All Exams >

Civil Engineering (CE) >

6 Months Preparation for GATE Civil Engg >

All Questions

All questions of Concrete - Constituents for Civil Engineering (CE) Exam

A cylinder with diameter D, length L, and P be the compressive load applied on cylinder, then split tensile strength is given by _______.- a)P / πLD

- b)2P / πLD

- c)4P / πLD

- d)16P / πLD

Correct answer is option 'B'. Can you explain this answer?

A cylinder with diameter D, length L, and P be the compressive load applied on cylinder, then split tensile strength is given by _______.

a)

P / πLD

b)

2P / πLD

c)

4P / πLD

d)

16P / πLD

|

|

Sanya Agarwal answered |

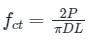

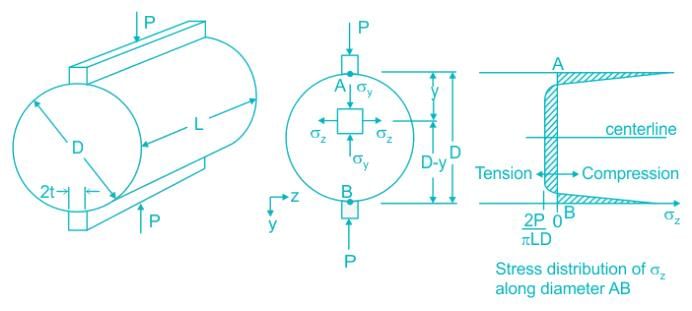

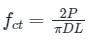

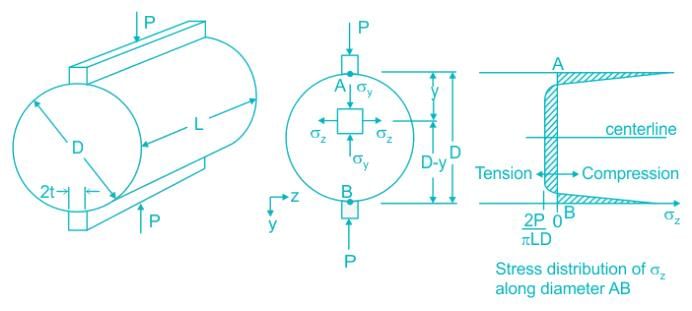

Splitting cylindrical test:

- The cylindrical sample is laid horizontal and it is subjected to the compressive load in the UTM machine.

- During this tensile stress is developed in the middle 5/6 portion of the section of the cylinder due to which its failure takes place.

- This test gives a more uniform and accurate result.

- The greatest advantage of this test is the same sample is used to find the compressive strength of the concrete.

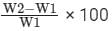

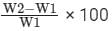

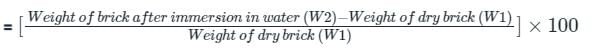

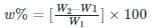

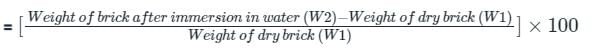

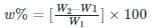

The magnitude of the tensile stress is obtained by –

where, P = Applied load, D = Diameter of the cylinder, L = Length of the cylinder

where, P = Applied load, D = Diameter of the cylinder, L = Length of the cylinder

______ has designated the concrete mixes into a number of grades as M10, M15.- a)IS 456-2000

- b)IS 456-2010

- c)IS 513-1999

- d)IS 465-2000

Correct answer is option 'A'. Can you explain this answer?

______ has designated the concrete mixes into a number of grades as M10, M15.

a)

IS 456-2000

b)

IS 456-2010

c)

IS 513-1999

d)

IS 465-2000

|

Aniket Ghoshal answered |

IS 456-2000

Designation of Concrete Mixes

- IS 456-2000 is the code for the design and construction of reinforced concrete structures.

- It has designated concrete mixes into a number of grades such as M10, M15, etc.

Explanation of Grades

- The designation M10, M15, etc., refers to the compressive strength of concrete mix after 28 days of curing.

- For example, M10 means the concrete mix has a characteristic compressive strength of 10 MPa or 10 N/mm².

Usage in Construction

- Different grades of concrete mixes are used for different applications based on the required strength and durability.

- Higher grade mixes like M20, M25, etc., are used for structural elements like beams, columns, slabs, etc., where high strength is required.

- Lower grade mixes like M10, M15, etc., are used for non-structural elements like paving blocks, plastering, etc.

Importance of Designation

- The designation of concrete mixes into grades helps in ensuring the desired strength and durability of concrete in various construction applications.

- It provides a standardized way of specifying concrete mixes to achieve the desired performance characteristics.

Designation of Concrete Mixes

- IS 456-2000 is the code for the design and construction of reinforced concrete structures.

- It has designated concrete mixes into a number of grades such as M10, M15, etc.

Explanation of Grades

- The designation M10, M15, etc., refers to the compressive strength of concrete mix after 28 days of curing.

- For example, M10 means the concrete mix has a characteristic compressive strength of 10 MPa or 10 N/mm².

Usage in Construction

- Different grades of concrete mixes are used for different applications based on the required strength and durability.

- Higher grade mixes like M20, M25, etc., are used for structural elements like beams, columns, slabs, etc., where high strength is required.

- Lower grade mixes like M10, M15, etc., are used for non-structural elements like paving blocks, plastering, etc.

Importance of Designation

- The designation of concrete mixes into grades helps in ensuring the desired strength and durability of concrete in various construction applications.

- It provides a standardized way of specifying concrete mixes to achieve the desired performance characteristics.

______ cement content to avoid shrinkage cracking due to temperature cycle in mass concrete.- a)Minimum

- b)Nominal

- c).5

- d)Maximum

Correct answer is option 'D'. Can you explain this answer?

______ cement content to avoid shrinkage cracking due to temperature cycle in mass concrete.

a)

Minimum

b)

Nominal

c)

.5

d)

Maximum

|

Ashwin Kulkarni answered |

To avoid shrinkage cracking due to temperature cycle in mass concrete, it is important to carefully consider the cement content. The correct answer is option 'D', which is the maximum cement content.

Mass concrete refers to large volumes of concrete, typically with dimensions greater than 12 inches (300 mm), such as in dams, foundations, or thick retaining walls. The excessive heat generated during the hydration process of cement in mass concrete can cause temperature differentials within the structure, leading to shrinkage and cracking. To mitigate this, the following factors need to be considered:

1. Thermal cracking:

- Temperature differentials can cause the concrete to expand and contract, leading to tensile stresses and potential cracking.

- Shrinkage cracking occurs when the tensile stresses exceed the tensile strength of the concrete.

- The goal is to minimize these temperature differentials to prevent cracking.

2. Cement content and heat generation:

- The heat of hydration generated by cement is directly proportional to its cement content.

- Higher cement content results in more heat generation during hydration, which can exacerbate temperature differentials and increase the risk of shrinkage cracking.

3. Maximum cement content:

- The maximum cement content is the upper limit of cement that can be used in concrete without causing excessive heat generation.

- It is determined based on factors such as the type of cement, aggregate properties, and specifications provided by relevant codes or guidelines.

- The maximum cement content is typically specified to avoid excessive heat generation and the associated risks of shrinkage cracking.

4. Other considerations:

- In addition to cement content, other measures can be taken to minimize temperature differentials and shrinkage cracking in mass concrete.

- These include using low-heat cement, incorporating mineral admixtures (such as fly ash or slag), and employing cooling measures during construction (such as precooling aggregates or using chilled water).

In conclusion, the maximum cement content should be considered to avoid shrinkage cracking due to temperature cycle in mass concrete. This helps to control the heat generation during hydration and minimize temperature differentials, reducing the risk of shrinkage cracking.

Mass concrete refers to large volumes of concrete, typically with dimensions greater than 12 inches (300 mm), such as in dams, foundations, or thick retaining walls. The excessive heat generated during the hydration process of cement in mass concrete can cause temperature differentials within the structure, leading to shrinkage and cracking. To mitigate this, the following factors need to be considered:

1. Thermal cracking:

- Temperature differentials can cause the concrete to expand and contract, leading to tensile stresses and potential cracking.

- Shrinkage cracking occurs when the tensile stresses exceed the tensile strength of the concrete.

- The goal is to minimize these temperature differentials to prevent cracking.

2. Cement content and heat generation:

- The heat of hydration generated by cement is directly proportional to its cement content.

- Higher cement content results in more heat generation during hydration, which can exacerbate temperature differentials and increase the risk of shrinkage cracking.

3. Maximum cement content:

- The maximum cement content is the upper limit of cement that can be used in concrete without causing excessive heat generation.

- It is determined based on factors such as the type of cement, aggregate properties, and specifications provided by relevant codes or guidelines.

- The maximum cement content is typically specified to avoid excessive heat generation and the associated risks of shrinkage cracking.

4. Other considerations:

- In addition to cement content, other measures can be taken to minimize temperature differentials and shrinkage cracking in mass concrete.

- These include using low-heat cement, incorporating mineral admixtures (such as fly ash or slag), and employing cooling measures during construction (such as precooling aggregates or using chilled water).

In conclusion, the maximum cement content should be considered to avoid shrinkage cracking due to temperature cycle in mass concrete. This helps to control the heat generation during hydration and minimize temperature differentials, reducing the risk of shrinkage cracking.

As per the terminology used for timber, the angle between the face of the cutter and the line joining the cutting edge to the center of the block is called:- a)Cutting angle

- b)Fibril angle

- c)Hook

- d)Bastard grain

Correct answer is option 'A'. Can you explain this answer?

As per the terminology used for timber, the angle between the face of the cutter and the line joining the cutting edge to the center of the block is called:

a)

Cutting angle

b)

Fibril angle

c)

Hook

d)

Bastard grain

|

|

Lavanya Menon answered |

The terminology used in Timber:

Rake angle:

Rake angle:

- The angle between the face of the tool and a plane parallel to its base. If this inclination is towards the shank, it is known as the back rake angle and if measured along with the side is known as the side rake angle.

Lip angle:

- The angle between the face and flank of the tool. As the lip angle increases, the cutting edge will go stronger.

Relief angle:

- The angle formed between the flank of the tool and a perpendicular line drawn from the cutting point to the base of the tool.

Cutting Angle:

- The angle between the face of the cutter and the line joining the cutting edge to the center of the block.

Bastard Grain:

- Timber or veneer, so saw that the annual growth rings make angles of 30o to 60o with the surface of the piece.

Chipped Grain:

- A defect caused by the breaking of the wood below the finished surface by the action of a tool or cutter.

What is the meaning of soundness of cement?- a)Ability to flow when mixed

- b)Ability to make ringing noise when struck

- c)Ability to form strong and sound structure

- d)Ability to retain volume after setting.

Correct answer is option 'D'. Can you explain this answer?

What is the meaning of soundness of cement?

a)

Ability to flow when mixed

b)

Ability to make ringing noise when struck

c)

Ability to form strong and sound structure

d)

Ability to retain volume after setting.

|

|

Lavanya Menon answered |

When cement paste hardens and sets, it should not undergo any volume change. Soundness ensures this and is tested using Autoclave expansion test.

For cylindrical concrete specimens, the number of strokes when compacting by hand is not less than ___________ to perform the compression test of concrete in the laboratory.- a)20 per layer

- b)25 per layer

- c)10 per layer

- d)35 per layer

Correct answer is option 'D'. Can you explain this answer?

For cylindrical concrete specimens, the number of strokes when compacting by hand is not less than ___________ to perform the compression test of concrete in the laboratory.

a)

20 per layer

b)

25 per layer

c)

10 per layer

d)

35 per layer

|

|

Lavanya Menon answered |

Compressive Strength Test of concrete:

According to IS: 516 (1959),

(Case 1)

According to IS: 516 (1959),

(Case 1)

- The concrete of 150×150 mm size is compacted with 35 strokes per layer

(Case2)

- Concrete of 100×100 mm size is compacted with 25 strokes per layer.

For testing the compressive strength we generally use, 150 mm size cube. So, we have to go for 35 in this particular question.

Additional Information

- Test specimens should be stored at a temperature of 27 ± 3 ℃ at 90% humidity for 24 ± 1/2 hours from the time of addition of water. After this time, specimens are removed from mould and placed in water and taken out just before the test.

- After 28 days or 7 days of curing, the specimen is placed in a compression testing machine which applies a gradual load of 14 MPa per minute.

- The average of three values is taken as the compressive strength of concrete, provided that individual variation is not more than ± 15% of the average.

- 7 days compressive strength = 2/3 of 28 days compressive strength.

- Cube strength = 1.25 cylindrical strength.

Which of the following effects of Fly Ash on cement concrete is INCORRECT?- a)Reduces the permeability of concrete

- b)Reduces the amount of air entraining agents

- c)Slightly improves the resistance to sulphate attack

- d)Increases the heat of hydration of concrete

Correct answer is option 'D'. Can you explain this answer?

Which of the following effects of Fly Ash on cement concrete is INCORRECT?

a)

Reduces the permeability of concrete

b)

Reduces the amount of air entraining agents

c)

Slightly improves the resistance to sulphate attack

d)

Increases the heat of hydration of concrete

|

Rithika Kaur answered |

Incorrect Effect of Fly Ash on Cement Concrete:

Increases the heat of hydration of concrete

One of the incorrect effects of Fly Ash on cement concrete is that it increases the heat of hydration of concrete. This statement is inaccurate because Fly Ash actually has the opposite effect on the heat of hydration.

Correct Effects of Fly Ash on Cement Concrete:

- Reduces the permeability of concrete: Fly Ash fills in the gaps in the concrete matrix, reducing the permeability and making the concrete more durable.

- Reduces the amount of air entraining agents: Fly Ash can act as a supplementary cementitious material, reducing the need for air entraining agents in concrete mixes.

- Slightly improves the resistance to sulphate attack: Fly Ash can improve the resistance of concrete to sulphate attack, increasing the durability of the structure.

In conclusion, while Fly Ash has many beneficial effects on cement concrete, it does not increase the heat of hydration.

Who invented Portland cement and in which year?

- a)William Aspdin, 1824

- b)Joseph Aspdin, 1824

- c)Joseph Aspdin, 1840s

- d)William Aspdin, 1840s

Correct answer is option 'B'. Can you explain this answer?

Who invented Portland cement and in which year?

a)

William Aspdin, 1824

b)

Joseph Aspdin, 1824

c)

Joseph Aspdin, 1840s

d)

William Aspdin, 1840s

|

|

Sanvi Kapoor answered |

Joseph Aspdin patented Portland cement in 1824. William Aspdin, his son is regarded as the inventor of modern Portland cement due to his developments in 1840s.

The addition of Fly-Ash as an additive in the brick mix proportions results in:- a)loss of compressive strength

- b)reduced fineness

- c)reduced drying shrinkage

- d)less fire resistance

Correct answer is option 'C'. Can you explain this answer?

The addition of Fly-Ash as an additive in the brick mix proportions results in:

a)

loss of compressive strength

b)

reduced fineness

c)

reduced drying shrinkage

d)

less fire resistance

|

|

Lavanya Menon answered |

Fly-ash:

Fly ash is a fairly divided residue that results from the combination of ground or powdered bituminous coal or sub-bituminous coal like lignite or pulverized coal. It is a by-product of many thermal power stations and other plants using pulverized coal or lignite as a source of heat for boilers.

Fly ash is a fairly divided residue that results from the combination of ground or powdered bituminous coal or sub-bituminous coal like lignite or pulverized coal. It is a by-product of many thermal power stations and other plants using pulverized coal or lignite as a source of heat for boilers.

Advantages of adding Fly ash as an additive in the brick mix:

- It reduces cost.

- It improves the appearance.

- It increases fire resistance.

- It improves thermal insulating properties.

- It reduces drying shrinkage.

- Reduce crack problems and permeability.

- It also improves strength, etc.

Which of the following defects occur in the seasoning process of wood?- a)Bow

- b)Brown rot

- c)Sap stain

- d)Blue stain

Correct answer is option 'A'. Can you explain this answer?

Which of the following defects occur in the seasoning process of wood?

a)

Bow

b)

Brown rot

c)

Sap stain

d)

Blue stain

|

Muskaan Sen answered |

Defects in the Seasoning Process of Wood

The seasoning process of wood refers to the process of drying the wood to reduce its moisture content. This is an essential step in the preparation of wood for various applications, as it helps to minimize shrinkage, improve dimensional stability, and enhance the overall quality of the wood. However, during the seasoning process, certain defects may occur, which can affect the usability and appearance of the wood.

One of the defects that can occur in the seasoning process of wood is bowing. This defect refers to the distortion of the wood where the board or plank curves along its length, resembling a bow. It can occur when the wood is not properly dried or when there is uneven moisture distribution within the wood. Bowing can lead to structural instability and make the wood unsuitable for certain applications.

Other defects that can occur in wood, but not specifically in the seasoning process, include brown rot, sap stain, and blue stain. Brown rot is a type of wood decay caused by fungal organisms, which can break down the cellulose and hemicellulose components of the wood, resulting in a brownish discoloration and a brittle, crumbly texture. Sap stain, on the other hand, is caused by fungi that colonize the sapwood of freshly cut wood, causing a blue or grayish discoloration. Blue stain is also caused by fungal growth in the sapwood, resulting in a blue or bluish-black discoloration.

In summary, while defects such as brown rot, sap stain, and blue stain can occur in wood, bowing specifically occurs as a defect in the seasoning process. Proper drying techniques and control of moisture content during seasoning are crucial to minimize the occurrence of defects and ensure the quality of the wood.

The seasoning process of wood refers to the process of drying the wood to reduce its moisture content. This is an essential step in the preparation of wood for various applications, as it helps to minimize shrinkage, improve dimensional stability, and enhance the overall quality of the wood. However, during the seasoning process, certain defects may occur, which can affect the usability and appearance of the wood.

One of the defects that can occur in the seasoning process of wood is bowing. This defect refers to the distortion of the wood where the board or plank curves along its length, resembling a bow. It can occur when the wood is not properly dried or when there is uneven moisture distribution within the wood. Bowing can lead to structural instability and make the wood unsuitable for certain applications.

Other defects that can occur in wood, but not specifically in the seasoning process, include brown rot, sap stain, and blue stain. Brown rot is a type of wood decay caused by fungal organisms, which can break down the cellulose and hemicellulose components of the wood, resulting in a brownish discoloration and a brittle, crumbly texture. Sap stain, on the other hand, is caused by fungi that colonize the sapwood of freshly cut wood, causing a blue or grayish discoloration. Blue stain is also caused by fungal growth in the sapwood, resulting in a blue or bluish-black discoloration.

In summary, while defects such as brown rot, sap stain, and blue stain can occur in wood, bowing specifically occurs as a defect in the seasoning process. Proper drying techniques and control of moisture content during seasoning are crucial to minimize the occurrence of defects and ensure the quality of the wood.

During the construction of a brick building using modular bricks, the impression made on one face of brick is called ________.- a)spalls

- b)half bat

- c)frog

- d)facing bond

Correct answer is option 'C'. Can you explain this answer?

During the construction of a brick building using modular bricks, the impression made on one face of brick is called ________.

a)

spalls

b)

half bat

c)

frog

d)

facing bond

|

|

Tanvi Shah answered |

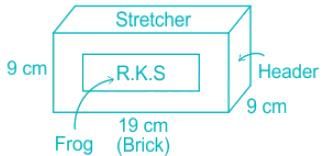

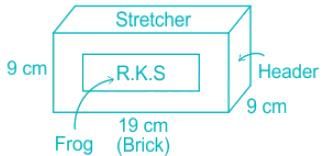

Frog:

A frog in brick is an indentation or depression in one side face, of a molded or pressed brick. If you pick up a brick with a frog, one side will be flat and the other will have a cavity built into it.

Size of frog = 10 cm × 4 cm × 2 cm

Purpose of forg in bricks:

A frog in brick is an indentation or depression in one side face, of a molded or pressed brick. If you pick up a brick with a frog, one side will be flat and the other will have a cavity built into it.

Size of frog = 10 cm × 4 cm × 2 cm

Purpose of forg in bricks:

- It facilitates good bonding between two layers of brick as mortar laid in the depressed area forms the good key.

- It reduces the weight of the brick.

- It is used for branding purposes.

The strength of timber is maximum- a)Parallel to the grain

- b)Perpendicular to the grain

- c)45° to the grain

- d)Same in all direction

Correct answer is option 'A'. Can you explain this answer?

The strength of timber is maximum

a)

Parallel to the grain

b)

Perpendicular to the grain

c)

45° to the grain

d)

Same in all direction

|

|

Sanya Agarwal answered |

Different type of strength of timber:

Compressive strength:

Compressive strength:

- The compressive strength is found to be the highest when acting parallel to the axis of growth.

- The compressive strength perpendicular to the fibers of wood is much lower than that parallel to fibers of the wood.

Tensile strength:

- Tensile strength along a direction parallel to the grains is found to have the greatest strength that can be developed under any kind of stress.

- Tensile strength parallel to fibers is of the order 80.0 to 190.0 N/cm2.

Shearing strength:

- Resistance to shear in across direction is found 3 to 4 times greater than that along fibers.

- The shear strength along the fiber is found of the order 6.5 to 14.5 N/mm2.

Explanation:

The strength of timber is the highest parallel to the grains and minimum perpendicular to grains.

The strength of timber is the highest parallel to the grains and minimum perpendicular to grains.

Additional Information

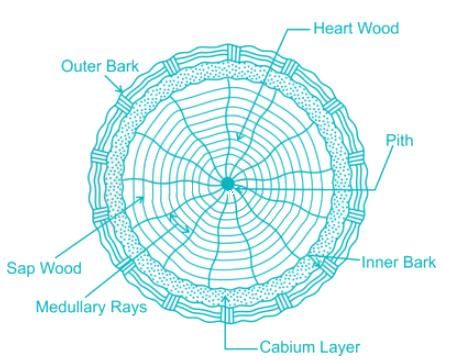

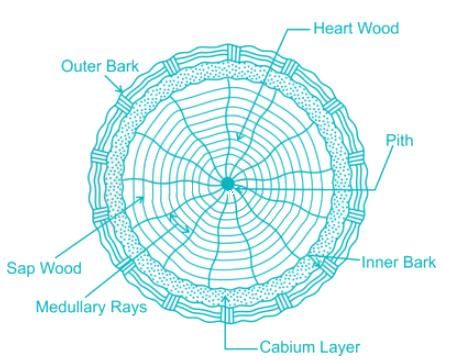

Timber:

The wood that is going to use for the building. The structure of the wood is:

Pith:

Timber:

The wood that is going to use for the building. The structure of the wood is:

Pith:

- The innermost central portion or core of the tree is called the pith or medulla.

- As the plant becomes old, the pith dies up and decays.

Sap Wood:

- Outer annual rings between the heartwood and cambium layer are the sapwood.

- It is light in color and weight.

- It takes an active part in the growth of the trees.

- It does not impart any strength.

Cambium Layer:

- A thin layer of sap in between the sapwood and inner bark is referred to as the cambium layer.

- It indicates the portion of the sap which is yet to be converted into the sapwood.

Bark:

The Outer protective layer or covering provided around the cambium layer is referred as bark.

The Outer protective layer or covering provided around the cambium layer is referred as bark.

When a part of the timber is affected by dry rot, the unaffected portion of the timber should be painted with a solution of _________- a)Aluminium nitrate

- b)Silver chloride

- c)Copper sulphate

- d)Lead acetate

Correct answer is option 'C'. Can you explain this answer?

When a part of the timber is affected by dry rot, the unaffected portion of the timber should be painted with a solution of _________

a)

Aluminium nitrate

b)

Silver chloride

c)

Copper sulphate

d)

Lead acetate

|

|

Sanvi Kapoor answered |

When a portion of the timber is affected by dry rot, the left out portion which is not affected should be painted with copper sulphate solution. While that portion of the timber which is affected and damaged due to dry rot should be completely taken out.

______ water-cement ratio content to give adequate durability for the particular site conditions.- a)Minimum

- b)Nominal

- c).5

- d)Maximum

Correct answer is option 'D'. Can you explain this answer?

______ water-cement ratio content to give adequate durability for the particular site conditions.

a)

Minimum

b)

Nominal

c)

.5

d)

Maximum

|

Harshad Iyer answered |

In civil engineering, the water-cement ratio is an important factor in determining the durability of concrete. The water-cement ratio refers to the ratio of the weight of water to the weight of cement used in a concrete mixture. It has a significant impact on the strength and durability of the concrete.

The correct answer is option 'D', which states that the maximum water-cement ratio should be used to provide adequate durability for the particular site conditions. This means that the amount of water used in the concrete mix should be at its maximum limit, while still maintaining the desired strength and durability.

Here are some reasons why the maximum water-cement ratio is preferred for durability:

1. Water-cement ratio and strength: The strength of concrete is inversely proportional to the water-cement ratio. As the water-cement ratio increases, the strength of the concrete decreases. Therefore, using the maximum water-cement ratio ensures that the concrete has the required strength for the site conditions.

2. Porosity and permeability: A higher water-cement ratio leads to increased porosity and permeability of the concrete. This means that water and other substances can easily penetrate the concrete, leading to deterioration and reduced durability. By using the maximum water-cement ratio, the porosity and permeability of the concrete can be minimized, enhancing its durability.

3. Resistance to freeze-thaw cycles: Concrete exposed to freeze-thaw cycles can undergo significant damage if it is not durable enough. The maximum water-cement ratio helps to improve the resistance of concrete to freeze-thaw cycles. This is because a lower water-cement ratio can result in more voids in the concrete, which can be filled with water. When this water freezes, it expands and can cause cracking and deterioration. By using the maximum water-cement ratio, the amount of water in the concrete is increased, reducing the risk of damage during freeze-thaw cycles.

4. Durability in aggressive environments: Concrete structures exposed to aggressive environments, such as marine environments or environments with high levels of chemical exposure, require higher durability. The maximum water-cement ratio helps to enhance the durability of the concrete in such environments by reducing the ingress of harmful substances and increasing the resistance to chemical attack.

In conclusion, the maximum water-cement ratio should be used to provide adequate durability for the particular site conditions. This ensures that the concrete has the required strength, reduces porosity and permeability, improves resistance to freeze-thaw cycles, and enhances durability in aggressive environments.

The correct answer is option 'D', which states that the maximum water-cement ratio should be used to provide adequate durability for the particular site conditions. This means that the amount of water used in the concrete mix should be at its maximum limit, while still maintaining the desired strength and durability.

Here are some reasons why the maximum water-cement ratio is preferred for durability:

1. Water-cement ratio and strength: The strength of concrete is inversely proportional to the water-cement ratio. As the water-cement ratio increases, the strength of the concrete decreases. Therefore, using the maximum water-cement ratio ensures that the concrete has the required strength for the site conditions.

2. Porosity and permeability: A higher water-cement ratio leads to increased porosity and permeability of the concrete. This means that water and other substances can easily penetrate the concrete, leading to deterioration and reduced durability. By using the maximum water-cement ratio, the porosity and permeability of the concrete can be minimized, enhancing its durability.

3. Resistance to freeze-thaw cycles: Concrete exposed to freeze-thaw cycles can undergo significant damage if it is not durable enough. The maximum water-cement ratio helps to improve the resistance of concrete to freeze-thaw cycles. This is because a lower water-cement ratio can result in more voids in the concrete, which can be filled with water. When this water freezes, it expands and can cause cracking and deterioration. By using the maximum water-cement ratio, the amount of water in the concrete is increased, reducing the risk of damage during freeze-thaw cycles.

4. Durability in aggressive environments: Concrete structures exposed to aggressive environments, such as marine environments or environments with high levels of chemical exposure, require higher durability. The maximum water-cement ratio helps to enhance the durability of the concrete in such environments by reducing the ingress of harmful substances and increasing the resistance to chemical attack.

In conclusion, the maximum water-cement ratio should be used to provide adequate durability for the particular site conditions. This ensures that the concrete has the required strength, reduces porosity and permeability, improves resistance to freeze-thaw cycles, and enhances durability in aggressive environments.

The _________ compressive strength required from structural consideration.- a)Nominal

- b)Minimum

- c)Maximum

- d)No

Correct answer is option 'B'. Can you explain this answer?

The _________ compressive strength required from structural consideration.

a)

Nominal

b)

Minimum

c)

Maximum

d)

No

|

Ankit Mukherjee answered |

Minimum Compressive Strength in Structural Consideration

The compressive strength of concrete is a crucial factor in the design of structures. It is the capacity of concrete to resist compressive forces without failing. The minimum compressive strength required from a structural consideration is as follows:

Importance of Minimum Compressive Strength

The minimum compressive strength of concrete is essential to ensure the structural safety and integrity of a building or any other construction. The minimum strength requirement is determined based on various factors such as the type of structure, loading conditions, and the environment where the structure is located.

Factors Affecting Minimum Compressive Strength

The following factors need to be considered while determining the minimum compressive strength of concrete:

1. Type of Structure: The minimum compressive strength required for a structure depends on the type of structure, such as a residential or commercial building, bridge, dam, or tunnel.

2. Load Conditions: The compressive strength of concrete should be calculated based on the maximum load that the structure is expected to carry.

3. Environment: The environment in which a structure is located also plays a crucial role in determining the minimum compressive strength of concrete. For instance, if the structure is located in an area with high moisture or temperature fluctuations, the minimum compressive strength requirement may increase.

Conclusion

In conclusion, the minimum compressive strength required from a structural consideration is crucial to ensure the safety and integrity of a building or any other construction. It should be determined based on various factors such as the type of structure, loading conditions, and environment. The minimum compressive strength requirement must be met to avoid any damages or failures of the structure.

The compressive strength of concrete is a crucial factor in the design of structures. It is the capacity of concrete to resist compressive forces without failing. The minimum compressive strength required from a structural consideration is as follows:

Importance of Minimum Compressive Strength

The minimum compressive strength of concrete is essential to ensure the structural safety and integrity of a building or any other construction. The minimum strength requirement is determined based on various factors such as the type of structure, loading conditions, and the environment where the structure is located.

Factors Affecting Minimum Compressive Strength

The following factors need to be considered while determining the minimum compressive strength of concrete:

1. Type of Structure: The minimum compressive strength required for a structure depends on the type of structure, such as a residential or commercial building, bridge, dam, or tunnel.

2. Load Conditions: The compressive strength of concrete should be calculated based on the maximum load that the structure is expected to carry.

3. Environment: The environment in which a structure is located also plays a crucial role in determining the minimum compressive strength of concrete. For instance, if the structure is located in an area with high moisture or temperature fluctuations, the minimum compressive strength requirement may increase.

Conclusion

In conclusion, the minimum compressive strength required from a structural consideration is crucial to ensure the safety and integrity of a building or any other construction. It should be determined based on various factors such as the type of structure, loading conditions, and environment. The minimum compressive strength requirement must be met to avoid any damages or failures of the structure.

The adequate workability necessary for _________ compaction with the compacting equipment available.- a)Half

- b)Quarter

- c)Full

- d)Double

Correct answer is option 'C'. Can you explain this answer?

The adequate workability necessary for _________ compaction with the compacting equipment available.

a)

Half

b)

Quarter

c)

Full

d)

Double

|

|

Tanvi Shah answered |

Option d can be eliminated easily because double compaction is not possible. The adequate workability necessary for full compaction with the compacting equipment available.

The pH value of water used in making concrete should be in the range of:- a)6

- b)9

- c)4

- d)5

Correct answer is option 'A'. Can you explain this answer?

The pH value of water used in making concrete should be in the range of:

a)

6

b)

9

c)

4

d)

5

|

|

Sanvi Kapoor answered |

The pH value of water for making reinforced cement concrete should be between 6 to 8.5.

Important properties of water for concrete:

Important properties of water for concrete:

- The pH value must not be less than 6.

- The presence of salts of manganese, tin, zinc, copper, and lead causes a reduction in strength.

- The presence of sugar causes retardation in the setting.

Important Points

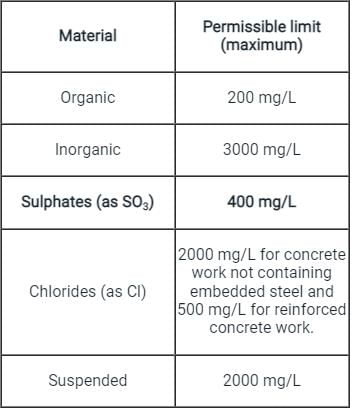

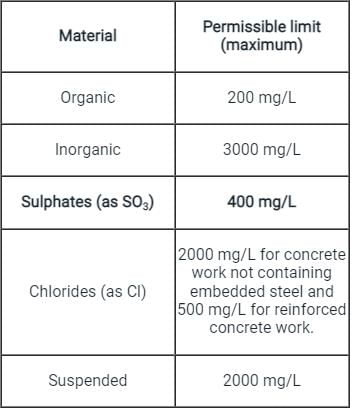

The permissible limit for solids as per IS 456 of 2000:

The permissible limit for solids as per IS 456 of 2000:

The assumed value of the standard deviation for the initial calculation of target compressive strength of M25 grade of concrete, as per IS 456 – 2000 for M25 is- a)3 MPa

- b)4 MPa

- c)5 MPa

- d)6 MPa

Correct answer is option 'B'. Can you explain this answer?

The assumed value of the standard deviation for the initial calculation of target compressive strength of M25 grade of concrete, as per IS 456 – 2000 for M25 is

a)

3 MPa

b)

4 MPa

c)

5 MPa

d)

6 MPa

|

Rounak Mehta answered |

As per IS 456 (Indian Standard Code of Practice for Plain and Reinforced Concrete), the assumed value of the standard deviation for the initial calculation of target compressive strength of M25 grade of concrete is 4.0 MPa (megapascals).

Hydrophoblic cement relates with IS code of:- a)IS: 8041-1990

- b)IS: 6909-1990

- c)IS: 6452-1989

- d)IS: 8043-1991

Correct answer is option 'D'. Can you explain this answer?

Hydrophoblic cement relates with IS code of:

a)

IS: 8041-1990

b)

IS: 6909-1990

c)

IS: 6452-1989

d)

IS: 8043-1991

|

Subhankar Khanna answered |

IS Code related to Hydrophobic Cement: IS 8043-1991

The Indian Standard (IS) code that deals with hydrophobic cement is IS 8043-1991. This code specifies requirements for hydrophobic Portland cement, which is designed to repel water and provide increased durability in environments exposed to moisture.

Key Points about IS 8043-1991:

- This standard covers the definition, physical requirements, chemical requirements, packing and marking of hydrophobic cement.

- Hydrophobic cement is particularly useful in structures exposed to water or moisture, such as basements, swimming pools, and water tanks.

- The use of hydrophobic cement can help prevent water penetration and reduce the risk of deterioration due to moisture.

- IS 8043-1991 ensures that hydrophobic cement meets certain quality standards to ensure its effectiveness in repelling water.

Benefits of Hydrophobic Cement:

- Increased durability in wet environments

- Reduced risk of water damage and deterioration

- Enhanced protection against moisture-related issues

In conclusion, IS 8043-1991 is the relevant IS code for hydrophobic cement, outlining the requirements and specifications for this specialized type of cement. Adhering to this standard can help ensure the quality and performance of hydrophobic cement in construction projects.

The Indian Standard (IS) code that deals with hydrophobic cement is IS 8043-1991. This code specifies requirements for hydrophobic Portland cement, which is designed to repel water and provide increased durability in environments exposed to moisture.

Key Points about IS 8043-1991:

- This standard covers the definition, physical requirements, chemical requirements, packing and marking of hydrophobic cement.

- Hydrophobic cement is particularly useful in structures exposed to water or moisture, such as basements, swimming pools, and water tanks.

- The use of hydrophobic cement can help prevent water penetration and reduce the risk of deterioration due to moisture.

- IS 8043-1991 ensures that hydrophobic cement meets certain quality standards to ensure its effectiveness in repelling water.

Benefits of Hydrophobic Cement:

- Increased durability in wet environments

- Reduced risk of water damage and deterioration

- Enhanced protection against moisture-related issues

In conclusion, IS 8043-1991 is the relevant IS code for hydrophobic cement, outlining the requirements and specifications for this specialized type of cement. Adhering to this standard can help ensure the quality and performance of hydrophobic cement in construction projects.

Why is natural cement used very limitedly? - a)Brown in Colour

- b)Standard consistency is not met withc

- c)Particle size is too fine

- d)Particle size is not too fine

Correct answer is option 'C'. Can you explain this answer?

Why is natural cement used very limitedly?

a)

Brown in Colour

b)

Standard consistency is not met withc

c)

Particle size is too fine

d)

Particle size is not too fine

|

Sanskriti Datta answered |

Natural cement is a type of cement that is made from naturally occurring materials such as limestone and clay. It was used extensively in the 19th century but is now used very limitedly due to certain limitations.

Particle size is too fine

One of the main reasons why natural cement is used very limitedly is because its particle size is too fine. This can make it difficult to achieve the desired consistency when mixing with water. The cement may become too thick or too runny, which can affect its performance in construction applications.

Lack of Standard Consistency

Another limitation of natural cement is the lack of standard consistency. Unlike modern cement, which is manufactured to meet specific standards, natural cement can vary in consistency from one batch to another. This can make it difficult to use in certain construction applications where consistency is critical, such as in the production of concrete.

Brown in Colour

Another limitation of natural cement is that it is brown in colour, which can be unappealing in some construction applications. Modern cement is typically grey in colour, which is more aesthetically pleasing and can blend in better with other building materials.

Conclusion

In conclusion, natural cement is used very limitedly due to its limitations, primarily its fine particle size, lack of standard consistency, and unappealing brown colour. Modern cement is manufactured to meet specific standards and is more consistent in its composition, making it a more reliable choice for construction applications.

Particle size is too fine

One of the main reasons why natural cement is used very limitedly is because its particle size is too fine. This can make it difficult to achieve the desired consistency when mixing with water. The cement may become too thick or too runny, which can affect its performance in construction applications.

Lack of Standard Consistency

Another limitation of natural cement is the lack of standard consistency. Unlike modern cement, which is manufactured to meet specific standards, natural cement can vary in consistency from one batch to another. This can make it difficult to use in certain construction applications where consistency is critical, such as in the production of concrete.

Brown in Colour

Another limitation of natural cement is that it is brown in colour, which can be unappealing in some construction applications. Modern cement is typically grey in colour, which is more aesthetically pleasing and can blend in better with other building materials.

Conclusion

In conclusion, natural cement is used very limitedly due to its limitations, primarily its fine particle size, lack of standard consistency, and unappealing brown colour. Modern cement is manufactured to meet specific standards and is more consistent in its composition, making it a more reliable choice for construction applications.

What is the average particle size of cement? - a)15 microns

- b)45 microns

- c)75 microns

- d)100 microns

Correct answer is option 'A'. Can you explain this answer?

What is the average particle size of cement?

a)

15 microns

b)

45 microns

c)

75 microns

d)

100 microns

|

Dipika Nambiar answered |

Average Particle Size of Cement

Particle size distribution of cement is an important factor that influences its properties and performance. The average particle size of cement refers to the size of particles that make up the bulk of the cement powder.

The average particle size of cement is determined by sieving the cement powder through a set of standard sieves. The size of the openings in the sieves is progressively smaller, and the amount of cement powder that is retained on each sieve is measured.

The average particle size of cement is typically reported in microns (µm), which is a unit of length equal to one-millionth of a meter.

Answer:

The average particle size of cement is 15 microns. Option A is the correct answer.

Particle size distribution of cement is an important factor that influences its properties and performance. The average particle size of cement refers to the size of particles that make up the bulk of the cement powder.

The average particle size of cement is determined by sieving the cement powder through a set of standard sieves. The size of the openings in the sieves is progressively smaller, and the amount of cement powder that is retained on each sieve is measured.

The average particle size of cement is typically reported in microns (µm), which is a unit of length equal to one-millionth of a meter.

Answer:

The average particle size of cement is 15 microns. Option A is the correct answer.

Dry rot is a defect caused in timber in which wood is converted into dry powder form by fungi. Which of the following statements about dry rot is not correct?- a)Unseasoned softwoods cannot be easily attacked by dry rot

- b)It usually occurs at places where there is no free circulation of air

- c)If the storage of timber after its felling is not done properly, it is liable for the attack of dry rot

- d)It is not essential to have damp conditions for the development of dry rot

Correct answer is option 'A'. Can you explain this answer?

Dry rot is a defect caused in timber in which wood is converted into dry powder form by fungi. Which of the following statements about dry rot is not correct?

a)

Unseasoned softwoods cannot be easily attacked by dry rot

b)

It usually occurs at places where there is no free circulation of air

c)

If the storage of timber after its felling is not done properly, it is liable for the attack of dry rot

d)

It is not essential to have damp conditions for the development of dry rot

|

Aniket Ghoshal answered |

Dry Rot in Timber

Dry rot is a type of fungal decay that affects timber. It is caused by the breakdown of wood cellulose and hemicellulose by fungi. Dry rot is a serious problem because it causes the wood to become brittle and weak. This can lead to structural failure and can be a safety hazard.

Incorrect Statement

The incorrect statement among the given options is:

Unseasoned softwoods cannot be easily attacked by dry rot.

This statement is not correct because unseasoned softwoods are actually more susceptible to dry rot than seasoned ones. This is because unseasoned wood has a higher moisture content, which provides a suitable environment for fungal growth. Softwoods, in general, are more prone to fungal decay than hardwoods because they have less natural resistance to decay.

Factors that Promote the Development of Dry Rot

Dry rot can occur in any type of timber, but certain conditions promote its development. These conditions include:

1. Moisture: Dry rot requires moisture to grow. The ideal moisture content for fungal growth is between 20% and 30%.

2. Warmth: Fungi grow best in warm temperatures, between 20°C and 30°C.

3. Oxygen: Fungi require oxygen to grow, but they can also survive in low-oxygen environments.

4. Poor Ventilation: Dry rot often occurs in areas where there is poor ventilation, such as behind walls or under floors.

5. Nutrients: Fungi require nutrients to grow, and timber provides an ideal source of nutrients.

Preventing Dry Rot

To prevent dry rot, it is important to control the conditions that promote fungal growth. This can be done by:

1. Keeping the timber dry: Avoid exposing timber to moisture and ensure good ventilation.

2. Treating timber with preservatives: Timber can be treated with preservatives that help prevent fungal growth.

3. Regular maintenance: Regular inspection and maintenance of timber structures can help identify and prevent dry rot.

Conclusion

In conclusion, dry rot is a serious problem that affects timber structures. It requires moisture, warmth, oxygen, poor ventilation, and nutrients to grow. Unseasoned softwoods are more susceptible to dry rot than seasoned ones, making it important to properly store and treat timber to prevent fungal growth. Regular maintenance and inspection can help prevent dry rot and ensure the safety of timber structures.

Dry rot is a type of fungal decay that affects timber. It is caused by the breakdown of wood cellulose and hemicellulose by fungi. Dry rot is a serious problem because it causes the wood to become brittle and weak. This can lead to structural failure and can be a safety hazard.

Incorrect Statement

The incorrect statement among the given options is:

Unseasoned softwoods cannot be easily attacked by dry rot.

This statement is not correct because unseasoned softwoods are actually more susceptible to dry rot than seasoned ones. This is because unseasoned wood has a higher moisture content, which provides a suitable environment for fungal growth. Softwoods, in general, are more prone to fungal decay than hardwoods because they have less natural resistance to decay.

Factors that Promote the Development of Dry Rot

Dry rot can occur in any type of timber, but certain conditions promote its development. These conditions include:

1. Moisture: Dry rot requires moisture to grow. The ideal moisture content for fungal growth is between 20% and 30%.

2. Warmth: Fungi grow best in warm temperatures, between 20°C and 30°C.

3. Oxygen: Fungi require oxygen to grow, but they can also survive in low-oxygen environments.

4. Poor Ventilation: Dry rot often occurs in areas where there is poor ventilation, such as behind walls or under floors.

5. Nutrients: Fungi require nutrients to grow, and timber provides an ideal source of nutrients.

Preventing Dry Rot

To prevent dry rot, it is important to control the conditions that promote fungal growth. This can be done by:

1. Keeping the timber dry: Avoid exposing timber to moisture and ensure good ventilation.

2. Treating timber with preservatives: Timber can be treated with preservatives that help prevent fungal growth.

3. Regular maintenance: Regular inspection and maintenance of timber structures can help identify and prevent dry rot.

Conclusion

In conclusion, dry rot is a serious problem that affects timber structures. It requires moisture, warmth, oxygen, poor ventilation, and nutrients to grow. Unseasoned softwoods are more susceptible to dry rot than seasoned ones, making it important to properly store and treat timber to prevent fungal growth. Regular maintenance and inspection can help prevent dry rot and ensure the safety of timber structures.

Which of the following is not a variety of industrial timber?- a)Veneers

- b)Plywood

- c)Fibreboard

- d)Baulk

Correct answer is option 'D'. Can you explain this answer?

Which of the following is not a variety of industrial timber?

a)

Veneers

b)

Plywood

c)

Fibreboard

d)

Baulk

|

Prashanth Rane answered |

Industrial Timber Varieties

Industrial timber refers to the timber that is used for various industrial purposes such as construction, furniture, and paper production. The following are some of the varieties of industrial timber:

1. Veneers

Veneers are thin slices of wood that are used to cover surfaces of furniture or to make decorative panels. They are usually made from hardwood trees such as oak, maple, and cherry.

2. Plywood

Plywood is a type of engineered wood that is made by gluing together several layers of thin wood veneers. It is used for various applications such as furniture, flooring, and construction.

3. Fibreboard

Fibreboard is a type of engineered wood that is made by breaking down wood fibers and then gluing them together under high pressure. It is used for various applications such as furniture, flooring, and construction.

4. Baulk

Baulk is not a variety of industrial timber. Baulk refers to a large, rough piece of timber that is used for various applications such as construction, shipbuilding, and bridge building. Baulks are usually made from hardwood trees such as oak, elm, and ash.

Conclusion

The correct answer to the given question is option 'D', Baulk. Baulk is not a variety of industrial timber.

Industrial timber refers to the timber that is used for various industrial purposes such as construction, furniture, and paper production. The following are some of the varieties of industrial timber:

1. Veneers

Veneers are thin slices of wood that are used to cover surfaces of furniture or to make decorative panels. They are usually made from hardwood trees such as oak, maple, and cherry.

2. Plywood

Plywood is a type of engineered wood that is made by gluing together several layers of thin wood veneers. It is used for various applications such as furniture, flooring, and construction.

3. Fibreboard

Fibreboard is a type of engineered wood that is made by breaking down wood fibers and then gluing them together under high pressure. It is used for various applications such as furniture, flooring, and construction.

4. Baulk

Baulk is not a variety of industrial timber. Baulk refers to a large, rough piece of timber that is used for various applications such as construction, shipbuilding, and bridge building. Baulks are usually made from hardwood trees such as oak, elm, and ash.

Conclusion

The correct answer to the given question is option 'D', Baulk. Baulk is not a variety of industrial timber.

The minimum thickness of the wall where single Flemish bond is used- a)One brick thick

- b)One and a half brick thick

- c)Two and a half brick thick

- d)None of the above

Correct answer is option 'B'. Can you explain this answer?

The minimum thickness of the wall where single Flemish bond is used

a)

One brick thick

b)

One and a half brick thick

c)

Two and a half brick thick

d)

None of the above

|

Ananya Sharma answered |

Introduction:

The Flemish bond is a traditional brickwork pattern that consists of alternating headers (bricks laid with their short end facing outwards) and stretchers (bricks laid with their long end facing outwards) in each course of the wall. This creates a visually appealing pattern and provides structural stability to the wall. The minimum thickness of the wall required for single Flemish bond is determined by the number of bricks used in each course.

Explanation:

The thickness of the wall in Flemish bond is determined by the number of bricks used in each course. Let's analyze the options given:

A) One brick thick:

If the wall is one brick thick, it means that only one layer of bricks is used in each course. In this case, it is not possible to achieve a single Flemish bond pattern. The Flemish bond requires alternating headers and stretchers in each course, which means at least two layers of bricks are needed.

B) One and a half brick thick:

If the wall is one and a half brick thick, it means that one header and one stretcher are used in each course. This allows for the creation of a single Flemish bond pattern. The header and stretcher are placed side by side, resulting in a visually appealing alternating pattern. This is the correct answer as it fulfills the requirements of the Flemish bond pattern.

C) Two and a half brick thick:

If the wall is two and a half brick thick, it means that two headers and two stretchers are used in each course. While this thickness allows for the creation of a Flemish bond pattern, it is not the minimum thickness required. The minimum thickness required for single Flemish bond is one and a half brick thick.

D) None of the above:

This option is incorrect as option B (one and a half brick thick) is the correct answer. None of the other options fulfill the requirements of the Flemish bond pattern.

Conclusion:

The minimum thickness of the wall required for single Flemish bond is one and a half brick thick. This allows for the placement of one header and one stretcher in each course, creating the desired alternating pattern.

The Flemish bond is a traditional brickwork pattern that consists of alternating headers (bricks laid with their short end facing outwards) and stretchers (bricks laid with their long end facing outwards) in each course of the wall. This creates a visually appealing pattern and provides structural stability to the wall. The minimum thickness of the wall required for single Flemish bond is determined by the number of bricks used in each course.

Explanation:

The thickness of the wall in Flemish bond is determined by the number of bricks used in each course. Let's analyze the options given:

A) One brick thick:

If the wall is one brick thick, it means that only one layer of bricks is used in each course. In this case, it is not possible to achieve a single Flemish bond pattern. The Flemish bond requires alternating headers and stretchers in each course, which means at least two layers of bricks are needed.

B) One and a half brick thick:

If the wall is one and a half brick thick, it means that one header and one stretcher are used in each course. This allows for the creation of a single Flemish bond pattern. The header and stretcher are placed side by side, resulting in a visually appealing alternating pattern. This is the correct answer as it fulfills the requirements of the Flemish bond pattern.

C) Two and a half brick thick:

If the wall is two and a half brick thick, it means that two headers and two stretchers are used in each course. While this thickness allows for the creation of a Flemish bond pattern, it is not the minimum thickness required. The minimum thickness required for single Flemish bond is one and a half brick thick.

D) None of the above:

This option is incorrect as option B (one and a half brick thick) is the correct answer. None of the other options fulfill the requirements of the Flemish bond pattern.

Conclusion:

The minimum thickness of the wall required for single Flemish bond is one and a half brick thick. This allows for the placement of one header and one stretcher in each course, creating the desired alternating pattern.

The estimated volume of cement required to prepare 150 Cu-m of 1:2:4 concrete is _____.- a)26 Cu-m

- b)36 Cu-m

- c)23 Cu-m

- d)33 Cu-m

Correct answer is option 'D'. Can you explain this answer?

The estimated volume of cement required to prepare 150 Cu-m of 1:2:4 concrete is _____.

a)

26 Cu-m

b)

36 Cu-m

c)

23 Cu-m

d)

33 Cu-m

|

|

Tanvi Shah answered |

1:2:4 concrete mix denotes, 1 part of cement, 2 parts of sand, and 4 parts of coarse aggregate in that particular concrete mix.

1 m3 freshly mixed concrete corresponds to 1.54 m3 dry volume of concrete.

Calculation:

Given,

Wet volume of concrete = 150 Cum, Concrete mix = 1:2:4

1 m3 freshly mixed concrete corresponds to 1.54 m3 dry volume of concrete.

150 m3 freshly mixed concrete corresponds = 150 × 1.54 = 231 m3 dry volume of concrete

In a concrete mix of 1:2:4, Total parts = (1 + 2 + 4) = 7

In a total of 7 parts, cement volume is 1 part, i.e. 1/7

Hence, Cement volume for 231 m3 dry concrete = (1/7) × 231 = 33 m3

1 m3 freshly mixed concrete corresponds to 1.54 m3 dry volume of concrete.

Calculation:

Given,

Wet volume of concrete = 150 Cum, Concrete mix = 1:2:4

1 m3 freshly mixed concrete corresponds to 1.54 m3 dry volume of concrete.

150 m3 freshly mixed concrete corresponds = 150 × 1.54 = 231 m3 dry volume of concrete

In a concrete mix of 1:2:4, Total parts = (1 + 2 + 4) = 7

In a total of 7 parts, cement volume is 1 part, i.e. 1/7

Hence, Cement volume for 231 m3 dry concrete = (1/7) × 231 = 33 m3

Why is natural cement used very limitedly?- a)Brown in Colour

- b)Standard consistency is not met with

- c)Sets too quickly

- d)Particle size is too fine

Correct answer is option 'C'. Can you explain this answer?

Why is natural cement used very limitedly?

a)

Brown in Colour

b)

Standard consistency is not met with

c)

Sets too quickly

d)

Particle size is too fine

|

Aditya Patel answered |

Understanding Natural Cement

Natural cement is derived from limestone and clay, and while it has its applications, its usage is limited due to several reasons. Among these, the rapid setting time is a significant factor.

Reasons for Limited Use of Natural Cement

- Sets Too Quickly

- Natural cement has a tendency to set very quickly. This rapid hardening can be problematic, especially in construction projects that require time for placement, alignment, and finishing.

- If the cement sets too quickly, it can lead to difficulties in workability, making it challenging for laborers to effectively apply the material before it hardens.

- Brown Color

- While the brown color of natural cement may not be aesthetically pleasing in all applications, it is not the primary reason for its limited use.

- Standard Consistency

- Natural cement may not consistently meet standardized performance metrics, but this is generally a secondary concern compared to its setting time.

- Particle Size

- The particle size of natural cement is often finer, which affects its hydration and bonding characteristics. However, this aspect does not directly limit its use as severely as the rapid setting property.

Conclusion

The rapid setting nature of natural cement is a critical limitation, particularly for large-scale construction projects that require flexibility and extended working times. Understanding these characteristics helps construction professionals choose the right materials for their specific needs.

Natural cement is derived from limestone and clay, and while it has its applications, its usage is limited due to several reasons. Among these, the rapid setting time is a significant factor.

Reasons for Limited Use of Natural Cement

- Sets Too Quickly

- Natural cement has a tendency to set very quickly. This rapid hardening can be problematic, especially in construction projects that require time for placement, alignment, and finishing.

- If the cement sets too quickly, it can lead to difficulties in workability, making it challenging for laborers to effectively apply the material before it hardens.

- Brown Color

- While the brown color of natural cement may not be aesthetically pleasing in all applications, it is not the primary reason for its limited use.

- Standard Consistency

- Natural cement may not consistently meet standardized performance metrics, but this is generally a secondary concern compared to its setting time.

- Particle Size

- The particle size of natural cement is often finer, which affects its hydration and bonding characteristics. However, this aspect does not directly limit its use as severely as the rapid setting property.

Conclusion

The rapid setting nature of natural cement is a critical limitation, particularly for large-scale construction projects that require flexibility and extended working times. Understanding these characteristics helps construction professionals choose the right materials for their specific needs.

What is the temperature range in a cement kiln?- a)1300 to 1500°C

- b)500 to 1000°C

- c)1100 to 1200°C

- d)300 to 800°C

Correct answer is option 'A'. Can you explain this answer?

What is the temperature range in a cement kiln?

a)

1300 to 1500°C

b)

500 to 1000°C

c)

1100 to 1200°C

d)

300 to 800°C

|

|

Tanvi Shah answered |

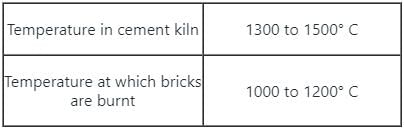

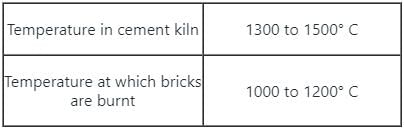

Different temperature range for a cement kiln are as follows:

Additional Information

Raw material ingredients used for manufacturing of Portland Cement are as follows:

Calcareous Materials:

Additional Information

Raw material ingredients used for manufacturing of Portland Cement are as follows:

Calcareous Materials:

- Calcareous Materials are compounds of calcium and magnesium. Limestones are common calcareous material used in manufacturing cement. Chalk and shells are also used as calcareous material.

Argillaceous Materials:

- Argillaceous Materials are mainly silica, alumina and oxides of iron. Clay and shale are common argillaceous material used as cement ingredient in the process of manufacturing cement.

The natural heartwood timber used for structural purposes and of high durability would have average life of minimum M months, where M is- a)90

- b)120

- c)75

- d)60

Correct answer is option 'B'. Can you explain this answer?

The natural heartwood timber used for structural purposes and of high durability would have average life of minimum M months, where M is

a)

90

b)

120

c)

75

d)

60

|

Divya Kulkarni answered |

Heading: Explanation of the answer

The natural heartwood timber used for structural purposes and of high durability would have an average life of a minimum of M months. The correct option is B, which states that the minimum life of the timber is 120 months.

Heading: Reasoning

The natural heartwood timber is obtained from the innermost part of the tree trunk, which is the oldest and densest part of the tree. It is known for its high durability, strength, and resistance to decay, insects, and fungi. Owing to these properties, it is widely used in construction for structural purposes, such as beams, columns, and decking.

Heading: Average life of timber

The average life of the heartwood timber depends on various factors such as the species of the tree, environmental conditions, and maintenance. However, the minimum life of the timber is determined based on its durability class. Durability class is a classification system that indicates the timber's ability to resist decay and biological attack. The higher the durability class, the longer the life of the timber.

Heading: Minimum life of heartwood timber

According to the European standard EN 350-2, the minimum life of heartwood timber of durability class 1 is 25 years, durability class 2 is 15 years, and durability class 3 is 10 years. The minimum life of timber of durability class 4 is not specified, but it is assumed to be less than 10 years.

Heading: Conclusion

Therefore, based on the EN 350-2 standard, the heartwood timber used for structural purposes and of high durability, which is classified as durability class 1, would have a minimum life of 25 years. However, the question does not specify the durability class of the timber. Therefore, the correct answer is option B, which states that the minimum life of the timber is 120 months or 10 years, assuming that the timber is of durability class 2 or higher.

The natural heartwood timber used for structural purposes and of high durability would have an average life of a minimum of M months. The correct option is B, which states that the minimum life of the timber is 120 months.

Heading: Reasoning

The natural heartwood timber is obtained from the innermost part of the tree trunk, which is the oldest and densest part of the tree. It is known for its high durability, strength, and resistance to decay, insects, and fungi. Owing to these properties, it is widely used in construction for structural purposes, such as beams, columns, and decking.

Heading: Average life of timber

The average life of the heartwood timber depends on various factors such as the species of the tree, environmental conditions, and maintenance. However, the minimum life of the timber is determined based on its durability class. Durability class is a classification system that indicates the timber's ability to resist decay and biological attack. The higher the durability class, the longer the life of the timber.

Heading: Minimum life of heartwood timber

According to the European standard EN 350-2, the minimum life of heartwood timber of durability class 1 is 25 years, durability class 2 is 15 years, and durability class 3 is 10 years. The minimum life of timber of durability class 4 is not specified, but it is assumed to be less than 10 years.

Heading: Conclusion

Therefore, based on the EN 350-2 standard, the heartwood timber used for structural purposes and of high durability, which is classified as durability class 1, would have a minimum life of 25 years. However, the question does not specify the durability class of the timber. Therefore, the correct answer is option B, which states that the minimum life of the timber is 120 months or 10 years, assuming that the timber is of durability class 2 or higher.

Which one of the following is not a preservation of timber?- a)solution of barium hydroxide

- b)creosote

- c)chemical salt

- d)solignum salt

Correct answer is option 'A'. Can you explain this answer?

Which one of the following is not a preservation of timber?

a)

solution of barium hydroxide

b)

creosote

c)

chemical salt

d)

solignum salt

|

Ishan Kapoor answered |

Preservation of timber is the process of treating wood to protect it from decay, insect infestation, and other forms of damage. There are various methods and substances used for timber preservation. Among the options given, the one that is not a preservation method is option A, the solution of barium hydroxide.

Barium hydroxide is a chemical compound that is not commonly used for timber preservation. It is primarily used in industries such as manufacturing, ceramics, and electronics, but not for treating wood.

Let's discuss the other options and why they are used for timber preservation:

b) Creosote:

Creosote is a mixture of chemicals derived from coal tar. It is widely used as a wood preservative due to its effectiveness in preventing decay, insect attack, and fungal growth. Creosote is commonly used for treating railroad ties, utility poles, and other outdoor wooden structures.

c) Chemical salt:

Chemical salts, such as copper sulfate, are commonly used for timber preservation. These salts are water-soluble and can penetrate the wood fibers, providing protection against rot and insects. Copper sulfate is particularly effective against fungi and has been used for centuries to preserve wood.

d) Solignum salt:

Solignum is a brand name for a range of wood preservatives that contain various active ingredients, including copper naphthenate and synthetic pyrethroids. These preservatives are effective against decay fungi, termites, and other wood-damaging organisms. Solignum salts are widely used for the protection of wooden structures and furniture.

In summary, the solution of barium hydroxide is not a commonly used method for timber preservation. The other options - creosote, chemical salts, and Solignum salt - are widely used and effective in protecting wood from decay and insect infestation.

Barium hydroxide is a chemical compound that is not commonly used for timber preservation. It is primarily used in industries such as manufacturing, ceramics, and electronics, but not for treating wood.

Let's discuss the other options and why they are used for timber preservation:

b) Creosote:

Creosote is a mixture of chemicals derived from coal tar. It is widely used as a wood preservative due to its effectiveness in preventing decay, insect attack, and fungal growth. Creosote is commonly used for treating railroad ties, utility poles, and other outdoor wooden structures.

c) Chemical salt:

Chemical salts, such as copper sulfate, are commonly used for timber preservation. These salts are water-soluble and can penetrate the wood fibers, providing protection against rot and insects. Copper sulfate is particularly effective against fungi and has been used for centuries to preserve wood.

d) Solignum salt:

Solignum is a brand name for a range of wood preservatives that contain various active ingredients, including copper naphthenate and synthetic pyrethroids. These preservatives are effective against decay fungi, termites, and other wood-damaging organisms. Solignum salts are widely used for the protection of wooden structures and furniture.

In summary, the solution of barium hydroxide is not a commonly used method for timber preservation. The other options - creosote, chemical salts, and Solignum salt - are widely used and effective in protecting wood from decay and insect infestation.

Who invented Portland cement and in which year? - a)William Aspdin, 1824

- b)William Aspdin, 1840s

- c)Joseph Aspdin, 1840s

- d)Joseph Aspdin, 1824

Correct answer is option 'B'. Can you explain this answer?

Who invented Portland cement and in which year?

a)

William Aspdin, 1824

b)

William Aspdin, 1840s

c)

Joseph Aspdin, 1840s

d)

Joseph Aspdin, 1824

|

|

Lavanya Menon answered |

Joseph Aspdin patented Portland cement in 1824. William Aspdin, his son is regarded as the inventor of modern Portland cement due to his developments in 1840s.

What is the average particle size of cement?- a)15 microns

- b)45 microns

- c)75 microns

- d)100 microns

Correct answer is option 'A'. Can you explain this answer?

What is the average particle size of cement?

a)

15 microns

b)

45 microns

c)

75 microns

d)

100 microns

|

|

Lavanya Menon answered |

Approximately 95% of cement particles are smaller than 45 microns and the average particle size is 15 microns.

IS 287-1993 specifies:- a)Recommendations for Maximum moisture content of timber.

- b)Recommendations for Maximum moisture content of concrete.

- c)Recommendations for Maximum moisture content of fine aggregates.

- d)Recommendations for Maximum moisture content of brick

Correct answer is option 'A'. Can you explain this answer?

IS 287-1993 specifies:

a)

Recommendations for Maximum moisture content of timber.

b)

Recommendations for Maximum moisture content of concrete.

c)

Recommendations for Maximum moisture content of fine aggregates.

d)

Recommendations for Maximum moisture content of brick

|

|

Sanvi Kapoor answered |

IS 287-1993

- The permissible moisture content for timber used for different purposes recommendations.

Important Points

Some important IS codes are following

Some important IS codes are following

- IS: 456-2000 – Plain reinforced concrete

- IS: 800-2007 – General construction of steel

- IS: 1343- 1980 – code for practice for prestressed

- IS: 383- 1970 – Coarse and fine aggregate for concrete-specification

- IS: 875- 1987 – Practice for the design of dead load (Part 1) , live load (Part 2) , wind load (Part 3) , snow load (Part 4) , special load & load combination (Part 5)

- IS: 1893- 2002 – Earthquake resistance design of the structure

- IS 10262- 2009 – Guidelines for concrete mix design proportioning

- IS: 269 – 2013 – Specification for 33 grade OPC

- IS: 8112 – 2013 – Specification for 43 grade OPC

- IS: 12269 – 2013 – Specification for 53 grade OPC

- IS 1237 - Cement Concrete Flooring Tile

- IS 893 - Criteria for Earthquake Resistant Design of Structure

Which one of the following ingredients of the brick earth enables the brick to retain its shape- a)alumina

- b)magnesia

- c)iron

- d)silica

Correct answer is option 'D'. Can you explain this answer?

Which one of the following ingredients of the brick earth enables the brick to retain its shape

a)

alumina

b)

magnesia

c)

iron

d)

silica

|

Garima Basak answered |

Brick Earth and its Ingredients

Brick earth is a type of soil that is commonly used for making bricks. It is composed of various ingredients that contribute to the properties of the soil. The main ingredients of brick earth are:

- Alumina

- Silica

- Lime

- Magnesia

- Iron oxide

- Potash and soda

Out of these ingredients, silica plays a crucial role in retaining the shape of the brick.

Role of Silica in Retaining Brick Shape

Silica is a hard and durable mineral that is found in abundance in brick earth. When the brick is fired in a kiln, the silica in the clay starts to melt and fuse together. This process is called vitrification, and it creates a glassy matrix that binds the other ingredients together.