CAT Exam > CAT Questions > DIRECTIONSfor the question:Analyse the graph/...

Start Learning for Free

DIRECTIONS for the question: Analyse the graph/s given below and answer the question that follows.

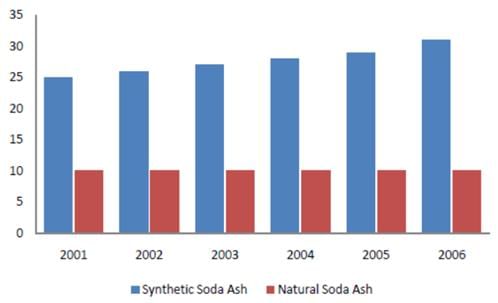

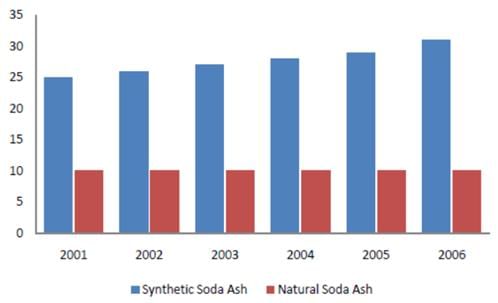

Sodium carbonate, also called as soda ash is an important ingredient for glass, soaps and detergents, and many other products. There were two ways of producing soda ash. The first is producing soda ash from trona obtained naturally. The second method was producing soda ash from common salt through Solvay process. Soda ash produced thus was called synthetic soda ash Tata Chemicals was one of largest producer of soda ash. Given below are two charts- first chart shows production of two varieties of soda ash at Tata Chemicals. The second chart shows production of varieties of soda ash in the world.

Sodium carbonate, also called as soda ash is an important ingredient for glass, soaps and detergents, and many other products. There were two ways of producing soda ash. The first is producing soda ash from trona obtained naturally. The second method was producing soda ash from common salt through Solvay process. Soda ash produced thus was called synthetic soda ash Tata Chemicals was one of largest producer of soda ash. Given below are two charts- first chart shows production of two varieties of soda ash at Tata Chemicals. The second chart shows production of varieties of soda ash in the world.

Q. It was expected that global soda ash production would be same for 2006, 2007 and 2008 (only for this question). What could be a possible reason for different pattern of production in Tata Chemicals and the world?

- a)Tata Chemicals built new plants of 2.2 MT natural soda ash capacity in 2007

- b)Tata Chemicals built 3.2 MT of natural soda ash capacity from 2005 to 2008

- c)Tata Chemicals produced 2.7% of total soda ash in the world

- d)Tata Chemicals might have acquired 0.3 MT of natural soda ash facility in 2007

- e)None of above conclusions could possibly be drawn

Correct answer is option 'B'. Can you explain this answer?

| FREE This question is part of | Download PDF Attempt this Test |

Verified Answer

DIRECTIONSfor the question:Analyse the graph/s given below and answer ...

The possible reasons for different patterns could be that either Tata Chemicals built 3.2 MT of natural soda ash capacity or it has acquired one or more companies in the given period.

|

Explore Courses for CAT exam

|

|

Similar CAT Doubts

DIRECTIONSfor the question:Analyse the graph/s given below and answer the question that follows.Sodium carbonate, also called as soda ash is an important ingredient for glass, soaps and detergents, and many other products. There were two ways of producing soda ash. The first is producing soda ash from trona obtained naturally. The second method was producing soda ash from common salt through Solvay process. Soda ash produced thus was called synthetic soda ash Tata Chemicals was one of largest producer of soda ash. Given below are two charts- first chart shows production of two varieties of soda ash at Tata Chemicals. The second chart shows production of varieties of soda ash in the world.Q.It was expected that global soda ash production would be same for 2006, 2007 and 2008 (only for this question). What could be a possible reason for different pattern of production in Tata Chemicals and the world?a)Tata Chemicals built new plants of 2.2 MT natural soda ash capacity in 2007b)Tata Chemicals built 3.2 MT of natural soda ash capacity from 2005 to 2008c)Tata Chemicals produced 2.7% of total soda ash in the worldd)Tata Chemicals might have acquired 0.3 MT of natural soda ash facility in 2007e)None of above conclusions could possibly be drawnCorrect answer is option 'B'. Can you explain this answer?

Question Description

DIRECTIONSfor the question:Analyse the graph/s given below and answer the question that follows.Sodium carbonate, also called as soda ash is an important ingredient for glass, soaps and detergents, and many other products. There were two ways of producing soda ash. The first is producing soda ash from trona obtained naturally. The second method was producing soda ash from common salt through Solvay process. Soda ash produced thus was called synthetic soda ash Tata Chemicals was one of largest producer of soda ash. Given below are two charts- first chart shows production of two varieties of soda ash at Tata Chemicals. The second chart shows production of varieties of soda ash in the world.Q.It was expected that global soda ash production would be same for 2006, 2007 and 2008 (only for this question). What could be a possible reason for different pattern of production in Tata Chemicals and the world?a)Tata Chemicals built new plants of 2.2 MT natural soda ash capacity in 2007b)Tata Chemicals built 3.2 MT of natural soda ash capacity from 2005 to 2008c)Tata Chemicals produced 2.7% of total soda ash in the worldd)Tata Chemicals might have acquired 0.3 MT of natural soda ash facility in 2007e)None of above conclusions could possibly be drawnCorrect answer is option 'B'. Can you explain this answer? for CAT 2024 is part of CAT preparation. The Question and answers have been prepared according to the CAT exam syllabus. Information about DIRECTIONSfor the question:Analyse the graph/s given below and answer the question that follows.Sodium carbonate, also called as soda ash is an important ingredient for glass, soaps and detergents, and many other products. There were two ways of producing soda ash. The first is producing soda ash from trona obtained naturally. The second method was producing soda ash from common salt through Solvay process. Soda ash produced thus was called synthetic soda ash Tata Chemicals was one of largest producer of soda ash. Given below are two charts- first chart shows production of two varieties of soda ash at Tata Chemicals. The second chart shows production of varieties of soda ash in the world.Q.It was expected that global soda ash production would be same for 2006, 2007 and 2008 (only for this question). What could be a possible reason for different pattern of production in Tata Chemicals and the world?a)Tata Chemicals built new plants of 2.2 MT natural soda ash capacity in 2007b)Tata Chemicals built 3.2 MT of natural soda ash capacity from 2005 to 2008c)Tata Chemicals produced 2.7% of total soda ash in the worldd)Tata Chemicals might have acquired 0.3 MT of natural soda ash facility in 2007e)None of above conclusions could possibly be drawnCorrect answer is option 'B'. Can you explain this answer? covers all topics & solutions for CAT 2024 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for DIRECTIONSfor the question:Analyse the graph/s given below and answer the question that follows.Sodium carbonate, also called as soda ash is an important ingredient for glass, soaps and detergents, and many other products. There were two ways of producing soda ash. The first is producing soda ash from trona obtained naturally. The second method was producing soda ash from common salt through Solvay process. Soda ash produced thus was called synthetic soda ash Tata Chemicals was one of largest producer of soda ash. Given below are two charts- first chart shows production of two varieties of soda ash at Tata Chemicals. The second chart shows production of varieties of soda ash in the world.Q.It was expected that global soda ash production would be same for 2006, 2007 and 2008 (only for this question). What could be a possible reason for different pattern of production in Tata Chemicals and the world?a)Tata Chemicals built new plants of 2.2 MT natural soda ash capacity in 2007b)Tata Chemicals built 3.2 MT of natural soda ash capacity from 2005 to 2008c)Tata Chemicals produced 2.7% of total soda ash in the worldd)Tata Chemicals might have acquired 0.3 MT of natural soda ash facility in 2007e)None of above conclusions could possibly be drawnCorrect answer is option 'B'. Can you explain this answer?.

DIRECTIONSfor the question:Analyse the graph/s given below and answer the question that follows.Sodium carbonate, also called as soda ash is an important ingredient for glass, soaps and detergents, and many other products. There were two ways of producing soda ash. The first is producing soda ash from trona obtained naturally. The second method was producing soda ash from common salt through Solvay process. Soda ash produced thus was called synthetic soda ash Tata Chemicals was one of largest producer of soda ash. Given below are two charts- first chart shows production of two varieties of soda ash at Tata Chemicals. The second chart shows production of varieties of soda ash in the world.Q.It was expected that global soda ash production would be same for 2006, 2007 and 2008 (only for this question). What could be a possible reason for different pattern of production in Tata Chemicals and the world?a)Tata Chemicals built new plants of 2.2 MT natural soda ash capacity in 2007b)Tata Chemicals built 3.2 MT of natural soda ash capacity from 2005 to 2008c)Tata Chemicals produced 2.7% of total soda ash in the worldd)Tata Chemicals might have acquired 0.3 MT of natural soda ash facility in 2007e)None of above conclusions could possibly be drawnCorrect answer is option 'B'. Can you explain this answer? for CAT 2024 is part of CAT preparation. The Question and answers have been prepared according to the CAT exam syllabus. Information about DIRECTIONSfor the question:Analyse the graph/s given below and answer the question that follows.Sodium carbonate, also called as soda ash is an important ingredient for glass, soaps and detergents, and many other products. There were two ways of producing soda ash. The first is producing soda ash from trona obtained naturally. The second method was producing soda ash from common salt through Solvay process. Soda ash produced thus was called synthetic soda ash Tata Chemicals was one of largest producer of soda ash. Given below are two charts- first chart shows production of two varieties of soda ash at Tata Chemicals. The second chart shows production of varieties of soda ash in the world.Q.It was expected that global soda ash production would be same for 2006, 2007 and 2008 (only for this question). What could be a possible reason for different pattern of production in Tata Chemicals and the world?a)Tata Chemicals built new plants of 2.2 MT natural soda ash capacity in 2007b)Tata Chemicals built 3.2 MT of natural soda ash capacity from 2005 to 2008c)Tata Chemicals produced 2.7% of total soda ash in the worldd)Tata Chemicals might have acquired 0.3 MT of natural soda ash facility in 2007e)None of above conclusions could possibly be drawnCorrect answer is option 'B'. Can you explain this answer? covers all topics & solutions for CAT 2024 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for DIRECTIONSfor the question:Analyse the graph/s given below and answer the question that follows.Sodium carbonate, also called as soda ash is an important ingredient for glass, soaps and detergents, and many other products. There were two ways of producing soda ash. The first is producing soda ash from trona obtained naturally. The second method was producing soda ash from common salt through Solvay process. Soda ash produced thus was called synthetic soda ash Tata Chemicals was one of largest producer of soda ash. Given below are two charts- first chart shows production of two varieties of soda ash at Tata Chemicals. The second chart shows production of varieties of soda ash in the world.Q.It was expected that global soda ash production would be same for 2006, 2007 and 2008 (only for this question). What could be a possible reason for different pattern of production in Tata Chemicals and the world?a)Tata Chemicals built new plants of 2.2 MT natural soda ash capacity in 2007b)Tata Chemicals built 3.2 MT of natural soda ash capacity from 2005 to 2008c)Tata Chemicals produced 2.7% of total soda ash in the worldd)Tata Chemicals might have acquired 0.3 MT of natural soda ash facility in 2007e)None of above conclusions could possibly be drawnCorrect answer is option 'B'. Can you explain this answer?.

Solutions for DIRECTIONSfor the question:Analyse the graph/s given below and answer the question that follows.Sodium carbonate, also called as soda ash is an important ingredient for glass, soaps and detergents, and many other products. There were two ways of producing soda ash. The first is producing soda ash from trona obtained naturally. The second method was producing soda ash from common salt through Solvay process. Soda ash produced thus was called synthetic soda ash Tata Chemicals was one of largest producer of soda ash. Given below are two charts- first chart shows production of two varieties of soda ash at Tata Chemicals. The second chart shows production of varieties of soda ash in the world.Q.It was expected that global soda ash production would be same for 2006, 2007 and 2008 (only for this question). What could be a possible reason for different pattern of production in Tata Chemicals and the world?a)Tata Chemicals built new plants of 2.2 MT natural soda ash capacity in 2007b)Tata Chemicals built 3.2 MT of natural soda ash capacity from 2005 to 2008c)Tata Chemicals produced 2.7% of total soda ash in the worldd)Tata Chemicals might have acquired 0.3 MT of natural soda ash facility in 2007e)None of above conclusions could possibly be drawnCorrect answer is option 'B'. Can you explain this answer? in English & in Hindi are available as part of our courses for CAT.

Download more important topics, notes, lectures and mock test series for CAT Exam by signing up for free.

Here you can find the meaning of DIRECTIONSfor the question:Analyse the graph/s given below and answer the question that follows.Sodium carbonate, also called as soda ash is an important ingredient for glass, soaps and detergents, and many other products. There were two ways of producing soda ash. The first is producing soda ash from trona obtained naturally. The second method was producing soda ash from common salt through Solvay process. Soda ash produced thus was called synthetic soda ash Tata Chemicals was one of largest producer of soda ash. Given below are two charts- first chart shows production of two varieties of soda ash at Tata Chemicals. The second chart shows production of varieties of soda ash in the world.Q.It was expected that global soda ash production would be same for 2006, 2007 and 2008 (only for this question). What could be a possible reason for different pattern of production in Tata Chemicals and the world?a)Tata Chemicals built new plants of 2.2 MT natural soda ash capacity in 2007b)Tata Chemicals built 3.2 MT of natural soda ash capacity from 2005 to 2008c)Tata Chemicals produced 2.7% of total soda ash in the worldd)Tata Chemicals might have acquired 0.3 MT of natural soda ash facility in 2007e)None of above conclusions could possibly be drawnCorrect answer is option 'B'. Can you explain this answer? defined & explained in the simplest way possible. Besides giving the explanation of

DIRECTIONSfor the question:Analyse the graph/s given below and answer the question that follows.Sodium carbonate, also called as soda ash is an important ingredient for glass, soaps and detergents, and many other products. There were two ways of producing soda ash. The first is producing soda ash from trona obtained naturally. The second method was producing soda ash from common salt through Solvay process. Soda ash produced thus was called synthetic soda ash Tata Chemicals was one of largest producer of soda ash. Given below are two charts- first chart shows production of two varieties of soda ash at Tata Chemicals. The second chart shows production of varieties of soda ash in the world.Q.It was expected that global soda ash production would be same for 2006, 2007 and 2008 (only for this question). What could be a possible reason for different pattern of production in Tata Chemicals and the world?a)Tata Chemicals built new plants of 2.2 MT natural soda ash capacity in 2007b)Tata Chemicals built 3.2 MT of natural soda ash capacity from 2005 to 2008c)Tata Chemicals produced 2.7% of total soda ash in the worldd)Tata Chemicals might have acquired 0.3 MT of natural soda ash facility in 2007e)None of above conclusions could possibly be drawnCorrect answer is option 'B'. Can you explain this answer?, a detailed solution for DIRECTIONSfor the question:Analyse the graph/s given below and answer the question that follows.Sodium carbonate, also called as soda ash is an important ingredient for glass, soaps and detergents, and many other products. There were two ways of producing soda ash. The first is producing soda ash from trona obtained naturally. The second method was producing soda ash from common salt through Solvay process. Soda ash produced thus was called synthetic soda ash Tata Chemicals was one of largest producer of soda ash. Given below are two charts- first chart shows production of two varieties of soda ash at Tata Chemicals. The second chart shows production of varieties of soda ash in the world.Q.It was expected that global soda ash production would be same for 2006, 2007 and 2008 (only for this question). What could be a possible reason for different pattern of production in Tata Chemicals and the world?a)Tata Chemicals built new plants of 2.2 MT natural soda ash capacity in 2007b)Tata Chemicals built 3.2 MT of natural soda ash capacity from 2005 to 2008c)Tata Chemicals produced 2.7% of total soda ash in the worldd)Tata Chemicals might have acquired 0.3 MT of natural soda ash facility in 2007e)None of above conclusions could possibly be drawnCorrect answer is option 'B'. Can you explain this answer? has been provided alongside types of DIRECTIONSfor the question:Analyse the graph/s given below and answer the question that follows.Sodium carbonate, also called as soda ash is an important ingredient for glass, soaps and detergents, and many other products. There were two ways of producing soda ash. The first is producing soda ash from trona obtained naturally. The second method was producing soda ash from common salt through Solvay process. Soda ash produced thus was called synthetic soda ash Tata Chemicals was one of largest producer of soda ash. Given below are two charts- first chart shows production of two varieties of soda ash at Tata Chemicals. The second chart shows production of varieties of soda ash in the world.Q.It was expected that global soda ash production would be same for 2006, 2007 and 2008 (only for this question). What could be a possible reason for different pattern of production in Tata Chemicals and the world?a)Tata Chemicals built new plants of 2.2 MT natural soda ash capacity in 2007b)Tata Chemicals built 3.2 MT of natural soda ash capacity from 2005 to 2008c)Tata Chemicals produced 2.7% of total soda ash in the worldd)Tata Chemicals might have acquired 0.3 MT of natural soda ash facility in 2007e)None of above conclusions could possibly be drawnCorrect answer is option 'B'. Can you explain this answer? theory, EduRev gives you an

ample number of questions to practice DIRECTIONSfor the question:Analyse the graph/s given below and answer the question that follows.Sodium carbonate, also called as soda ash is an important ingredient for glass, soaps and detergents, and many other products. There were two ways of producing soda ash. The first is producing soda ash from trona obtained naturally. The second method was producing soda ash from common salt through Solvay process. Soda ash produced thus was called synthetic soda ash Tata Chemicals was one of largest producer of soda ash. Given below are two charts- first chart shows production of two varieties of soda ash at Tata Chemicals. The second chart shows production of varieties of soda ash in the world.Q.It was expected that global soda ash production would be same for 2006, 2007 and 2008 (only for this question). What could be a possible reason for different pattern of production in Tata Chemicals and the world?a)Tata Chemicals built new plants of 2.2 MT natural soda ash capacity in 2007b)Tata Chemicals built 3.2 MT of natural soda ash capacity from 2005 to 2008c)Tata Chemicals produced 2.7% of total soda ash in the worldd)Tata Chemicals might have acquired 0.3 MT of natural soda ash facility in 2007e)None of above conclusions could possibly be drawnCorrect answer is option 'B'. Can you explain this answer? tests, examples and also practice CAT tests.

|

Explore Courses for CAT exam

|

|

Suggested Free Tests

Signup for Free!

Signup to see your scores go up within 7 days! Learn & Practice with 1000+ FREE Notes, Videos & Tests.