Civil Engineering (CE) Exam > Civil Engineering (CE) Questions > A test specimen is stressed slightly beyond t...

Start Learning for Free

A test specimen is stressed slightly beyond the yield point and then unloaded. Its yield strength

- a)decreases

- b)increases

- c)remains same

- d)becomes equal to ultimate tensile strength

Correct answer is option 'B'. Can you explain this answer?

Verified Answer

A test specimen is stressed slightly beyond the yield point and then u...

Most Upvoted Answer

A test specimen is stressed slightly beyond the yield point and then u...

Explanation:

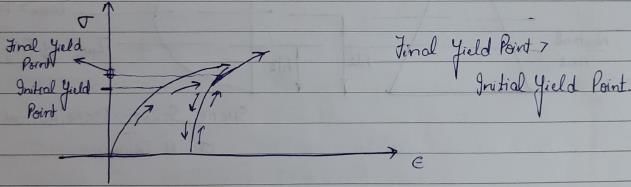

When a test specimen is stressed slightly beyond the yield point and then unloaded, its yield strength increases. This can be explained as follows:

What is Yield Strength?

Yield strength is the stress at which a material begins to deform plastically. In other words, if a material is loaded beyond its yield point, it will not return to its original shape when the load is removed.

What happens when a test specimen is stressed slightly beyond the yield point?

When a test specimen is stressed slightly beyond the yield point, it undergoes plastic deformation. This means that its shape changes permanently. The amount of plastic deformation depends on the amount of stress applied beyond the yield point.

Why does the yield strength increase when a test specimen is stressed slightly beyond the yield point?

When a test specimen is stressed slightly beyond the yield point, dislocations are introduced into its crystal structure. Dislocations are defects in the crystal structure that make it easier for the material to deform plastically. When the load is removed, some of these dislocations remain in the crystal structure, making it easier for the material to deform plastically in the future. This means that the yield strength of the material has increased.

Conclusion:

In conclusion, when a test specimen is stressed slightly beyond the yield point and then unloaded, its yield strength increases due to the introduction of dislocations into its crystal structure.

When a test specimen is stressed slightly beyond the yield point and then unloaded, its yield strength increases. This can be explained as follows:

What is Yield Strength?

Yield strength is the stress at which a material begins to deform plastically. In other words, if a material is loaded beyond its yield point, it will not return to its original shape when the load is removed.

What happens when a test specimen is stressed slightly beyond the yield point?

When a test specimen is stressed slightly beyond the yield point, it undergoes plastic deformation. This means that its shape changes permanently. The amount of plastic deformation depends on the amount of stress applied beyond the yield point.

Why does the yield strength increase when a test specimen is stressed slightly beyond the yield point?

When a test specimen is stressed slightly beyond the yield point, dislocations are introduced into its crystal structure. Dislocations are defects in the crystal structure that make it easier for the material to deform plastically. When the load is removed, some of these dislocations remain in the crystal structure, making it easier for the material to deform plastically in the future. This means that the yield strength of the material has increased.

Conclusion:

In conclusion, when a test specimen is stressed slightly beyond the yield point and then unloaded, its yield strength increases due to the introduction of dislocations into its crystal structure.

|

Explore Courses for Civil Engineering (CE) exam

|

|

Question Description

A test specimen is stressed slightly beyond the yield point and then unloaded. Its yield strengtha)decreasesb)increasesc)remains samed)becomes equal to ultimate tensile strengthCorrect answer is option 'B'. Can you explain this answer? for Civil Engineering (CE) 2025 is part of Civil Engineering (CE) preparation. The Question and answers have been prepared according to the Civil Engineering (CE) exam syllabus. Information about A test specimen is stressed slightly beyond the yield point and then unloaded. Its yield strengtha)decreasesb)increasesc)remains samed)becomes equal to ultimate tensile strengthCorrect answer is option 'B'. Can you explain this answer? covers all topics & solutions for Civil Engineering (CE) 2025 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for A test specimen is stressed slightly beyond the yield point and then unloaded. Its yield strengtha)decreasesb)increasesc)remains samed)becomes equal to ultimate tensile strengthCorrect answer is option 'B'. Can you explain this answer?.

A test specimen is stressed slightly beyond the yield point and then unloaded. Its yield strengtha)decreasesb)increasesc)remains samed)becomes equal to ultimate tensile strengthCorrect answer is option 'B'. Can you explain this answer? for Civil Engineering (CE) 2025 is part of Civil Engineering (CE) preparation. The Question and answers have been prepared according to the Civil Engineering (CE) exam syllabus. Information about A test specimen is stressed slightly beyond the yield point and then unloaded. Its yield strengtha)decreasesb)increasesc)remains samed)becomes equal to ultimate tensile strengthCorrect answer is option 'B'. Can you explain this answer? covers all topics & solutions for Civil Engineering (CE) 2025 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for A test specimen is stressed slightly beyond the yield point and then unloaded. Its yield strengtha)decreasesb)increasesc)remains samed)becomes equal to ultimate tensile strengthCorrect answer is option 'B'. Can you explain this answer?.

Solutions for A test specimen is stressed slightly beyond the yield point and then unloaded. Its yield strengtha)decreasesb)increasesc)remains samed)becomes equal to ultimate tensile strengthCorrect answer is option 'B'. Can you explain this answer? in English & in Hindi are available as part of our courses for Civil Engineering (CE).

Download more important topics, notes, lectures and mock test series for Civil Engineering (CE) Exam by signing up for free.

Here you can find the meaning of A test specimen is stressed slightly beyond the yield point and then unloaded. Its yield strengtha)decreasesb)increasesc)remains samed)becomes equal to ultimate tensile strengthCorrect answer is option 'B'. Can you explain this answer? defined & explained in the simplest way possible. Besides giving the explanation of

A test specimen is stressed slightly beyond the yield point and then unloaded. Its yield strengtha)decreasesb)increasesc)remains samed)becomes equal to ultimate tensile strengthCorrect answer is option 'B'. Can you explain this answer?, a detailed solution for A test specimen is stressed slightly beyond the yield point and then unloaded. Its yield strengtha)decreasesb)increasesc)remains samed)becomes equal to ultimate tensile strengthCorrect answer is option 'B'. Can you explain this answer? has been provided alongside types of A test specimen is stressed slightly beyond the yield point and then unloaded. Its yield strengtha)decreasesb)increasesc)remains samed)becomes equal to ultimate tensile strengthCorrect answer is option 'B'. Can you explain this answer? theory, EduRev gives you an

ample number of questions to practice A test specimen is stressed slightly beyond the yield point and then unloaded. Its yield strengtha)decreasesb)increasesc)remains samed)becomes equal to ultimate tensile strengthCorrect answer is option 'B'. Can you explain this answer? tests, examples and also practice Civil Engineering (CE) tests.

|

Explore Courses for Civil Engineering (CE) exam

|

|

Signup for Free!

Signup to see your scores go up within 7 days! Learn & Practice with 1000+ FREE Notes, Videos & Tests.