Mechanical Engineering Exam > Mechanical Engineering Questions > The frictional torque transmitted by a disc o...

Start Learning for Free

The frictional torque transmitted by a disc or plate clutch is same as that of ________ bearing.

- a)Conical pivot

- b)Flat pivot

- c)Trapezoidal pivot

- d)Flat collar

Correct answer is option 'D'. Can you explain this answer?

| FREE This question is part of | Download PDF Attempt this Test |

Verified Answer

The frictional torque transmitted by a disc or plate clutch is same as...

Most Upvoted Answer

The frictional torque transmitted by a disc or plate clutch is same as...

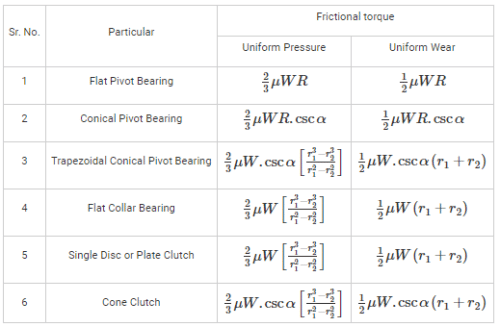

Frictional torque in a disc or plate clutch compared to a flat collar bearing

Introduction:

A clutch is a mechanical device used to transmit torque from one shaft to another shaft, typically in an automotive system. One type of clutch is the disc or plate clutch, which consists of a set of friction plates that are pressed together to transmit torque. On the other hand, a flat collar bearing is a type of bearing that supports a rotating shaft with a flat collar. Both the disc or plate clutch and the flat collar bearing rely on friction to transmit torque. In this context, let's compare the frictional torque transmitted by a disc or plate clutch to that of a flat collar bearing.

Frictional torque in a disc or plate clutch:

- A disc or plate clutch consists of a set of friction plates, typically made of a high-friction material such as organic or metallic material.

- When the clutch is engaged, the friction plates are pressed together, creating frictional contact.

- The frictional torque in a disc or plate clutch is generated by the frictional forces between the contacting surfaces of the plates.

- The frictional torque is proportional to the normal force between the plates and the coefficient of friction between the contacting surfaces.

- The frictional torque can be calculated using the equation: T = μ * R * F, where T is the torque, μ is the coefficient of friction, R is the effective radius of the contact surface, and F is the normal force.

Frictional torque in a flat collar bearing:

- A flat collar bearing consists of a flat collar that supports a rotating shaft.

- The frictional torque in a flat collar bearing is also generated by the frictional forces between the contacting surfaces of the collar and the shaft.

- The frictional torque is proportional to the normal force between the collar and the shaft and the coefficient of friction between the contacting surfaces.

- The frictional torque can be calculated using the equation: T = μ * R * F, where T is the torque, μ is the coefficient of friction, R is the effective radius of the contact surface, and F is the normal force.

Comparison:

- From the above explanations, it is clear that the frictional torque in both a disc or plate clutch and a flat collar bearing can be calculated using the same equation: T = μ * R * F.

- The factors affecting the frictional torque, such as the coefficient of friction, effective radius, and normal force, are similar for both the clutch and the bearing.

- Therefore, the frictional torque transmitted by a disc or plate clutch is the same as that of a flat collar bearing.

Conclusion:

The frictional torque transmitted by a disc or plate clutch is the same as that of a flat collar bearing. Both the clutch and the bearing rely on friction to transmit torque, and the factors affecting the frictional torque are similar for both.

Introduction:

A clutch is a mechanical device used to transmit torque from one shaft to another shaft, typically in an automotive system. One type of clutch is the disc or plate clutch, which consists of a set of friction plates that are pressed together to transmit torque. On the other hand, a flat collar bearing is a type of bearing that supports a rotating shaft with a flat collar. Both the disc or plate clutch and the flat collar bearing rely on friction to transmit torque. In this context, let's compare the frictional torque transmitted by a disc or plate clutch to that of a flat collar bearing.

Frictional torque in a disc or plate clutch:

- A disc or plate clutch consists of a set of friction plates, typically made of a high-friction material such as organic or metallic material.

- When the clutch is engaged, the friction plates are pressed together, creating frictional contact.

- The frictional torque in a disc or plate clutch is generated by the frictional forces between the contacting surfaces of the plates.

- The frictional torque is proportional to the normal force between the plates and the coefficient of friction between the contacting surfaces.

- The frictional torque can be calculated using the equation: T = μ * R * F, where T is the torque, μ is the coefficient of friction, R is the effective radius of the contact surface, and F is the normal force.

Frictional torque in a flat collar bearing:

- A flat collar bearing consists of a flat collar that supports a rotating shaft.

- The frictional torque in a flat collar bearing is also generated by the frictional forces between the contacting surfaces of the collar and the shaft.

- The frictional torque is proportional to the normal force between the collar and the shaft and the coefficient of friction between the contacting surfaces.

- The frictional torque can be calculated using the equation: T = μ * R * F, where T is the torque, μ is the coefficient of friction, R is the effective radius of the contact surface, and F is the normal force.

Comparison:

- From the above explanations, it is clear that the frictional torque in both a disc or plate clutch and a flat collar bearing can be calculated using the same equation: T = μ * R * F.

- The factors affecting the frictional torque, such as the coefficient of friction, effective radius, and normal force, are similar for both the clutch and the bearing.

- Therefore, the frictional torque transmitted by a disc or plate clutch is the same as that of a flat collar bearing.

Conclusion:

The frictional torque transmitted by a disc or plate clutch is the same as that of a flat collar bearing. Both the clutch and the bearing rely on friction to transmit torque, and the factors affecting the frictional torque are similar for both.

Attention Mechanical Engineering Students!

To make sure you are not studying endlessly, EduRev has designed Mechanical Engineering study material, with Structured Courses, Videos, & Test Series. Plus get personalized analysis, doubt solving and improvement plans to achieve a great score in Mechanical Engineering.

|

Explore Courses for Mechanical Engineering exam

|

|

Similar Mechanical Engineering Doubts

The frictional torque transmitted by a disc or plate clutch is same as that of ________ bearing.a)Conical pivotb)Flat pivotc)Trapezoidal pivotd)Flat collarCorrect answer is option 'D'. Can you explain this answer?

Question Description

The frictional torque transmitted by a disc or plate clutch is same as that of ________ bearing.a)Conical pivotb)Flat pivotc)Trapezoidal pivotd)Flat collarCorrect answer is option 'D'. Can you explain this answer? for Mechanical Engineering 2024 is part of Mechanical Engineering preparation. The Question and answers have been prepared according to the Mechanical Engineering exam syllabus. Information about The frictional torque transmitted by a disc or plate clutch is same as that of ________ bearing.a)Conical pivotb)Flat pivotc)Trapezoidal pivotd)Flat collarCorrect answer is option 'D'. Can you explain this answer? covers all topics & solutions for Mechanical Engineering 2024 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for The frictional torque transmitted by a disc or plate clutch is same as that of ________ bearing.a)Conical pivotb)Flat pivotc)Trapezoidal pivotd)Flat collarCorrect answer is option 'D'. Can you explain this answer?.

The frictional torque transmitted by a disc or plate clutch is same as that of ________ bearing.a)Conical pivotb)Flat pivotc)Trapezoidal pivotd)Flat collarCorrect answer is option 'D'. Can you explain this answer? for Mechanical Engineering 2024 is part of Mechanical Engineering preparation. The Question and answers have been prepared according to the Mechanical Engineering exam syllabus. Information about The frictional torque transmitted by a disc or plate clutch is same as that of ________ bearing.a)Conical pivotb)Flat pivotc)Trapezoidal pivotd)Flat collarCorrect answer is option 'D'. Can you explain this answer? covers all topics & solutions for Mechanical Engineering 2024 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for The frictional torque transmitted by a disc or plate clutch is same as that of ________ bearing.a)Conical pivotb)Flat pivotc)Trapezoidal pivotd)Flat collarCorrect answer is option 'D'. Can you explain this answer?.

Solutions for The frictional torque transmitted by a disc or plate clutch is same as that of ________ bearing.a)Conical pivotb)Flat pivotc)Trapezoidal pivotd)Flat collarCorrect answer is option 'D'. Can you explain this answer? in English & in Hindi are available as part of our courses for Mechanical Engineering.

Download more important topics, notes, lectures and mock test series for Mechanical Engineering Exam by signing up for free.

Here you can find the meaning of The frictional torque transmitted by a disc or plate clutch is same as that of ________ bearing.a)Conical pivotb)Flat pivotc)Trapezoidal pivotd)Flat collarCorrect answer is option 'D'. Can you explain this answer? defined & explained in the simplest way possible. Besides giving the explanation of

The frictional torque transmitted by a disc or plate clutch is same as that of ________ bearing.a)Conical pivotb)Flat pivotc)Trapezoidal pivotd)Flat collarCorrect answer is option 'D'. Can you explain this answer?, a detailed solution for The frictional torque transmitted by a disc or plate clutch is same as that of ________ bearing.a)Conical pivotb)Flat pivotc)Trapezoidal pivotd)Flat collarCorrect answer is option 'D'. Can you explain this answer? has been provided alongside types of The frictional torque transmitted by a disc or plate clutch is same as that of ________ bearing.a)Conical pivotb)Flat pivotc)Trapezoidal pivotd)Flat collarCorrect answer is option 'D'. Can you explain this answer? theory, EduRev gives you an

ample number of questions to practice The frictional torque transmitted by a disc or plate clutch is same as that of ________ bearing.a)Conical pivotb)Flat pivotc)Trapezoidal pivotd)Flat collarCorrect answer is option 'D'. Can you explain this answer? tests, examples and also practice Mechanical Engineering tests.

|

Explore Courses for Mechanical Engineering exam

|

|

Suggested Free Tests

Signup for Free!

Signup to see your scores go up within 7 days! Learn & Practice with 1000+ FREE Notes, Videos & Tests.