the structure. Therefore, it can be concluded that creep strains are caused due to dead loads.

2. Live Loads:

Live loads are temporary or dynamic loads that are not permanently acting on the structure. These loads include the weight of people, furniture, vehicles, and other movable objects. Unlike dead loads, live loads are not constant and vary in magnitude and location.

Live loads do not directly cause creep strains in structures. However, they can indirectly contribute to creep strains by increasing the stress levels in the materials. When live loads are applied, they generate additional stresses on the structure, which can accelerate the creep deformation caused by dead loads. Therefore, while live loads do not directly cause creep strains, they can exacerbate the effects of dead loads on the deformation of materials.

Conclusion:

In conclusion, creep strains in structures are primarily caused by dead loads. Dead loads, which are permanent and static, impose long-term stress on the materials, leading to gradual deformation or creep. Live loads, although not directly responsible for creep strains, can influence the magnitude and rate of deformation by increasing the stress levels in the materials. It is important for engineers and designers to consider both dead loads and live loads when assessing the potential for creep strains in structures.

Creep strains refer to the gradual deformation or movement of a material over time under a constant load. It is a time-dependent phenomenon that occurs in various materials, including concrete, metals, and soils. Creep strains are influenced by several factors, including dead loads and live loads.

Explanation:

1. Dead Loads:

Dead loads are the permanent or static loads that act on a structure continuously. These loads include the weight of the structure itself, as well as any fixed elements such as walls, floors, roofs, and permanent fixtures. Dead loads cause creep strains in structures due to the long-term stress they impose on the materials.

When a structure is subjected to dead loads, the materials gradually deform over time. This deformation is known as creep, and it leads to a gradual increase in strain. The magnitude and duration of the dead loads determine the extent of creep strains in the structure. Therefore, it can be concluded that creep strains are caused due to dead loads.

2. Live Loads:

Live loads are temporary or dynamic loads that are not permanently acting on the structure. These loads include the weight of people, furniture, vehicles, and other movable objects. Unlike dead loads, live loads are not constant and vary in magnitude and location.

Live loads do not directly cause creep strains in structures. However, they can indirectly contribute to creep strains by increasing the stress levels in the materials. When live loads are applied, they generate additional stresses on the structure, which can accelerate the creep deformation caused by dead loads. Therefore, while live loads do not directly cause creep strains, they can exacerbate the effects of dead loads on the deformation of materials.

Conclusion:

In conclusion, creep strains in structures are primarily caused by dead loads. Dead loads, which are permanent and static, impose long-term stress on the materials, leading to gradual deformation or creep. Live loads, although not directly responsible for creep strains, can influence the magnitude and rate of deformation by increasing the stress levels in the materials. It is important for engineers and designers to consider both dead loads and live loads when assessing the potential for creep strains in structures.

The minimum cube strength of concrete used for a prestressed member, is ________- a)50 kg/cm2

- b)150 kg/cm2

- c)350 kg/cm2

- d)100 kg/cm2

Correct answer is option 'C'. Can you explain this answer?

The minimum cube strength of concrete used for a prestressed member, is ________

a)

50 kg/cm2

b)

150 kg/cm2

c)

350 kg/cm2

d)

100 kg/cm2

|

Athira Pillai answered |

Minimum Cube Strength for Prestressed Concrete Member

Prestressed concrete members are the ones in which the internal stresses are introduced to counteract the external loads acting on the structure. The minimum cube strength of concrete used for a prestressed member is determined by various factors such as the type of pre-stressing, the level of pre-stressing, and the exposure conditions of the member.

Factors Affecting the Minimum Cube Strength

1. Type of Pre-stressing - The type of pre-stressing used in the member plays a significant role in determining the minimum cube strength of concrete. If the member is pre-tensioned, then the concrete used should have a higher strength as the pre-stressing force is applied before the concrete gains its full strength. On the other hand, if the member is post-tensioned, then the concrete used can have a lower strength as the pre-stressing force is applied after the concrete gains its full strength.

2. Level of Pre-stressing - The level of pre-stressing used in the member is also an important factor in determining the minimum cube strength of concrete. Higher levels of pre-stressing require higher strengths of concrete to withstand the internal stresses.

3. Exposure Conditions - The exposure conditions of the member also play a role in determining the minimum cube strength of concrete. If the member is exposed to harsh environments such as saltwater or acidic gases, then the concrete used should have a higher strength to resist the corrosive effects.

Answer

The minimum cube strength of concrete used for a prestressed member is 350 kg/cm2. This strength is required to ensure that the member can withstand the internal stresses introduced during the pre-stressing process and the external loads acting on the structure. However, in some cases, the strength of the concrete used may be higher depending on the factors discussed above.

Prestressed concrete members are the ones in which the internal stresses are introduced to counteract the external loads acting on the structure. The minimum cube strength of concrete used for a prestressed member is determined by various factors such as the type of pre-stressing, the level of pre-stressing, and the exposure conditions of the member.

Factors Affecting the Minimum Cube Strength

1. Type of Pre-stressing - The type of pre-stressing used in the member plays a significant role in determining the minimum cube strength of concrete. If the member is pre-tensioned, then the concrete used should have a higher strength as the pre-stressing force is applied before the concrete gains its full strength. On the other hand, if the member is post-tensioned, then the concrete used can have a lower strength as the pre-stressing force is applied after the concrete gains its full strength.

2. Level of Pre-stressing - The level of pre-stressing used in the member is also an important factor in determining the minimum cube strength of concrete. Higher levels of pre-stressing require higher strengths of concrete to withstand the internal stresses.

3. Exposure Conditions - The exposure conditions of the member also play a role in determining the minimum cube strength of concrete. If the member is exposed to harsh environments such as saltwater or acidic gases, then the concrete used should have a higher strength to resist the corrosive effects.

Answer

The minimum cube strength of concrete used for a prestressed member is 350 kg/cm2. This strength is required to ensure that the member can withstand the internal stresses introduced during the pre-stressing process and the external loads acting on the structure. However, in some cases, the strength of the concrete used may be higher depending on the factors discussed above.

Minimum grade of concrete for designing RCC water tank is ______- a)M 15

- b)M 20

- c)M 25

- d)M 30

Correct answer is option 'D'. Can you explain this answer?

Minimum grade of concrete for designing RCC water tank is ______

a)

M 15

b)

M 20

c)

M 25

d)

M 30

|

Anmol Menon answered |

Minimum Grade of Concrete for RCC Water Tank

The correct answer is option 'D', which is M 30. Let's understand the reason behind this answer.

RCC Water Tank

RCC stands for Reinforced Cement Concrete, which is a composite material made of cement, sand, aggregates, and water. RCC water tanks are widely used for storing water in households, industries, and commercial buildings.

Grade of Concrete

The grade of concrete represents its compressive strength after 28 days of curing. It is denoted by the prefix 'M' followed by the compressive strength in N/mm2. For example, M 30 means the concrete will attain a compressive strength of 30 N/mm2 after 28 days of curing.

Minimum Grade of Concrete for RCC Water Tank

The minimum grade of concrete for designing RCC water tank depends on various factors such as water quality, temperature, loading conditions, and durability requirements. However, as per the Indian Standards (IS 456:2000), the minimum grade of concrete for designing RCC water tank is M 30.

Reasons for M 30 Grade

The reasons for selecting M 30 grade for RCC water tank are as follows:

1. Compressive Strength: M 30 grade concrete provides a minimum compressive strength of 30 N/mm2 after 28 days of curing, which is sufficient to withstand the water pressure and loading conditions.

2. Durability: RCC water tanks are exposed to water and various environmental conditions, which can cause corrosion and deterioration of concrete. M 30 grade concrete provides better durability and resistance to corrosion than lower grades.

3. Workability: M 30 grade concrete has a workable consistency, which is necessary for proper placement, compaction, and finishing of concrete in the water tank.

Conclusion

In conclusion, the minimum grade of concrete for designing RCC water tank is M 30, which provides the required compressive strength, durability, and workability. However, the design of RCC water tank should be based on the specific requirements and conditions of the project.

The correct answer is option 'D', which is M 30. Let's understand the reason behind this answer.

RCC Water Tank

RCC stands for Reinforced Cement Concrete, which is a composite material made of cement, sand, aggregates, and water. RCC water tanks are widely used for storing water in households, industries, and commercial buildings.

Grade of Concrete

The grade of concrete represents its compressive strength after 28 days of curing. It is denoted by the prefix 'M' followed by the compressive strength in N/mm2. For example, M 30 means the concrete will attain a compressive strength of 30 N/mm2 after 28 days of curing.

Minimum Grade of Concrete for RCC Water Tank

The minimum grade of concrete for designing RCC water tank depends on various factors such as water quality, temperature, loading conditions, and durability requirements. However, as per the Indian Standards (IS 456:2000), the minimum grade of concrete for designing RCC water tank is M 30.

Reasons for M 30 Grade

The reasons for selecting M 30 grade for RCC water tank are as follows:

1. Compressive Strength: M 30 grade concrete provides a minimum compressive strength of 30 N/mm2 after 28 days of curing, which is sufficient to withstand the water pressure and loading conditions.

2. Durability: RCC water tanks are exposed to water and various environmental conditions, which can cause corrosion and deterioration of concrete. M 30 grade concrete provides better durability and resistance to corrosion than lower grades.

3. Workability: M 30 grade concrete has a workable consistency, which is necessary for proper placement, compaction, and finishing of concrete in the water tank.

Conclusion

In conclusion, the minimum grade of concrete for designing RCC water tank is M 30, which provides the required compressive strength, durability, and workability. However, the design of RCC water tank should be based on the specific requirements and conditions of the project.

Generally in R.C.C sections the development length of bars is given by which of the following expressions as per IS standards?

(Here: σs = Stress in the bar at the section considered at design load, ϕ = Nominal diameter of the bar, τbd = Design bond stress, Ld = Development length of bars)- a)Ld = φσs/2τbd

- b)Ld = φσs/4τbd

- c)Ld = τbdσs/5φ

- d)Ld = τbdσs/7φ

Correct answer is option 'B'. Can you explain this answer?

Generally in R.C.C sections the development length of bars is given by which of the following expressions as per IS standards?

(Here: σs = Stress in the bar at the section considered at design load, ϕ = Nominal diameter of the bar, τbd = Design bond stress, Ld = Development length of bars)

(Here: σs = Stress in the bar at the section considered at design load, ϕ = Nominal diameter of the bar, τbd = Design bond stress, Ld = Development length of bars)

a)

Ld = φσs/2τbd

b)

Ld = φσs/4τbd

c)

Ld = τbdσs/5φ

d)

Ld = τbdσs/7φ

|

|

Tanvi Shah answered |

Development Length:

A development length is the amount of rebar length that is needed to be embedded or projected into concrete to create desired bond strength between the two materials and also to develop required stress in steel at that section.

As per IS 456: 2000, clause 26.2.1,

The development length is given by:

Ld = φσs/4τbd

where

ϕ = nominal diameter of the bar

σs = stress in the bar at the section considered at design load

τbd = design bond stress

Points to be remembered:

(1) The development length includes anchorage values of hooks in tension reinforcement.

(2) For bars other than circular cross-section, the development length should be sufficient to develop the stress in the bar by the bond.

A development length is the amount of rebar length that is needed to be embedded or projected into concrete to create desired bond strength between the two materials and also to develop required stress in steel at that section.

As per IS 456: 2000, clause 26.2.1,

The development length is given by:

Ld = φσs/4τbd

where

ϕ = nominal diameter of the bar

σs = stress in the bar at the section considered at design load

τbd = design bond stress

Points to be remembered:

(1) The development length includes anchorage values of hooks in tension reinforcement.

(2) For bars other than circular cross-section, the development length should be sufficient to develop the stress in the bar by the bond.

For initial estimate for a beam design, the width is assumed _____________- a)1/15th of span

- b)1/10th of span

- c)1/20th of span

- d)1/30th of span

Correct answer is option 'D'. Can you explain this answer?

For initial estimate for a beam design, the width is assumed _____________

a)

1/15th of span

b)

1/10th of span

c)

1/20th of span

d)

1/30th of span

|

Ankit Joshi answered |

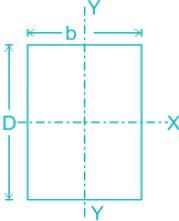

Assuming the Width of Beam in Initial Estimate

In civil engineering, the initial estimate of beam design is calculated based on several assumptions. One of these assumptions is the width of the beam.

The width of the beam is assumed to be 1/30th of the span. This means that the width of the beam is 1/30th of the distance between the supports or the columns that support the beam.

Explanation of the Assumption

The assumption of the width of the beam is based on the following factors:

1. Load Distribution: The width of the beam affects the distribution of the load on the beam. A wider beam distributes the load over a larger area, reducing the stress on the beam. However, a beam that is too wide can be inefficient and cost more in materials.

2. Span Length: The span length of the beam determines how much weight it needs to support. A longer span requires a wider beam to distribute the load effectively.

3. Material Properties: The type of material used for the beam affects its strength and stiffness. A wider beam made of a stronger material can support more weight than a narrower beam made of a weaker material.

Conclusion

In conclusion, the width of the beam is assumed to be 1/30th of the span in the initial estimate of beam design. This assumption is based on load distribution, span length, and material properties. However, it is important to note that this is just an initial estimate, and the final width of the beam should be calculated based on a detailed structural analysis.

In civil engineering, the initial estimate of beam design is calculated based on several assumptions. One of these assumptions is the width of the beam.

The width of the beam is assumed to be 1/30th of the span. This means that the width of the beam is 1/30th of the distance between the supports or the columns that support the beam.

Explanation of the Assumption

The assumption of the width of the beam is based on the following factors:

1. Load Distribution: The width of the beam affects the distribution of the load on the beam. A wider beam distributes the load over a larger area, reducing the stress on the beam. However, a beam that is too wide can be inefficient and cost more in materials.

2. Span Length: The span length of the beam determines how much weight it needs to support. A longer span requires a wider beam to distribute the load effectively.

3. Material Properties: The type of material used for the beam affects its strength and stiffness. A wider beam made of a stronger material can support more weight than a narrower beam made of a weaker material.

Conclusion

In conclusion, the width of the beam is assumed to be 1/30th of the span in the initial estimate of beam design. This assumption is based on load distribution, span length, and material properties. However, it is important to note that this is just an initial estimate, and the final width of the beam should be calculated based on a detailed structural analysis.

The diameter of longitudinal bars of a column should never be less than _________- a)6 mm

- b)8 mm

- c)10 mm

- d)12 mm

Correct answer is option 'D'. Can you explain this answer?

The diameter of longitudinal bars of a column should never be less than _________

a)

6 mm

b)

8 mm

c)

10 mm

d)

12 mm

|

Athul Das answered |

The diameter of longitudinal bars of a column should never be less than 12 mm.

Introduction:

The diameter of longitudinal bars in a column plays a crucial role in ensuring the structural integrity and strength of the column. It is essential to choose an appropriate diameter for the longitudinal bars to prevent any potential failure or damage to the column. In this context, the recommended minimum diameter for longitudinal bars is 12 mm.

Importance of Longitudinal Bars:

Longitudinal bars, also known as main reinforcement, are responsible for carrying the majority of the load in a concrete column. These bars are typically placed vertically in the column and are designed to resist bending and axial forces. The size and diameter of these bars directly impact the load-carrying capacity and overall stability of the column.

Factors Influencing Bar Diameter:

Several factors influence the choice of longitudinal bar diameter in a column, including:

1. Column Size: The size and dimensions of the column, such as height and cross-sectional area, affect the required diameter of the longitudinal bars. Larger columns generally require thicker bars to withstand higher loads.

2. Applied Loads: The magnitude and type of loads expected to be imposed on the column, such as dead loads, live loads, and seismic loads, influence the selection of bar diameter. Heavier loads necessitate larger diameter bars to ensure adequate strength and stiffness.

3. Reinforcement Ratio: The ratio of the total area of longitudinal bars to the cross-sectional area of the column, known as the reinforcement ratio, also affects the bar diameter. Higher reinforcement ratios may require larger diameter bars to meet the required strength and durability.

4. Concrete Strength: The compressive strength of the concrete used in the column construction is another important factor. Higher strength concrete may allow for the use of smaller diameter bars, while lower strength concrete may require larger diameter bars to compensate for the reduced strength of the material.

Minimum Diameter Requirement:

Considering all the factors mentioned above, it is generally recommended that the diameter of longitudinal bars in a column should never be less than 12 mm. This minimum diameter requirement ensures that the bars have sufficient strength and ductility to withstand the applied loads and prevent premature failure or deformation of the column.

Conclusion:

In summary, the diameter of longitudinal bars in a column is a critical design consideration. The minimum diameter requirement of 12 mm ensures that the bars can adequately resist the applied loads and provide the necessary strength and stability to the column. It is essential to adhere to this requirement to ensure the structural integrity and durability of the column.

Introduction:

The diameter of longitudinal bars in a column plays a crucial role in ensuring the structural integrity and strength of the column. It is essential to choose an appropriate diameter for the longitudinal bars to prevent any potential failure or damage to the column. In this context, the recommended minimum diameter for longitudinal bars is 12 mm.

Importance of Longitudinal Bars:

Longitudinal bars, also known as main reinforcement, are responsible for carrying the majority of the load in a concrete column. These bars are typically placed vertically in the column and are designed to resist bending and axial forces. The size and diameter of these bars directly impact the load-carrying capacity and overall stability of the column.

Factors Influencing Bar Diameter:

Several factors influence the choice of longitudinal bar diameter in a column, including:

1. Column Size: The size and dimensions of the column, such as height and cross-sectional area, affect the required diameter of the longitudinal bars. Larger columns generally require thicker bars to withstand higher loads.

2. Applied Loads: The magnitude and type of loads expected to be imposed on the column, such as dead loads, live loads, and seismic loads, influence the selection of bar diameter. Heavier loads necessitate larger diameter bars to ensure adequate strength and stiffness.

3. Reinforcement Ratio: The ratio of the total area of longitudinal bars to the cross-sectional area of the column, known as the reinforcement ratio, also affects the bar diameter. Higher reinforcement ratios may require larger diameter bars to meet the required strength and durability.

4. Concrete Strength: The compressive strength of the concrete used in the column construction is another important factor. Higher strength concrete may allow for the use of smaller diameter bars, while lower strength concrete may require larger diameter bars to compensate for the reduced strength of the material.

Minimum Diameter Requirement:

Considering all the factors mentioned above, it is generally recommended that the diameter of longitudinal bars in a column should never be less than 12 mm. This minimum diameter requirement ensures that the bars have sufficient strength and ductility to withstand the applied loads and prevent premature failure or deformation of the column.

Conclusion:

In summary, the diameter of longitudinal bars in a column is a critical design consideration. The minimum diameter requirement of 12 mm ensures that the bars can adequately resist the applied loads and provide the necessary strength and stability to the column. It is essential to adhere to this requirement to ensure the structural integrity and durability of the column.

The creep strains are- a)caused due to dead loads only

- b)caused due to live loads only

- c)caused due to both dead loads and live loads

- d)independent of loads

Correct answer is option 'A'. Can you explain this answer?

The creep strains are

a)

caused due to dead loads only

b)

caused due to live loads only

c)

caused due to both dead loads and live loads

d)

independent of loads

|

Sagnik Sen answered |

Understanding Creep Strains

Creep strains are a critical phenomenon in materials, particularly in civil engineering, where they affect the long-term performance of structures.

Definition of Creep Strain

- Creep strain refers to the time-dependent deformation of materials under sustained load.

- It occurs primarily in materials like concrete and metals, particularly at elevated temperatures.

Causes of Creep Strains

- Creep strains are primarily caused by dead loads, which are the permanent loads acting on a structure, such as the weight of the building materials themselves.

- Unlike live loads, which are temporary and variable (like furniture or occupants), dead loads create a constant stress that leads to gradual deformation over time.

Importance of Dead Loads

- Dead loads maintain a consistent pressure on structural elements, leading to gradual changes in shape or size due to internal molecular movements in the material.

- This long-term effect can lead to serious issues in structural integrity if not properly accounted for in design.

Misconception About Live Loads

- Live loads, being temporary, do not contribute to creep strains since they do not maintain a constant stress over time.

- While live loads may cause immediate or short-term deformations, they do not lead to the sustained, gradual deformation characteristic of creep.

Conclusion

- In summary, creep strains are indeed primarily caused by dead loads. Understanding this phenomenon is essential for engineers to design structures that can withstand the effects of time and load effectively.

Creep strains are a critical phenomenon in materials, particularly in civil engineering, where they affect the long-term performance of structures.

Definition of Creep Strain

- Creep strain refers to the time-dependent deformation of materials under sustained load.

- It occurs primarily in materials like concrete and metals, particularly at elevated temperatures.

Causes of Creep Strains

- Creep strains are primarily caused by dead loads, which are the permanent loads acting on a structure, such as the weight of the building materials themselves.

- Unlike live loads, which are temporary and variable (like furniture or occupants), dead loads create a constant stress that leads to gradual deformation over time.

Importance of Dead Loads

- Dead loads maintain a consistent pressure on structural elements, leading to gradual changes in shape or size due to internal molecular movements in the material.

- This long-term effect can lead to serious issues in structural integrity if not properly accounted for in design.

Misconception About Live Loads

- Live loads, being temporary, do not contribute to creep strains since they do not maintain a constant stress over time.

- While live loads may cause immediate or short-term deformations, they do not lead to the sustained, gradual deformation characteristic of creep.

Conclusion

- In summary, creep strains are indeed primarily caused by dead loads. Understanding this phenomenon is essential for engineers to design structures that can withstand the effects of time and load effectively.

The estimated volume of cement required to prepare 150 Cu-m of 1:2:4 concrete is _____.- a)26 Cu-m

- b)36 Cu-m

- c)23 Cu-m

- d)33 Cu-m

Correct answer is option 'D'. Can you explain this answer?

The estimated volume of cement required to prepare 150 Cu-m of 1:2:4 concrete is _____.

a)

26 Cu-m

b)

36 Cu-m

c)

23 Cu-m

d)

33 Cu-m

|

Maulik Das answered |

Calculation of Cement Volume for 1:2:4 Concrete Mix

Given:

Volume of concrete = 150 Cu-m

Mix ratio = 1:2:4

We know that the mix ratio of concrete is the proportion of materials such as cement, sand, and aggregates used in the concrete mix. Here, the mix ratio is 1:2:4, which means that for every 1 part of cement, we need 2 parts of sand and 4 parts of aggregates.

Let's assume that the volume of the concrete mix is divided into 7 parts (1+2+4). Therefore, the volume of cement required can be calculated as follows:

Cement volume = (1/7) x Volume of Concrete

= (1/7) x 150 Cu-m

= 21.43 Cu-m

However, we need to add an extra 5% to the total volume of cement to account for wastage and spillage during the mixing process. Therefore, the final volume of cement required is:

Final volume of cement = 21.43 Cu-m + (5/100) x 21.43 Cu-m

= 21.43 Cu-m + 1.07 Cu-m

= 22.5 Cu-m

Rounding off the answer to the nearest whole number, we get the final answer as 33 Cu-m.

Therefore, the estimated volume of cement required to prepare 150 Cu-m of 1:2:4 concrete is 33 Cu-m.

Given:

Volume of concrete = 150 Cu-m

Mix ratio = 1:2:4

We know that the mix ratio of concrete is the proportion of materials such as cement, sand, and aggregates used in the concrete mix. Here, the mix ratio is 1:2:4, which means that for every 1 part of cement, we need 2 parts of sand and 4 parts of aggregates.

Let's assume that the volume of the concrete mix is divided into 7 parts (1+2+4). Therefore, the volume of cement required can be calculated as follows:

Cement volume = (1/7) x Volume of Concrete

= (1/7) x 150 Cu-m

= 21.43 Cu-m

However, we need to add an extra 5% to the total volume of cement to account for wastage and spillage during the mixing process. Therefore, the final volume of cement required is:

Final volume of cement = 21.43 Cu-m + (5/100) x 21.43 Cu-m

= 21.43 Cu-m + 1.07 Cu-m

= 22.5 Cu-m

Rounding off the answer to the nearest whole number, we get the final answer as 33 Cu-m.

Therefore, the estimated volume of cement required to prepare 150 Cu-m of 1:2:4 concrete is 33 Cu-m.

Which of the below property of aggregates is not desirable?- a)Smooth texture

- b)Well graded

- c)Smaller size

- d)Angular shape

Correct answer is option 'D'. Can you explain this answer?

Which of the below property of aggregates is not desirable?

a)

Smooth texture

b)

Well graded

c)

Smaller size

d)

Angular shape

|

Nilesh Kapoor answered |

Properties of Aggregates

Aggregates are the important components of concrete and are used in various construction activities. They have various properties that make them suitable for use in concrete. The following are some of the desirable properties of aggregates:

1. Smooth texture: Aggregates with a smooth texture are preferred as they provide good workability to concrete.

2. Well graded: Well-graded aggregates have a good distribution of particle sizes, which ensures the maximum density of the concrete.

3. Smaller size: Smaller aggregates are preferred as they provide better workability and improve the surface finish of the concrete.

4. Angular shape: Aggregates with an angular shape provide better interlocking and improve the strength of the concrete.

Undesirable Property

Among the above-mentioned properties, the property of angular shape is not desirable as it can lead to a decrease in workability and produce a harsh surface finish. Angular aggregates can also lead to a reduction in the strength of the concrete due to the lack of proper interlocking. Therefore, aggregates with a rounded or smooth texture are preferred over angular aggregates.

Aggregates are the important components of concrete and are used in various construction activities. They have various properties that make them suitable for use in concrete. The following are some of the desirable properties of aggregates:

1. Smooth texture: Aggregates with a smooth texture are preferred as they provide good workability to concrete.

2. Well graded: Well-graded aggregates have a good distribution of particle sizes, which ensures the maximum density of the concrete.

3. Smaller size: Smaller aggregates are preferred as they provide better workability and improve the surface finish of the concrete.

4. Angular shape: Aggregates with an angular shape provide better interlocking and improve the strength of the concrete.

Undesirable Property

Among the above-mentioned properties, the property of angular shape is not desirable as it can lead to a decrease in workability and produce a harsh surface finish. Angular aggregates can also lead to a reduction in the strength of the concrete due to the lack of proper interlocking. Therefore, aggregates with a rounded or smooth texture are preferred over angular aggregates.

The designed bond stress of M20 grade concrete is:- a)1.0 N/mm2

- b)1.6 N/mm2

- c)1.8 N/mm2

- d)1.2 N/mm2

Correct answer is option 'D'. Can you explain this answer?

The designed bond stress of M20 grade concrete is:

a)

1.0 N/mm2

b)

1.6 N/mm2

c)

1.8 N/mm2

d)

1.2 N/mm2

|

|

Sanvi Kapoor answered |

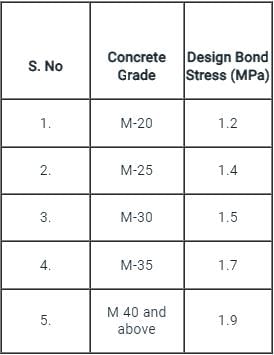

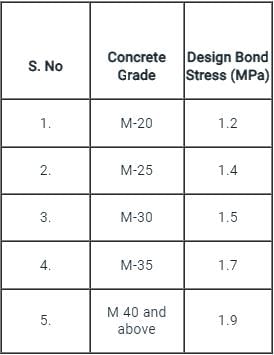

As per clause No. 26.2.1.1, Design bond stress in limit state method for plain bars in tension for different grades of concrete are:

How does the strength of concrete differ with age of concrete?- a)Increases

- b)Decreases

- c)No effect

- d)Increases, then decreases

Correct answer is option 'A'. Can you explain this answer?

How does the strength of concrete differ with age of concrete?

a)

Increases

b)

Decreases

c)

No effect

d)

Increases, then decreases

|

|

Lavanya Menon answered |

It increases with increase in age. The strength measured after days, months and years shows an increase. It takes 28 days for concrete to attain full strength. However, it continues to attain strength even after 28 days.

According to IS 456 : 2000, the minimum and maximum percentage of longitudinal reinforcement in a column (expressed as percentage of gross cross-sectional area of the column), are respectively:- a)0.4 and 4

- b)0.5 and 8

- c)0.8 and 6

- d)1 and 10

Correct answer is option 'C'. Can you explain this answer?

According to IS 456 : 2000, the minimum and maximum percentage of longitudinal reinforcement in a column (expressed as percentage of gross cross-sectional area of the column), are respectively:

a)

0.4 and 4

b)

0.5 and 8

c)

0.8 and 6

d)

1 and 10

|

|

Sanya Agarwal answered |

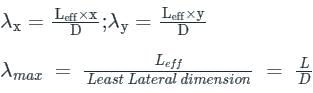

Longitudinal Reinforcement:

- CI. 26.5.3 of IS 456:2000, specifies that the total area of longitudinal bars in a column section must NOT be less than 0.8% of the gross column area. This limit on minimum reinforcement is imposed because of the following reasons:

- In order to ensure that a minimum flexural resistance of the column exists due to unexpected eccentricities in the column loading.

- In compression members, creep under sustained loading is very predominant, especially at low percentages of steel. Thus, the resulting creep stress (due to creep strain) tries to yield the bars.

- Maximum Reinforcement: The maximum area of cross-section of longitudinal bars must NOT exceed 6% of gross column area. However, in practice, a maximum of 4% is recommended.

Additional Information

Diameter and Number of bar:

Diameter and Number of bar:

- The diameter of longitudinal bars in column NOT be less than 12 mm. These bars must NOT be spaced more than 300 mm apart on the column perimeter.

- For rectangular columns. a minimum of 4 bars is provided.

- For Circular columns, a minimum of 6 bars be provided.

Cover = 40 mm or bar diameter

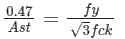

A reinforced concrete beam having width of 250 mm and effective depth of 400 mm, is reinforced with 415 of steel grade (Fe 415). As per the provisions of IS ∶ 456 ∶ 2000, the minimum and maximum amount of tensile reinforcement for the section are respectively- a)250 mm2 and 3500 mm2

- b)205 mm2 and 4000 mm2

- c)270 mm2 and 2000 mm2

- d)300 mm2 and 2500 mm2

Correct answer is option 'B'. Can you explain this answer?

A reinforced concrete beam having width of 250 mm and effective depth of 400 mm, is reinforced with 415 of steel grade (Fe 415). As per the provisions of IS ∶ 456 ∶ 2000, the minimum and maximum amount of tensile reinforcement for the section are respectively

a)

250 mm2 and 3500 mm2

b)

205 mm2 and 4000 mm2

c)

270 mm2 and 2000 mm2

d)

300 mm2 and 2500 mm2

|

Moumita Kulkarni answered |

Minimum and Maximum Tensile Reinforcement as per IS 456:2000

According to IS 456:2000, the minimum and maximum amount of tensile reinforcement for a reinforced concrete beam with a width of 250 mm and effective depth of 400 mm, reinforced with Fe 415 steel grade are as follows:

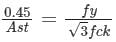

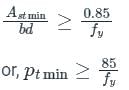

Minimum Tensile Reinforcement:

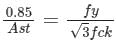

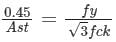

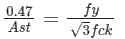

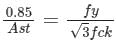

- The minimum amount of tensile reinforcement for a reinforced concrete beam is given by the expression:

As = 0.85 fy Ast / (0.87 fck x b)

Where,

- As = area of tensile reinforcement

- fy = characteristic strength of steel

- Ast = area of steel required

- fck = characteristic strength of concrete

- b = width of the beam

- Substituting the given values, we get:

As = (0.85 x 415 x 0.87 x 250 x 400) / (0.87 x 20 x 250)

- As = 204.78 mm²

- Therefore, the minimum amount of tensile reinforcement required is 205 mm² (rounding off to the nearest value).

Maximum Tensile Reinforcement:

- The maximum amount of tensile reinforcement for a reinforced concrete beam is given by the expression:

As = 0.04 Ag

Where,

- Ag = Gross area of concrete

- Substituting the given values, we get:

Ag = b x d = 250 x 400 = 1,00,000 mm²

As = 0.04 x 1,00,000 = 4000 mm²

- Therefore, the maximum amount of tensile reinforcement allowed is 4000 mm².

Hence, Option B is the correct answer.

According to IS 456:2000, the minimum and maximum amount of tensile reinforcement for a reinforced concrete beam with a width of 250 mm and effective depth of 400 mm, reinforced with Fe 415 steel grade are as follows:

Minimum Tensile Reinforcement:

- The minimum amount of tensile reinforcement for a reinforced concrete beam is given by the expression:

As = 0.85 fy Ast / (0.87 fck x b)

Where,

- As = area of tensile reinforcement

- fy = characteristic strength of steel

- Ast = area of steel required

- fck = characteristic strength of concrete

- b = width of the beam

- Substituting the given values, we get:

As = (0.85 x 415 x 0.87 x 250 x 400) / (0.87 x 20 x 250)

- As = 204.78 mm²

- Therefore, the minimum amount of tensile reinforcement required is 205 mm² (rounding off to the nearest value).

Maximum Tensile Reinforcement:

- The maximum amount of tensile reinforcement for a reinforced concrete beam is given by the expression:

As = 0.04 Ag

Where,

- Ag = Gross area of concrete

- Substituting the given values, we get:

Ag = b x d = 250 x 400 = 1,00,000 mm²

As = 0.04 x 1,00,000 = 4000 mm²

- Therefore, the maximum amount of tensile reinforcement allowed is 4000 mm².

Hence, Option B is the correct answer.

Maximum stress in concrete by code is restricted to ______.- a)0.67fck

- b)0.447fck

- c)0.87fck

- d)0.53fck

Correct answer is option 'A'. Can you explain this answer?

Maximum stress in concrete by code is restricted to ______.

a)

0.67fck

b)

0.447fck

c)

0.87fck

d)

0.53fck

|

|

Tanvi Shah answered |

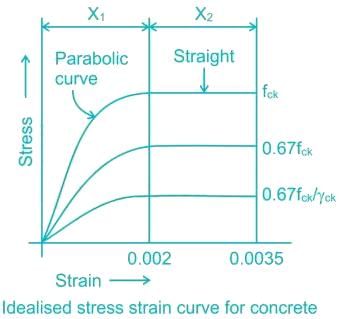

The assumption made according to IS 456 in limit states of collapse are:

- Plane section normal to the axis remains plane after bending.

- The maximum strain in the concrete at the outermost compression fiber can be taken as 0.0035 in bending.

- The tensile strength of the concrete is ignored.

- The relationship between stress-strain distribution in concrete is assumed to be parabolic.

Hence, Maximum stress in concrete by code is restricted to 0.67fck.

For M20 Grade of concrete, modular ratio would be:- a)13.23

- b)15.54

- c)12.89

- d)11.56

Correct answer is option 'A'. Can you explain this answer?

For M20 Grade of concrete, modular ratio would be:

a)

13.23

b)

15.54

c)

12.89

d)

11.56

|

Sarthak Kulkarni answered |

Modular ratio in concrete design represents the ratio of elastic modulus of steel to that of concrete. It is denoted by m.

Formula for modular ratio:

m = Es/Ec

Where, Es = Elastic modulus of steel

Ec = Elastic modulus of concrete

For M20 grade of concrete, the elastic modulus of concrete is assumed to be 5000√fck MPa, where fck is the characteristic compressive strength of concrete in N/mm2 at 28 days. For M20 grade, fck = 20 N/mm2.

Therefore, Ec = 5000√20 = 5000 x 4.47 = 22350 MPa

The elastic modulus of steel is taken as 2 x 105 MPa.

Therefore, Es = 2 x 105 MPa

Hence, modular ratio (m) = Es/Ec = (2 x 105)/22350 = 13.23

Therefore, the correct answer is option A, i.e., 13.23.

Formula for modular ratio:

m = Es/Ec

Where, Es = Elastic modulus of steel

Ec = Elastic modulus of concrete

For M20 grade of concrete, the elastic modulus of concrete is assumed to be 5000√fck MPa, where fck is the characteristic compressive strength of concrete in N/mm2 at 28 days. For M20 grade, fck = 20 N/mm2.

Therefore, Ec = 5000√20 = 5000 x 4.47 = 22350 MPa

The elastic modulus of steel is taken as 2 x 105 MPa.

Therefore, Es = 2 x 105 MPa

Hence, modular ratio (m) = Es/Ec = (2 x 105)/22350 = 13.23

Therefore, the correct answer is option A, i.e., 13.23.

The bars shall NOT be lapped unless the length required exceeds ______ .- a)the engineering specifications

- b)the maximum available length

- c)contractor requirements

- d)IS code requirements

Correct answer is option 'B'. Can you explain this answer?

The bars shall NOT be lapped unless the length required exceeds ______ .

a)

the engineering specifications

b)

the maximum available length

c)

contractor requirements

d)

IS code requirements

|

|

Tanvi Shah answered |

Lapping of Bars:

The lapping of bars is done to increase the height of the column. As the bars come in a specific size, hence to increase the length of the column, 2 or more bars needed to be joined together. Hence only the required length exceeds the available length. This is known as the lapping of bars.

Clause 26.2.5.1 of IS 456:2000 gives clear guidelines regarding the lap splices and their length and diameter.

Lap Length;

The lapping of bars is done to increase the height of the column. As the bars come in a specific size, hence to increase the length of the column, 2 or more bars needed to be joined together. Hence only the required length exceeds the available length. This is known as the lapping of bars.

Clause 26.2.5.1 of IS 456:2000 gives clear guidelines regarding the lap splices and their length and diameter.

Lap Length;

- For bars in flexural tension - Ld or 30 ϕ whichever is greater

- For bars in direct tension - 2Ld or 30 ϕ whichever is greater

- For a bar in compression - Ld or 24 ϕ whichever is greater

- Lap splices shall not be used for bars larger than the diameter of 36 mm

- For larger diameter bars the bars may be welded.

Additional Information

- According to 3rd amendment of IS 456: 2000 in 2007, the value was changed from 36 mm to 32 mm.

- So, 36 mm is an old provision and 32 mm is a new provision

The accumulation of water on the outer surface of the concrete is:- a)Transpiration

- b)Bleeding

- c)Guttation

- d)Ponding

Correct answer is option 'B'. Can you explain this answer?

The accumulation of water on the outer surface of the concrete is:

a)

Transpiration

b)

Bleeding

c)

Guttation

d)

Ponding

|

|

Sanya Agarwal answered |

Bleeding can be good as well as bad for fresh concrete. Sometimes due to improper mixing, the water forms a thin layer on the outer surface, by oozing out through voids.

Which of the below property of aggregates is not desirable?- a)Smooth texture

- b)Well graded

- c)Angular shape

- d)Smaller size

Correct answer is option 'C'. Can you explain this answer?

Which of the below property of aggregates is not desirable?

a)

Smooth texture

b)

Well graded

c)

Angular shape

d)

Smaller size

|

Maulik Joshi answered |

**Angular Shaped**

Aggregates are commonly used in construction materials such as concrete and asphalt. They are typically composed of crushed stone, gravel, or sand. The properties of aggregates play a crucial role in determining the strength, durability, and workability of the final construction material. Among the properties of aggregates, the angular shape is considered undesirable. Here's why:

**1. Interlocking and Bonding:**

Smooth aggregates tend to interlock and bond well with each other, creating a stronger and more stable structure. The smooth texture allows for better contact and adhesion between the aggregates, leading to improved load-bearing capacity. In contrast, angular aggregates have less contact area, resulting in reduced interlocking and bonding.

**2. Workability:**

Workability refers to the ease of handling and placing the concrete or asphalt mix. Smooth aggregates provide a more workable mixture as they can slide past each other easily, allowing for better compaction and shaping. On the other hand, angular aggregates tend to have more friction between particles, making the mixture less workable and more difficult to handle.

**3. Surface Abrasion:**

During transportation and placement of aggregates, they can undergo abrasion due to rubbing against each other or other surfaces. Smooth aggregates are less prone to surface abrasion since there are no sharp edges or corners that can break off. Angular aggregates, however, have sharp edges that are more susceptible to abrasion, leading to a loss of material and potential weakening of the overall structure.

**4. Water Demand:**

Water demand is an important consideration in the design of concrete. Smooth aggregates require less water to achieve the desired workability compared to angular aggregates. This is because the smooth texture allows for better lubrication and flow of water within the mixture. Angular aggregates, on the other hand, have more surface area and can absorb more water, increasing the water demand and potentially affecting the overall strength and durability of the concrete.

In conclusion, the angular shape of aggregates is considered undesirable due to its negative effects on interlocking, bonding, workability, surface abrasion, and water demand. Smooth aggregates are preferred in construction materials to ensure a stronger, more durable, and easier-to-handle final product.

Aggregates are commonly used in construction materials such as concrete and asphalt. They are typically composed of crushed stone, gravel, or sand. The properties of aggregates play a crucial role in determining the strength, durability, and workability of the final construction material. Among the properties of aggregates, the angular shape is considered undesirable. Here's why:

**1. Interlocking and Bonding:**

Smooth aggregates tend to interlock and bond well with each other, creating a stronger and more stable structure. The smooth texture allows for better contact and adhesion between the aggregates, leading to improved load-bearing capacity. In contrast, angular aggregates have less contact area, resulting in reduced interlocking and bonding.

**2. Workability:**

Workability refers to the ease of handling and placing the concrete or asphalt mix. Smooth aggregates provide a more workable mixture as they can slide past each other easily, allowing for better compaction and shaping. On the other hand, angular aggregates tend to have more friction between particles, making the mixture less workable and more difficult to handle.

**3. Surface Abrasion:**

During transportation and placement of aggregates, they can undergo abrasion due to rubbing against each other or other surfaces. Smooth aggregates are less prone to surface abrasion since there are no sharp edges or corners that can break off. Angular aggregates, however, have sharp edges that are more susceptible to abrasion, leading to a loss of material and potential weakening of the overall structure.

**4. Water Demand:**

Water demand is an important consideration in the design of concrete. Smooth aggregates require less water to achieve the desired workability compared to angular aggregates. This is because the smooth texture allows for better lubrication and flow of water within the mixture. Angular aggregates, on the other hand, have more surface area and can absorb more water, increasing the water demand and potentially affecting the overall strength and durability of the concrete.

In conclusion, the angular shape of aggregates is considered undesirable due to its negative effects on interlocking, bonding, workability, surface abrasion, and water demand. Smooth aggregates are preferred in construction materials to ensure a stronger, more durable, and easier-to-handle final product.

Thickened part of a flat slab over its supporting column, is technically known as ______- a)drop panel

- b)capital

- c)column head

- d)cannot be determined

Correct answer is option 'A'. Can you explain this answer?

Thickened part of a flat slab over its supporting column, is technically known as ______

a)

drop panel

b)

capital

c)

column head

d)

cannot be determined

|

Sankar Rane answered |

The correct answer is option 'A' - drop panel.

Explanation:

A drop panel, also known as a drop cap or thickened panel, is a localized thickening of a flat slab over its supporting column. It is a common feature in the design of flat slabs to enhance its structural performance.

Drop panels are used to increase the strength, stiffness, and load-carrying capacity of the slab-column connection. They are typically located directly above the columns and are formed by thickening the slab in the shape of a rectangular or circular panel.

The purpose of using drop panels is to redistribute the load from the slab to the supporting column in a more efficient manner. The additional thickness of the drop panel helps in reducing the shear and bending moments at the column face, thereby improving the overall structural behavior of the slab-column system.

Benefits of using drop panels:

1. Increased load-carrying capacity: The additional thickness provided by the drop panel increases the load-carrying capacity of the slab by increasing the effective depth of the slab near the columns.

2. Improved stiffness: The presence of drop panels enhances the stiffness of the slab-column connection, reducing the deflection and improving the overall performance of the structure.

3. Enhanced punching shear resistance: The increased thickness of the drop panel improves the resistance of the slab to punching shear, which is a critical failure mode in flat slabs.

4. Redistributed load: The drop panel helps in redistributing the load from the slab to the supporting column, reducing the stresses in the slab and preventing premature failure.

In conclusion, a drop panel is a technical term used in civil engineering to describe the thickened part of a flat slab over its supporting column. It is an important design feature that improves the structural performance and load-carrying capacity of the slab-column system.

Explanation:

A drop panel, also known as a drop cap or thickened panel, is a localized thickening of a flat slab over its supporting column. It is a common feature in the design of flat slabs to enhance its structural performance.

Drop panels are used to increase the strength, stiffness, and load-carrying capacity of the slab-column connection. They are typically located directly above the columns and are formed by thickening the slab in the shape of a rectangular or circular panel.

The purpose of using drop panels is to redistribute the load from the slab to the supporting column in a more efficient manner. The additional thickness of the drop panel helps in reducing the shear and bending moments at the column face, thereby improving the overall structural behavior of the slab-column system.

Benefits of using drop panels:

1. Increased load-carrying capacity: The additional thickness provided by the drop panel increases the load-carrying capacity of the slab by increasing the effective depth of the slab near the columns.

2. Improved stiffness: The presence of drop panels enhances the stiffness of the slab-column connection, reducing the deflection and improving the overall performance of the structure.

3. Enhanced punching shear resistance: The increased thickness of the drop panel improves the resistance of the slab to punching shear, which is a critical failure mode in flat slabs.

4. Redistributed load: The drop panel helps in redistributing the load from the slab to the supporting column, reducing the stresses in the slab and preventing premature failure.

In conclusion, a drop panel is a technical term used in civil engineering to describe the thickened part of a flat slab over its supporting column. It is an important design feature that improves the structural performance and load-carrying capacity of the slab-column system.

A reinforced cement concrete beam is considered to be made of- a)homogeneous material

- b)heterogeneous material

- c)composite material

- d)isotropic material

Correct answer is option 'B'. Can you explain this answer?

A reinforced cement concrete beam is considered to be made of

a)

homogeneous material

b)

heterogeneous material

c)

composite material

d)

isotropic material

|

Nilanjan Rane answered |

Reinforced Cement Concrete Beam as Heterogeneous Material

Reinforced Cement Concrete (RCC) is a composite material consisting of cement, water, aggregates, and reinforcement. A reinforced cement concrete beam is a structural element that is used to support loads and resist bending, shear, and axial forces. This type of beam is considered to be made of a heterogeneous material due to the following reasons:

1. Composition: RCC is a composite material consisting of different materials such as cement, water, aggregates, and reinforcement. These materials have different properties and characteristics, which makes RCC a heterogeneous material.

2. Variation: The properties of RCC are not uniform throughout the beam. There may be variations in the composition, strength, and stiffness of the material due to various factors such as construction practices, curing, and environmental conditions.

3. Reinforcement: The reinforcement used in RCC beams is typically made of steel, which is a different material with different properties than cement and aggregates. The reinforcement is added to increase the strength and ductility of the beam, but it also makes the beam a heterogeneous material.

4. Anisotropy: RCC beams exhibit anisotropic behavior, which means that their properties may vary depending on the direction of loading. This is because the reinforcement is added in specific locations and orientations to provide the required strength and stiffness.

Conclusion

In conclusion, RCC beams are considered to be made of a heterogeneous material due to their composition, variation, reinforcement, and anisotropy. This has important implications for their design, analysis, and construction, as the properties of the material may vary significantly throughout the beam. Therefore, engineers need to carefully consider the properties of the material and the loads that the beam will be subjected to when designing and constructing RCC beams.

Reinforced Cement Concrete (RCC) is a composite material consisting of cement, water, aggregates, and reinforcement. A reinforced cement concrete beam is a structural element that is used to support loads and resist bending, shear, and axial forces. This type of beam is considered to be made of a heterogeneous material due to the following reasons: