Civil Engineering (CE) Exam > Civil Engineering (CE) Questions > Usually, a plate girder is called as economic...

Start Learning for Free

Usually, a plate girder is called as economical if it corresponds to minimum:

- a)weight

- b)depth

- c)width

- d)web thickness

Correct answer is option 'A'. Can you explain this answer?

| FREE This question is part of | Download PDF Attempt this Test |

Most Upvoted Answer

Usually, a plate girder is called as economical if it corresponds to m...

Plate Girder:

A plate girder is a type of beam that is constructed from plates of steel. It consists of top and bottom flanges connected by a web. Plate girders are commonly used in the construction industry for various applications, such as bridges, buildings, and industrial structures.

Economical Plate Girder:

An economical plate girder is one that requires the minimum amount of steel while still meeting the structural requirements. The term "economical" in this context refers to the cost-effectiveness of the design. The goal is to minimize the weight of the plate girder without compromising its structural integrity.

Determining Factors:

Several factors need to be considered when designing an economical plate girder. These factors include weight, depth, width, and web thickness. However, among these factors, the weight of the girder is the most critical in determining its economy.

The Importance of Weight:

The weight of a plate girder directly affects its cost and transportation requirements. A heavier girder requires more steel, which increases the material cost. Additionally, transportation costs are higher for heavier girders, as they require larger cranes and more substantial support structures during installation.

The Role of Depth, Width, and Web Thickness:

While depth, width, and web thickness also influence the weight of the plate girder, they are not as significant as weight itself. These dimensions are primarily determined by the structural requirements and the loads the girder must support. Therefore, the design must ensure that the girder is structurally sound and can safely carry the applied loads.

Conclusion:

In conclusion, a plate girder is considered economical when it corresponds to the minimum weight. While depth, width, and web thickness are important design considerations, the weight of the girder is the most critical factor in determining its cost-effectiveness. By minimizing the weight of the girder, the overall material and transportation costs can be reduced, making it an economical choice for construction projects.

A plate girder is a type of beam that is constructed from plates of steel. It consists of top and bottom flanges connected by a web. Plate girders are commonly used in the construction industry for various applications, such as bridges, buildings, and industrial structures.

Economical Plate Girder:

An economical plate girder is one that requires the minimum amount of steel while still meeting the structural requirements. The term "economical" in this context refers to the cost-effectiveness of the design. The goal is to minimize the weight of the plate girder without compromising its structural integrity.

Determining Factors:

Several factors need to be considered when designing an economical plate girder. These factors include weight, depth, width, and web thickness. However, among these factors, the weight of the girder is the most critical in determining its economy.

The Importance of Weight:

The weight of a plate girder directly affects its cost and transportation requirements. A heavier girder requires more steel, which increases the material cost. Additionally, transportation costs are higher for heavier girders, as they require larger cranes and more substantial support structures during installation.

The Role of Depth, Width, and Web Thickness:

While depth, width, and web thickness also influence the weight of the plate girder, they are not as significant as weight itself. These dimensions are primarily determined by the structural requirements and the loads the girder must support. Therefore, the design must ensure that the girder is structurally sound and can safely carry the applied loads.

Conclusion:

In conclusion, a plate girder is considered economical when it corresponds to the minimum weight. While depth, width, and web thickness are important design considerations, the weight of the girder is the most critical factor in determining its cost-effectiveness. By minimizing the weight of the girder, the overall material and transportation costs can be reduced, making it an economical choice for construction projects.

Free Test

FREE

| Start Free Test |

Community Answer

Usually, a plate girder is called as economical if it corresponds to m...

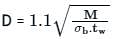

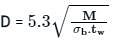

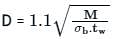

Economical depth of plate girder (D):

Compressive member are always based function of their depth. The depth at which the weight of girder is minimum is its economical depth.

For riveted plate girder,

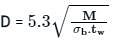

For welded plate girder,

where M=Maximum bending moment,

σb = Permissible bending stress

If the depth of girder is less than 750mm, it is called shallow plate girder.

If the depth is more than 750mm, it is called deep plate girder.

∴ Economical depth of a plate girder corresponds to minimum weight.

Compressive member are always based function of their depth. The depth at which the weight of girder is minimum is its economical depth.

For riveted plate girder,

For welded plate girder,

where M=Maximum bending moment,

σb = Permissible bending stress

If the depth of girder is less than 750mm, it is called shallow plate girder.

If the depth is more than 750mm, it is called deep plate girder.

∴ Economical depth of a plate girder corresponds to minimum weight.

Attention Civil Engineering (CE) Students!

To make sure you are not studying endlessly, EduRev has designed Civil Engineering (CE) study material, with Structured Courses, Videos, & Test Series. Plus get personalized analysis, doubt solving and improvement plans to achieve a great score in Civil Engineering (CE).

|

Explore Courses for Civil Engineering (CE) exam

|

|

Similar Civil Engineering (CE) Doubts

Usually, a plate girder is called as economical if it corresponds to minimum:a)weightb)depthc)widthd)web thicknessCorrect answer is option 'A'. Can you explain this answer?

Question Description

Usually, a plate girder is called as economical if it corresponds to minimum:a)weightb)depthc)widthd)web thicknessCorrect answer is option 'A'. Can you explain this answer? for Civil Engineering (CE) 2024 is part of Civil Engineering (CE) preparation. The Question and answers have been prepared according to the Civil Engineering (CE) exam syllabus. Information about Usually, a plate girder is called as economical if it corresponds to minimum:a)weightb)depthc)widthd)web thicknessCorrect answer is option 'A'. Can you explain this answer? covers all topics & solutions for Civil Engineering (CE) 2024 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for Usually, a plate girder is called as economical if it corresponds to minimum:a)weightb)depthc)widthd)web thicknessCorrect answer is option 'A'. Can you explain this answer?.

Usually, a plate girder is called as economical if it corresponds to minimum:a)weightb)depthc)widthd)web thicknessCorrect answer is option 'A'. Can you explain this answer? for Civil Engineering (CE) 2024 is part of Civil Engineering (CE) preparation. The Question and answers have been prepared according to the Civil Engineering (CE) exam syllabus. Information about Usually, a plate girder is called as economical if it corresponds to minimum:a)weightb)depthc)widthd)web thicknessCorrect answer is option 'A'. Can you explain this answer? covers all topics & solutions for Civil Engineering (CE) 2024 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for Usually, a plate girder is called as economical if it corresponds to minimum:a)weightb)depthc)widthd)web thicknessCorrect answer is option 'A'. Can you explain this answer?.

Solutions for Usually, a plate girder is called as economical if it corresponds to minimum:a)weightb)depthc)widthd)web thicknessCorrect answer is option 'A'. Can you explain this answer? in English & in Hindi are available as part of our courses for Civil Engineering (CE).

Download more important topics, notes, lectures and mock test series for Civil Engineering (CE) Exam by signing up for free.

Here you can find the meaning of Usually, a plate girder is called as economical if it corresponds to minimum:a)weightb)depthc)widthd)web thicknessCorrect answer is option 'A'. Can you explain this answer? defined & explained in the simplest way possible. Besides giving the explanation of

Usually, a plate girder is called as economical if it corresponds to minimum:a)weightb)depthc)widthd)web thicknessCorrect answer is option 'A'. Can you explain this answer?, a detailed solution for Usually, a plate girder is called as economical if it corresponds to minimum:a)weightb)depthc)widthd)web thicknessCorrect answer is option 'A'. Can you explain this answer? has been provided alongside types of Usually, a plate girder is called as economical if it corresponds to minimum:a)weightb)depthc)widthd)web thicknessCorrect answer is option 'A'. Can you explain this answer? theory, EduRev gives you an

ample number of questions to practice Usually, a plate girder is called as economical if it corresponds to minimum:a)weightb)depthc)widthd)web thicknessCorrect answer is option 'A'. Can you explain this answer? tests, examples and also practice Civil Engineering (CE) tests.

|

Explore Courses for Civil Engineering (CE) exam

|

|

Suggested Free Tests

Signup for Free!

Signup to see your scores go up within 7 days! Learn & Practice with 1000+ FREE Notes, Videos & Tests.