Railways Exam > Railways Questions > The efficiency of a centrifugal pump is maxim...

Start Learning for Free

The efficiency of a centrifugal pump is maximum when its blades are:

- a)Bent forward

- b)Bent backward

- c)Bent forward first and then backward

- d)Bent backward first and then forward

Correct answer is option 'B'. Can you explain this answer?

| FREE This question is part of | Download PDF Attempt this Test |

Verified Answer

The efficiency of a centrifugal pump is maximum when its blades are:a)...

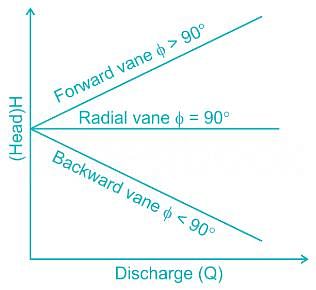

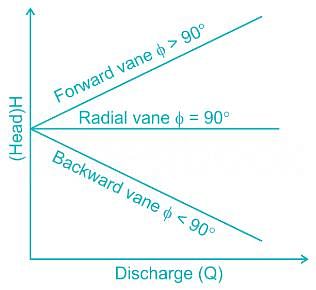

Backward curved vanes are commonly used (though the H-Q curve is declining) because these pumps operate at high efficiency than in case of forward curved vanes.

Most Upvoted Answer

The efficiency of a centrifugal pump is maximum when its blades are:a)...

Efficiency of a Centrifugal Pump

Efficiency is an important parameter when it comes to evaluating the performance of a centrifugal pump. It indicates how effectively the pump converts input power into useful output power. The efficiency of a centrifugal pump is determined by various factors, including the design of its blades.

Understanding Centrifugal Pump Blades

Centrifugal pumps consist of a rotating impeller with curved blades. These blades play a crucial role in the pump's performance. They are responsible for accelerating the fluid and generating the required pressure to move it through the pump and into the discharge pipe.

Effect of Blade Design on Efficiency

The efficiency of a centrifugal pump is influenced by the angle at which the blades are bent. The direction of the blade curvature can significantly impact the pump's performance.

Bent Forward vs. Bent Backward Blades

When the blades of a centrifugal pump are bent forward, the fluid experiences a greater acceleration as it passes through the impeller. This results in higher pressure and flow rate. However, the forward-bent blades also create a higher degree of turbulence and friction losses, which can reduce the overall efficiency of the pump.

On the other hand, when the blades are bent backward, the fluid experiences a smoother flow with reduced turbulence and friction losses. This improves the pump's efficiency. The backward-bent blades also allow for better fluid control and reduce the risk of cavitation, a phenomenon that can damage the pump.

Optimal Blade Design

To maximize the efficiency of a centrifugal pump, the blades are typically designed to be bent backward. This configuration allows for a more efficient fluid flow, minimizing losses and turbulence. Backward-bent blades promote a smoother flow and better energy transfer, resulting in higher overall efficiency.

Conclusion

In conclusion, the efficiency of a centrifugal pump is maximum when its blades are bent backward. This blade design minimizes turbulence, friction losses, and the risk of cavitation, leading to improved fluid flow and energy transfer. By optimizing the blade design, centrifugal pumps can operate at their highest efficiency levels, ensuring optimal performance in various applications.

Efficiency is an important parameter when it comes to evaluating the performance of a centrifugal pump. It indicates how effectively the pump converts input power into useful output power. The efficiency of a centrifugal pump is determined by various factors, including the design of its blades.

Understanding Centrifugal Pump Blades

Centrifugal pumps consist of a rotating impeller with curved blades. These blades play a crucial role in the pump's performance. They are responsible for accelerating the fluid and generating the required pressure to move it through the pump and into the discharge pipe.

Effect of Blade Design on Efficiency

The efficiency of a centrifugal pump is influenced by the angle at which the blades are bent. The direction of the blade curvature can significantly impact the pump's performance.

Bent Forward vs. Bent Backward Blades

When the blades of a centrifugal pump are bent forward, the fluid experiences a greater acceleration as it passes through the impeller. This results in higher pressure and flow rate. However, the forward-bent blades also create a higher degree of turbulence and friction losses, which can reduce the overall efficiency of the pump.

On the other hand, when the blades are bent backward, the fluid experiences a smoother flow with reduced turbulence and friction losses. This improves the pump's efficiency. The backward-bent blades also allow for better fluid control and reduce the risk of cavitation, a phenomenon that can damage the pump.

Optimal Blade Design

To maximize the efficiency of a centrifugal pump, the blades are typically designed to be bent backward. This configuration allows for a more efficient fluid flow, minimizing losses and turbulence. Backward-bent blades promote a smoother flow and better energy transfer, resulting in higher overall efficiency.

Conclusion

In conclusion, the efficiency of a centrifugal pump is maximum when its blades are bent backward. This blade design minimizes turbulence, friction losses, and the risk of cavitation, leading to improved fluid flow and energy transfer. By optimizing the blade design, centrifugal pumps can operate at their highest efficiency levels, ensuring optimal performance in various applications.

Attention Railways Students!

To make sure you are not studying endlessly, EduRev has designed Railways study material, with Structured Courses, Videos, & Test Series. Plus get personalized analysis, doubt solving and improvement plans to achieve a great score in Railways.

|

Explore Courses for Railways exam

|

|

Similar Railways Doubts

The efficiency of a centrifugal pump is maximum when its blades are:a)Bent forwardb)Bent backwardc)Bent forward first and then backwardd)Bent backward first and then forwardCorrect answer is option 'B'. Can you explain this answer?

Question Description

The efficiency of a centrifugal pump is maximum when its blades are:a)Bent forwardb)Bent backwardc)Bent forward first and then backwardd)Bent backward first and then forwardCorrect answer is option 'B'. Can you explain this answer? for Railways 2024 is part of Railways preparation. The Question and answers have been prepared according to the Railways exam syllabus. Information about The efficiency of a centrifugal pump is maximum when its blades are:a)Bent forwardb)Bent backwardc)Bent forward first and then backwardd)Bent backward first and then forwardCorrect answer is option 'B'. Can you explain this answer? covers all topics & solutions for Railways 2024 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for The efficiency of a centrifugal pump is maximum when its blades are:a)Bent forwardb)Bent backwardc)Bent forward first and then backwardd)Bent backward first and then forwardCorrect answer is option 'B'. Can you explain this answer?.

The efficiency of a centrifugal pump is maximum when its blades are:a)Bent forwardb)Bent backwardc)Bent forward first and then backwardd)Bent backward first and then forwardCorrect answer is option 'B'. Can you explain this answer? for Railways 2024 is part of Railways preparation. The Question and answers have been prepared according to the Railways exam syllabus. Information about The efficiency of a centrifugal pump is maximum when its blades are:a)Bent forwardb)Bent backwardc)Bent forward first and then backwardd)Bent backward first and then forwardCorrect answer is option 'B'. Can you explain this answer? covers all topics & solutions for Railways 2024 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for The efficiency of a centrifugal pump is maximum when its blades are:a)Bent forwardb)Bent backwardc)Bent forward first and then backwardd)Bent backward first and then forwardCorrect answer is option 'B'. Can you explain this answer?.

Solutions for The efficiency of a centrifugal pump is maximum when its blades are:a)Bent forwardb)Bent backwardc)Bent forward first and then backwardd)Bent backward first and then forwardCorrect answer is option 'B'. Can you explain this answer? in English & in Hindi are available as part of our courses for Railways.

Download more important topics, notes, lectures and mock test series for Railways Exam by signing up for free.

Here you can find the meaning of The efficiency of a centrifugal pump is maximum when its blades are:a)Bent forwardb)Bent backwardc)Bent forward first and then backwardd)Bent backward first and then forwardCorrect answer is option 'B'. Can you explain this answer? defined & explained in the simplest way possible. Besides giving the explanation of

The efficiency of a centrifugal pump is maximum when its blades are:a)Bent forwardb)Bent backwardc)Bent forward first and then backwardd)Bent backward first and then forwardCorrect answer is option 'B'. Can you explain this answer?, a detailed solution for The efficiency of a centrifugal pump is maximum when its blades are:a)Bent forwardb)Bent backwardc)Bent forward first and then backwardd)Bent backward first and then forwardCorrect answer is option 'B'. Can you explain this answer? has been provided alongside types of The efficiency of a centrifugal pump is maximum when its blades are:a)Bent forwardb)Bent backwardc)Bent forward first and then backwardd)Bent backward first and then forwardCorrect answer is option 'B'. Can you explain this answer? theory, EduRev gives you an

ample number of questions to practice The efficiency of a centrifugal pump is maximum when its blades are:a)Bent forwardb)Bent backwardc)Bent forward first and then backwardd)Bent backward first and then forwardCorrect answer is option 'B'. Can you explain this answer? tests, examples and also practice Railways tests.

|

Explore Courses for Railways exam

|

|

Suggested Free Tests

Signup for Free!

Signup to see your scores go up within 7 days! Learn & Practice with 1000+ FREE Notes, Videos & Tests.