Mechanical Engineering Exam > Mechanical Engineering Questions > An electronic equipment manufacturer has deci...

Start Learning for Free

An electronic equipment manufacturer has decided to add a component subassembly operation that can produce 80 units during a regular 8-hour shift.This operation consists of three activities as belowFor line balancing the number of work stations required for the activities M, E and T would respectively be

[2004]

- a)2, 3, 1

- b)3, 2, 1

- c)2, 4, 2

- d)2, 1,3

Correct answer is option 'A'. Can you explain this answer?

| FREE This question is part of | Download PDF Attempt this Test |

Verified Answer

An electronic equipment manufacturer has decided to add a component su...

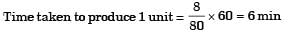

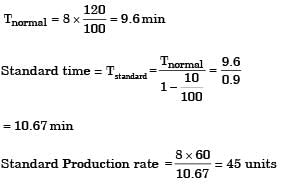

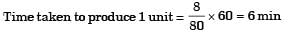

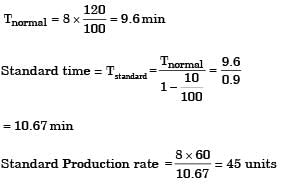

Number of units produce in a day = so units working hour in a day = 8 hours

T = 6 min

T = 6 min

Number of work station are the whole number more the function.

So no of work station required for the activities, M, E & T would be 2, 3, 4, 1 9. Normal time = Actual Time × Rating factor.

T = 6 min

T = 6 minNumber of work station are the whole number more the function.

So no of work station required for the activities, M, E & T would be 2, 3, 4, 1 9. Normal time = Actual Time × Rating factor.

Most Upvoted Answer

An electronic equipment manufacturer has decided to add a component su...

Line Balancing for Component Subassembly Operation

In order to determine the number of workstations required for the activities M, E, and T in the component subassembly operation, we need to consider the production rate and the time required for each activity.

Given:

- Production rate: 80 units per 8-hour shift

- Activities:

1. M (Manual Assembly)

2. E (Electrical Testing)

3. T (Final Testing)

Step 1: Determine the Cycle Time

The cycle time is the maximum time allowed for each workstation to complete its assigned task. It is calculated by dividing the total available working time by the desired production rate.

Total available working time = 8 hours = 8 * 60 minutes = 480 minutes

Desired production rate = 80 units per shift

Cycle time = Total available working time / Desired production rate

Cycle time = 480 minutes / 80 units = 6 minutes per unit

Step 2: Determine the Activity Times

The activity times for each activity can be determined based on the required operations and the time taken for each operation.

Activity M (Manual Assembly):

Let's assume that the manual assembly activity consists of three operations: A, B, and C.

- Operation A: 1 minute

- Operation B: 2 minutes

- Operation C: 3 minutes

Total time for activity M = Sum of operation times = 1 minute + 2 minutes + 3 minutes = 6 minutes

Activity E (Electrical Testing):

Let's assume that the electrical testing activity consists of two operations: D and E.

- Operation D: 2 minutes

- Operation E: 3 minutes

Total time for activity E = Sum of operation times = 2 minutes + 3 minutes = 5 minutes

Activity T (Final Testing):

Let's assume that the final testing activity consists of one operation: F.

- Operation F: 4 minutes

Total time for activity T = 4 minutes

Step 3: Determine the Number of Workstations

The number of workstations required for each activity can be determined by dividing the total time for the activity by the cycle time.

Number of workstations for activity M = Total time for activity M / Cycle time = 6 minutes / 6 minutes per unit = 1 workstation

Number of workstations for activity E = Total time for activity E / Cycle time = 5 minutes / 6 minutes per unit = 0.83 workstations (approx. 1 workstation)

Number of workstations for activity T = Total time for activity T / Cycle time = 4 minutes / 6 minutes per unit = 0.67 workstations (approx. 1 workstation)

Final Answer:

Therefore, the number of workstations required for the activities M, E, and T would be 1, 1, and 1 respectively. Hence, the correct answer is option A: 2, 3, 1.

In order to determine the number of workstations required for the activities M, E, and T in the component subassembly operation, we need to consider the production rate and the time required for each activity.

Given:

- Production rate: 80 units per 8-hour shift

- Activities:

1. M (Manual Assembly)

2. E (Electrical Testing)

3. T (Final Testing)

Step 1: Determine the Cycle Time

The cycle time is the maximum time allowed for each workstation to complete its assigned task. It is calculated by dividing the total available working time by the desired production rate.

Total available working time = 8 hours = 8 * 60 minutes = 480 minutes

Desired production rate = 80 units per shift

Cycle time = Total available working time / Desired production rate

Cycle time = 480 minutes / 80 units = 6 minutes per unit

Step 2: Determine the Activity Times

The activity times for each activity can be determined based on the required operations and the time taken for each operation.

Activity M (Manual Assembly):

Let's assume that the manual assembly activity consists of three operations: A, B, and C.

- Operation A: 1 minute

- Operation B: 2 minutes

- Operation C: 3 minutes

Total time for activity M = Sum of operation times = 1 minute + 2 minutes + 3 minutes = 6 minutes

Activity E (Electrical Testing):

Let's assume that the electrical testing activity consists of two operations: D and E.

- Operation D: 2 minutes

- Operation E: 3 minutes

Total time for activity E = Sum of operation times = 2 minutes + 3 minutes = 5 minutes

Activity T (Final Testing):

Let's assume that the final testing activity consists of one operation: F.

- Operation F: 4 minutes

Total time for activity T = 4 minutes

Step 3: Determine the Number of Workstations

The number of workstations required for each activity can be determined by dividing the total time for the activity by the cycle time.

Number of workstations for activity M = Total time for activity M / Cycle time = 6 minutes / 6 minutes per unit = 1 workstation

Number of workstations for activity E = Total time for activity E / Cycle time = 5 minutes / 6 minutes per unit = 0.83 workstations (approx. 1 workstation)

Number of workstations for activity T = Total time for activity T / Cycle time = 4 minutes / 6 minutes per unit = 0.67 workstations (approx. 1 workstation)

Final Answer:

Therefore, the number of workstations required for the activities M, E, and T would be 1, 1, and 1 respectively. Hence, the correct answer is option A: 2, 3, 1.

Attention Mechanical Engineering Students!

To make sure you are not studying endlessly, EduRev has designed Mechanical Engineering study material, with Structured Courses, Videos, & Test Series. Plus get personalized analysis, doubt solving and improvement plans to achieve a great score in Mechanical Engineering.

|

Explore Courses for Mechanical Engineering exam

|

|

Similar Mechanical Engineering Doubts

An electronic equipment manufacturer has decided to add a component subassembly operation that can produce 80 units during a regular 8-hour shift.This operation consists of three activities as belowFor line balancing the number of work stations required for the activities M, E and T would respectively be[2004]a)2, 3, 1b)3, 2, 1c)2, 4, 2d)2, 1,3Correct answer is option 'A'. Can you explain this answer?

Question Description

An electronic equipment manufacturer has decided to add a component subassembly operation that can produce 80 units during a regular 8-hour shift.This operation consists of three activities as belowFor line balancing the number of work stations required for the activities M, E and T would respectively be[2004]a)2, 3, 1b)3, 2, 1c)2, 4, 2d)2, 1,3Correct answer is option 'A'. Can you explain this answer? for Mechanical Engineering 2024 is part of Mechanical Engineering preparation. The Question and answers have been prepared according to the Mechanical Engineering exam syllabus. Information about An electronic equipment manufacturer has decided to add a component subassembly operation that can produce 80 units during a regular 8-hour shift.This operation consists of three activities as belowFor line balancing the number of work stations required for the activities M, E and T would respectively be[2004]a)2, 3, 1b)3, 2, 1c)2, 4, 2d)2, 1,3Correct answer is option 'A'. Can you explain this answer? covers all topics & solutions for Mechanical Engineering 2024 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for An electronic equipment manufacturer has decided to add a component subassembly operation that can produce 80 units during a regular 8-hour shift.This operation consists of three activities as belowFor line balancing the number of work stations required for the activities M, E and T would respectively be[2004]a)2, 3, 1b)3, 2, 1c)2, 4, 2d)2, 1,3Correct answer is option 'A'. Can you explain this answer?.

An electronic equipment manufacturer has decided to add a component subassembly operation that can produce 80 units during a regular 8-hour shift.This operation consists of three activities as belowFor line balancing the number of work stations required for the activities M, E and T would respectively be[2004]a)2, 3, 1b)3, 2, 1c)2, 4, 2d)2, 1,3Correct answer is option 'A'. Can you explain this answer? for Mechanical Engineering 2024 is part of Mechanical Engineering preparation. The Question and answers have been prepared according to the Mechanical Engineering exam syllabus. Information about An electronic equipment manufacturer has decided to add a component subassembly operation that can produce 80 units during a regular 8-hour shift.This operation consists of three activities as belowFor line balancing the number of work stations required for the activities M, E and T would respectively be[2004]a)2, 3, 1b)3, 2, 1c)2, 4, 2d)2, 1,3Correct answer is option 'A'. Can you explain this answer? covers all topics & solutions for Mechanical Engineering 2024 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for An electronic equipment manufacturer has decided to add a component subassembly operation that can produce 80 units during a regular 8-hour shift.This operation consists of three activities as belowFor line balancing the number of work stations required for the activities M, E and T would respectively be[2004]a)2, 3, 1b)3, 2, 1c)2, 4, 2d)2, 1,3Correct answer is option 'A'. Can you explain this answer?.

Solutions for An electronic equipment manufacturer has decided to add a component subassembly operation that can produce 80 units during a regular 8-hour shift.This operation consists of three activities as belowFor line balancing the number of work stations required for the activities M, E and T would respectively be[2004]a)2, 3, 1b)3, 2, 1c)2, 4, 2d)2, 1,3Correct answer is option 'A'. Can you explain this answer? in English & in Hindi are available as part of our courses for Mechanical Engineering.

Download more important topics, notes, lectures and mock test series for Mechanical Engineering Exam by signing up for free.

Here you can find the meaning of An electronic equipment manufacturer has decided to add a component subassembly operation that can produce 80 units during a regular 8-hour shift.This operation consists of three activities as belowFor line balancing the number of work stations required for the activities M, E and T would respectively be[2004]a)2, 3, 1b)3, 2, 1c)2, 4, 2d)2, 1,3Correct answer is option 'A'. Can you explain this answer? defined & explained in the simplest way possible. Besides giving the explanation of

An electronic equipment manufacturer has decided to add a component subassembly operation that can produce 80 units during a regular 8-hour shift.This operation consists of three activities as belowFor line balancing the number of work stations required for the activities M, E and T would respectively be[2004]a)2, 3, 1b)3, 2, 1c)2, 4, 2d)2, 1,3Correct answer is option 'A'. Can you explain this answer?, a detailed solution for An electronic equipment manufacturer has decided to add a component subassembly operation that can produce 80 units during a regular 8-hour shift.This operation consists of three activities as belowFor line balancing the number of work stations required for the activities M, E and T would respectively be[2004]a)2, 3, 1b)3, 2, 1c)2, 4, 2d)2, 1,3Correct answer is option 'A'. Can you explain this answer? has been provided alongside types of An electronic equipment manufacturer has decided to add a component subassembly operation that can produce 80 units during a regular 8-hour shift.This operation consists of three activities as belowFor line balancing the number of work stations required for the activities M, E and T would respectively be[2004]a)2, 3, 1b)3, 2, 1c)2, 4, 2d)2, 1,3Correct answer is option 'A'. Can you explain this answer? theory, EduRev gives you an

ample number of questions to practice An electronic equipment manufacturer has decided to add a component subassembly operation that can produce 80 units during a regular 8-hour shift.This operation consists of three activities as belowFor line balancing the number of work stations required for the activities M, E and T would respectively be[2004]a)2, 3, 1b)3, 2, 1c)2, 4, 2d)2, 1,3Correct answer is option 'A'. Can you explain this answer? tests, examples and also practice Mechanical Engineering tests.

|

Explore Courses for Mechanical Engineering exam

|

|

Suggested Free Tests

Signup for Free!

Signup to see your scores go up within 7 days! Learn & Practice with 1000+ FREE Notes, Videos & Tests.