All Exams >

Mechanical Engineering >

Engineering Materials >

All Questions

All questions of Mechanical Properties of Metals for Mechanical Engineering Exam

Brittle fracture is more dangerous than ductile fracture because- a)no warning sign

- b)crack propagates at very high speed

- c)no need for extra stress during crack propagation

- d)all of these

Correct answer is option 'D'. Can you explain this answer?

Brittle fracture is more dangerous than ductile fracture because

a)

no warning sign

b)

crack propagates at very high speed

c)

no need for extra stress during crack propagation

d)

all of these

|

|

Athul Kumar answered |

Brittle fracture is more dangerous than ductile fracture because of several reasons. Let's discuss each reason in detail.

No warning sign:

- Brittle materials do not show any warning signs before fracturing, unlike ductile materials.

- Ductile materials undergo plastic deformation before fracturing, which gives a warning sign to prevent catastrophic failure.

- Brittle fracture can occur suddenly without any warning sign, making it more dangerous.

Crack propagates at a very high speed:

- In brittle materials, the crack propagates at a very high speed once it starts.

- Due to the absence of warning signs, there is no time to detect and control the crack propagation.

- The high-speed crack propagation can cause catastrophic failure in a very short time.

No need for extra stress during crack propagation:

- Brittle fracture can occur even at a low level of stress, which makes it more dangerous.

- In ductile fracture, the crack propagation requires extra stress to continue, which can be controlled to prevent catastrophic failure.

All of these:

- All the above reasons make brittle fracture more dangerous than ductile fracture.

- The absence of warning signs, high-speed crack propagation, and no need for extra stress during crack propagation can cause catastrophic failure in a very short time.

Therefore, it is important to understand the differences between brittle and ductile fracture and take appropriate precautions to prevent catastrophic failure in brittle materials.

No warning sign:

- Brittle materials do not show any warning signs before fracturing, unlike ductile materials.

- Ductile materials undergo plastic deformation before fracturing, which gives a warning sign to prevent catastrophic failure.

- Brittle fracture can occur suddenly without any warning sign, making it more dangerous.

Crack propagates at a very high speed:

- In brittle materials, the crack propagates at a very high speed once it starts.

- Due to the absence of warning signs, there is no time to detect and control the crack propagation.

- The high-speed crack propagation can cause catastrophic failure in a very short time.

No need for extra stress during crack propagation:

- Brittle fracture can occur even at a low level of stress, which makes it more dangerous.

- In ductile fracture, the crack propagation requires extra stress to continue, which can be controlled to prevent catastrophic failure.

All of these:

- All the above reasons make brittle fracture more dangerous than ductile fracture.

- The absence of warning signs, high-speed crack propagation, and no need for extra stress during crack propagation can cause catastrophic failure in a very short time.

Therefore, it is important to understand the differences between brittle and ductile fracture and take appropriate precautions to prevent catastrophic failure in brittle materials.

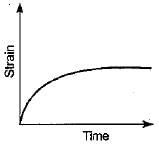

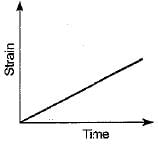

Ternary stage creep is associated with- a)strain hardening

- b)recovery

- c)necking

- d)none of these

Correct answer is option 'C'. Can you explain this answer?

Ternary stage creep is associated with

a)

strain hardening

b)

recovery

c)

necking

d)

none of these

|

Swati Patel answered |

Ternary stage creep is associated with necking.

Explanation:

Creep is the time-dependent deformation that occurs in a material under a constant load or stress. It is a common phenomenon in materials exposed to high temperatures and constant loading conditions. Creep can be divided into three stages: primary (or transient), secondary (or steady-state), and tertiary (or accelerated) creep.

Ternary stage creep, also known as tertiary creep, is the final stage of creep where the deformation rate increases rapidly. During this stage, the material experiences significant necking.

Necking is the localized reduction in cross-sectional area of a material under tension. It typically occurs in ductile materials and is characterized by the formation of a narrow region of reduced diameter or thickness. Necking is a result of strain localization and can lead to fracture.

During the primary and secondary creep stages, the material undergoes uniform deformation without significant necking. The deformation is distributed evenly across the material. However, as the material enters the tertiary creep stage, the deformation becomes highly localized, and necking occurs. This is often accompanied by a rapid increase in the deformation rate.

Necking in the context of ternary stage creep is an important phenomenon to consider because it indicates that the material is approaching its ultimate failure. It signifies that the material has undergone significant plastic deformation and is getting closer to fracture. Therefore, the occurrence of necking during ternary stage creep is a critical factor in assessing the remaining life and structural integrity of the material.

In conclusion, ternary stage creep is associated with necking, which is the localized reduction in cross-sectional area of a material under tension. Necking occurs during the final stage of creep when the material undergoes rapid deformation and is an important indicator of impending failure.

Explanation:

Creep is the time-dependent deformation that occurs in a material under a constant load or stress. It is a common phenomenon in materials exposed to high temperatures and constant loading conditions. Creep can be divided into three stages: primary (or transient), secondary (or steady-state), and tertiary (or accelerated) creep.

Ternary stage creep, also known as tertiary creep, is the final stage of creep where the deformation rate increases rapidly. During this stage, the material experiences significant necking.

Necking is the localized reduction in cross-sectional area of a material under tension. It typically occurs in ductile materials and is characterized by the formation of a narrow region of reduced diameter or thickness. Necking is a result of strain localization and can lead to fracture.

During the primary and secondary creep stages, the material undergoes uniform deformation without significant necking. The deformation is distributed evenly across the material. However, as the material enters the tertiary creep stage, the deformation becomes highly localized, and necking occurs. This is often accompanied by a rapid increase in the deformation rate.

Necking in the context of ternary stage creep is an important phenomenon to consider because it indicates that the material is approaching its ultimate failure. It signifies that the material has undergone significant plastic deformation and is getting closer to fracture. Therefore, the occurrence of necking during ternary stage creep is a critical factor in assessing the remaining life and structural integrity of the material.

In conclusion, ternary stage creep is associated with necking, which is the localized reduction in cross-sectional area of a material under tension. Necking occurs during the final stage of creep when the material undergoes rapid deformation and is an important indicator of impending failure.

Consider the following effects of yield point:

1. Luders bands

2. Strain ageing

3. Blue brittleness

4. Orange peel effect

Q. Which of the above are true?- a)1,2 and 4

- b)2 and 4

- c)1,3 and 4

- d)all of these

Correct answer is option 'B'. Can you explain this answer?

Consider the following effects of yield point:

1. Luders bands

2. Strain ageing

3. Blue brittleness

4. Orange peel effect

Q. Which of the above are true?

1. Luders bands

2. Strain ageing

3. Blue brittleness

4. Orange peel effect

Q. Which of the above are true?

a)

1,2 and 4

b)

2 and 4

c)

1,3 and 4

d)

all of these

|

|

Suyash Patel answered |

Luders Bands: These represents the marking on the surface of a tensile test sample, formed at the points of stress concentration like fillets.

Strain Ageing: It refers to changes in the properties of an over strained alloy with time. Strain ageing or strain-age-hardening is accompanied by hardening due to increase in stress value.

Blue Brittleness: When the temperature range of the test is raised, the yield point becomes less pronounced and blue brittleness effect is produced.

Orange Peel effects: During stretching, these markings appear on metals.

Strain Ageing: It refers to changes in the properties of an over strained alloy with time. Strain ageing or strain-age-hardening is accompanied by hardening due to increase in stress value.

Blue Brittleness: When the temperature range of the test is raised, the yield point becomes less pronounced and blue brittleness effect is produced.

Orange Peel effects: During stretching, these markings appear on metals.

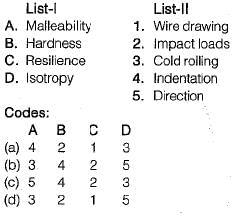

Match List-I with List-ll and select the correct answer using the codes given below the lists:

List-I

A. Malleability

B. Hardness

C. Resilience

D. Plasticity

List-ll

1. Absorb energy elastically

2. Resistance against deformation

3. Making sheets

4. Permanent deformation

Codes:

A B C D

(a) 3 4 2 1

(b) 4 3 1 2

(c) 1 2 3 4

(d) 3 2 1 4- a)(a)

- b)(b)

- c)(c)

- d)(d)

Correct answer is option 'D'. Can you explain this answer?

Match List-I with List-ll and select the correct answer using the codes given below the lists:

List-I

A. Malleability

B. Hardness

C. Resilience

D. Plasticity

List-ll

1. Absorb energy elastically

2. Resistance against deformation

3. Making sheets

4. Permanent deformation

Codes:

A B C D

(a) 3 4 2 1

(b) 4 3 1 2

(c) 1 2 3 4

(d) 3 2 1 4

List-I

A. Malleability

B. Hardness

C. Resilience

D. Plasticity

List-ll

1. Absorb energy elastically

2. Resistance against deformation

3. Making sheets

4. Permanent deformation

Codes:

A B C D

(a) 3 4 2 1

(b) 4 3 1 2

(c) 1 2 3 4

(d) 3 2 1 4

a)

(a)

b)

(b)

c)

(c)

d)

(d)

|

|

Prateek Mukherjee answered |

Resilience is the property of material to absorb energy when it is deformed elastically.

Plasticity is the property by virtue of which it can be deformed permanently.

Hardness is. the resistance against indentation or scratch.

Malleability is the property by which metal can be drawn in the form of sheets.

Plasticity is the property by virtue of which it can be deformed permanently.

Hardness is. the resistance against indentation or scratch.

Malleability is the property by which metal can be drawn in the form of sheets.

Rockwell hardness test uses- a)depth of penetration of indenter

- b)surface area of indentation

- c)projected area of indentation

- d)height of rebound

Correct answer is option 'A'. Can you explain this answer?

Rockwell hardness test uses

a)

depth of penetration of indenter

b)

surface area of indentation

c)

projected area of indentation

d)

height of rebound

|

|

Siddharth Menon answered |

Rockwell hardness test is a commonly used method to determine the hardness of a material. It involves measuring the depth of penetration of an indenter into the material, which is then correlated to the hardness value. The correct answer is option 'A', which states that the Rockwell hardness test uses the depth of penetration of the indenter.

The Rockwell hardness test is based on the principle of measuring the depth of penetration of an indenter under a known load. The indenter used in this test is typically a diamond cone or a hardened steel ball. The test is performed by applying a minor load to preload the indenter onto the material surface, followed by applying a major load. After the major load is removed, the depth of penetration of the indenter is measured.

The depth of penetration is determined by measuring the difference between the depth of penetration under the major load and the depth of penetration under the minor load. This difference is then converted into a hardness value using a Rockwell hardness scale. The Rockwell hardness scale is a standardized scale that correlates the depth of penetration to a hardness value.

The depth of penetration is measured using an optical microscope or a depth-measuring device. The measurement is usually taken at a specific location on the indentation, typically at the center. The depth of penetration is a direct measure of the resistance of the material to indentation and is related to the material's hardness.

The Rockwell hardness test is widely used in various industries to determine the hardness of materials. It is a relatively simple and quick test that provides a reliable measure of hardness. The test can be performed on a wide range of materials, including metals, plastics, and ceramics.

In conclusion, the Rockwell hardness test uses the depth of penetration of an indenter to determine the hardness of a material. The depth of penetration is measured and correlated to a hardness value using a standardized Rockwell hardness scale. This test is widely used in various industries for its simplicity and reliability.

The Rockwell hardness test is based on the principle of measuring the depth of penetration of an indenter under a known load. The indenter used in this test is typically a diamond cone or a hardened steel ball. The test is performed by applying a minor load to preload the indenter onto the material surface, followed by applying a major load. After the major load is removed, the depth of penetration of the indenter is measured.

The depth of penetration is determined by measuring the difference between the depth of penetration under the major load and the depth of penetration under the minor load. This difference is then converted into a hardness value using a Rockwell hardness scale. The Rockwell hardness scale is a standardized scale that correlates the depth of penetration to a hardness value.

The depth of penetration is measured using an optical microscope or a depth-measuring device. The measurement is usually taken at a specific location on the indentation, typically at the center. The depth of penetration is a direct measure of the resistance of the material to indentation and is related to the material's hardness.

The Rockwell hardness test is widely used in various industries to determine the hardness of materials. It is a relatively simple and quick test that provides a reliable measure of hardness. The test can be performed on a wide range of materials, including metals, plastics, and ceramics.

In conclusion, the Rockwell hardness test uses the depth of penetration of an indenter to determine the hardness of a material. The depth of penetration is measured and correlated to a hardness value using a standardized Rockwell hardness scale. This test is widely used in various industries for its simplicity and reliability.

Fatigue strength for non-ferrous materials is defined at X stress cycles. The value of X is- a)103

- b)105

- c)107

- d)109

Correct answer is option 'C'. Can you explain this answer?

Fatigue strength for non-ferrous materials is defined at X stress cycles. The value of X is

a)

103

b)

105

c)

107

d)

109

|

|

Nayanika Yadav answered |

Definition of Fatigue Strength:

Fatigue strength is the maximum stress that a material can withstand for a specified number of stress cycles before it fails due to fatigue.

Value of X for non-ferrous materials:

- For non-ferrous materials, the value of X for fatigue strength is typically defined at 10^7 stress cycles.

- This means that the material can withstand a certain stress level for 10 million stress cycles before failure due to fatigue.

Significance of X value:

- Determining the fatigue strength at a specific number of stress cycles is important for designing components that will be subjected to cyclic loading.

- Knowing the fatigue strength at X stress cycles helps engineers ensure the reliability and durability of the component under real-world operating conditions.

Importance of considering non-ferrous materials:

- Non-ferrous materials such as aluminum, copper, and titanium are commonly used in various industries due to their desirable properties like lightweight, corrosion resistance, and electrical conductivity.

- Understanding the fatigue behavior of non-ferrous materials is crucial for designing components that meet performance requirements and safety standards.

Conclusion:

In conclusion, the value of X for fatigue strength of non-ferrous materials is typically defined at 10^7 stress cycles. This value plays a significant role in ensuring the reliability and durability of components subjected to cyclic loading in various engineering applications.

Fatigue strength is the maximum stress that a material can withstand for a specified number of stress cycles before it fails due to fatigue.

Value of X for non-ferrous materials:

- For non-ferrous materials, the value of X for fatigue strength is typically defined at 10^7 stress cycles.

- This means that the material can withstand a certain stress level for 10 million stress cycles before failure due to fatigue.

Significance of X value:

- Determining the fatigue strength at a specific number of stress cycles is important for designing components that will be subjected to cyclic loading.

- Knowing the fatigue strength at X stress cycles helps engineers ensure the reliability and durability of the component under real-world operating conditions.

Importance of considering non-ferrous materials:

- Non-ferrous materials such as aluminum, copper, and titanium are commonly used in various industries due to their desirable properties like lightweight, corrosion resistance, and electrical conductivity.

- Understanding the fatigue behavior of non-ferrous materials is crucial for designing components that meet performance requirements and safety standards.

Conclusion:

In conclusion, the value of X for fatigue strength of non-ferrous materials is typically defined at 10^7 stress cycles. This value plays a significant role in ensuring the reliability and durability of components subjected to cyclic loading in various engineering applications.

The property of material which enables it to retain the deformation permanently is called- a)Brittleness

- b)Ductility

- c)Malleability

- d)Plasticity

Correct answer is option 'D'. Can you explain this answer?

The property of material which enables it to retain the deformation permanently is called

a)

Brittleness

b)

Ductility

c)

Malleability

d)

Plasticity

|

|

Aditya Chavan answered |

Plasticity is that property of a material by virtue of which it may be permanently deformed when it has been subjected to an externally applied force great enough to exceed the elastic limit.

The highest stress that a material can withstand for a specified length of time without excessive deformation is called- a)fatigue strength

- b)endurance strength

- c)creep strength

- d)creep rupture strength

Correct answer is option 'D'. Can you explain this answer?

The highest stress that a material can withstand for a specified length of time without excessive deformation is called

a)

fatigue strength

b)

endurance strength

c)

creep strength

d)

creep rupture strength

|

|

Arnav Menon answered |

Creep Rupture Strength

The highest stress that a material can bear for a specified length of time without excessive deformation is called its creep rupture strength. It is a measure of a material's ability to withstand high temperatures and constant stress over an extended period of time without breaking down.

Creep is a phenomenon that occurs at high temperatures and under constant stress, in which a material slowly deforms over time. This can eventually lead to the material rupturing or breaking down entirely. The creep rupture strength of a material is the maximum stress it can withstand before such a failure occurs.

Factors Affecting Creep Rupture Strength

Several factors can influence the creep rupture strength of a material, including:

1. Temperature: Higher temperatures can increase the rate of creep and reduce the material's creep rupture strength.

2. Stress level: Higher levels of stress can also increase the rate of creep and reduce the material's creep rupture strength.

3. Time: Longer exposure to high temperatures and constant stress can increase the likelihood of creep and reduce the material's creep rupture strength.

Applications

Creep rupture strength is an essential property to consider in high-temperature applications, such as:

1. Gas turbine engines

2. Nuclear power plants

3. Chemical processing plants

4. Aerospace materials

5. High-temperature alloys and composites

Conclusion

In conclusion, creep rupture strength is a critical property to consider in materials that will be exposed to high temperatures and constant stress over an extended period. It is a measure of a material's ability to withstand these conditions without breaking down or rupturing. Factors such as temperature, stress level, and time can all affect a material's creep rupture strength.

The highest stress that a material can bear for a specified length of time without excessive deformation is called its creep rupture strength. It is a measure of a material's ability to withstand high temperatures and constant stress over an extended period of time without breaking down.

Creep is a phenomenon that occurs at high temperatures and under constant stress, in which a material slowly deforms over time. This can eventually lead to the material rupturing or breaking down entirely. The creep rupture strength of a material is the maximum stress it can withstand before such a failure occurs.

Factors Affecting Creep Rupture Strength

Several factors can influence the creep rupture strength of a material, including:

1. Temperature: Higher temperatures can increase the rate of creep and reduce the material's creep rupture strength.

2. Stress level: Higher levels of stress can also increase the rate of creep and reduce the material's creep rupture strength.

3. Time: Longer exposure to high temperatures and constant stress can increase the likelihood of creep and reduce the material's creep rupture strength.

Applications

Creep rupture strength is an essential property to consider in high-temperature applications, such as:

1. Gas turbine engines

2. Nuclear power plants

3. Chemical processing plants

4. Aerospace materials

5. High-temperature alloys and composites

Conclusion

In conclusion, creep rupture strength is a critical property to consider in materials that will be exposed to high temperatures and constant stress over an extended period. It is a measure of a material's ability to withstand these conditions without breaking down or rupturing. Factors such as temperature, stress level, and time can all affect a material's creep rupture strength.

Which one of the following properties is more sensitive to increase in strain rate?- a)Yield strength

- b)Proportional limit

- c)Elastic limit

- d)Tensile strength

Correct answer is option 'A'. Can you explain this answer?

Which one of the following properties is more sensitive to increase in strain rate?

a)

Yield strength

b)

Proportional limit

c)

Elastic limit

d)

Tensile strength

|

Rajat Sen answered |

Introduction:

When a material is subjected to an external force, it undergoes deformation. The rate at which this deformation occurs is known as the strain rate. Different mechanical properties of a material can be affected by the strain rate. In this context, we will discuss which property is more sensitive to an increase in strain rate.

Explanation:

To understand which property is more sensitive to an increase in strain rate, let's briefly define each of the properties mentioned in the options:

1. Yield strength: The yield strength is the point at which a material begins to deform plastically, i.e., permanent deformation occurs without any increase in the applied load.

2. Proportional limit: The proportional limit is the maximum stress a material can withstand without undergoing permanent deformation.

3. Elastic limit: The elastic limit is the maximum stress a material can withstand and still return to its original shape after the load is removed.

4. Tensile strength: The tensile strength is the maximum stress a material can withstand before it fails in a tensile test, i.e., the maximum stress a material can withstand while being pulled apart.

Sensitivity to Strain Rate:

Among the given options, yield strength is the property that is more sensitive to an increase in strain rate. Here's why:

1. Strain rate sensitivity: The strain rate sensitivity of a material determines its ability to deform at different rates. Some materials may exhibit a higher strain rate sensitivity, which means their mechanical properties can vary significantly with changes in strain rate.

2. Plastic deformation: Yield strength is a measure of a material's ability to resist plastic deformation. When the strain rate increases, the material experiences more rapid deformation, causing a higher strain rate at the onset of plastic deformation.

3. Strain rate hardening: Strain rate hardening refers to the increase in yield strength with an increase in strain rate. Some materials exhibit strain rate hardening behavior, where the yield strength increases as the strain rate increases.

4. Dynamic loading: In many real-world applications, materials are subjected to dynamic loading conditions, where the strain rate is relatively high. In such cases, the yield strength becomes a critical property in determining the material's response to the applied load.

Therefore, among the given options, yield strength is the property that is more sensitive to an increase in strain rate. Changes in strain rate can significantly affect the yield strength of a material, making it an important consideration in designing and analyzing materials for dynamic loading conditions.

When a material is subjected to an external force, it undergoes deformation. The rate at which this deformation occurs is known as the strain rate. Different mechanical properties of a material can be affected by the strain rate. In this context, we will discuss which property is more sensitive to an increase in strain rate.

Explanation:

To understand which property is more sensitive to an increase in strain rate, let's briefly define each of the properties mentioned in the options:

1. Yield strength: The yield strength is the point at which a material begins to deform plastically, i.e., permanent deformation occurs without any increase in the applied load.

2. Proportional limit: The proportional limit is the maximum stress a material can withstand without undergoing permanent deformation.

3. Elastic limit: The elastic limit is the maximum stress a material can withstand and still return to its original shape after the load is removed.

4. Tensile strength: The tensile strength is the maximum stress a material can withstand before it fails in a tensile test, i.e., the maximum stress a material can withstand while being pulled apart.

Sensitivity to Strain Rate:

Among the given options, yield strength is the property that is more sensitive to an increase in strain rate. Here's why:

1. Strain rate sensitivity: The strain rate sensitivity of a material determines its ability to deform at different rates. Some materials may exhibit a higher strain rate sensitivity, which means their mechanical properties can vary significantly with changes in strain rate.

2. Plastic deformation: Yield strength is a measure of a material's ability to resist plastic deformation. When the strain rate increases, the material experiences more rapid deformation, causing a higher strain rate at the onset of plastic deformation.

3. Strain rate hardening: Strain rate hardening refers to the increase in yield strength with an increase in strain rate. Some materials exhibit strain rate hardening behavior, where the yield strength increases as the strain rate increases.

4. Dynamic loading: In many real-world applications, materials are subjected to dynamic loading conditions, where the strain rate is relatively high. In such cases, the yield strength becomes a critical property in determining the material's response to the applied load.

Therefore, among the given options, yield strength is the property that is more sensitive to an increase in strain rate. Changes in strain rate can significantly affect the yield strength of a material, making it an important consideration in designing and analyzing materials for dynamic loading conditions.

Visco-elastic behaviour would be exhibited by- a)organic polymers

- b)neoprene

- c)ceramics

- d)steel

Correct answer is option 'B'. Can you explain this answer?

Visco-elastic behaviour would be exhibited by

a)

organic polymers

b)

neoprene

c)

ceramics

d)

steel

|

|

Prateek Mukherjee answered |

Visco-elastic behaviour would be exhibited by Neoprene.

Neoprene is a synthetic rubber that displays visco-elastic behavior. To understand why Neoprene exhibits this behavior, let's first define what visco-elasticity is.

Visco-elasticity is the property of a material to exhibit both viscous and elastic characteristics when undergoing deformation. Viscous behavior refers to the ability of a material to undergo continuous deformation under constant stress, while elastic behavior refers to the ability of a material to return to its original shape after deformation when the stress is removed. Visco-elastic materials exhibit a combination of these two behaviors.

Visco-elasticity in Neoprene can be explained using the following key points:

1. Molecular structure: Neoprene is composed of long chains of polymers that are cross-linked, resulting in a three-dimensional network. This structure allows for both the viscous and elastic behavior observed in visco-elastic materials.

2. Viscous behavior: When a stress is applied to Neoprene, the cross-linked polymer chains can slide and move past each other, resulting in continuous deformation. This behavior is similar to the flow of a viscous fluid.

3. Elastic behavior: When the stress is removed, the cross-linked polymer chains can return to their original positions, causing the material to recover its original shape. This behavior is similar to the elastic deformation observed in solid materials.

4. Time-dependent response: Visco-elastic materials, including Neoprene, also exhibit a time-dependent response. This means that the deformation and recovery processes are influenced by the rate at which the stress is applied or removed. The material may exhibit different mechanical properties under different loading conditions.

5. Applications: The visco-elastic behavior of Neoprene makes it suitable for a variety of applications. It is commonly used in the production of gaskets, seals, and other components that require both flexibility and resilience. Neoprene's ability to absorb and dampen vibrations also makes it useful in the manufacture of shock absorbers and vibration isolation mounts.

In conclusion, Neoprene exhibits visco-elastic behavior due to its molecular structure and cross-linked polymer chains. This behavior allows the material to undergo both viscous and elastic deformation, making it useful in various mechanical engineering applications.

Neoprene is a synthetic rubber that displays visco-elastic behavior. To understand why Neoprene exhibits this behavior, let's first define what visco-elasticity is.

Visco-elasticity is the property of a material to exhibit both viscous and elastic characteristics when undergoing deformation. Viscous behavior refers to the ability of a material to undergo continuous deformation under constant stress, while elastic behavior refers to the ability of a material to return to its original shape after deformation when the stress is removed. Visco-elastic materials exhibit a combination of these two behaviors.

Visco-elasticity in Neoprene can be explained using the following key points:

1. Molecular structure: Neoprene is composed of long chains of polymers that are cross-linked, resulting in a three-dimensional network. This structure allows for both the viscous and elastic behavior observed in visco-elastic materials.

2. Viscous behavior: When a stress is applied to Neoprene, the cross-linked polymer chains can slide and move past each other, resulting in continuous deformation. This behavior is similar to the flow of a viscous fluid.

3. Elastic behavior: When the stress is removed, the cross-linked polymer chains can return to their original positions, causing the material to recover its original shape. This behavior is similar to the elastic deformation observed in solid materials.

4. Time-dependent response: Visco-elastic materials, including Neoprene, also exhibit a time-dependent response. This means that the deformation and recovery processes are influenced by the rate at which the stress is applied or removed. The material may exhibit different mechanical properties under different loading conditions.

5. Applications: The visco-elastic behavior of Neoprene makes it suitable for a variety of applications. It is commonly used in the production of gaskets, seals, and other components that require both flexibility and resilience. Neoprene's ability to absorb and dampen vibrations also makes it useful in the manufacture of shock absorbers and vibration isolation mounts.

In conclusion, Neoprene exhibits visco-elastic behavior due to its molecular structure and cross-linked polymer chains. This behavior allows the material to undergo both viscous and elastic deformation, making it useful in various mechanical engineering applications.

Most often machine components fail by- a)Buckling

- b)Creep

- c)Fatigue

- d)All of these

Correct answer is option 'C'. Can you explain this answer?

Most often machine components fail by

a)

Buckling

b)

Creep

c)

Fatigue

d)

All of these

|

Garima Basak answered |

Causes of Machine Component Failure

Machine components can fail due to various reasons. One of the most common causes of failure is fatigue, which occurs when a material is subjected to repeated loading and unloading, leading to the formation and propagation of cracks over time.

Factors contributing to fatigue failure:

- Inadequate design considerations

- Improper material selection

- High stress concentrations

- Vibrations or dynamic loading

- Corrosion or environmental effects

Understanding Creep Failure:

Another factor that can lead to machine component failure is creep, which is the gradual deformation of a material under a constant load over an extended period. Creep failure is more likely to occur at elevated temperatures and can result in permanent deformation or rupture of the component.

Common scenarios causing creep failure:

- High temperatures

- Prolonged exposure to stress

- Inadequate material properties

- Insufficient support or constraints

Impact of Buckling on Machine Components:

Buckling is another mechanism that can cause machine components to fail. It occurs when a structural element suddenly deflects laterally under compressive loads, leading to instability and potential collapse of the component.

Factors influencing buckling failure:

- Inadequate bracing or support

- Excessive compressive loads

- Insufficient stiffness or rigidity

- Improper alignment or geometry

Conclusion

In conclusion, machine components can fail due to various mechanisms, with fatigue, creep, and buckling being among the most common factors. It is essential for engineers to consider these failure modes during the design and analysis of machine components to ensure their reliability and longevity.

Knoop hardness test is used to measure the hardness of- a)ductile materials

- b)fragile materials

- c)difficult-to-machine materials

- d)rubber

Correct answer is option 'B'. Can you explain this answer?

Knoop hardness test is used to measure the hardness of

a)

ductile materials

b)

fragile materials

c)

difficult-to-machine materials

d)

rubber

|

|

Isha Nambiar answered |

Knoop hardness test is used to measure the hardness of brittle or fragile materials. It is a micro-indentation test that uses a diamond indenter to create an impression in the material being tested. The Knoop test is similar to the Vickers test, but the Knoop indenter has a longer, more pointed shape that allows for more precise testing of small or thin samples.

Headings:

- What is Knoop hardness test?

- How does Knoop hardness test work?

- What materials can be tested using Knoop hardness test?

What is Knoop hardness test?

Knoop hardness test is a type of micro-indentation test used to measure the hardness of brittle or fragile materials. It was developed by Frederick Knoop in the 1930s and is widely used in materials science and engineering.

How does Knoop hardness test work?

Knoop hardness test works by pressing a diamond indenter into the surface of the material being tested. The indenter creates a small, elongated impression in the material, which is then measured under a microscope. The length of the impression is used to calculate the hardness of the material, which is expressed in Knoop hardness number (KHN).

What materials can be tested using Knoop hardness test?

Knoop hardness test is particularly useful for testing brittle or fragile materials, such as ceramics, glasses, and thin films. It is also used to test the hardness of harder materials, such as metals and alloys, at low loads. Knoop hardness test is less commonly used for testing soft materials, such as rubber, as the indentation can be difficult to measure accurately.

Headings:

- What is Knoop hardness test?

- How does Knoop hardness test work?

- What materials can be tested using Knoop hardness test?

What is Knoop hardness test?

Knoop hardness test is a type of micro-indentation test used to measure the hardness of brittle or fragile materials. It was developed by Frederick Knoop in the 1930s and is widely used in materials science and engineering.

How does Knoop hardness test work?

Knoop hardness test works by pressing a diamond indenter into the surface of the material being tested. The indenter creates a small, elongated impression in the material, which is then measured under a microscope. The length of the impression is used to calculate the hardness of the material, which is expressed in Knoop hardness number (KHN).

What materials can be tested using Knoop hardness test?

Knoop hardness test is particularly useful for testing brittle or fragile materials, such as ceramics, glasses, and thin films. It is also used to test the hardness of harder materials, such as metals and alloys, at low loads. Knoop hardness test is less commonly used for testing soft materials, such as rubber, as the indentation can be difficult to measure accurately.

Fracture voids usually form at- a)Inclusions

- b)Second phase particles

- c)Grain boundary triple points

- d)All of these

Correct answer is option 'D'. Can you explain this answer?

Fracture voids usually form at

a)

Inclusions

b)

Second phase particles

c)

Grain boundary triple points

d)

All of these

|

|

Raghav Saini answered |

Fracture Voids in Mechanical Engineering

Fracture voids refer to the empty spaces or gaps that form within a material when it undergoes fracture or failure. These voids can have a significant impact on the mechanical properties of the material, including its strength, toughness, and ductility.

Formation of Fracture Voids

Fracture voids can form through various mechanisms, including:

1. Inclusions: Inclusions refer to foreign particles or impurities that are present within a material. These inclusions can act as stress concentrators, leading to the formation of voids under applied stress.

2. Second phase particles: Second phase particles refer to particles of a different material that are present within the matrix of the material. These particles can also act as stress concentrators, leading to the formation of voids.

3. Grain boundary triple points: Grain boundaries refer to the regions between different grains within a material. At the intersection of three grain boundaries, known as triple points, there can be a concentration of stress that can lead to the formation of voids.

Impact of Fracture Voids

The presence of fracture voids can have a significant impact on the mechanical properties of a material. Some of these impacts include:

1. Reduced strength: Fracture voids can act as stress concentrators, leading to a reduction in the strength of the material.

2. Reduced toughness: Fracture voids can also act as sites for crack initiation and propagation, leading to a reduction in the toughness of the material.

3. Reduced ductility: Fracture voids can also lead to a reduction in the ductility of the material, as they can act as sites for localized deformation and eventual fracture.

Conclusion

Fracture voids are a common feature in materials that have undergone fracture or failure. They can form through various mechanisms, including the presence of inclusions, second phase particles, and grain boundary triple points. The presence of these voids can have a significant impact on the mechanical properties of the material, including its strength, toughness, and ductility.

Fracture voids refer to the empty spaces or gaps that form within a material when it undergoes fracture or failure. These voids can have a significant impact on the mechanical properties of the material, including its strength, toughness, and ductility.

Formation of Fracture Voids

Fracture voids can form through various mechanisms, including:

1. Inclusions: Inclusions refer to foreign particles or impurities that are present within a material. These inclusions can act as stress concentrators, leading to the formation of voids under applied stress.

2. Second phase particles: Second phase particles refer to particles of a different material that are present within the matrix of the material. These particles can also act as stress concentrators, leading to the formation of voids.

3. Grain boundary triple points: Grain boundaries refer to the regions between different grains within a material. At the intersection of three grain boundaries, known as triple points, there can be a concentration of stress that can lead to the formation of voids.

Impact of Fracture Voids

The presence of fracture voids can have a significant impact on the mechanical properties of a material. Some of these impacts include:

1. Reduced strength: Fracture voids can act as stress concentrators, leading to a reduction in the strength of the material.

2. Reduced toughness: Fracture voids can also act as sites for crack initiation and propagation, leading to a reduction in the toughness of the material.

3. Reduced ductility: Fracture voids can also lead to a reduction in the ductility of the material, as they can act as sites for localized deformation and eventual fracture.

Conclusion

Fracture voids are a common feature in materials that have undergone fracture or failure. They can form through various mechanisms, including the presence of inclusions, second phase particles, and grain boundary triple points. The presence of these voids can have a significant impact on the mechanical properties of the material, including its strength, toughness, and ductility.

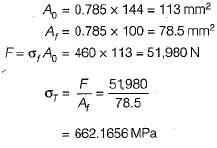

A cylindrical specimen of steel having an original diameter of 12 mm is tensile tested to fracture and found to have an engineering fracture strength  of 460 MPa. if its c/s diameter at fracture is 10 mm, what is the true stress at fracture?

of 460 MPa. if its c/s diameter at fracture is 10 mm, what is the true stress at fracture?- a)580 MPa

- b)662 MPa

- c)700 MPa

- d)724 MPa

Correct answer is option 'B'. Can you explain this answer?

A cylindrical specimen of steel having an original diameter of 12 mm is tensile tested to fracture and found to have an engineering fracture strength  of 460 MPa. if its c/s diameter at fracture is 10 mm, what is the true stress at fracture?

of 460 MPa. if its c/s diameter at fracture is 10 mm, what is the true stress at fracture?

of 460 MPa. if its c/s diameter at fracture is 10 mm, what is the true stress at fracture?

of 460 MPa. if its c/s diameter at fracture is 10 mm, what is the true stress at fracture?a)

580 MPa

b)

662 MPa

c)

700 MPa

d)

724 MPa

|

Naina Das answered |

Material exhibiting time bound behaviour are known as- a)Viscoelastic

- b)Anelastic

- c)Isotropic

- d)None of these

Correct answer is option 'C'. Can you explain this answer?

Material exhibiting time bound behaviour are known as

a)

Viscoelastic

b)

Anelastic

c)

Isotropic

d)

None of these

|

Aditya Majumdar answered |

Understanding Time Bound Behavior in Materials

When discussing materials that exhibit time-bound behavior, it's essential to differentiate between various types of mechanical responses. The correct answer is actually option 'B' (Anelastic), not 'C' (Isotropic). Here’s a detailed explanation:

What is Anelastic Behavior?

- Anelastic materials exhibit time-dependent strain when subjected to stress.

- This means that their deformation is not only dependent on the applied stress but also on the duration of that stress.

- When the stress is removed, these materials do not return immediately to their original shape; instead, they take time to recover, which characterizes their time-bound behavior.

Viscoelastic vs. Anelastic

- Viscoelastic materials show both viscous and elastic characteristics when deformed.

- They exhibit time-dependent strain but also have a recoverable strain component.

- In contrast, anelasticity involves a permanent deformation component that can be time-dependent.

Isotropic Materials Explained

- Isotropic materials have uniform properties in all directions; their mechanical behavior is not influenced by time.

- They respond uniformly regardless of how load is applied, making them distinct from time-bound materials.

Conclusion

In summary, the term "time-bound behavior" is more accurately associated with anelastic materials, as they exhibit a significant time-dependent response. Understanding these distinctions is crucial for applications in mechanical engineering, where material behavior under stress is critical for design and analysis.

When discussing materials that exhibit time-bound behavior, it's essential to differentiate between various types of mechanical responses. The correct answer is actually option 'B' (Anelastic), not 'C' (Isotropic). Here’s a detailed explanation:

What is Anelastic Behavior?

- Anelastic materials exhibit time-dependent strain when subjected to stress.

- This means that their deformation is not only dependent on the applied stress but also on the duration of that stress.

- When the stress is removed, these materials do not return immediately to their original shape; instead, they take time to recover, which characterizes their time-bound behavior.

Viscoelastic vs. Anelastic

- Viscoelastic materials show both viscous and elastic characteristics when deformed.

- They exhibit time-dependent strain but also have a recoverable strain component.

- In contrast, anelasticity involves a permanent deformation component that can be time-dependent.

Isotropic Materials Explained

- Isotropic materials have uniform properties in all directions; their mechanical behavior is not influenced by time.

- They respond uniformly regardless of how load is applied, making them distinct from time-bound materials.

Conclusion

In summary, the term "time-bound behavior" is more accurately associated with anelastic materials, as they exhibit a significant time-dependent response. Understanding these distinctions is crucial for applications in mechanical engineering, where material behavior under stress is critical for design and analysis.

The fatigue strength of mild steel is- a)equal to its yield strength

- b)lower than its yield strength

- c)equal to its tensile strength

- d)lower than its tensile strength

Correct answer is option 'B'. Can you explain this answer?

The fatigue strength of mild steel is

a)

equal to its yield strength

b)

lower than its yield strength

c)

equal to its tensile strength

d)

lower than its tensile strength

|

Preethi Choudhury answered |

Fatigue Strength of Mild Steel

Fatigue strength is defined as the maximum stress that a material can withstand for a given number of cycles without failure. It is an important property for materials that are subjected to cyclic loading, such as in mechanical components and structures.

Mild steel is a low carbon steel that is commonly used in the construction of machinery, structures, and components due to its high ductility, toughness, and affordability. However, like all materials, mild steel is also subject to fatigue failure when subjected to cyclic loading.

Factors affecting fatigue strength include the material's chemical composition, microstructure, surface finish, and loading conditions. The fatigue strength of mild steel is lower than its yield strength and tensile strength due to the following reasons:

- Fatigue failure occurs at stresses much lower than the yield strength of the material. This is because fatigue failure is a cumulative damage process that occurs over a large number of cycles, whereas yield strength is a measure of the material's resistance to plastic deformation under static loading.

- Mild steel has a microstructure that consists of ferrite and pearlite phases. The presence of pearlite, which is a harder and more brittle phase, reduces the material's resistance to fatigue failure.

- Surface finish also plays a significant role in the fatigue strength of mild steel. Components with rough surfaces or surface defects are more prone to fatigue failure due to stress concentration effects.

Conclusion

In conclusion, the fatigue strength of mild steel is lower than its yield strength and tensile strength due to the cumulative damage process that occurs over a large number of cycles, the presence of pearlite in its microstructure, and the effects of surface finish and defects. It is important to consider these factors when designing mechanical components and structures that are subjected to cyclic loading to prevent fatigue failure.

Fatigue strength is defined as the maximum stress that a material can withstand for a given number of cycles without failure. It is an important property for materials that are subjected to cyclic loading, such as in mechanical components and structures.

Mild steel is a low carbon steel that is commonly used in the construction of machinery, structures, and components due to its high ductility, toughness, and affordability. However, like all materials, mild steel is also subject to fatigue failure when subjected to cyclic loading.

Factors affecting fatigue strength include the material's chemical composition, microstructure, surface finish, and loading conditions. The fatigue strength of mild steel is lower than its yield strength and tensile strength due to the following reasons:

- Fatigue failure occurs at stresses much lower than the yield strength of the material. This is because fatigue failure is a cumulative damage process that occurs over a large number of cycles, whereas yield strength is a measure of the material's resistance to plastic deformation under static loading.

- Mild steel has a microstructure that consists of ferrite and pearlite phases. The presence of pearlite, which is a harder and more brittle phase, reduces the material's resistance to fatigue failure.

- Surface finish also plays a significant role in the fatigue strength of mild steel. Components with rough surfaces or surface defects are more prone to fatigue failure due to stress concentration effects.

Conclusion

In conclusion, the fatigue strength of mild steel is lower than its yield strength and tensile strength due to the cumulative damage process that occurs over a large number of cycles, the presence of pearlite in its microstructure, and the effects of surface finish and defects. It is important to consider these factors when designing mechanical components and structures that are subjected to cyclic loading to prevent fatigue failure.

Durometer is used to measure- a)ductility of a material

- b)hardness of a brittle material

- c)toughness of a brittle material

- d)hardness of rubber

Correct answer is option 'D'. Can you explain this answer?

Durometer is used to measure

a)

ductility of a material

b)

hardness of a brittle material

c)

toughness of a brittle material

d)

hardness of rubber

|

Gauri Sarkar answered |

Durometer is used to measure the hardness of rubber.

Explanation:

Durometer is a measurement device used to determine the hardness of materials, particularly non-metallic materials such as rubber, elastomers, and plastics. It is widely used in industries such as automotive, construction, and manufacturing, where the hardness of rubber materials is crucial for their performance and durability.

How does Durometer measure hardness?

Durometer measures hardness by assessing the material's resistance to indentation. It consists of a calibrated spring-loaded indenter that is pressed against the surface of the material being tested. The depth of indentation is then measured, and the hardness value is determined based on the scale of the particular durometer used.

Durometer scales:

There are different durometer scales used to measure the hardness of various materials. The most commonly used scale for rubber is the Shore durometer scale. It provides a numerical value representing the material's hardness, ranging from 0 to 100. The higher the durometer reading, the harder the material.

Why is hardness important in rubber?

Rubber hardness is a critical property that affects its performance and suitability for specific applications. The hardness of rubber determines its resistance to deformation, abrasion, compression set, and other mechanical forces. Different rubber compounds with varying hardness levels are used for different purposes. For example, softer rubber with lower durometer readings is used for applications requiring flexibility and shock absorption, while harder rubber with higher durometer readings is used for applications needing rigidity and durability.

Significance of durometer measurement:

- Quality Control: Durometer measurements ensure the consistency and quality of rubber products by verifying that they meet the specified hardness requirements.

- Material Selection: Durometer measurements help engineers and designers select the appropriate rubber compounds with the desired hardness for specific applications.

- Comparison: Durometer readings allow for the comparison of different rubber materials and their suitability for different environments or operating conditions.

- Troubleshooting: Durometer measurements can help identify issues such as over- or under-curing of rubber compounds, which can affect their hardness and performance.

In conclusion, durometer is a valuable tool for measuring the hardness of rubber and other non-metallic materials. It helps ensure the quality and performance of rubber products and aids in material selection for various applications.

Explanation:

Durometer is a measurement device used to determine the hardness of materials, particularly non-metallic materials such as rubber, elastomers, and plastics. It is widely used in industries such as automotive, construction, and manufacturing, where the hardness of rubber materials is crucial for their performance and durability.

How does Durometer measure hardness?

Durometer measures hardness by assessing the material's resistance to indentation. It consists of a calibrated spring-loaded indenter that is pressed against the surface of the material being tested. The depth of indentation is then measured, and the hardness value is determined based on the scale of the particular durometer used.

Durometer scales:

There are different durometer scales used to measure the hardness of various materials. The most commonly used scale for rubber is the Shore durometer scale. It provides a numerical value representing the material's hardness, ranging from 0 to 100. The higher the durometer reading, the harder the material.

Why is hardness important in rubber?

Rubber hardness is a critical property that affects its performance and suitability for specific applications. The hardness of rubber determines its resistance to deformation, abrasion, compression set, and other mechanical forces. Different rubber compounds with varying hardness levels are used for different purposes. For example, softer rubber with lower durometer readings is used for applications requiring flexibility and shock absorption, while harder rubber with higher durometer readings is used for applications needing rigidity and durability.

Significance of durometer measurement:

- Quality Control: Durometer measurements ensure the consistency and quality of rubber products by verifying that they meet the specified hardness requirements.

- Material Selection: Durometer measurements help engineers and designers select the appropriate rubber compounds with the desired hardness for specific applications.

- Comparison: Durometer readings allow for the comparison of different rubber materials and their suitability for different environments or operating conditions.

- Troubleshooting: Durometer measurements can help identify issues such as over- or under-curing of rubber compounds, which can affect their hardness and performance.

In conclusion, durometer is a valuable tool for measuring the hardness of rubber and other non-metallic materials. It helps ensure the quality and performance of rubber products and aids in material selection for various applications.

Among the following material properties at room temperature

P. Ductility

Q. Modulus of Elasticity

R. Hardness

S. Thermal conductivity

Q. Microstructure sensitive properties are:- a)P and Q

- b)Q and R

- c)R and S

- d)P and R

Correct answer is option 'B'. Can you explain this answer?

Among the following material properties at room temperature

P. Ductility

Q. Modulus of Elasticity

R. Hardness

S. Thermal conductivity

Q. Microstructure sensitive properties are:

P. Ductility

Q. Modulus of Elasticity

R. Hardness

S. Thermal conductivity

Q. Microstructure sensitive properties are:

a)

P and Q

b)

Q and R

c)

R and S

d)

P and R

|

Nayanika Joshi answered |

Understanding Microstructure Sensitive Properties

Microstructure sensitive properties are those that are significantly influenced by the material's internal structure at the microscopic level. Let's analyze the given properties:

1. Ductility (P)

- Ductility refers to a material's ability to undergo significant plastic deformation before rupture.

- It is influenced by the arrangement of atoms and the presence of grain boundaries.

2. Modulus of Elasticity (Q)

- This is a measure of a material's stiffness and is defined as the ratio of stress to strain.

- The modulus of elasticity is primarily a function of the material's atomic bonding and does not vary significantly with microstructure.

3. Hardness (R)

- Hardness denotes a material's resistance to localized plastic deformation (like indentation).

- It is highly affected by microstructural features such as grain size, phase distribution, and the presence of dislocations.

4. Thermal Conductivity (S)

- This property measures a material's ability to conduct heat.

- While it can be influenced by microstructure, it is more related to the atomic arrangement and bonding types.

Examining the Correct Answer (B: Q and R)

- The correct answer states that the microstructure sensitive properties are Q (Modulus of Elasticity) and R (Hardness). However, this interpretation is misleading.

- The modulus of elasticity (Q) is more of a fundamental material property and less sensitive to changes in microstructure compared to hardness (R).

- Hardness (R) is indeed microstructure sensitive, while modulus of elasticity (Q) remains relatively constant across different microstructural states.

Thus, a more accurate interpretation would suggest that properties like P (Ductility) and R (Hardness) are more closely tied to microstructural changes than Q (Modulus of Elasticity).

In summary, the expected answer should focus on properties that exhibit significant variations with microstructure, such as ductility and hardness.

Microstructure sensitive properties are those that are significantly influenced by the material's internal structure at the microscopic level. Let's analyze the given properties:

1. Ductility (P)

- Ductility refers to a material's ability to undergo significant plastic deformation before rupture.

- It is influenced by the arrangement of atoms and the presence of grain boundaries.

2. Modulus of Elasticity (Q)

- This is a measure of a material's stiffness and is defined as the ratio of stress to strain.

- The modulus of elasticity is primarily a function of the material's atomic bonding and does not vary significantly with microstructure.

3. Hardness (R)

- Hardness denotes a material's resistance to localized plastic deformation (like indentation).

- It is highly affected by microstructural features such as grain size, phase distribution, and the presence of dislocations.

4. Thermal Conductivity (S)

- This property measures a material's ability to conduct heat.

- While it can be influenced by microstructure, it is more related to the atomic arrangement and bonding types.

Examining the Correct Answer (B: Q and R)

- The correct answer states that the microstructure sensitive properties are Q (Modulus of Elasticity) and R (Hardness). However, this interpretation is misleading.

- The modulus of elasticity (Q) is more of a fundamental material property and less sensitive to changes in microstructure compared to hardness (R).

- Hardness (R) is indeed microstructure sensitive, while modulus of elasticity (Q) remains relatively constant across different microstructural states.

Thus, a more accurate interpretation would suggest that properties like P (Ductility) and R (Hardness) are more closely tied to microstructural changes than Q (Modulus of Elasticity).

In summary, the expected answer should focus on properties that exhibit significant variations with microstructure, such as ductility and hardness.

A material to be rolled or beaten into thin sheets have this property- a)Ductility

- b)Malleability

- c)Elasticity

- d)Plasticity

Correct answer is option 'B'. Can you explain this answer?

A material to be rolled or beaten into thin sheets have this property

a)

Ductility

b)

Malleability

c)

Elasticity

d)

Plasticity

|

|

Devansh Nambiar answered |

The ability of metal to be formed by hammering or rolling is called malleability.

It refers to the capability of some materials to undergo very large elongation before failure which can be of the order of few hundered percent to as much as 200 percent. This is in context of- a)Plasticity

- b)Elasticity

- c)Superplasticity

- d)Superelasticity

Correct answer is option 'C'. Can you explain this answer?

It refers to the capability of some materials to undergo very large elongation before failure which can be of the order of few hundered percent to as much as 200 percent. This is in context of

a)

Plasticity

b)

Elasticity

c)

Superplasticity

d)

Superelasticity

|

|

Priyanka Tiwari answered |

Superplasticity refers to the capability of certain materials to undergo significant elongation before failure, typically in the range of a few hundred percent to as much as 200 percent. This unique property allows these materials to be formed into complex shapes and achieve high levels of deformation without breaking or cracking. Superplasticity is commonly observed in some metals and ceramics, and it has important applications in various industries, including automotive, aerospace, and manufacturing.

The following are the key points that explain the concept of superplasticity:

1. Definition of Superplasticity:

- Superplasticity is the ability of a material to exhibit extraordinary plastic deformation without fracture or failure.

- It is characterized by a high strain rate sensitivity, which means that the material's flow stress decreases as the strain rate increases.

2. Materials Exhibiting Superplasticity:

- Superplasticity is commonly observed in certain metals and ceramics, such as aluminum alloys, titanium alloys, nickel-based alloys, and some oxide ceramics.

- These materials possess fine-grained microstructures, which contribute to their superplastic behavior.

3. Mechanisms of Superplasticity:

- Superplastic deformation is primarily governed by two mechanisms: grain boundary sliding and dislocation creep.

- Grain boundary sliding occurs when the grains in a material slide past each other under an applied stress, allowing for significant plastic deformation.

- Dislocation creep involves the movement of dislocations within the crystal lattice, which enables the material to undergo plastic deformation at high temperatures.

4. Factors Affecting Superplasticity:

- The presence of a fine-grained microstructure is crucial for promoting superplastic behavior.

- High temperature is necessary for activating the mechanisms of grain boundary sliding and dislocation creep.

- Strain rate also plays a significant role, as slower strain rates tend to enhance superplasticity.

5. Applications of Superplasticity:

- Superplasticity has numerous practical applications in industries where complex and intricate shapes need to be formed.

- It is utilized in the aerospace industry for manufacturing components such as engine turbine blades and structural panels.

- In the automotive industry, superplastic forming is used to shape lightweight materials like aluminum and magnesium into automotive body parts.

In conclusion, superplasticity is a remarkable property observed in certain materials that allows for extraordinary plastic deformation without fracture or failure. It is characterized by high elongation capabilities and is beneficial for industries requiring complex shaping and forming processes.

The following are the key points that explain the concept of superplasticity:

1. Definition of Superplasticity:

- Superplasticity is the ability of a material to exhibit extraordinary plastic deformation without fracture or failure.

- It is characterized by a high strain rate sensitivity, which means that the material's flow stress decreases as the strain rate increases.

2. Materials Exhibiting Superplasticity:

- Superplasticity is commonly observed in certain metals and ceramics, such as aluminum alloys, titanium alloys, nickel-based alloys, and some oxide ceramics.

- These materials possess fine-grained microstructures, which contribute to their superplastic behavior.

3. Mechanisms of Superplasticity:

- Superplastic deformation is primarily governed by two mechanisms: grain boundary sliding and dislocation creep.

- Grain boundary sliding occurs when the grains in a material slide past each other under an applied stress, allowing for significant plastic deformation.

- Dislocation creep involves the movement of dislocations within the crystal lattice, which enables the material to undergo plastic deformation at high temperatures.

4. Factors Affecting Superplasticity:

- The presence of a fine-grained microstructure is crucial for promoting superplastic behavior.

- High temperature is necessary for activating the mechanisms of grain boundary sliding and dislocation creep.

- Strain rate also plays a significant role, as slower strain rates tend to enhance superplasticity.

5. Applications of Superplasticity:

- Superplasticity has numerous practical applications in industries where complex and intricate shapes need to be formed.

- It is utilized in the aerospace industry for manufacturing components such as engine turbine blades and structural panels.

- In the automotive industry, superplastic forming is used to shape lightweight materials like aluminum and magnesium into automotive body parts.

In conclusion, superplasticity is a remarkable property observed in certain materials that allows for extraordinary plastic deformation without fracture or failure. It is characterized by high elongation capabilities and is beneficial for industries requiring complex shaping and forming processes.

Superplastic behaviour is observed in- a)Steel and Cast iron

- b)Aluminium, Zinc and Magnesium

- c)Bubble gum, Glass and Thermoplastics

- d)Cement and Bricks

Correct answer is option 'C'. Can you explain this answer?

Superplastic behaviour is observed in

a)

Steel and Cast iron

b)

Aluminium, Zinc and Magnesium

c)

Bubble gum, Glass and Thermoplastics

d)

Cement and Bricks

|

Rounak Mehta answered |

Understanding Superplastic Behavior

Superplasticity refers to the ability of certain materials to undergo extreme deformation without necking or breaking. This phenomenon is particularly notable in some polymers and non-metallic materials.

Materials Exhibiting Superplastic Behavior

- Bubble Gum:

- Exhibits high ductility when stretched, allowing for significant elongation without breaking.

- Glass:

- At elevated temperatures, glass can flow and deform like a superplastic material, especially in forming processes.

- Thermoplastics:

- Certain thermoplastic polymers can be heated to a point where they become soft and pliable, allowing for extensive shaping and forming.

Why Other Options Do Not Qualify

- Steel and Cast Iron:

- While these materials are ductile and can undergo plastic deformation, they do not exhibit superplastic behavior under standard conditions.

- Aluminium, Zinc, and Magnesium:

- These metals can show good formability but lack the extreme elongation characteristics typical of superplastic materials without specific processing conditions.

- Cement and Bricks:

- These materials are brittle and do not exhibit superplastic behavior. They can fracture under stress rather than deform significantly.

Conclusion

In summary, the correct answer is option 'C' because bubble gum, glass, and thermoplastics can undergo significant deformation without breaking, illustrating the essential characteristics of superplastic behavior. They are capable of large strains, making them unique in their mechanical properties.

Superplasticity refers to the ability of certain materials to undergo extreme deformation without necking or breaking. This phenomenon is particularly notable in some polymers and non-metallic materials.

Materials Exhibiting Superplastic Behavior

- Bubble Gum:

- Exhibits high ductility when stretched, allowing for significant elongation without breaking.

- Glass:

- At elevated temperatures, glass can flow and deform like a superplastic material, especially in forming processes.

- Thermoplastics:

- Certain thermoplastic polymers can be heated to a point where they become soft and pliable, allowing for extensive shaping and forming.

Why Other Options Do Not Qualify

- Steel and Cast Iron:

- While these materials are ductile and can undergo plastic deformation, they do not exhibit superplastic behavior under standard conditions.

- Aluminium, Zinc, and Magnesium:

- These metals can show good formability but lack the extreme elongation characteristics typical of superplastic materials without specific processing conditions.

- Cement and Bricks:

- These materials are brittle and do not exhibit superplastic behavior. They can fracture under stress rather than deform significantly.

Conclusion

In summary, the correct answer is option 'C' because bubble gum, glass, and thermoplastics can undergo significant deformation without breaking, illustrating the essential characteristics of superplastic behavior. They are capable of large strains, making them unique in their mechanical properties.

Which one of the following metal would work- harden more quickly than the others- a)Copper

- b)Brass

- c)Lead

- d)Aluminium

Correct answer is option 'B'. Can you explain this answer?

Which one of the following metal would work- harden more quickly than the others

a)

Copper

b)

Brass

c)

Lead

d)

Aluminium

|

Jyoti Choudhury answered |

Answer:

To determine which metal would work-harden more quickly than the others, we need to understand the concept of work hardening and the properties of the given metals.

What is work hardening?

Work hardening, also known as strain hardening, is a process in which a metal becomes stronger and harder as it is deformed or worked. This occurs due to the movement of dislocations within the metal's crystal structure. Dislocations are line defects in the crystal lattice, and their movement requires energy, which increases the strength of the material.

Properties of the given metals:

Let's examine the properties of each metal to determine which one would work-harden more quickly.

1. Copper:

- Copper is a relatively soft metal with good electrical and thermal conductivity.

- It has a face-centered cubic (FCC) crystal structure, which allows for easier movement of dislocations.

- Due to its high ductility, copper is known to exhibit significant work hardening.

2. Brass:

- Brass is an alloy composed primarily of copper and zinc.

- By varying the proportion of copper and zinc, the mechanical properties of brass can be adjusted.

- Brass typically has a FCC crystal structure similar to copper.

- However, the addition of zinc can hinder the movement of dislocations, making brass less prone to work hardening compared to pure copper.

3. Lead:

- Lead is a soft and malleable metal with low tensile strength.

- It has a face-centered cubic (FCC) crystal structure, similar to copper.

- Due to its low strength and limited dislocation movement, lead does not work harden significantly.

4. Aluminium:

- Aluminium is a lightweight metal with good strength-to-weight ratio.

- It has a face-centered cubic (FCC) crystal structure, similar to copper and lead.

- Aluminium is known to exhibit work hardening, but its rate of work hardening is generally slower compared to copper.

Conclusion:

Based on the properties discussed above, brass would work-harden more slowly than copper. This is because the addition of zinc in brass can hinder the movement of dislocations, making it less prone to work hardening compared to pure copper. Therefore, option B (brass) is the correct answer.

To determine which metal would work-harden more quickly than the others, we need to understand the concept of work hardening and the properties of the given metals.

What is work hardening?