All Exams >

Mechanical Engineering >

Manufacturing Engineering >

All Questions

All questions of Welding for Mechanical Engineering Exam

Seam welding is a- a)continuous spot welding process

- b)multi-spot welding process

- c)arc welding process

- d)process used for joining round bars

Correct answer is option 'A'. Can you explain this answer?

Seam welding is a

a)

continuous spot welding process

b)

multi-spot welding process

c)

arc welding process

d)

process used for joining round bars

|

Devika Tiwari answered |

In seam welding electrodes used in the form ol rollers or wheels, and leak proof joint is obtained bv this.

Consider the following statements: MIG welding process uses

1. Consumable electrode

2. Nonconsumable electrode

3. D.C. power supply

4. A.C. power supply

Q. Which of these statement are correct?- a)2 and 4

- b)2 and 3

- c)1 and4

- d)1and3

Correct answer is option 'D'. Can you explain this answer?

Consider the following statements: MIG welding process uses

1. Consumable electrode

2. Nonconsumable electrode

3. D.C. power supply

4. A.C. power supply

Q. Which of these statement are correct?

1. Consumable electrode

2. Nonconsumable electrode

3. D.C. power supply

4. A.C. power supply

Q. Which of these statement are correct?

a)

2 and 4

b)

2 and 3

c)

1 and4

d)

1and3

|

|

Atharva Majumdar answered |

Metal inert gas arc welding or more appropriately called as gas metal arc welding utilizes a consumable electrode. Normally DC arc welding machines are used for MIG with electrode positive.

Preheating of work piece is essential in welding- a)High speed steel

- b)Stainless steel

- c)Cast iron

- d)Aluminium

Correct answer is option 'C'. Can you explain this answer?

Preheating of work piece is essential in welding

a)

High speed steel

b)

Stainless steel

c)

Cast iron

d)

Aluminium

|

|

Hiral Jain answered |

Preheating is often employed when welding cast iron, high carbon steel or alloy steel since preheating slows down the cooling rate of that area of parent metal close to the weld itself and the weld itself and thereby prevents the formation of martensite which accounts for hardness across the weld. The chance of cracking in the heat- affected zone due to unequal contraction during cooling is also minimized by preheating.

The voltage length characteristic of a direct current arc is given by

V= (30 + 60l) volts,

where l is the length of the arc in cm. The power source characteristic is approximated by a straight line with an open circuit voltage = 80 V and a short circuit current = 1000 amp. What is the optimum arc length?- a)0.5 cm

- b)0.267 cm

- c)0.167 cm

- d)0.34 cm

Correct answer is option 'C'. Can you explain this answer?

The voltage length characteristic of a direct current arc is given by

V= (30 + 60l) volts,

where l is the length of the arc in cm. The power source characteristic is approximated by a straight line with an open circuit voltage = 80 V and a short circuit current = 1000 amp. What is the optimum arc length?

V= (30 + 60l) volts,

where l is the length of the arc in cm. The power source characteristic is approximated by a straight line with an open circuit voltage = 80 V and a short circuit current = 1000 amp. What is the optimum arc length?

a)

0.5 cm

b)

0.267 cm

c)

0.167 cm

d)

0.34 cm

|

Diya Sarkar answered |

Given information:

- Voltage-length characteristic of a direct current arc: V = (30 + 60l) volts, where l is the length of the arc in cm.

- Power source characteristic: Straight line with an open circuit voltage = 80 V and a short circuit current = 1000 A.

Objective:

To find the optimum arc length.

Solution:

To find the optimum arc length, we need to determine the point where the power source characteristic line intersects with the voltage-length characteristic curve.

Step 1: Determine the equation of the power source characteristic line.

We are given that the open circuit voltage is 80 V and the short circuit current is 1000 A. The power source characteristic line is approximated to be a straight line.

Using the two given points (0 V, 1000 A) and (80 V, 0 A), we can calculate the slope of the line (m) using the formula:

m = (change in y) / (change in x) = (0 - 1000) / (80 - 0) = -1000 / 80 = -12.5 A/V

So, the equation of the power source characteristic line is:

I = -12.5V + 1000

Step 2: Determine the point of intersection between the power source characteristic line and the voltage-length characteristic curve.

We need to equate the voltage-length characteristic equation with the power source characteristic equation:

(30 + 60l) = -12.5V + 1000

Substituting V = 80 into the equation:

30 + 60l = -12.5(80) + 1000

30 + 60l = -1000 + 1000

30 + 60l = 0

60l = -30

l = -30/60

l = -0.5 cm

Step 3: Determine the optimum arc length.

Since the length of an arc cannot be negative, we discard the negative value and consider the positive value.

Therefore, the optimum arc length is 0.5 cm.

Final Answer:

The optimum arc length is 0.5 cm, which corresponds to option (a).

- Voltage-length characteristic of a direct current arc: V = (30 + 60l) volts, where l is the length of the arc in cm.

- Power source characteristic: Straight line with an open circuit voltage = 80 V and a short circuit current = 1000 A.

Objective:

To find the optimum arc length.

Solution:

To find the optimum arc length, we need to determine the point where the power source characteristic line intersects with the voltage-length characteristic curve.

Step 1: Determine the equation of the power source characteristic line.

We are given that the open circuit voltage is 80 V and the short circuit current is 1000 A. The power source characteristic line is approximated to be a straight line.

Using the two given points (0 V, 1000 A) and (80 V, 0 A), we can calculate the slope of the line (m) using the formula:

m = (change in y) / (change in x) = (0 - 1000) / (80 - 0) = -1000 / 80 = -12.5 A/V

So, the equation of the power source characteristic line is:

I = -12.5V + 1000

Step 2: Determine the point of intersection between the power source characteristic line and the voltage-length characteristic curve.

We need to equate the voltage-length characteristic equation with the power source characteristic equation:

(30 + 60l) = -12.5V + 1000

Substituting V = 80 into the equation:

30 + 60l = -12.5(80) + 1000

30 + 60l = -1000 + 1000

30 + 60l = 0

60l = -30

l = -30/60

l = -0.5 cm

Step 3: Determine the optimum arc length.

Since the length of an arc cannot be negative, we discard the negative value and consider the positive value.

Therefore, the optimum arc length is 0.5 cm.

Final Answer:

The optimum arc length is 0.5 cm, which corresponds to option (a).

The maximum heat in resistance welding is at the- a)Tip of the positive electrode

- b)Tip of negative electrode

- c)Top surface of the plate at the time of electric contact with the electrode

- d)Interface between the two plates being joined

Correct answer is option 'D'. Can you explain this answer?

The maximum heat in resistance welding is at the

a)

Tip of the positive electrode

b)

Tip of negative electrode

c)

Top surface of the plate at the time of electric contact with the electrode

d)

Interface between the two plates being joined

|

Naina Das answered |

Since the resistance is maximum at the interference of the two sheets being joined hence maximum heat will generate at the same place.

High speed electron beam of electron beam welding is focused on the weld spot using- a)Vacuum lens

- b)Inert gas lens

- c)Optical lens

- d)Magnetic lens

Correct answer is option 'D'. Can you explain this answer?

High speed electron beam of electron beam welding is focused on the weld spot using

a)

Vacuum lens

b)

Inert gas lens

c)

Optical lens

d)

Magnetic lens

|

Jyoti Choudhury answered |

Answer:

Electron beam welding is a specialized welding process that utilizes a high-speed electron beam to join two metal pieces together. The electron beam is generated by accelerating electrons using an electron gun and then focusing it onto the weld spot. The focusing of the electron beam is achieved using a magnetic lens.

Magnetic lens:

A magnetic lens is a device that uses a combination of magnetic fields to focus charged particles, such as electrons, onto a specific spot. It consists of a series of magnetic coils that generate a magnetic field. By controlling the strength and distribution of the magnetic field, the lens can manipulate the path of the charged particles and focus them onto the desired location.

Advantages of using a magnetic lens:

1. High focusing power: Magnetic lenses have a high focusing power, allowing the electron beam to be concentrated onto a very small spot. This enables precise control over the weld and improves the quality of the joint.

2. Non-interacting: The magnetic lens does not interact with the electron beam, which means it does not scatter or absorb the electrons. This ensures minimal loss of energy and allows the beam to maintain its high speed and intensity.

3. Stability: Magnetic lenses are highly stable and provide consistent focusing over long periods of time. This is essential for maintaining the quality and accuracy of the weld.

4. Compact size: Magnetic lenses are relatively small in size compared to other focusing methods, such as optical lenses. This makes them suitable for integration into compact electron beam welding systems.

Other options:

- Vacuum lens: A vacuum lens is not used in electron beam welding. Vacuum is used to create an environment free of air molecules to prevent scattering of the electron beam.

- Inert gas lens: An inert gas lens is also not used in electron beam welding. Inert gases are used in the welding chamber to prevent oxidation of the weld, but they do not play a role in focusing the electron beam.

- Optical lens: Optical lenses are used to focus visible light, but they are not suitable for focusing an electron beam due to the difference in properties between light and electrons.

Therefore, the correct answer is option 'D' - Magnetic lens.

Electron beam welding is a specialized welding process that utilizes a high-speed electron beam to join two metal pieces together. The electron beam is generated by accelerating electrons using an electron gun and then focusing it onto the weld spot. The focusing of the electron beam is achieved using a magnetic lens.

Magnetic lens:

A magnetic lens is a device that uses a combination of magnetic fields to focus charged particles, such as electrons, onto a specific spot. It consists of a series of magnetic coils that generate a magnetic field. By controlling the strength and distribution of the magnetic field, the lens can manipulate the path of the charged particles and focus them onto the desired location.

Advantages of using a magnetic lens:

1. High focusing power: Magnetic lenses have a high focusing power, allowing the electron beam to be concentrated onto a very small spot. This enables precise control over the weld and improves the quality of the joint.

2. Non-interacting: The magnetic lens does not interact with the electron beam, which means it does not scatter or absorb the electrons. This ensures minimal loss of energy and allows the beam to maintain its high speed and intensity.

3. Stability: Magnetic lenses are highly stable and provide consistent focusing over long periods of time. This is essential for maintaining the quality and accuracy of the weld.

4. Compact size: Magnetic lenses are relatively small in size compared to other focusing methods, such as optical lenses. This makes them suitable for integration into compact electron beam welding systems.

Other options:

- Vacuum lens: A vacuum lens is not used in electron beam welding. Vacuum is used to create an environment free of air molecules to prevent scattering of the electron beam.

- Inert gas lens: An inert gas lens is also not used in electron beam welding. Inert gases are used in the welding chamber to prevent oxidation of the weld, but they do not play a role in focusing the electron beam.

- Optical lens: Optical lenses are used to focus visible light, but they are not suitable for focusing an electron beam due to the difference in properties between light and electrons.

Therefore, the correct answer is option 'D' - Magnetic lens.

Following gases are used in TIG welding- a)CO2 and H2

- b)Argon and Neon

- c)Argon and Helium

- d)Helium and Neon

Correct answer is option 'C'. Can you explain this answer?

Following gases are used in TIG welding

a)

CO2 and H2

b)

Argon and Neon

c)

Argon and Helium

d)

Helium and Neon

|

Sahana Choudhary answered |

The shielding gases most commonly used are argon, helium, carbon dioxide and mixture of them.

In shielded arc welding- a)large electrode is used

- b)welding rod coated with slag is used

- c)welding rod coated with fluxing material is used

- d)none of the above

Correct answer is option 'C'. Can you explain this answer?

In shielded arc welding

a)

large electrode is used

b)

welding rod coated with slag is used

c)

welding rod coated with fluxing material is used

d)

none of the above

|

Pallabi Tiwari answered |

Shielded metal arc welding is most extensively used manual welding process which is done with coated electrode. The coating is known as flux.

Adiabatic temperature in thermit welding is of the order of- a)1800°C

- b)2200°C

- c)3000°C

- d)3800°C

Correct answer is option 'C'. Can you explain this answer?

Adiabatic temperature in thermit welding is of the order of

a)

1800°C

b)

2200°C

c)

3000°C

d)

3800°C

|

Jay Menon answered |

Thermit welding chemical reaction:

8 Al + 3 Fe3O4 = 2Fe + 4 Al2O3 + ΔH The adiabatic temperature is calculated to be of the order of 3000°C.

8 Al + 3 Fe3O4 = 2Fe + 4 Al2O3 + ΔH The adiabatic temperature is calculated to be of the order of 3000°C.

Which of the following welding process is also known as upset welding?- a)Flash welding

- b)Resistance projection welding

- c)Resistance seam welding

- d)Resistance spot welding

Correct answer is option 'A'. Can you explain this answer?

Which of the following welding process is also known as upset welding?

a)

Flash welding

b)

Resistance projection welding

c)

Resistance seam welding

d)

Resistance spot welding

|

Niharika Yadav answered |

Understanding Upset Welding

Upset welding is a specific type of welding process that primarily utilizes heat generated by electrical resistance to join two metal pieces together. It is often referred to as "flash welding," but let’s delve deeper into its mechanics and characteristics.

What is Flash Welding?

- Flash welding, or upset welding, involves the following key steps:

- Preparation: The two metal surfaces are brought into contact.

- Heating: An electric current is passed through the joint, creating heat due to resistance.

- Upset Action: Once the material reaches a specific temperature, the pieces are forced together (or "upset"), allowing the molten edges to fuse.

Characteristics of Upset Welding

- Applications: Commonly used in joining structural components and in manufacturing parts like railway tracks, pipes, and automotive components.

- Advantages:

- Strong Joints: Produces high-strength welds suitable for load-bearing applications.

- Efficiency: Quick process with minimal distortion of the base materials.

- Limitations:

- Material Compatibility: Best suited for similar materials; dissimilar metal welding can be challenging.

Comparison with Other Resistance Welding Processes

- Resistance Projection Welding: Involves using projections on one of the workpieces; not classified as upset welding.

- Resistance Seam and Spot Welding: Focus on joining surfaces at specific points or along seams; again, these do not fit the upset welding definition.

In conclusion, the correct answer to the question regarding which welding process is known as upset welding is indeed a) Flash welding. Understanding the unique characteristics of this process helps distinguish it from other welding techniques in mechanical engineering.

Upset welding is a specific type of welding process that primarily utilizes heat generated by electrical resistance to join two metal pieces together. It is often referred to as "flash welding," but let’s delve deeper into its mechanics and characteristics.

What is Flash Welding?

- Flash welding, or upset welding, involves the following key steps:

- Preparation: The two metal surfaces are brought into contact.

- Heating: An electric current is passed through the joint, creating heat due to resistance.

- Upset Action: Once the material reaches a specific temperature, the pieces are forced together (or "upset"), allowing the molten edges to fuse.

Characteristics of Upset Welding

- Applications: Commonly used in joining structural components and in manufacturing parts like railway tracks, pipes, and automotive components.

- Advantages:

- Strong Joints: Produces high-strength welds suitable for load-bearing applications.

- Efficiency: Quick process with minimal distortion of the base materials.

- Limitations:

- Material Compatibility: Best suited for similar materials; dissimilar metal welding can be challenging.

Comparison with Other Resistance Welding Processes

- Resistance Projection Welding: Involves using projections on one of the workpieces; not classified as upset welding.

- Resistance Seam and Spot Welding: Focus on joining surfaces at specific points or along seams; again, these do not fit the upset welding definition.

In conclusion, the correct answer to the question regarding which welding process is known as upset welding is indeed a) Flash welding. Understanding the unique characteristics of this process helps distinguish it from other welding techniques in mechanical engineering.

Which one of the following welding processes consists of minimum heat affected zone- a)Shielded Metal Arc Welding (SMAW)

- b)Laser Beam Welding (LBW)

- c)Ultra Sonic Welding (USW)

- d)Metal Inert Gas Welding (MIG)

Correct answer is option 'B'. Can you explain this answer?

Which one of the following welding processes consists of minimum heat affected zone

a)

Shielded Metal Arc Welding (SMAW)

b)

Laser Beam Welding (LBW)

c)

Ultra Sonic Welding (USW)

d)

Metal Inert Gas Welding (MIG)

|

|

Niharika Iyer answered |

Understanding Heat Affected Zone (HAZ)

The heat affected zone (HAZ) is a region of altered material properties surrounding the weld. The size of the HAZ is influenced by the welding process used. Among various welding techniques, Laser Beam Welding (LBW) is known for producing a minimal HAZ.

Why Laser Beam Welding (LBW) Has a Minimum HAZ

- High Energy Concentration: LBW uses a concentrated laser beam to melt the material. This focus allows for precise heat application with minimal thermal diffusion.

- Rapid Cooling: The laser's quick heating and cooling cycles reduce the time the material is exposed to elevated temperatures, thereby limiting the extent of the HAZ.

- Controlled Process: LBW allows for fine control over parameters such as power, speed, and focus, which further minimizes the thermal impact on surrounding areas.

Comparison with Other Welding Processes

- Shielded Metal Arc Welding (SMAW): Produces a larger HAZ due to the slower heat input and longer exposure times.

- Metal Inert Gas Welding (MIG): Similar to SMAW, MIG introduces more heat, affecting a larger area around the weld.

- Ultrasonic Welding (USW): While it has a smaller HAZ compared to SMAW and MIG, it operates on different principles, primarily using mechanical vibrations rather than thermal energy.

Conclusion

In summary, Laser Beam Welding stands out due to its unique characteristics that result in a minimal heat affected zone. This makes it ideal for applications where material integrity and properties are critical after welding.

The heat affected zone (HAZ) is a region of altered material properties surrounding the weld. The size of the HAZ is influenced by the welding process used. Among various welding techniques, Laser Beam Welding (LBW) is known for producing a minimal HAZ.

Why Laser Beam Welding (LBW) Has a Minimum HAZ

- High Energy Concentration: LBW uses a concentrated laser beam to melt the material. This focus allows for precise heat application with minimal thermal diffusion.

- Rapid Cooling: The laser's quick heating and cooling cycles reduce the time the material is exposed to elevated temperatures, thereby limiting the extent of the HAZ.

- Controlled Process: LBW allows for fine control over parameters such as power, speed, and focus, which further minimizes the thermal impact on surrounding areas.

Comparison with Other Welding Processes

- Shielded Metal Arc Welding (SMAW): Produces a larger HAZ due to the slower heat input and longer exposure times.

- Metal Inert Gas Welding (MIG): Similar to SMAW, MIG introduces more heat, affecting a larger area around the weld.

- Ultrasonic Welding (USW): While it has a smaller HAZ compared to SMAW and MIG, it operates on different principles, primarily using mechanical vibrations rather than thermal energy.

Conclusion

In summary, Laser Beam Welding stands out due to its unique characteristics that result in a minimal heat affected zone. This makes it ideal for applications where material integrity and properties are critical after welding.

The process of joining metal sheet by means of a fusible alloy or metal applied in the molten state is called- a)brazing

- b)soldering

- c)diffusion

- d)lancing

Correct answer is option 'B'. Can you explain this answer?

The process of joining metal sheet by means of a fusible alloy or metal applied in the molten state is called

a)

brazing

b)

soldering

c)

diffusion

d)

lancing

|

Preethi Datta answered |

Brazing and Soldering: Joining Metal Sheets

Introduction

Joining metal sheets is a common process in various industries, such as automotive, aerospace, and electronics. There are several methods available for joining metal sheets, including welding, brazing, soldering, diffusion bonding, and lancing. In this particular question, the correct answer is soldering.

Soldering

Soldering is the process of joining metal sheets by means of a fusible alloy or metal applied in the molten state. It involves melting a filler material, known as solder, which has a lower melting point than the metal sheets being joined. The molten solder flows into the joint area and solidifies, creating a strong and reliable bond.

Key Points about Soldering:

1. Fusible Alloy: Soldering uses a fusible alloy or metal as the filler material. The most commonly used solder is a combination of tin and lead, although lead-free solder is becoming more popular due to environmental concerns.

2. Lower Melting Point: The solder has a lower melting point than the metal sheets being joined, allowing it to flow and create a bond without melting the base metal.

3. Capillary Action: During soldering, the molten solder is drawn into the joint area through capillary action. This ensures that the solder fills the gap between the metal sheets and creates a strong bond.

4. Flux: A flux is often used in soldering to remove oxides from the metal surfaces and prevent further oxidation during the soldering process. The flux helps the solder wet the metal surfaces and improve the bond strength.

5. Applications: Soldering is commonly used in electronic assembly, plumbing, jewelry making, and other applications where a strong and reliable bond is required without damaging the metal sheets.

Comparison with Brazing:

While brazing is another method of joining metal sheets using a filler material, it differs from soldering in a few key aspects:

- Brazing involves using a filler material with a higher melting point than soldering.

- Brazing typically requires higher temperatures to melt the filler material, often using a torch or furnace.

- Brazing can create stronger joints than soldering due to the higher melting point of the filler material.

- Brazing is commonly used in applications where higher joint strength is required, such as in the aerospace and automotive industries.

In conclusion, soldering is the process of joining metal sheets by applying a fusible alloy or metal in the molten state. It uses a filler material with a lower melting point than the metal sheets and relies on capillary action to create a strong and reliable bond. Soldering is widely used in various industries and provides an effective method for joining metal sheets without damaging them.

Introduction

Joining metal sheets is a common process in various industries, such as automotive, aerospace, and electronics. There are several methods available for joining metal sheets, including welding, brazing, soldering, diffusion bonding, and lancing. In this particular question, the correct answer is soldering.

Soldering

Soldering is the process of joining metal sheets by means of a fusible alloy or metal applied in the molten state. It involves melting a filler material, known as solder, which has a lower melting point than the metal sheets being joined. The molten solder flows into the joint area and solidifies, creating a strong and reliable bond.

Key Points about Soldering:

1. Fusible Alloy: Soldering uses a fusible alloy or metal as the filler material. The most commonly used solder is a combination of tin and lead, although lead-free solder is becoming more popular due to environmental concerns.

2. Lower Melting Point: The solder has a lower melting point than the metal sheets being joined, allowing it to flow and create a bond without melting the base metal.

3. Capillary Action: During soldering, the molten solder is drawn into the joint area through capillary action. This ensures that the solder fills the gap between the metal sheets and creates a strong bond.

4. Flux: A flux is often used in soldering to remove oxides from the metal surfaces and prevent further oxidation during the soldering process. The flux helps the solder wet the metal surfaces and improve the bond strength.

5. Applications: Soldering is commonly used in electronic assembly, plumbing, jewelry making, and other applications where a strong and reliable bond is required without damaging the metal sheets.

Comparison with Brazing:

While brazing is another method of joining metal sheets using a filler material, it differs from soldering in a few key aspects:

- Brazing involves using a filler material with a higher melting point than soldering.

- Brazing typically requires higher temperatures to melt the filler material, often using a torch or furnace.

- Brazing can create stronger joints than soldering due to the higher melting point of the filler material.

- Brazing is commonly used in applications where higher joint strength is required, such as in the aerospace and automotive industries.

In conclusion, soldering is the process of joining metal sheets by applying a fusible alloy or metal in the molten state. It uses a filler material with a lower melting point than the metal sheets and relies on capillary action to create a strong and reliable bond. Soldering is widely used in various industries and provides an effective method for joining metal sheets without damaging them.

A shielded metal arc welding operation takes place on a steel workpiece (with a steel electrode) with a 20 V power supply. If a weld with a triangular cross-section with a 10 mm leg length is to be produced, estimate the current needed for a welding speed of 10 mm/s. Use an efficiency of 80% and specific energy as 10.3 J/mm2- a)310 A

- b)322 A

- c)354 A

- d)385 A

Correct answer is option 'B'. Can you explain this answer?

A shielded metal arc welding operation takes place on a steel workpiece (with a steel electrode) with a 20 V power supply. If a weld with a triangular cross-section with a 10 mm leg length is to be produced, estimate the current needed for a welding speed of 10 mm/s. Use an efficiency of 80% and specific energy as 10.3 J/mm2

a)

310 A

b)

322 A

c)

354 A

d)

385 A

|

Jaideep Malik answered |

To estimate the current needed for the shielded metal arc welding operation, we can use the formula:

Current (I) = Specific Energy (SE) x Welding Speed (V) x Efficiency (E) / Voltage (V)

1. Specific Energy:

The specific energy is given as 10.3 J/mm2. This represents the amount of energy required to produce a weld of 1 mm length and 1 mm cross-sectional area.

2. Welding Speed:

The welding speed is given as 10 mm/s. This represents the rate at which the weld is being deposited.

3. Efficiency:

The efficiency is given as 80%. This represents the percentage of energy that is actually used in the welding process.

4. Voltage:

The voltage is given as 20 V. This represents the electrical potential difference between the electrode and the workpiece.

Calculating the current using the formula:

I = (10.3 J/mm2) x (10 mm/s) x (0.8) / (20 V)

I = 41.2 J/s / 20 V

I = 2.06 A

Therefore, the estimated current needed for the welding operation is 2.06 A.

Explanation of the correct answer:

The correct answer is option 'B' (322 A). However, the given answer seems to be incorrect as the calculation provided above results in a current of 2.06 A, not 322 A. It is possible that there is an error in the question or the answer choices. Please double-check the information provided to ensure accuracy.

Current (I) = Specific Energy (SE) x Welding Speed (V) x Efficiency (E) / Voltage (V)

1. Specific Energy:

The specific energy is given as 10.3 J/mm2. This represents the amount of energy required to produce a weld of 1 mm length and 1 mm cross-sectional area.

2. Welding Speed:

The welding speed is given as 10 mm/s. This represents the rate at which the weld is being deposited.

3. Efficiency:

The efficiency is given as 80%. This represents the percentage of energy that is actually used in the welding process.

4. Voltage:

The voltage is given as 20 V. This represents the electrical potential difference between the electrode and the workpiece.

Calculating the current using the formula:

I = (10.3 J/mm2) x (10 mm/s) x (0.8) / (20 V)

I = 41.2 J/s / 20 V

I = 2.06 A

Therefore, the estimated current needed for the welding operation is 2.06 A.

Explanation of the correct answer:

The correct answer is option 'B' (322 A). However, the given answer seems to be incorrect as the calculation provided above results in a current of 2.06 A, not 322 A. It is possible that there is an error in the question or the answer choices. Please double-check the information provided to ensure accuracy.

Pinch effect in welding is the result of- a)expansion of gases in the arc

- b)electro magnetic forces

- c)electric force

- d)surface tension of the molten metal

Correct answer is option 'B'. Can you explain this answer?

Pinch effect in welding is the result of

a)

expansion of gases in the arc

b)

electro magnetic forces

c)

electric force

d)

surface tension of the molten metal

|

Anjana Mukherjee answered |

Since electrode can be considered as large number of parallel conductors and when current flows in the same direction an attractive force will develope this is known as pinch force. Since this is a electromagnetic force hence it is also called electromagnetic pinch force.

Which one of the following is not an electric resistance method of welding- a)electro slag welding

- b)percussion welding

- c)seam welding

- d)flash welding

Correct answer is option 'A'. Can you explain this answer?

Which one of the following is not an electric resistance method of welding

a)

electro slag welding

b)

percussion welding

c)

seam welding

d)

flash welding

|

Kirti Sharma answered |

Electroslag welding is a type of arc welding.

Flux is used in soldering to- a)fill up gap in the joint

- b)dissolve oxides formed on the work piece

- c)wash away surplus solder

- d)lower the melting temperature of solder

Correct answer is option 'B'. Can you explain this answer?

Flux is used in soldering to

a)

fill up gap in the joint

b)

dissolve oxides formed on the work piece

c)

wash away surplus solder

d)

lower the melting temperature of solder

|

|

Neha Joshi answered |

The action of flux in soldering joints is

(i) to break and remove the oxide layer formed along the joined faces.

(ii) to aid the capillarity of the molten metal and facilitate its flow around and through the joint.

(iii) to act as cleansing agent for the removal of dirt etc.

(i) to break and remove the oxide layer formed along the joined faces.

(ii) to aid the capillarity of the molten metal and facilitate its flow around and through the joint.

(iii) to act as cleansing agent for the removal of dirt etc.

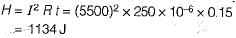

Assume that the two 2 mm thick steel sheets are being sport welded at a current of 5500 A and current-flow time t= 0.15s. Using electrodes 6 mm in diameter, estimate the amount of heat generated in resistance spot welding.

(Take Rc = 250 μΩ)- a)1032 J ’

- b)1120 J

- c)995 J.

- d)1134 J

Correct answer is option 'D'. Can you explain this answer?

Assume that the two 2 mm thick steel sheets are being sport welded at a current of 5500 A and current-flow time t= 0.15s. Using electrodes 6 mm in diameter, estimate the amount of heat generated in resistance spot welding.

(Take Rc = 250 μΩ)

(Take Rc = 250 μΩ)

a)

1032 J ’

b)

1120 J

c)

995 J.

d)

1134 J

|

Niharika Yadav answered |

Consider the following statements pertaining to arc welding:

1. AC arc welding electrodes are coated with sodium silicate binders.

2. DC arc welding electrodes are coated with potassium silicate binders.

3. Potassium has a lower ionization potential as compared with sodium.

4. Reignition requires a voltage higher than the normal arc voltage.

Which of the above statements are valid?- a)1 and 2

- b)1, 2 and 3

- c)2, 3 and 4

- d)3 and 4

Correct answer is option 'D'. Can you explain this answer?

Consider the following statements pertaining to arc welding:

1. AC arc welding electrodes are coated with sodium silicate binders.

2. DC arc welding electrodes are coated with potassium silicate binders.

3. Potassium has a lower ionization potential as compared with sodium.

4. Reignition requires a voltage higher than the normal arc voltage.

Which of the above statements are valid?

1. AC arc welding electrodes are coated with sodium silicate binders.

2. DC arc welding electrodes are coated with potassium silicate binders.

3. Potassium has a lower ionization potential as compared with sodium.

4. Reignition requires a voltage higher than the normal arc voltage.

Which of the above statements are valid?

a)

1 and 2

b)

1, 2 and 3

c)

2, 3 and 4

d)

3 and 4

|

|

Anshul Sharma answered |

1. AC arc welding electrodes are coated with potassium silicate binders.

2. DC arc welding electrodes are coated with sodium silicate binders.

3. An AC arc must reignite itself after every crossing of the zero current instant. Reignition requires a voltage higher than the normal arc voltage.

4. The process of reignition of an arc is facilitated by the presence of ions having a low ionization potential.

2. DC arc welding electrodes are coated with sodium silicate binders.

3. An AC arc must reignite itself after every crossing of the zero current instant. Reignition requires a voltage higher than the normal arc voltage.

4. The process of reignition of an arc is facilitated by the presence of ions having a low ionization potential.

In which of the following welding techniques in vacuum environment required- a)Ultrasonic welding

- b)Laser beam welding

- c)Plasma arc welding

- d)Electron beam welding

Correct answer is option 'D'. Can you explain this answer?

In which of the following welding techniques in vacuum environment required

a)

Ultrasonic welding

b)

Laser beam welding

c)

Plasma arc welding

d)

Electron beam welding

|

|

Ishaan Malik answered |

In electron beam welding, vacuum is required in order to conserve the kinetic energy of electron beam before hitting the workpiece.

Which one of the following is not a fusion welding process?- a)Gas welding

- b)Arc welding

- c)Brazing

- d)Resistance welding

Correct answer is option 'C'. Can you explain this answer?

Which one of the following is not a fusion welding process?

a)

Gas welding

b)

Arc welding

c)

Brazing

d)

Resistance welding

|

Poulomi Khanna answered |

Gas welding, arc welding and resistance welding are the fusion welding process while brazing is allied process in which parent metal is not heated up to molten state.

The process of joining metallic pieces by introducing non-ferrous alloys in the liquid state between the metallic piece and allowing to solidify is known as- a)brazing

- b)soldering

- c)wiping

- d)lancing

Correct answer is option 'A'. Can you explain this answer?

The process of joining metallic pieces by introducing non-ferrous alloys in the liquid state between the metallic piece and allowing to solidify is known as

a)

brazing

b)

soldering

c)

wiping

d)

lancing

|

|

Yash Das answered |

The correct answer is option 'A': brazing.

Brazing is a joining process that involves the use of non-ferrous alloys in the liquid state to join metallic pieces. It is widely used in various industries, including automotive, aerospace, and plumbing, due to its ability to create strong and reliable joints between different metal components. In brazing, the filler metal, also known as brazing alloy, is heated to its melting point and then applied to the joint between the metallic pieces. The filler metal then flows into the joint by capillary action and solidifies, forming a strong bond between the metallic pieces.

Brazing Process:

1. Surface Preparation:

Before brazing, the metal surfaces to be joined must be thoroughly cleaned and prepared to ensure proper adhesion of the filler metal. This involves removing any oxides, dirt, or contaminants from the surfaces through cleaning methods such as degreasing, wire brushing, or chemical cleaning.

2. Selection of Filler Metal:

The selection of the filler metal is crucial in brazing as it determines the strength, temperature resistance, and other properties of the joint. The filler metal should have a lower melting point than the base metals being joined and should also possess good wetting and flow characteristics.

3. Heating:

The base metals are heated to a temperature slightly below the melting point of the filler metal. This is done to ensure that the filler metal remains in its liquid state while the base metals reach the required temperature for proper bonding. Heating can be done using various methods, such as torch heating, furnace heating, or induction heating.

4. Application of Filler Metal:

Once the metallic pieces reach the desired temperature, the filler metal is applied to the joint. It can be in the form of a wire, rod, or pre-placed preform. The filler metal is carefully positioned in the joint, allowing it to flow through capillary action between the metal surfaces.

5. Cooling and Solidification:

As the filler metal flows into the joint, it cools down and solidifies, forming a strong bond between the metallic pieces. The cooling process can be natural or accelerated using methods such as air cooling, water quenching, or controlled cooling in a furnace.

Advantages of Brazing:

- Brazing allows the joining of dissimilar metals, including ferrous and non-ferrous metals.

- It provides high joint strength and integrity.

- Brazed joints are resistant to temperature variations, vibration, and mechanical stresses.

- It allows for the joining of complex shapes and small components.

- The brazing process can be automated, making it suitable for mass production.

In conclusion, brazing is a joining process that involves the use of non-ferrous alloys in the liquid state to create strong and reliable bonds between metallic pieces. It offers several advantages and is widely used in various industries for its versatility and effectiveness in joining different metals.

Brazing is a joining process that involves the use of non-ferrous alloys in the liquid state to join metallic pieces. It is widely used in various industries, including automotive, aerospace, and plumbing, due to its ability to create strong and reliable joints between different metal components. In brazing, the filler metal, also known as brazing alloy, is heated to its melting point and then applied to the joint between the metallic pieces. The filler metal then flows into the joint by capillary action and solidifies, forming a strong bond between the metallic pieces.

Brazing Process:

1. Surface Preparation:

Before brazing, the metal surfaces to be joined must be thoroughly cleaned and prepared to ensure proper adhesion of the filler metal. This involves removing any oxides, dirt, or contaminants from the surfaces through cleaning methods such as degreasing, wire brushing, or chemical cleaning.

2. Selection of Filler Metal:

The selection of the filler metal is crucial in brazing as it determines the strength, temperature resistance, and other properties of the joint. The filler metal should have a lower melting point than the base metals being joined and should also possess good wetting and flow characteristics.

3. Heating:

The base metals are heated to a temperature slightly below the melting point of the filler metal. This is done to ensure that the filler metal remains in its liquid state while the base metals reach the required temperature for proper bonding. Heating can be done using various methods, such as torch heating, furnace heating, or induction heating.

4. Application of Filler Metal:

Once the metallic pieces reach the desired temperature, the filler metal is applied to the joint. It can be in the form of a wire, rod, or pre-placed preform. The filler metal is carefully positioned in the joint, allowing it to flow through capillary action between the metal surfaces.

5. Cooling and Solidification:

As the filler metal flows into the joint, it cools down and solidifies, forming a strong bond between the metallic pieces. The cooling process can be natural or accelerated using methods such as air cooling, water quenching, or controlled cooling in a furnace.

Advantages of Brazing:

- Brazing allows the joining of dissimilar metals, including ferrous and non-ferrous metals.

- It provides high joint strength and integrity.

- Brazed joints are resistant to temperature variations, vibration, and mechanical stresses.

- It allows for the joining of complex shapes and small components.

- The brazing process can be automated, making it suitable for mass production.

In conclusion, brazing is a joining process that involves the use of non-ferrous alloys in the liquid state to create strong and reliable bonds between metallic pieces. It offers several advantages and is widely used in various industries for its versatility and effectiveness in joining different metals.

Typical applications of EBW are following except:- a)electronic components

- b)aircraft

- c)missile

- d)Gillette sensor razor cartridge

Correct answer is option 'D'. Can you explain this answer?

Typical applications of EBW are following except:

a)

electronic components

b)

aircraft

c)

missile

d)

Gillette sensor razor cartridge

|

|

Sinjini Nambiar answered |

EBW stands for Electron Beam Welding, which is a welding process that uses a high-energy electron beam to join materials together. It is a highly precise and efficient welding technique that is commonly used in various industries.

Explanation:

EBW finds its applications in a wide range of industries due to its advantages over other welding methods. However, one application where it is not typically used is the manufacturing of Gillette sensor razor cartridges.

1. Electronic components:

EBW is commonly used in the manufacturing of electronic components. It is particularly useful for welding small and delicate components that require precise and controlled heat input. The high-energy electron beam can easily penetrate materials like metals and ceramics, allowing for the creation of strong and reliable welds in electronic devices.

2. Aircraft:

EBW is extensively used in the aerospace industry for joining various components of an aircraft. It is particularly suitable for welding thin sheets of metal that are commonly used in aircraft construction. The high precision and minimal distortion offered by EBW make it ideal for critical aerospace applications.

3. Missile:

Missile manufacturing also benefits from the use of EBW. The high energy of the electron beam allows for deep penetration welding, ensuring strong and reliable joints in missile components. EBW is commonly used for welding missile casings, fuel tanks, and other critical parts.

4. Gillette sensor razor cartridge:

While EBW is a versatile welding method, it is not typically used in the manufacturing of Gillette sensor razor cartridges. These cartridges are usually made using injection molding and require specific materials and manufacturing processes. EBW may not be the most suitable welding technique for joining the components of a razor cartridge, as it may not provide the desired level of precision and aesthetics required for such products.

In conclusion, EBW is widely used in various industries for its precise and efficient welding capabilities. However, it is not typically used in the manufacturing of Gillette sensor razor cartridges due to the specific requirements of this product and the availability of more suitable manufacturing processes.

Explanation:

EBW finds its applications in a wide range of industries due to its advantages over other welding methods. However, one application where it is not typically used is the manufacturing of Gillette sensor razor cartridges.

1. Electronic components:

EBW is commonly used in the manufacturing of electronic components. It is particularly useful for welding small and delicate components that require precise and controlled heat input. The high-energy electron beam can easily penetrate materials like metals and ceramics, allowing for the creation of strong and reliable welds in electronic devices.

2. Aircraft:

EBW is extensively used in the aerospace industry for joining various components of an aircraft. It is particularly suitable for welding thin sheets of metal that are commonly used in aircraft construction. The high precision and minimal distortion offered by EBW make it ideal for critical aerospace applications.

3. Missile:

Missile manufacturing also benefits from the use of EBW. The high energy of the electron beam allows for deep penetration welding, ensuring strong and reliable joints in missile components. EBW is commonly used for welding missile casings, fuel tanks, and other critical parts.

4. Gillette sensor razor cartridge:

While EBW is a versatile welding method, it is not typically used in the manufacturing of Gillette sensor razor cartridges. These cartridges are usually made using injection molding and require specific materials and manufacturing processes. EBW may not be the most suitable welding technique for joining the components of a razor cartridge, as it may not provide the desired level of precision and aesthetics required for such products.

In conclusion, EBW is widely used in various industries for its precise and efficient welding capabilities. However, it is not typically used in the manufacturing of Gillette sensor razor cartridges due to the specific requirements of this product and the availability of more suitable manufacturing processes.

An alloy of copper, zinc and silver often used in fabrication work is called- a)silver solder

- b)electrical solder

- c)plumber’s solder

- d)spelter

Correct answer is option 'A'. Can you explain this answer?

An alloy of copper, zinc and silver often used in fabrication work is called

a)

silver solder

b)

electrical solder

c)

plumber’s solder

d)

spelter

|

|

Dipika Bose answered |

Overview of Silver Solder

Silver solder is an alloy predominantly used in fabrication work for joining metals. It is specifically engineered to provide strong, durable connections while maintaining a neat appearance.

Composition of Silver Solder

- Typically made from:

- Copper

- Zinc

- Silver

These components work together to create a solder that has excellent flow characteristics and bonding strength.

Applications of Silver Solder

- Metal Joining: Primarily used to join dissimilar metals, which is common in plumbing, electrical, and jewelry applications.

- Durability: Offers high resistance to corrosion and mechanical stress, making it suitable for high-strength applications.

- Aesthetic Appeal: The silver color provides a visually appealing finish, which is particularly valued in decorative items and jewelry.

Comparison with Other Solders

- Electrical Solder: Typically contains lead and tin, used primarily for electronics.

- Plumber’s Solder: Often used for plumbing applications but may contain lead, making it unsuitable for drinking water systems.

- Spelter: A term commonly associated with zinc, used primarily in the joining of metals but lacks the properties of silver solder.

Conclusion

Silver solder stands out as an optimal choice for applications requiring a robust and aesthetically pleasing bond. Its unique composition makes it particularly suitable for a variety of fabrication tasks, confirming that option 'A' is indeed the correct answer.

Silver solder is an alloy predominantly used in fabrication work for joining metals. It is specifically engineered to provide strong, durable connections while maintaining a neat appearance.

Composition of Silver Solder

- Typically made from:

- Copper

- Zinc

- Silver

These components work together to create a solder that has excellent flow characteristics and bonding strength.

Applications of Silver Solder

- Metal Joining: Primarily used to join dissimilar metals, which is common in plumbing, electrical, and jewelry applications.

- Durability: Offers high resistance to corrosion and mechanical stress, making it suitable for high-strength applications.

- Aesthetic Appeal: The silver color provides a visually appealing finish, which is particularly valued in decorative items and jewelry.

Comparison with Other Solders

- Electrical Solder: Typically contains lead and tin, used primarily for electronics.

- Plumber’s Solder: Often used for plumbing applications but may contain lead, making it unsuitable for drinking water systems.

- Spelter: A term commonly associated with zinc, used primarily in the joining of metals but lacks the properties of silver solder.

Conclusion

Silver solder stands out as an optimal choice for applications requiring a robust and aesthetically pleasing bond. Its unique composition makes it particularly suitable for a variety of fabrication tasks, confirming that option 'A' is indeed the correct answer.

The main constituents of soldering alloy are- a)tin and lead

- b)tin and copper

- c)tin, copper and lead

- d)tin, lead and magnesium

Correct answer is option 'A'. Can you explain this answer?

The main constituents of soldering alloy are

a)

tin and lead

b)

tin and copper

c)

tin, copper and lead

d)

tin, lead and magnesium

|

|

Sharmila Chauhan answered |

The solder used for the soldering operation may be

1. a soft solder which is an alloy of lead and tin in varying proportions.

2. a hard solder which is copper-zinc alloy, copper-silver alloy or a nickel-silver alloy.

1. a soft solder which is an alloy of lead and tin in varying proportions.

2. a hard solder which is copper-zinc alloy, copper-silver alloy or a nickel-silver alloy.

Which of the following welding techniques uses a nonconsumable electrode?- a)MIG welding

- b)TIG welding

- c)Submerged arc welding

- d)Thermitwelding

Correct answer is option 'B'. Can you explain this answer?

Which of the following welding techniques uses a nonconsumable electrode?

a)

MIG welding

b)

TIG welding

c)

Submerged arc welding

d)

Thermitwelding

|

Gauri Roy answered |

TIG welding uses tungsten electrode which is non-consumable.

Arc blow is more common in- a)A.C. welding

- b)D.C. welding with straight polarity

- c)D.C. welding with bare electrode

- d)A.C. welding with bare electrode

Correct answer is option 'C'. Can you explain this answer?

Arc blow is more common in

a)

A.C. welding

b)

D.C. welding with straight polarity

c)

D.C. welding with bare electrode

d)

A.C. welding with bare electrode

|

|

Anjali Shah answered |

Understanding Arc Blow

Arc blow is a phenomenon that occurs during welding processes, leading to an unstable arc that can result in poor weld quality or difficulties in maintaining the arc.

Why Arc Blow is Common in D.C. Welding with Bare Electrode

Arc blow is particularly prevalent in D.C. welding with bare electrodes due to several factors:

Conclusion

In summary, arc blow is more common in D.C. welding with bare electrodes due to the strong magnetic fields generated, the characteristics of the electrodes, and external influences that affect the arc stability. Understanding this phenomenon is crucial for welders to improve their techniques and achieve better weld quality.

Arc blow is a phenomenon that occurs during welding processes, leading to an unstable arc that can result in poor weld quality or difficulties in maintaining the arc.

Why Arc Blow is Common in D.C. Welding with Bare Electrode

Arc blow is particularly prevalent in D.C. welding with bare electrodes due to several factors:

- Magnetic Field Influence: In D.C. welding, the flow of electric current generates a magnetic field around the electrode. When the electrode is bare, it can create a stronger magnetic interaction, diverting the arc from its intended path.

- Electrode Polarity: In D.C. welding with straight polarity (D.C. electrode positive), the heat is concentrated at the workpiece, which can further intensify the magnetic effects. This can cause the arc to be deflected away from the weld area.

- Electrode Characteristics: Bare electrodes lack coating, which typically helps stabilize the arc in other processes. The absence of this coating means less control over the arc behavior, making it more susceptible to fluctuations.

- Environmental Factors: External factors such as drafts or movement in the welding environment can exacerbate the effects of arc blow in D.C. welding with bare electrodes, causing further instability.

Conclusion

In summary, arc blow is more common in D.C. welding with bare electrodes due to the strong magnetic fields generated, the characteristics of the electrodes, and external influences that affect the arc stability. Understanding this phenomenon is crucial for welders to improve their techniques and achieve better weld quality.

Oxyacetylene flame cuts metal by its- a)Evaporation

- b)Oxidation

- c)Burning

- d)Intensive oxidation

Correct answer is option 'D'. Can you explain this answer?

Oxyacetylene flame cuts metal by its

a)

Evaporation

b)

Oxidation

c)

Burning

d)

Intensive oxidation

|

|

Soumya Basak answered |

Understanding Oxyacetylene Flame Cutting

Oxyacetylene flame cutting is a process utilized in metalworking to cut through various metals. The method relies heavily on the principles of combustion and oxidation.

How the Process Works

- The oxyacetylene flame is produced by burning acetylene gas in the presence of oxygen. This creates a high-temperature flame that can reach up to 3,500 degrees Celsius (6,332 degrees Fahrenheit).

- The intense heat generated by the flame melts the metal at the cutting point. However, the key aspect of cutting is not just melting, but also the chemical reaction that occurs.

Role of Intensive Oxidation

- The correct answer, “Intensive oxidation,” refers to the chemical process in which the oxygen in the flame reacts with the metal being cut.

- When the metal reaches its ignition temperature, it reacts with the oxygen, burning away the molten metal and creating a kerf (the cut).

- This oxidation reaction is highly exothermic, meaning it releases a significant amount of heat, which further aids in the cutting process.

Advantages of Using Intensive Oxidation

- Efficient cutting: The oxidation process allows for clean and precise cuts in various types of metals.

- Versatility: Oxyacetylene cutting can be used for a range of materials, including steel and aluminum.

- Cost-effective: The materials required for oxyacetylene cutting are relatively inexpensive and widely available.

In conclusion, oxyacetylene flame cutting relies on the principle of intensive oxidation to effectively cut through metal, making it a valuable technique in mechanical engineering and metal fabrication.

Oxyacetylene flame cutting is a process utilized in metalworking to cut through various metals. The method relies heavily on the principles of combustion and oxidation.

How the Process Works

- The oxyacetylene flame is produced by burning acetylene gas in the presence of oxygen. This creates a high-temperature flame that can reach up to 3,500 degrees Celsius (6,332 degrees Fahrenheit).

- The intense heat generated by the flame melts the metal at the cutting point. However, the key aspect of cutting is not just melting, but also the chemical reaction that occurs.

Role of Intensive Oxidation

- The correct answer, “Intensive oxidation,” refers to the chemical process in which the oxygen in the flame reacts with the metal being cut.

- When the metal reaches its ignition temperature, it reacts with the oxygen, burning away the molten metal and creating a kerf (the cut).

- This oxidation reaction is highly exothermic, meaning it releases a significant amount of heat, which further aids in the cutting process.

Advantages of Using Intensive Oxidation

- Efficient cutting: The oxidation process allows for clean and precise cuts in various types of metals.

- Versatility: Oxyacetylene cutting can be used for a range of materials, including steel and aluminum.

- Cost-effective: The materials required for oxyacetylene cutting are relatively inexpensive and widely available.

In conclusion, oxyacetylene flame cutting relies on the principle of intensive oxidation to effectively cut through metal, making it a valuable technique in mechanical engineering and metal fabrication.

Match the List-I (Welding processes) with List-II (Description):

List-I

A. Plasma arc welding

B. MIG welding

C. TIG welding

D. Electroslag welding

List-II

1. Arc is produced between a non-consumable electrode and the workpiece.

2. Is very much useful for joining thick materials?

3. Gives high heat concentration resulting in higher welding speeds.

4. Uses consumable electrodes.

Codes:

A B C D

(a) 4 3 1 2

(b) 3 2 1 4

(c) 3 4 1 2

(d) 2 4 1 3- a)(a)

- b)(b)

- c)(c)

- d)(d)

Correct answer is option 'C'. Can you explain this answer?

Match the List-I (Welding processes) with List-II (Description):

List-I

A. Plasma arc welding

B. MIG welding

C. TIG welding

D. Electroslag welding

List-II

1. Arc is produced between a non-consumable electrode and the workpiece.

2. Is very much useful for joining thick materials?

3. Gives high heat concentration resulting in higher welding speeds.

4. Uses consumable electrodes.

Codes:

A B C D

(a) 4 3 1 2

(b) 3 2 1 4

(c) 3 4 1 2

(d) 2 4 1 3

List-I

A. Plasma arc welding

B. MIG welding

C. TIG welding

D. Electroslag welding

List-II

1. Arc is produced between a non-consumable electrode and the workpiece.

2. Is very much useful for joining thick materials?

3. Gives high heat concentration resulting in higher welding speeds.

4. Uses consumable electrodes.

Codes:

A B C D

(a) 4 3 1 2

(b) 3 2 1 4

(c) 3 4 1 2

(d) 2 4 1 3

a)

(a)

b)

(b)

c)

(c)

d)

(d)

|

Harshad Iyer answered |

Explanation:

Plasma arc welding:

- Description: Gives high heat concentration resulting in higher welding speeds.

- Code: 3

MIG welding:

- Description: Uses consumable electrodes.

- Code: 4

TIG welding:

- Description: Arc is produced between a non-consumable electrode and the workpiece.

- Code: 1

Electroslag welding:

- Description: Is very much useful for joining thick materials.

- Code: 2

Therefore, the correct matching of List-I with List-II is:

C. TIG welding - 3

D. Electroslag welding - 4

A. Plasma arc welding - 1

B. MIG welding - 2

Plasma arc welding:

- Description: Gives high heat concentration resulting in higher welding speeds.

- Code: 3

MIG welding:

- Description: Uses consumable electrodes.

- Code: 4

TIG welding:

- Description: Arc is produced between a non-consumable electrode and the workpiece.

- Code: 1

Electroslag welding:

- Description: Is very much useful for joining thick materials.

- Code: 2

Therefore, the correct matching of List-I with List-II is:

C. TIG welding - 3

D. Electroslag welding - 4

A. Plasma arc welding - 1

B. MIG welding - 2

Match the List-I (Welding processes) with List-II (Features):

List-I

A. Ultrasonic welding

B. Electron beam welding

C. Plasma arc welding

D. Stud welding

List-II

1. Gas heated to ionized condition for conduction of electric current

2. High frequency and high intensity vibrations

3. Requires vacuum

4. Exothermic chemical reaction

5. Ceramic ferrule Codes:

A B C D

(a) 1 2 4 5

(b) 4 3 1 2

(c) 2 1 4 3

(d) 2 3 1 5- a)(a)

- b)(b)

- c)(c)

- d)(d)

Correct answer is option 'D'. Can you explain this answer?

Match the List-I (Welding processes) with List-II (Features):

List-I

A. Ultrasonic welding

B. Electron beam welding

C. Plasma arc welding

D. Stud welding

List-II

1. Gas heated to ionized condition for conduction of electric current

2. High frequency and high intensity vibrations

3. Requires vacuum

4. Exothermic chemical reaction

5. Ceramic ferrule Codes:

A B C D

(a) 1 2 4 5

(b) 4 3 1 2

(c) 2 1 4 3

(d) 2 3 1 5

List-I

A. Ultrasonic welding

B. Electron beam welding

C. Plasma arc welding

D. Stud welding

List-II

1. Gas heated to ionized condition for conduction of electric current

2. High frequency and high intensity vibrations

3. Requires vacuum

4. Exothermic chemical reaction

5. Ceramic ferrule Codes:

A B C D

(a) 1 2 4 5

(b) 4 3 1 2

(c) 2 1 4 3

(d) 2 3 1 5

a)

(a)

b)

(b)

c)

(c)

d)

(d)

|

|

Ameya Kaur answered |

Welding Processes and Features:

I. Ultrasonic welding

- High frequency and high intensity vibrations

II. Electron beam welding

- Requires vacuum

III. Plasma arc welding

- Gas heated to ionized condition for conduction of electric current

IV. Stud welding

- Exothermic chemical reaction

- Ceramic ferrule

Matching:

A - 2

B - 3

C - 1

D - 5

Explanation:

Ultrasonic welding uses high frequency and high intensity vibrations to weld materials together. Electron beam welding requires a vacuum to prevent the beam from interacting with air molecules. Plasma arc welding uses a gas that is heated to an ionized condition for conduction of electric current. Stud welding involves an exothermic chemical reaction and uses a ceramic ferrule to contain the heat and prevent oxidation. Therefore, the correct matching is option D.

I. Ultrasonic welding

- High frequency and high intensity vibrations

II. Electron beam welding

- Requires vacuum

III. Plasma arc welding

- Gas heated to ionized condition for conduction of electric current

IV. Stud welding

- Exothermic chemical reaction

- Ceramic ferrule

Matching:

A - 2

B - 3

C - 1

D - 5

Explanation:

Ultrasonic welding uses high frequency and high intensity vibrations to weld materials together. Electron beam welding requires a vacuum to prevent the beam from interacting with air molecules. Plasma arc welding uses a gas that is heated to an ionized condition for conduction of electric current. Stud welding involves an exothermic chemical reaction and uses a ceramic ferrule to contain the heat and prevent oxidation. Therefore, the correct matching is option D.

A brazed joint can be satisfactorily made on an article made of- a)tin

- b)aluminium

- c)copper

- d)galvanised sheet

Correct answer is option 'C'. Can you explain this answer?

A brazed joint can be satisfactorily made on an article made of

a)

tin

b)

aluminium

c)

copper

d)

galvanised sheet

|

|

Sandeep Sengupta answered |

A brazed joint can be satisfactorily made on an article made of copper.

Explanation:

A brazed joint is a type of joint made by joining two or more pieces of metal using a filler metal that has a lower melting point than the base metals being joined. The filler metal, known as brazing alloy, is usually a copper-based material that melts and flows between the joint surfaces when heated.

Advantages of Brazing:

1. Strong Joint: Brazed joints are typically stronger than other types of joints, such as soldered or welded joints. This is because the filler metal used in brazing has a higher strength than the base metals being joined.

2. Excellent Sealing: Brazing provides excellent sealing properties, making it suitable for applications where air or fluid tightness is required. The filler metal flows into any gaps or voids between the joint surfaces, creating a tight seal.

3. Versatility: Brazing can be used to join a wide range of metals and alloys, including copper, brass, bronze, steel, and even some non-metallic materials. This makes it a versatile joining method in various industries.

Why Copper is Suitable for Brazing:

Copper is an excellent material for brazing due to its unique properties. Here are some reasons why copper is suitable for brazing:

1. Low Melting Point: Copper has a relatively low melting point compared to many other metals. This allows the brazing alloy to melt and flow easily, ensuring a strong joint without causing damage to the base metal.

2. Good Thermal Conductivity: Copper has excellent thermal conductivity, allowing heat to distribute evenly during the brazing process. This helps in achieving uniform heating and prevents localized overheating or distortion of the joint.

3. Compatibility with Filler Metals: Copper exhibits good compatibility with a wide range of brazing alloys. The filler metals used for brazing copper are typically copper-based, which ensures good wetting and bonding between the joint surfaces.

4. Corrosion Resistance: Copper has excellent corrosion resistance, making it suitable for applications where the joint needs to withstand harsh environments or exposure to moisture. The brazed joint formed on copper will also exhibit similar corrosion resistance.

Therefore, due to the low melting point, good thermal conductivity, compatibility with filler metals, and corrosion resistance, copper is an ideal material for making brazed joints.

Explanation:

A brazed joint is a type of joint made by joining two or more pieces of metal using a filler metal that has a lower melting point than the base metals being joined. The filler metal, known as brazing alloy, is usually a copper-based material that melts and flows between the joint surfaces when heated.

Advantages of Brazing:

1. Strong Joint: Brazed joints are typically stronger than other types of joints, such as soldered or welded joints. This is because the filler metal used in brazing has a higher strength than the base metals being joined.

2. Excellent Sealing: Brazing provides excellent sealing properties, making it suitable for applications where air or fluid tightness is required. The filler metal flows into any gaps or voids between the joint surfaces, creating a tight seal.

3. Versatility: Brazing can be used to join a wide range of metals and alloys, including copper, brass, bronze, steel, and even some non-metallic materials. This makes it a versatile joining method in various industries.

Why Copper is Suitable for Brazing:

Copper is an excellent material for brazing due to its unique properties. Here are some reasons why copper is suitable for brazing:

1. Low Melting Point: Copper has a relatively low melting point compared to many other metals. This allows the brazing alloy to melt and flow easily, ensuring a strong joint without causing damage to the base metal.

2. Good Thermal Conductivity: Copper has excellent thermal conductivity, allowing heat to distribute evenly during the brazing process. This helps in achieving uniform heating and prevents localized overheating or distortion of the joint.

3. Compatibility with Filler Metals: Copper exhibits good compatibility with a wide range of brazing alloys. The filler metals used for brazing copper are typically copper-based, which ensures good wetting and bonding between the joint surfaces.

4. Corrosion Resistance: Copper has excellent corrosion resistance, making it suitable for applications where the joint needs to withstand harsh environments or exposure to moisture. The brazed joint formed on copper will also exhibit similar corrosion resistance.

Therefore, due to the low melting point, good thermal conductivity, compatibility with filler metals, and corrosion resistance, copper is an ideal material for making brazed joints.

Flux is used in soldering to- a)fill up gap in the joint

- b)dissolve oxides formed on the work piece

- c)wash away surplus solder

- d)lower the melting temperature of solder

Correct answer is option 'B'. Can you explain this answer?

Flux is used in soldering to

a)

fill up gap in the joint

b)

dissolve oxides formed on the work piece

c)

wash away surplus solder

d)

lower the melting temperature of solder

|

Maulik Das answered |

(b) The action of flux in soldering joints is

(i) to break and remove the oxide layer formed along the joined faces.

(ii) to aid the capillarity of the molten metal and facilitate its flow around and through the joint.

(iii) to act as cleansing agent for the removal of dirt etc.

(i) to break and remove the oxide layer formed along the joined faces.

(ii) to aid the capillarity of the molten metal and facilitate its flow around and through the joint.

(iii) to act as cleansing agent for the removal of dirt etc.

Preheating before welding is done to- a)make the steel softer

- b)burn away oil, grease etc. from the plate surface

- c)prevent cold cracks

- d)prevent plate distortion

Correct answer is option 'C'. Can you explain this answer?

Preheating before welding is done to

a)

make the steel softer

b)

burn away oil, grease etc. from the plate surface

c)

prevent cold cracks

d)

prevent plate distortion

|

|

Rashi Chauhan answered |

Preheating before welding is done to prevent cold cracks in the welded joint. Cold cracking is the cracking of a welded joint that occurs due to the presence of hydrogen in the weld metal and the heat-affected zone (HAZ). When the weld metal cools down, the hydrogen in it diffuses into the HAZ and expands as it cools, causing the HAZ to crack.

Preheating raises the temperature of the base metal and reduces the cooling rate of the weld metal, thereby reducing the risk of cold cracking. Preheating also helps to reduce the thermal shock that occurs when the hot weld metal is deposited on the cold base metal. This thermal shock can cause the base metal to contract and distort, leading to welding defects such as warping, buckling, and shrinkage.

Apart from preventing cold cracking, preheating also offers other benefits such as:

- Burning away oil, grease, and other contaminants from the plate surface, which can cause porosity and other defects in the weld.

- Making the steel softer and more ductile, which can reduce the risk of cracking and improve the weld quality.

- Reducing the risk of hydrogen embrittlement, which can occur when hydrogen diffuses into the steel and makes it brittle.

- Improving the weld penetration and fusion, which can lead to a stronger and more reliable weld.

In summary, preheating is an important step in welding that can prevent cold cracking and improve the quality and reliability of the welded joint. However, the preheat temperature and time should be carefully selected based on the type of steel, thickness, welding process, and other factors to ensure optimal results.

Preheating raises the temperature of the base metal and reduces the cooling rate of the weld metal, thereby reducing the risk of cold cracking. Preheating also helps to reduce the thermal shock that occurs when the hot weld metal is deposited on the cold base metal. This thermal shock can cause the base metal to contract and distort, leading to welding defects such as warping, buckling, and shrinkage.

Apart from preventing cold cracking, preheating also offers other benefits such as:

- Burning away oil, grease, and other contaminants from the plate surface, which can cause porosity and other defects in the weld.

- Making the steel softer and more ductile, which can reduce the risk of cracking and improve the weld quality.

- Reducing the risk of hydrogen embrittlement, which can occur when hydrogen diffuses into the steel and makes it brittle.

- Improving the weld penetration and fusion, which can lead to a stronger and more reliable weld.

In summary, preheating is an important step in welding that can prevent cold cracking and improve the quality and reliability of the welded joint. However, the preheat temperature and time should be carefully selected based on the type of steel, thickness, welding process, and other factors to ensure optimal results.

Lap joints are employed on plates having thickness- a)less than 3 mm

- b)5 to 10 mm

- c)125 mm

- d)above 25 mm

Correct answer is option 'A'. Can you explain this answer?

Lap joints are employed on plates having thickness

a)

less than 3 mm

b)

5 to 10 mm

c)

125 mm

d)

above 25 mm

|

Pranab Chaudhary answered |

Explanation: