Mechanical Engineering Exam > Mechanical Engineering Questions > The percentage elongation of a material as - ...

Start Learning for Free

The percentage elongation of a material as - obtained from static tension test depends upon the

- a)diameter of the test specimen

- b)gauge length of the specimen

- c)nature of end-grips of the testing machine

- d)geometry of the test specimen

Correct answer is option 'B'. Can you explain this answer?

| FREE This question is part of | Download PDF Attempt this Test |

Verified Answer

The percentage elongation of a material as - obtained from static tens...

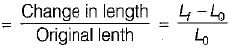

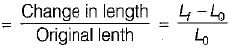

Percentage elongation

where

Lo = original gauge length

Lf = final length between the gauge mark measured after fracture

since local yielding occurs before the fracture of the specimen, the percentage elongation depends upon the gauge length of the specimen.

where

Lo = original gauge length

Lf = final length between the gauge mark measured after fracture

since local yielding occurs before the fracture of the specimen, the percentage elongation depends upon the gauge length of the specimen.

Most Upvoted Answer

The percentage elongation of a material as - obtained from static tens...

The percentage elongation of a material as obtained from a static tension test depends upon the gauge length of the specimen.

The gauge length is the portion of the specimen over which the elongation is measured during the test. It is the distance between two reference points on the specimen, typically marked by two dots or lines. When the material is subjected to tension, it undergoes deformation and elongation. The gauge length is used to measure the elongation of the material.

Explanation:

1. Gauge Length: The gauge length is an important parameter in the static tension test. It determines the portion of the specimen that undergoes deformation and elongation. The elongation is measured by comparing the change in length of the gauge length before and after the test. The longer the gauge length, the more elongation can be measured accurately.

2. Diameter of the Test Specimen: The diameter of the test specimen does not directly affect the percentage elongation. It primarily affects other properties such as the load-bearing capacity and stress distribution. The percentage elongation is mainly influenced by the gauge length.

3. Nature of End-Grips: The nature of end-grips of the testing machine does not significantly affect the percentage elongation. The end-grips are used to hold the specimen securely during the test, but they do not directly impact the measurement of elongation. The gauge length is the key parameter that determines the elongation.

4. Geometry of the Test Specimen: The geometry of the test specimen, such as its shape and dimensions, may indirectly affect the percentage elongation. However, the gauge length is still the primary factor that determines the elongation. The geometry of the specimen primarily affects other properties such as the stress concentration and strain distribution.

In conclusion, the percentage elongation of a material as obtained from a static tension test depends mainly upon the gauge length of the specimen. The gauge length determines the portion of the specimen over which the elongation is measured. Other factors such as the diameter of the test specimen, nature of end-grips, and geometry of the specimen may have indirect effects but are not the primary determinants of elongation.

The gauge length is the portion of the specimen over which the elongation is measured during the test. It is the distance between two reference points on the specimen, typically marked by two dots or lines. When the material is subjected to tension, it undergoes deformation and elongation. The gauge length is used to measure the elongation of the material.

Explanation:

1. Gauge Length: The gauge length is an important parameter in the static tension test. It determines the portion of the specimen that undergoes deformation and elongation. The elongation is measured by comparing the change in length of the gauge length before and after the test. The longer the gauge length, the more elongation can be measured accurately.

2. Diameter of the Test Specimen: The diameter of the test specimen does not directly affect the percentage elongation. It primarily affects other properties such as the load-bearing capacity and stress distribution. The percentage elongation is mainly influenced by the gauge length.

3. Nature of End-Grips: The nature of end-grips of the testing machine does not significantly affect the percentage elongation. The end-grips are used to hold the specimen securely during the test, but they do not directly impact the measurement of elongation. The gauge length is the key parameter that determines the elongation.

4. Geometry of the Test Specimen: The geometry of the test specimen, such as its shape and dimensions, may indirectly affect the percentage elongation. However, the gauge length is still the primary factor that determines the elongation. The geometry of the specimen primarily affects other properties such as the stress concentration and strain distribution.

In conclusion, the percentage elongation of a material as obtained from a static tension test depends mainly upon the gauge length of the specimen. The gauge length determines the portion of the specimen over which the elongation is measured. Other factors such as the diameter of the test specimen, nature of end-grips, and geometry of the specimen may have indirect effects but are not the primary determinants of elongation.

Attention Mechanical Engineering Students!

To make sure you are not studying endlessly, EduRev has designed Mechanical Engineering study material, with Structured Courses, Videos, & Test Series. Plus get personalized analysis, doubt solving and improvement plans to achieve a great score in Mechanical Engineering.

|

Explore Courses for Mechanical Engineering exam

|

|

Similar Mechanical Engineering Doubts

The percentage elongation of a material as - obtained from static tension test depends upon thea)diameter of the test specimenb)gauge length of the specimenc)nature of end-grips of the testing machined)geometry of the test specimenCorrect answer is option 'B'. Can you explain this answer?

Question Description

The percentage elongation of a material as - obtained from static tension test depends upon thea)diameter of the test specimenb)gauge length of the specimenc)nature of end-grips of the testing machined)geometry of the test specimenCorrect answer is option 'B'. Can you explain this answer? for Mechanical Engineering 2024 is part of Mechanical Engineering preparation. The Question and answers have been prepared according to the Mechanical Engineering exam syllabus. Information about The percentage elongation of a material as - obtained from static tension test depends upon thea)diameter of the test specimenb)gauge length of the specimenc)nature of end-grips of the testing machined)geometry of the test specimenCorrect answer is option 'B'. Can you explain this answer? covers all topics & solutions for Mechanical Engineering 2024 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for The percentage elongation of a material as - obtained from static tension test depends upon thea)diameter of the test specimenb)gauge length of the specimenc)nature of end-grips of the testing machined)geometry of the test specimenCorrect answer is option 'B'. Can you explain this answer?.

The percentage elongation of a material as - obtained from static tension test depends upon thea)diameter of the test specimenb)gauge length of the specimenc)nature of end-grips of the testing machined)geometry of the test specimenCorrect answer is option 'B'. Can you explain this answer? for Mechanical Engineering 2024 is part of Mechanical Engineering preparation. The Question and answers have been prepared according to the Mechanical Engineering exam syllabus. Information about The percentage elongation of a material as - obtained from static tension test depends upon thea)diameter of the test specimenb)gauge length of the specimenc)nature of end-grips of the testing machined)geometry of the test specimenCorrect answer is option 'B'. Can you explain this answer? covers all topics & solutions for Mechanical Engineering 2024 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for The percentage elongation of a material as - obtained from static tension test depends upon thea)diameter of the test specimenb)gauge length of the specimenc)nature of end-grips of the testing machined)geometry of the test specimenCorrect answer is option 'B'. Can you explain this answer?.

Solutions for The percentage elongation of a material as - obtained from static tension test depends upon thea)diameter of the test specimenb)gauge length of the specimenc)nature of end-grips of the testing machined)geometry of the test specimenCorrect answer is option 'B'. Can you explain this answer? in English & in Hindi are available as part of our courses for Mechanical Engineering.

Download more important topics, notes, lectures and mock test series for Mechanical Engineering Exam by signing up for free.

Here you can find the meaning of The percentage elongation of a material as - obtained from static tension test depends upon thea)diameter of the test specimenb)gauge length of the specimenc)nature of end-grips of the testing machined)geometry of the test specimenCorrect answer is option 'B'. Can you explain this answer? defined & explained in the simplest way possible. Besides giving the explanation of

The percentage elongation of a material as - obtained from static tension test depends upon thea)diameter of the test specimenb)gauge length of the specimenc)nature of end-grips of the testing machined)geometry of the test specimenCorrect answer is option 'B'. Can you explain this answer?, a detailed solution for The percentage elongation of a material as - obtained from static tension test depends upon thea)diameter of the test specimenb)gauge length of the specimenc)nature of end-grips of the testing machined)geometry of the test specimenCorrect answer is option 'B'. Can you explain this answer? has been provided alongside types of The percentage elongation of a material as - obtained from static tension test depends upon thea)diameter of the test specimenb)gauge length of the specimenc)nature of end-grips of the testing machined)geometry of the test specimenCorrect answer is option 'B'. Can you explain this answer? theory, EduRev gives you an

ample number of questions to practice The percentage elongation of a material as - obtained from static tension test depends upon thea)diameter of the test specimenb)gauge length of the specimenc)nature of end-grips of the testing machined)geometry of the test specimenCorrect answer is option 'B'. Can you explain this answer? tests, examples and also practice Mechanical Engineering tests.

|

Explore Courses for Mechanical Engineering exam

|

|

Suggested Free Tests

Signup for Free!

Signup to see your scores go up within 7 days! Learn & Practice with 1000+ FREE Notes, Videos & Tests.