Mechanical Engineering Exam > Mechanical Engineering Questions > The angle between the face of the tool and th...

Start Learning for Free

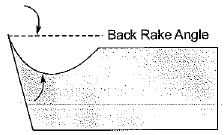

The angle between the face of the tool and the plane parallel to the base of the cutting tool is called

- a)Rake angle

- b)Cutting edge angle

- c)Clearance angle

- d)Lip angle

Correct answer is option 'A'. Can you explain this answer?

Verified Answer

The angle between the face of the tool and the plane parallel to the b...

Most Upvoted Answer

The angle between the face of the tool and the plane parallel to the b...

Option A is correct answer ..... The angle between the face of the tool and the plane parallel to the base of the cutting tool is called Rake Angle.

Free Test

FREE

| Start Free Test |

Community Answer

The angle between the face of the tool and the plane parallel to the b...

The angle between the face of the tool and the plane parallel to the base of the cutting tool is called the rake angle.

The rake angle is an important parameter that affects the cutting performance and efficiency of a cutting tool. It determines the direction and magnitude of the cutting force, as well as the chip formation and chip flow during machining operations. It is usually measured in degrees and can have a significant impact on the tool life, surface finish, and cutting forces.

Importance of Rake Angle:

The rake angle plays a crucial role in determining the cutting action and performance of a tool. It affects various aspects of the machining process, including:

1. Cutting Forces: The rake angle influences the magnitude and direction of cutting forces. A positive rake angle (where the face of the tool is inclined towards the workpiece) reduces the cutting forces, resulting in lower power consumption and improved tool life. On the other hand, a negative rake angle (where the face of the tool is inclined away from the workpiece) increases the cutting forces, which may lead to higher power consumption and reduced tool life.

2. Chip Formation: The rake angle influences the chip formation process. A positive rake angle promotes continuous chip formation, where the chips are long and continuous. This is beneficial for chip disposal and reduces the chances of chip clogging and built-up edge formation. A negative rake angle promotes discontinuous chip formation, where the chips are short and fragmented. This can lead to difficulties in chip evacuation and may result in poor surface finish and increased tool wear.

3. Tool Life: The rake angle affects the tool life by influencing the cutting forces, chip formation, and heat generation. A positive rake angle reduces the cutting forces and heat generation, resulting in improved tool life. It also promotes chip evacuation and reduces the chances of built-up edge formation. Conversely, a negative rake angle increases the cutting forces and heat generation, which can lead to reduced tool life.

In summary, the rake angle is a crucial parameter that affects the cutting action, chip formation, cutting forces, and tool life. It is important to select an appropriate rake angle based on the specific machining requirements, workpiece material, and cutting conditions to achieve optimal cutting performance and tool life.

The rake angle is an important parameter that affects the cutting performance and efficiency of a cutting tool. It determines the direction and magnitude of the cutting force, as well as the chip formation and chip flow during machining operations. It is usually measured in degrees and can have a significant impact on the tool life, surface finish, and cutting forces.

Importance of Rake Angle:

The rake angle plays a crucial role in determining the cutting action and performance of a tool. It affects various aspects of the machining process, including:

1. Cutting Forces: The rake angle influences the magnitude and direction of cutting forces. A positive rake angle (where the face of the tool is inclined towards the workpiece) reduces the cutting forces, resulting in lower power consumption and improved tool life. On the other hand, a negative rake angle (where the face of the tool is inclined away from the workpiece) increases the cutting forces, which may lead to higher power consumption and reduced tool life.

2. Chip Formation: The rake angle influences the chip formation process. A positive rake angle promotes continuous chip formation, where the chips are long and continuous. This is beneficial for chip disposal and reduces the chances of chip clogging and built-up edge formation. A negative rake angle promotes discontinuous chip formation, where the chips are short and fragmented. This can lead to difficulties in chip evacuation and may result in poor surface finish and increased tool wear.

3. Tool Life: The rake angle affects the tool life by influencing the cutting forces, chip formation, and heat generation. A positive rake angle reduces the cutting forces and heat generation, resulting in improved tool life. It also promotes chip evacuation and reduces the chances of built-up edge formation. Conversely, a negative rake angle increases the cutting forces and heat generation, which can lead to reduced tool life.

In summary, the rake angle is a crucial parameter that affects the cutting action, chip formation, cutting forces, and tool life. It is important to select an appropriate rake angle based on the specific machining requirements, workpiece material, and cutting conditions to achieve optimal cutting performance and tool life.

|

Explore Courses for Mechanical Engineering exam

|

|

Question Description

The angle between the face of the tool and the plane parallel to the base of the cutting tool is calleda)Rake angleb)Cutting edge anglec)Clearance angled)Lip angleCorrect answer is option 'A'. Can you explain this answer? for Mechanical Engineering 2025 is part of Mechanical Engineering preparation. The Question and answers have been prepared according to the Mechanical Engineering exam syllabus. Information about The angle between the face of the tool and the plane parallel to the base of the cutting tool is calleda)Rake angleb)Cutting edge anglec)Clearance angled)Lip angleCorrect answer is option 'A'. Can you explain this answer? covers all topics & solutions for Mechanical Engineering 2025 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for The angle between the face of the tool and the plane parallel to the base of the cutting tool is calleda)Rake angleb)Cutting edge anglec)Clearance angled)Lip angleCorrect answer is option 'A'. Can you explain this answer?.

The angle between the face of the tool and the plane parallel to the base of the cutting tool is calleda)Rake angleb)Cutting edge anglec)Clearance angled)Lip angleCorrect answer is option 'A'. Can you explain this answer? for Mechanical Engineering 2025 is part of Mechanical Engineering preparation. The Question and answers have been prepared according to the Mechanical Engineering exam syllabus. Information about The angle between the face of the tool and the plane parallel to the base of the cutting tool is calleda)Rake angleb)Cutting edge anglec)Clearance angled)Lip angleCorrect answer is option 'A'. Can you explain this answer? covers all topics & solutions for Mechanical Engineering 2025 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for The angle between the face of the tool and the plane parallel to the base of the cutting tool is calleda)Rake angleb)Cutting edge anglec)Clearance angled)Lip angleCorrect answer is option 'A'. Can you explain this answer?.

Solutions for The angle between the face of the tool and the plane parallel to the base of the cutting tool is calleda)Rake angleb)Cutting edge anglec)Clearance angled)Lip angleCorrect answer is option 'A'. Can you explain this answer? in English & in Hindi are available as part of our courses for Mechanical Engineering.

Download more important topics, notes, lectures and mock test series for Mechanical Engineering Exam by signing up for free.

Here you can find the meaning of The angle between the face of the tool and the plane parallel to the base of the cutting tool is calleda)Rake angleb)Cutting edge anglec)Clearance angled)Lip angleCorrect answer is option 'A'. Can you explain this answer? defined & explained in the simplest way possible. Besides giving the explanation of

The angle between the face of the tool and the plane parallel to the base of the cutting tool is calleda)Rake angleb)Cutting edge anglec)Clearance angled)Lip angleCorrect answer is option 'A'. Can you explain this answer?, a detailed solution for The angle between the face of the tool and the plane parallel to the base of the cutting tool is calleda)Rake angleb)Cutting edge anglec)Clearance angled)Lip angleCorrect answer is option 'A'. Can you explain this answer? has been provided alongside types of The angle between the face of the tool and the plane parallel to the base of the cutting tool is calleda)Rake angleb)Cutting edge anglec)Clearance angled)Lip angleCorrect answer is option 'A'. Can you explain this answer? theory, EduRev gives you an

ample number of questions to practice The angle between the face of the tool and the plane parallel to the base of the cutting tool is calleda)Rake angleb)Cutting edge anglec)Clearance angled)Lip angleCorrect answer is option 'A'. Can you explain this answer? tests, examples and also practice Mechanical Engineering tests.

|

Explore Courses for Mechanical Engineering exam

|

|

Signup for Free!

Signup to see your scores go up within 7 days! Learn & Practice with 1000+ FREE Notes, Videos & Tests.