CAT Exam > CAT Questions > Direction: A toy-producing factory has a set...

Start Learning for Free

Direction: A toy-producing factory has a setup that requires 3 stages stage 1, stage 2, stage 3 and the manufacturing of toys must take place in the order of stage 1, stage 2, and stage 3. There is one machine each for every stage and the following things are known about the factory

1. Production happens in batches and 1 batch contains 50,000 toys

2. Machine for stage 1 takes 25 minutes to process 1 batch. Time taken for stage 2 and stage 3 is 40 minutes and 30 minutes respectively.

3. Stage 1 machine is stopped for maintenance for 15 minutes after completing every 3 batches.

4. Stage 2 machine is stopped for 10 minutes for maintenance after completing every 4 batches. Stage 3 machine is stopped for 20 minutes for maintenance after completing every 4 batches.

5. Even if the machine is idle between the batches, the maintenance has to happen only after the defined number of batches have been produced.

6. There is no time delay in switching to other batches or maintenance.

7. The factory is operating from 9 am to 5 pm. No machine is supposed to be running after 5 pm.

8. The production is carried out in such a way that all the stages are completed on the same day.

Q. What is the absolute difference (in minutes) in time when batch 6 was completed and when the factory began operating?

Correct answer is '305'. Can you explain this answer?

Most Upvoted Answer

Direction: A toy-producing factory has a setup that requires 3 stages...

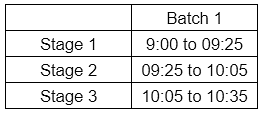

Let us start by manufacturing the first batch.

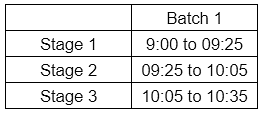

First machine will take 25 minutes and finish at 09:25. the other 2 stages happen after that and the table for batch 1 will look as follows:

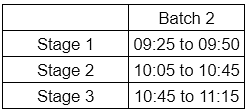

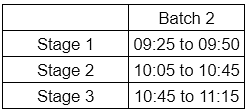

Thus Batch 2 will start at 09:25 and finish at 09:50. Stage 2 can start only after 10:05 and will go till 10:45. Stage 3 will start from 10:45 and go till 11:15

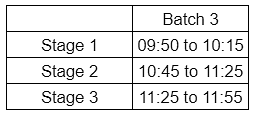

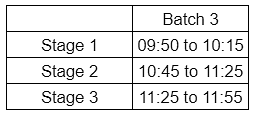

For Batch 3, stage 1 will start at 09:50 to 10:15. Stage 2 can start after 10:45 and go till 11:25. Stage 3 can start at 11:25 and go till 11:55

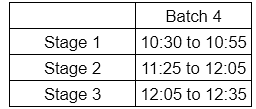

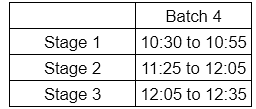

For Batch 4, stage 1 will start at 10:30 to 10:55 as there is 15-minute maintenance. Stage 2 can start after 11:25 and go till 12:05.

Stage 3 can start at 11:25 and go till 11:55

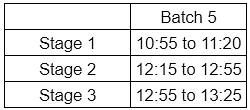

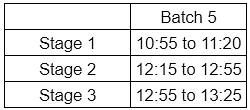

Now for batch 5, stage 1 will start at 10:55 and go till 11:20. Stage 2 machine will undergo maintenance for 10 minutes as it manufactured 4 batches and can only start from 12:15 and will go till 12:55. Stage 3 will also undergo maintenance but it will be done from 12:35 to 12:50

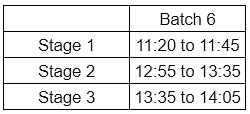

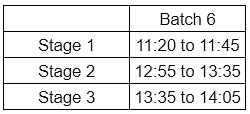

Now for batch 6, stage 1 will start at 11:20 and go till 11:45. Stage 2 machine will available after 12:55 and will go till 13:35. Stage 3 will start from 13:35 and go till 14:05

Now for batch 7, stage 1 will start at 12:00 as it underwent 15 minutes maintenance and go till 12:25. Stage 2 machine will be available after 13:35 and will go till 14:15. Stage 3 will start from 14:15 and go till 14:45

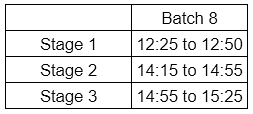

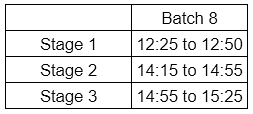

Now for batch 8, stage 1 will start at 12:25 and go till 12:50. Stage 2 machine will available after 14:15 and will go till 14:55. Stage 3 will start from 14:55 and go till 15:25

Since stage 2 and stage 3 machine has manufactured 4 batches each they will undergo maintenance. Stage 2 will be available from 15:05 and stage 3 will be available from 15:40.

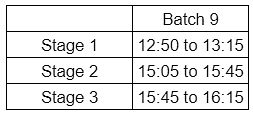

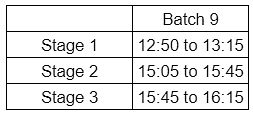

For batch 9, stage 1 will go from 12:50 to 13:15. Stage 2 will start from 15:05 and go till 15:45. Stage 3 will start from 15:45 to 16:15

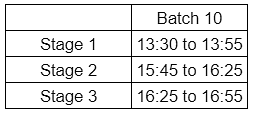

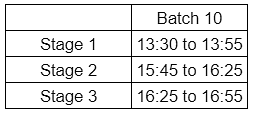

For batch 10, stage 1 will go from 13:30 to 13:55. as it went maintenance for 5 minutes. Stage 2 will start at 15:45 and go till 16:25. Stage 3 will start from 16:25 to 16:55

We see that Batch 10 ends at 16:55. Any more batch will lead to completion after 17:00. Thus a total of 10 batches are made.

Batch 6 starts from 11:20 and ends at 14:05 which is 165 minutes

Community Answer

Direction: A toy-producing factory has a setup that requires 3 stages...

Calculation of time difference between batch 6 completion and factory start

In order to find the absolute difference in time when batch 6 was completed and when the factory began operating, we need to calculate the total time taken to produce 6 batches of toys.

Time taken for each stage

- Stage 1: 25 minutes per batch

- Stage 2: 40 minutes per batch

- Stage 3: 30 minutes per batch

Time taken for maintenance

- Stage 1: 15 minutes after every 3 batches

- Stage 2: 10 minutes after every 4 batches

- Stage 3: 20 minutes after every 4 batches

Calculation for batch 6

- For batch 1 to 3, Stage 1 runs continuously without maintenance

- For batch 4, Stage 1 goes down for maintenance for 15 minutes

- For batch 5, Stage 1 runs continuously

- For batch 6, Stage 1 goes down for maintenance for 15 minutes

Total time taken

- For stage 1: (25 minutes x 3 batches) + 15 minutes + (25 minutes x 2 batches) + 15 minutes = 130 minutes

- For stage 2: 40 minutes x 6 batches = 240 minutes

- For stage 3: 30 minutes x 6 batches = 180 minutes

Adding all stages together

Total time taken = 130 minutes (Stage 1) + 240 minutes (Stage 2) + 180 minutes (Stage 3) = 550 minutes

Calculation of time difference

The factory operates from 9 am to 5 pm, which is 8 hours or 480 minutes. The time difference is therefore 550 minutes (total time taken) - 480 minutes (factory operating time) = 70 minutes.

Therefore, the absolute difference in time when batch 6 was completed and when the factory began operating is 70 minutes.

In order to find the absolute difference in time when batch 6 was completed and when the factory began operating, we need to calculate the total time taken to produce 6 batches of toys.

Time taken for each stage

- Stage 1: 25 minutes per batch

- Stage 2: 40 minutes per batch

- Stage 3: 30 minutes per batch

Time taken for maintenance

- Stage 1: 15 minutes after every 3 batches

- Stage 2: 10 minutes after every 4 batches

- Stage 3: 20 minutes after every 4 batches

Calculation for batch 6

- For batch 1 to 3, Stage 1 runs continuously without maintenance

- For batch 4, Stage 1 goes down for maintenance for 15 minutes

- For batch 5, Stage 1 runs continuously

- For batch 6, Stage 1 goes down for maintenance for 15 minutes

Total time taken

- For stage 1: (25 minutes x 3 batches) + 15 minutes + (25 minutes x 2 batches) + 15 minutes = 130 minutes

- For stage 2: 40 minutes x 6 batches = 240 minutes

- For stage 3: 30 minutes x 6 batches = 180 minutes

Adding all stages together

Total time taken = 130 minutes (Stage 1) + 240 minutes (Stage 2) + 180 minutes (Stage 3) = 550 minutes

Calculation of time difference

The factory operates from 9 am to 5 pm, which is 8 hours or 480 minutes. The time difference is therefore 550 minutes (total time taken) - 480 minutes (factory operating time) = 70 minutes.

Therefore, the absolute difference in time when batch 6 was completed and when the factory began operating is 70 minutes.

Attention CAT Students!

To make sure you are not studying endlessly, EduRev has designed CAT study material, with Structured Courses, Videos, & Test Series. Plus get personalized analysis, doubt solving and improvement plans to achieve a great score in CAT.

|

Explore Courses for CAT exam

|

|

Similar CAT Doubts

Direction: A toy-producing factory has a setup that requires 3 stages stage 1, stage 2, stage 3 and the manufacturing of toys must take place in the order of stage 1, stage 2, and stage 3. There is one machine each for every stage and the following things are known about the factory1. Production happens in batches and 1 batch contains 50,000 toys2. Machine for stage 1 takes 25 minutes to process 1 batch. Time taken for stage 2 and stage 3 is 40 minutes and 30 minutes respectively.3. Stage 1 machine is stopped for maintenance for 15 minutes after completing every 3 batches.4. Stage 2 machine is stopped for 10 minutes for maintenance after completing every 4 batches. Stage 3 machine is stopped for 20 minutes for maintenance after completing every 4 batches.5. Even if the machine is idle between the batches, the maintenance has to happen only after the defined number of batches have been produced.6. There is no time delay in switching to other batches or maintenance.7. The factory is operating from 9 am to 5 pm. No machine is supposed to be running after 5 pm.8. The production is carried out in such a way that all the stages are completed on the same day.Q. What is the absolute difference (in minutes) in time when batch 6 was completed and when the factory began operating?Correct answer is '305'. Can you explain this answer?

Question Description

Direction: A toy-producing factory has a setup that requires 3 stages stage 1, stage 2, stage 3 and the manufacturing of toys must take place in the order of stage 1, stage 2, and stage 3. There is one machine each for every stage and the following things are known about the factory1. Production happens in batches and 1 batch contains 50,000 toys2. Machine for stage 1 takes 25 minutes to process 1 batch. Time taken for stage 2 and stage 3 is 40 minutes and 30 minutes respectively.3. Stage 1 machine is stopped for maintenance for 15 minutes after completing every 3 batches.4. Stage 2 machine is stopped for 10 minutes for maintenance after completing every 4 batches. Stage 3 machine is stopped for 20 minutes for maintenance after completing every 4 batches.5. Even if the machine is idle between the batches, the maintenance has to happen only after the defined number of batches have been produced.6. There is no time delay in switching to other batches or maintenance.7. The factory is operating from 9 am to 5 pm. No machine is supposed to be running after 5 pm.8. The production is carried out in such a way that all the stages are completed on the same day.Q. What is the absolute difference (in minutes) in time when batch 6 was completed and when the factory began operating?Correct answer is '305'. Can you explain this answer? for CAT 2024 is part of CAT preparation. The Question and answers have been prepared according to the CAT exam syllabus. Information about Direction: A toy-producing factory has a setup that requires 3 stages stage 1, stage 2, stage 3 and the manufacturing of toys must take place in the order of stage 1, stage 2, and stage 3. There is one machine each for every stage and the following things are known about the factory1. Production happens in batches and 1 batch contains 50,000 toys2. Machine for stage 1 takes 25 minutes to process 1 batch. Time taken for stage 2 and stage 3 is 40 minutes and 30 minutes respectively.3. Stage 1 machine is stopped for maintenance for 15 minutes after completing every 3 batches.4. Stage 2 machine is stopped for 10 minutes for maintenance after completing every 4 batches. Stage 3 machine is stopped for 20 minutes for maintenance after completing every 4 batches.5. Even if the machine is idle between the batches, the maintenance has to happen only after the defined number of batches have been produced.6. There is no time delay in switching to other batches or maintenance.7. The factory is operating from 9 am to 5 pm. No machine is supposed to be running after 5 pm.8. The production is carried out in such a way that all the stages are completed on the same day.Q. What is the absolute difference (in minutes) in time when batch 6 was completed and when the factory began operating?Correct answer is '305'. Can you explain this answer? covers all topics & solutions for CAT 2024 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for Direction: A toy-producing factory has a setup that requires 3 stages stage 1, stage 2, stage 3 and the manufacturing of toys must take place in the order of stage 1, stage 2, and stage 3. There is one machine each for every stage and the following things are known about the factory1. Production happens in batches and 1 batch contains 50,000 toys2. Machine for stage 1 takes 25 minutes to process 1 batch. Time taken for stage 2 and stage 3 is 40 minutes and 30 minutes respectively.3. Stage 1 machine is stopped for maintenance for 15 minutes after completing every 3 batches.4. Stage 2 machine is stopped for 10 minutes for maintenance after completing every 4 batches. Stage 3 machine is stopped for 20 minutes for maintenance after completing every 4 batches.5. Even if the machine is idle between the batches, the maintenance has to happen only after the defined number of batches have been produced.6. There is no time delay in switching to other batches or maintenance.7. The factory is operating from 9 am to 5 pm. No machine is supposed to be running after 5 pm.8. The production is carried out in such a way that all the stages are completed on the same day.Q. What is the absolute difference (in minutes) in time when batch 6 was completed and when the factory began operating?Correct answer is '305'. Can you explain this answer?.

Direction: A toy-producing factory has a setup that requires 3 stages stage 1, stage 2, stage 3 and the manufacturing of toys must take place in the order of stage 1, stage 2, and stage 3. There is one machine each for every stage and the following things are known about the factory1. Production happens in batches and 1 batch contains 50,000 toys2. Machine for stage 1 takes 25 minutes to process 1 batch. Time taken for stage 2 and stage 3 is 40 minutes and 30 minutes respectively.3. Stage 1 machine is stopped for maintenance for 15 minutes after completing every 3 batches.4. Stage 2 machine is stopped for 10 minutes for maintenance after completing every 4 batches. Stage 3 machine is stopped for 20 minutes for maintenance after completing every 4 batches.5. Even if the machine is idle between the batches, the maintenance has to happen only after the defined number of batches have been produced.6. There is no time delay in switching to other batches or maintenance.7. The factory is operating from 9 am to 5 pm. No machine is supposed to be running after 5 pm.8. The production is carried out in such a way that all the stages are completed on the same day.Q. What is the absolute difference (in minutes) in time when batch 6 was completed and when the factory began operating?Correct answer is '305'. Can you explain this answer? for CAT 2024 is part of CAT preparation. The Question and answers have been prepared according to the CAT exam syllabus. Information about Direction: A toy-producing factory has a setup that requires 3 stages stage 1, stage 2, stage 3 and the manufacturing of toys must take place in the order of stage 1, stage 2, and stage 3. There is one machine each for every stage and the following things are known about the factory1. Production happens in batches and 1 batch contains 50,000 toys2. Machine for stage 1 takes 25 minutes to process 1 batch. Time taken for stage 2 and stage 3 is 40 minutes and 30 minutes respectively.3. Stage 1 machine is stopped for maintenance for 15 minutes after completing every 3 batches.4. Stage 2 machine is stopped for 10 minutes for maintenance after completing every 4 batches. Stage 3 machine is stopped for 20 minutes for maintenance after completing every 4 batches.5. Even if the machine is idle between the batches, the maintenance has to happen only after the defined number of batches have been produced.6. There is no time delay in switching to other batches or maintenance.7. The factory is operating from 9 am to 5 pm. No machine is supposed to be running after 5 pm.8. The production is carried out in such a way that all the stages are completed on the same day.Q. What is the absolute difference (in minutes) in time when batch 6 was completed and when the factory began operating?Correct answer is '305'. Can you explain this answer? covers all topics & solutions for CAT 2024 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for Direction: A toy-producing factory has a setup that requires 3 stages stage 1, stage 2, stage 3 and the manufacturing of toys must take place in the order of stage 1, stage 2, and stage 3. There is one machine each for every stage and the following things are known about the factory1. Production happens in batches and 1 batch contains 50,000 toys2. Machine for stage 1 takes 25 minutes to process 1 batch. Time taken for stage 2 and stage 3 is 40 minutes and 30 minutes respectively.3. Stage 1 machine is stopped for maintenance for 15 minutes after completing every 3 batches.4. Stage 2 machine is stopped for 10 minutes for maintenance after completing every 4 batches. Stage 3 machine is stopped for 20 minutes for maintenance after completing every 4 batches.5. Even if the machine is idle between the batches, the maintenance has to happen only after the defined number of batches have been produced.6. There is no time delay in switching to other batches or maintenance.7. The factory is operating from 9 am to 5 pm. No machine is supposed to be running after 5 pm.8. The production is carried out in such a way that all the stages are completed on the same day.Q. What is the absolute difference (in minutes) in time when batch 6 was completed and when the factory began operating?Correct answer is '305'. Can you explain this answer?.

Solutions for Direction: A toy-producing factory has a setup that requires 3 stages stage 1, stage 2, stage 3 and the manufacturing of toys must take place in the order of stage 1, stage 2, and stage 3. There is one machine each for every stage and the following things are known about the factory1. Production happens in batches and 1 batch contains 50,000 toys2. Machine for stage 1 takes 25 minutes to process 1 batch. Time taken for stage 2 and stage 3 is 40 minutes and 30 minutes respectively.3. Stage 1 machine is stopped for maintenance for 15 minutes after completing every 3 batches.4. Stage 2 machine is stopped for 10 minutes for maintenance after completing every 4 batches. Stage 3 machine is stopped for 20 minutes for maintenance after completing every 4 batches.5. Even if the machine is idle between the batches, the maintenance has to happen only after the defined number of batches have been produced.6. There is no time delay in switching to other batches or maintenance.7. The factory is operating from 9 am to 5 pm. No machine is supposed to be running after 5 pm.8. The production is carried out in such a way that all the stages are completed on the same day.Q. What is the absolute difference (in minutes) in time when batch 6 was completed and when the factory began operating?Correct answer is '305'. Can you explain this answer? in English & in Hindi are available as part of our courses for CAT.

Download more important topics, notes, lectures and mock test series for CAT Exam by signing up for free.

Here you can find the meaning of Direction: A toy-producing factory has a setup that requires 3 stages stage 1, stage 2, stage 3 and the manufacturing of toys must take place in the order of stage 1, stage 2, and stage 3. There is one machine each for every stage and the following things are known about the factory1. Production happens in batches and 1 batch contains 50,000 toys2. Machine for stage 1 takes 25 minutes to process 1 batch. Time taken for stage 2 and stage 3 is 40 minutes and 30 minutes respectively.3. Stage 1 machine is stopped for maintenance for 15 minutes after completing every 3 batches.4. Stage 2 machine is stopped for 10 minutes for maintenance after completing every 4 batches. Stage 3 machine is stopped for 20 minutes for maintenance after completing every 4 batches.5. Even if the machine is idle between the batches, the maintenance has to happen only after the defined number of batches have been produced.6. There is no time delay in switching to other batches or maintenance.7. The factory is operating from 9 am to 5 pm. No machine is supposed to be running after 5 pm.8. The production is carried out in such a way that all the stages are completed on the same day.Q. What is the absolute difference (in minutes) in time when batch 6 was completed and when the factory began operating?Correct answer is '305'. Can you explain this answer? defined & explained in the simplest way possible. Besides giving the explanation of

Direction: A toy-producing factory has a setup that requires 3 stages stage 1, stage 2, stage 3 and the manufacturing of toys must take place in the order of stage 1, stage 2, and stage 3. There is one machine each for every stage and the following things are known about the factory1. Production happens in batches and 1 batch contains 50,000 toys2. Machine for stage 1 takes 25 minutes to process 1 batch. Time taken for stage 2 and stage 3 is 40 minutes and 30 minutes respectively.3. Stage 1 machine is stopped for maintenance for 15 minutes after completing every 3 batches.4. Stage 2 machine is stopped for 10 minutes for maintenance after completing every 4 batches. Stage 3 machine is stopped for 20 minutes for maintenance after completing every 4 batches.5. Even if the machine is idle between the batches, the maintenance has to happen only after the defined number of batches have been produced.6. There is no time delay in switching to other batches or maintenance.7. The factory is operating from 9 am to 5 pm. No machine is supposed to be running after 5 pm.8. The production is carried out in such a way that all the stages are completed on the same day.Q. What is the absolute difference (in minutes) in time when batch 6 was completed and when the factory began operating?Correct answer is '305'. Can you explain this answer?, a detailed solution for Direction: A toy-producing factory has a setup that requires 3 stages stage 1, stage 2, stage 3 and the manufacturing of toys must take place in the order of stage 1, stage 2, and stage 3. There is one machine each for every stage and the following things are known about the factory1. Production happens in batches and 1 batch contains 50,000 toys2. Machine for stage 1 takes 25 minutes to process 1 batch. Time taken for stage 2 and stage 3 is 40 minutes and 30 minutes respectively.3. Stage 1 machine is stopped for maintenance for 15 minutes after completing every 3 batches.4. Stage 2 machine is stopped for 10 minutes for maintenance after completing every 4 batches. Stage 3 machine is stopped for 20 minutes for maintenance after completing every 4 batches.5. Even if the machine is idle between the batches, the maintenance has to happen only after the defined number of batches have been produced.6. There is no time delay in switching to other batches or maintenance.7. The factory is operating from 9 am to 5 pm. No machine is supposed to be running after 5 pm.8. The production is carried out in such a way that all the stages are completed on the same day.Q. What is the absolute difference (in minutes) in time when batch 6 was completed and when the factory began operating?Correct answer is '305'. Can you explain this answer? has been provided alongside types of Direction: A toy-producing factory has a setup that requires 3 stages stage 1, stage 2, stage 3 and the manufacturing of toys must take place in the order of stage 1, stage 2, and stage 3. There is one machine each for every stage and the following things are known about the factory1. Production happens in batches and 1 batch contains 50,000 toys2. Machine for stage 1 takes 25 minutes to process 1 batch. Time taken for stage 2 and stage 3 is 40 minutes and 30 minutes respectively.3. Stage 1 machine is stopped for maintenance for 15 minutes after completing every 3 batches.4. Stage 2 machine is stopped for 10 minutes for maintenance after completing every 4 batches. Stage 3 machine is stopped for 20 minutes for maintenance after completing every 4 batches.5. Even if the machine is idle between the batches, the maintenance has to happen only after the defined number of batches have been produced.6. There is no time delay in switching to other batches or maintenance.7. The factory is operating from 9 am to 5 pm. No machine is supposed to be running after 5 pm.8. The production is carried out in such a way that all the stages are completed on the same day.Q. What is the absolute difference (in minutes) in time when batch 6 was completed and when the factory began operating?Correct answer is '305'. Can you explain this answer? theory, EduRev gives you an

ample number of questions to practice Direction: A toy-producing factory has a setup that requires 3 stages stage 1, stage 2, stage 3 and the manufacturing of toys must take place in the order of stage 1, stage 2, and stage 3. There is one machine each for every stage and the following things are known about the factory1. Production happens in batches and 1 batch contains 50,000 toys2. Machine for stage 1 takes 25 minutes to process 1 batch. Time taken for stage 2 and stage 3 is 40 minutes and 30 minutes respectively.3. Stage 1 machine is stopped for maintenance for 15 minutes after completing every 3 batches.4. Stage 2 machine is stopped for 10 minutes for maintenance after completing every 4 batches. Stage 3 machine is stopped for 20 minutes for maintenance after completing every 4 batches.5. Even if the machine is idle between the batches, the maintenance has to happen only after the defined number of batches have been produced.6. There is no time delay in switching to other batches or maintenance.7. The factory is operating from 9 am to 5 pm. No machine is supposed to be running after 5 pm.8. The production is carried out in such a way that all the stages are completed on the same day.Q. What is the absolute difference (in minutes) in time when batch 6 was completed and when the factory began operating?Correct answer is '305'. Can you explain this answer? tests, examples and also practice CAT tests.

|

Explore Courses for CAT exam

|

|

Suggested Free Tests

Signup for Free!

Signup to see your scores go up within 7 days! Learn & Practice with 1000+ FREE Notes, Videos & Tests.