CAT Exam > CAT Questions > DIRECTIONS for the question:Go through the gr...

Start Learning for Free

DIRECTIONS for the question: Go through the graph and the information given below and answer the question that follows.

In a factory there are six polishing machines - A, B, C, D, E and F. The factory produces item X. Polishing is the last step of manufacturing process. Each of the machines A, B, C, D, E and F takes 3, 2, 3, 1, 2 and 4 hours respectively to polish one unit of X, which is called one polish time. After polishing each unit the machines need a rest of 3, 1, 1, 2, 2 and 2 hours respectively. Every machine starts polishing at 6.00 a.m. and no machine works after 4.00 p.m. Each unit of item X needs to be polished exactly thrice. These three polishing should be done on three different machines. There should be a time gap of at least two hours between two successive polishings of a unit. The total time taken for an item to be polished is the time taken from the starting of the first polish to the end of the third polish. No polish time has any break in between. No machine takes more or less time than the stipulated rest time between two consecutive polishings in a day.

If the total time taken for completion of polishing an item is the minimum possible, then what can be maximum possible value (in hours) of the sum of the time gaps between any two successive polishings? (in numerical value)

Correct answer is '5'. Can you explain this answer?

| FREE This question is part of | Download PDF Attempt this Test |

Verified Answer

DIRECTIONS for the question:Go through the graph and the information g...

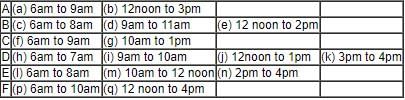

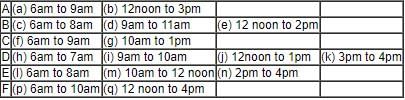

Let us first make a list of the timings in a day when a particular machine works. The letters in each box represents the time period.

For each of the cases referred earlier the sum of the time gaps are as follows.

For each of the cases referred earlier the sum of the time gaps are as follows.

(i) 4 hours

(ii) 5 hours

(iii) 5 hours

(iv) 4 hours

(ii) 5 hours

(iii) 5 hours

(iv) 4 hours

∴ Maximum value of the sum of the time gaps is 5 hours

Most Upvoted Answer

DIRECTIONS for the question:Go through the graph and the information g...

Explanation:

Understanding the Problem:

- There are 6 machines (A, B, C, D, E, F) with different polish times and rest times.

- Each unit of item X needs to be polished thrice on different machines with a 2-hour gap between each polishing.

- The total time taken should be minimized.

Minimum Possible Time Gaps:

- To minimize the total time, we need to minimize the time gaps between successive polishings.

- The maximum time gap possible between two successive polishings is when we use machine D (1 hour polish time) first, followed by machines B (2 hours) and E (2 hours).

- The time gaps in this case would be 3 hours (rest after D), 2 hours (after B), and 2 hours (after E), totaling to 7 hours.

Optimizing Time Gaps:

- To minimize the total time, we can start with machine D, followed by machines B and E, as explained above.

- However, we can optimize the time gaps by using machines C (3 hours) and F (4 hours) for the second and third polishings.

- This arrangement will minimize the total time taken for all three polishings while still maintaining a 2-hour gap between them.

- The sum of time gaps between any two successive polishings would be 3 hours (rest after D), 1 hour (after C), and 1 hour (after F), totaling to 5 hours.

Therefore, the maximum possible value of the sum of time gaps between any two successive polishings is 5 hours when the polishing sequence is D -> B -> E -> C -> F.

Understanding the Problem:

- There are 6 machines (A, B, C, D, E, F) with different polish times and rest times.

- Each unit of item X needs to be polished thrice on different machines with a 2-hour gap between each polishing.

- The total time taken should be minimized.

Minimum Possible Time Gaps:

- To minimize the total time, we need to minimize the time gaps between successive polishings.

- The maximum time gap possible between two successive polishings is when we use machine D (1 hour polish time) first, followed by machines B (2 hours) and E (2 hours).

- The time gaps in this case would be 3 hours (rest after D), 2 hours (after B), and 2 hours (after E), totaling to 7 hours.

Optimizing Time Gaps:

- To minimize the total time, we can start with machine D, followed by machines B and E, as explained above.

- However, we can optimize the time gaps by using machines C (3 hours) and F (4 hours) for the second and third polishings.

- This arrangement will minimize the total time taken for all three polishings while still maintaining a 2-hour gap between them.

- The sum of time gaps between any two successive polishings would be 3 hours (rest after D), 1 hour (after C), and 1 hour (after F), totaling to 5 hours.

Therefore, the maximum possible value of the sum of time gaps between any two successive polishings is 5 hours when the polishing sequence is D -> B -> E -> C -> F.

Attention CAT Students!

To make sure you are not studying endlessly, EduRev has designed CAT study material, with Structured Courses, Videos, & Test Series. Plus get personalized analysis, doubt solving and improvement plans to achieve a great score in CAT.

|

Explore Courses for CAT exam

|

|

Similar CAT Doubts

DIRECTIONS for the question:Go through the graph and the information given below and answer the question that follows.In a factory there are six polishing machines - A, B, C, D, E and F. The factory produces item X. Polishing is the last step of manufacturing process. Each of the machines A, B, C, D, E and F takes 3, 2, 3, 1, 2 and 4 hours respectively to polish one unit of X, which is called one polish time. After polishing each unit the machines need a rest of 3, 1, 1, 2, 2 and 2 hours respectively. Every machine starts polishing at 6.00 a.m. and no machine works after 4.00 p.m. Each unit of item X needs to be polished exactly thrice. These three polishing should be done on three different machines. There should be a time gap of at least two hours between two successive polishings of a unit. The total time taken for an item to be polished is the time taken from the starting of the first polish to the end of the third polish. No polish time has any break in between. No machine takes more or less time than the stipulated rest time between two consecutive polishings in a day.If the total time taken for completion of polishing an item is the minimum possible, then what can be maximum possible value (in hours) of the sum of the time gaps between any two successive polishings? (in numerical value)Correct answer is '5'. Can you explain this answer?

Question Description

DIRECTIONS for the question:Go through the graph and the information given below and answer the question that follows.In a factory there are six polishing machines - A, B, C, D, E and F. The factory produces item X. Polishing is the last step of manufacturing process. Each of the machines A, B, C, D, E and F takes 3, 2, 3, 1, 2 and 4 hours respectively to polish one unit of X, which is called one polish time. After polishing each unit the machines need a rest of 3, 1, 1, 2, 2 and 2 hours respectively. Every machine starts polishing at 6.00 a.m. and no machine works after 4.00 p.m. Each unit of item X needs to be polished exactly thrice. These three polishing should be done on three different machines. There should be a time gap of at least two hours between two successive polishings of a unit. The total time taken for an item to be polished is the time taken from the starting of the first polish to the end of the third polish. No polish time has any break in between. No machine takes more or less time than the stipulated rest time between two consecutive polishings in a day.If the total time taken for completion of polishing an item is the minimum possible, then what can be maximum possible value (in hours) of the sum of the time gaps between any two successive polishings? (in numerical value)Correct answer is '5'. Can you explain this answer? for CAT 2024 is part of CAT preparation. The Question and answers have been prepared according to the CAT exam syllabus. Information about DIRECTIONS for the question:Go through the graph and the information given below and answer the question that follows.In a factory there are six polishing machines - A, B, C, D, E and F. The factory produces item X. Polishing is the last step of manufacturing process. Each of the machines A, B, C, D, E and F takes 3, 2, 3, 1, 2 and 4 hours respectively to polish one unit of X, which is called one polish time. After polishing each unit the machines need a rest of 3, 1, 1, 2, 2 and 2 hours respectively. Every machine starts polishing at 6.00 a.m. and no machine works after 4.00 p.m. Each unit of item X needs to be polished exactly thrice. These three polishing should be done on three different machines. There should be a time gap of at least two hours between two successive polishings of a unit. The total time taken for an item to be polished is the time taken from the starting of the first polish to the end of the third polish. No polish time has any break in between. No machine takes more or less time than the stipulated rest time between two consecutive polishings in a day.If the total time taken for completion of polishing an item is the minimum possible, then what can be maximum possible value (in hours) of the sum of the time gaps between any two successive polishings? (in numerical value)Correct answer is '5'. Can you explain this answer? covers all topics & solutions for CAT 2024 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for DIRECTIONS for the question:Go through the graph and the information given below and answer the question that follows.In a factory there are six polishing machines - A, B, C, D, E and F. The factory produces item X. Polishing is the last step of manufacturing process. Each of the machines A, B, C, D, E and F takes 3, 2, 3, 1, 2 and 4 hours respectively to polish one unit of X, which is called one polish time. After polishing each unit the machines need a rest of 3, 1, 1, 2, 2 and 2 hours respectively. Every machine starts polishing at 6.00 a.m. and no machine works after 4.00 p.m. Each unit of item X needs to be polished exactly thrice. These three polishing should be done on three different machines. There should be a time gap of at least two hours between two successive polishings of a unit. The total time taken for an item to be polished is the time taken from the starting of the first polish to the end of the third polish. No polish time has any break in between. No machine takes more or less time than the stipulated rest time between two consecutive polishings in a day.If the total time taken for completion of polishing an item is the minimum possible, then what can be maximum possible value (in hours) of the sum of the time gaps between any two successive polishings? (in numerical value)Correct answer is '5'. Can you explain this answer?.

DIRECTIONS for the question:Go through the graph and the information given below and answer the question that follows.In a factory there are six polishing machines - A, B, C, D, E and F. The factory produces item X. Polishing is the last step of manufacturing process. Each of the machines A, B, C, D, E and F takes 3, 2, 3, 1, 2 and 4 hours respectively to polish one unit of X, which is called one polish time. After polishing each unit the machines need a rest of 3, 1, 1, 2, 2 and 2 hours respectively. Every machine starts polishing at 6.00 a.m. and no machine works after 4.00 p.m. Each unit of item X needs to be polished exactly thrice. These three polishing should be done on three different machines. There should be a time gap of at least two hours between two successive polishings of a unit. The total time taken for an item to be polished is the time taken from the starting of the first polish to the end of the third polish. No polish time has any break in between. No machine takes more or less time than the stipulated rest time between two consecutive polishings in a day.If the total time taken for completion of polishing an item is the minimum possible, then what can be maximum possible value (in hours) of the sum of the time gaps between any two successive polishings? (in numerical value)Correct answer is '5'. Can you explain this answer? for CAT 2024 is part of CAT preparation. The Question and answers have been prepared according to the CAT exam syllabus. Information about DIRECTIONS for the question:Go through the graph and the information given below and answer the question that follows.In a factory there are six polishing machines - A, B, C, D, E and F. The factory produces item X. Polishing is the last step of manufacturing process. Each of the machines A, B, C, D, E and F takes 3, 2, 3, 1, 2 and 4 hours respectively to polish one unit of X, which is called one polish time. After polishing each unit the machines need a rest of 3, 1, 1, 2, 2 and 2 hours respectively. Every machine starts polishing at 6.00 a.m. and no machine works after 4.00 p.m. Each unit of item X needs to be polished exactly thrice. These three polishing should be done on three different machines. There should be a time gap of at least two hours between two successive polishings of a unit. The total time taken for an item to be polished is the time taken from the starting of the first polish to the end of the third polish. No polish time has any break in between. No machine takes more or less time than the stipulated rest time between two consecutive polishings in a day.If the total time taken for completion of polishing an item is the minimum possible, then what can be maximum possible value (in hours) of the sum of the time gaps between any two successive polishings? (in numerical value)Correct answer is '5'. Can you explain this answer? covers all topics & solutions for CAT 2024 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for DIRECTIONS for the question:Go through the graph and the information given below and answer the question that follows.In a factory there are six polishing machines - A, B, C, D, E and F. The factory produces item X. Polishing is the last step of manufacturing process. Each of the machines A, B, C, D, E and F takes 3, 2, 3, 1, 2 and 4 hours respectively to polish one unit of X, which is called one polish time. After polishing each unit the machines need a rest of 3, 1, 1, 2, 2 and 2 hours respectively. Every machine starts polishing at 6.00 a.m. and no machine works after 4.00 p.m. Each unit of item X needs to be polished exactly thrice. These three polishing should be done on three different machines. There should be a time gap of at least two hours between two successive polishings of a unit. The total time taken for an item to be polished is the time taken from the starting of the first polish to the end of the third polish. No polish time has any break in between. No machine takes more or less time than the stipulated rest time between two consecutive polishings in a day.If the total time taken for completion of polishing an item is the minimum possible, then what can be maximum possible value (in hours) of the sum of the time gaps between any two successive polishings? (in numerical value)Correct answer is '5'. Can you explain this answer?.

Solutions for DIRECTIONS for the question:Go through the graph and the information given below and answer the question that follows.In a factory there are six polishing machines - A, B, C, D, E and F. The factory produces item X. Polishing is the last step of manufacturing process. Each of the machines A, B, C, D, E and F takes 3, 2, 3, 1, 2 and 4 hours respectively to polish one unit of X, which is called one polish time. After polishing each unit the machines need a rest of 3, 1, 1, 2, 2 and 2 hours respectively. Every machine starts polishing at 6.00 a.m. and no machine works after 4.00 p.m. Each unit of item X needs to be polished exactly thrice. These three polishing should be done on three different machines. There should be a time gap of at least two hours between two successive polishings of a unit. The total time taken for an item to be polished is the time taken from the starting of the first polish to the end of the third polish. No polish time has any break in between. No machine takes more or less time than the stipulated rest time between two consecutive polishings in a day.If the total time taken for completion of polishing an item is the minimum possible, then what can be maximum possible value (in hours) of the sum of the time gaps between any two successive polishings? (in numerical value)Correct answer is '5'. Can you explain this answer? in English & in Hindi are available as part of our courses for CAT.

Download more important topics, notes, lectures and mock test series for CAT Exam by signing up for free.

Here you can find the meaning of DIRECTIONS for the question:Go through the graph and the information given below and answer the question that follows.In a factory there are six polishing machines - A, B, C, D, E and F. The factory produces item X. Polishing is the last step of manufacturing process. Each of the machines A, B, C, D, E and F takes 3, 2, 3, 1, 2 and 4 hours respectively to polish one unit of X, which is called one polish time. After polishing each unit the machines need a rest of 3, 1, 1, 2, 2 and 2 hours respectively. Every machine starts polishing at 6.00 a.m. and no machine works after 4.00 p.m. Each unit of item X needs to be polished exactly thrice. These three polishing should be done on three different machines. There should be a time gap of at least two hours between two successive polishings of a unit. The total time taken for an item to be polished is the time taken from the starting of the first polish to the end of the third polish. No polish time has any break in between. No machine takes more or less time than the stipulated rest time between two consecutive polishings in a day.If the total time taken for completion of polishing an item is the minimum possible, then what can be maximum possible value (in hours) of the sum of the time gaps between any two successive polishings? (in numerical value)Correct answer is '5'. Can you explain this answer? defined & explained in the simplest way possible. Besides giving the explanation of

DIRECTIONS for the question:Go through the graph and the information given below and answer the question that follows.In a factory there are six polishing machines - A, B, C, D, E and F. The factory produces item X. Polishing is the last step of manufacturing process. Each of the machines A, B, C, D, E and F takes 3, 2, 3, 1, 2 and 4 hours respectively to polish one unit of X, which is called one polish time. After polishing each unit the machines need a rest of 3, 1, 1, 2, 2 and 2 hours respectively. Every machine starts polishing at 6.00 a.m. and no machine works after 4.00 p.m. Each unit of item X needs to be polished exactly thrice. These three polishing should be done on three different machines. There should be a time gap of at least two hours between two successive polishings of a unit. The total time taken for an item to be polished is the time taken from the starting of the first polish to the end of the third polish. No polish time has any break in between. No machine takes more or less time than the stipulated rest time between two consecutive polishings in a day.If the total time taken for completion of polishing an item is the minimum possible, then what can be maximum possible value (in hours) of the sum of the time gaps between any two successive polishings? (in numerical value)Correct answer is '5'. Can you explain this answer?, a detailed solution for DIRECTIONS for the question:Go through the graph and the information given below and answer the question that follows.In a factory there are six polishing machines - A, B, C, D, E and F. The factory produces item X. Polishing is the last step of manufacturing process. Each of the machines A, B, C, D, E and F takes 3, 2, 3, 1, 2 and 4 hours respectively to polish one unit of X, which is called one polish time. After polishing each unit the machines need a rest of 3, 1, 1, 2, 2 and 2 hours respectively. Every machine starts polishing at 6.00 a.m. and no machine works after 4.00 p.m. Each unit of item X needs to be polished exactly thrice. These three polishing should be done on three different machines. There should be a time gap of at least two hours between two successive polishings of a unit. The total time taken for an item to be polished is the time taken from the starting of the first polish to the end of the third polish. No polish time has any break in between. No machine takes more or less time than the stipulated rest time between two consecutive polishings in a day.If the total time taken for completion of polishing an item is the minimum possible, then what can be maximum possible value (in hours) of the sum of the time gaps between any two successive polishings? (in numerical value)Correct answer is '5'. Can you explain this answer? has been provided alongside types of DIRECTIONS for the question:Go through the graph and the information given below and answer the question that follows.In a factory there are six polishing machines - A, B, C, D, E and F. The factory produces item X. Polishing is the last step of manufacturing process. Each of the machines A, B, C, D, E and F takes 3, 2, 3, 1, 2 and 4 hours respectively to polish one unit of X, which is called one polish time. After polishing each unit the machines need a rest of 3, 1, 1, 2, 2 and 2 hours respectively. Every machine starts polishing at 6.00 a.m. and no machine works after 4.00 p.m. Each unit of item X needs to be polished exactly thrice. These three polishing should be done on three different machines. There should be a time gap of at least two hours between two successive polishings of a unit. The total time taken for an item to be polished is the time taken from the starting of the first polish to the end of the third polish. No polish time has any break in between. No machine takes more or less time than the stipulated rest time between two consecutive polishings in a day.If the total time taken for completion of polishing an item is the minimum possible, then what can be maximum possible value (in hours) of the sum of the time gaps between any two successive polishings? (in numerical value)Correct answer is '5'. Can you explain this answer? theory, EduRev gives you an

ample number of questions to practice DIRECTIONS for the question:Go through the graph and the information given below and answer the question that follows.In a factory there are six polishing machines - A, B, C, D, E and F. The factory produces item X. Polishing is the last step of manufacturing process. Each of the machines A, B, C, D, E and F takes 3, 2, 3, 1, 2 and 4 hours respectively to polish one unit of X, which is called one polish time. After polishing each unit the machines need a rest of 3, 1, 1, 2, 2 and 2 hours respectively. Every machine starts polishing at 6.00 a.m. and no machine works after 4.00 p.m. Each unit of item X needs to be polished exactly thrice. These three polishing should be done on three different machines. There should be a time gap of at least two hours between two successive polishings of a unit. The total time taken for an item to be polished is the time taken from the starting of the first polish to the end of the third polish. No polish time has any break in between. No machine takes more or less time than the stipulated rest time between two consecutive polishings in a day.If the total time taken for completion of polishing an item is the minimum possible, then what can be maximum possible value (in hours) of the sum of the time gaps between any two successive polishings? (in numerical value)Correct answer is '5'. Can you explain this answer? tests, examples and also practice CAT tests.

|

Explore Courses for CAT exam

|

|

Suggested Free Tests

Signup for Free!

Signup to see your scores go up within 7 days! Learn & Practice with 1000+ FREE Notes, Videos & Tests.