Mechanical Engineering Exam > Mechanical Engineering Questions > The net requirements of an item over 5 consec...

Start Learning for Free

The net requirements of an item over 5 consecutive weeks are 50-015-20-20. The inventory carrying costs are Re. 1 per item per week and Rs. 100 per order respectively. Starting inventory is zero. Use “Least Unit Const Technique” for developing the plan. The const of the plan (in Rs.) is:

- a)200

- b)250

- c)255

- d)260

Correct answer is option 'B'. Can you explain this answer?

| FREE This question is part of | Download PDF Attempt this Test |

Verified Answer

The net requirements of an item over 5 consecutive weeks are 50-015-20...

Ans.

Option (b)

Most Upvoted Answer

The net requirements of an item over 5 consecutive weeks are 50-015-20...

The Least Unit Cost Technique

The Least Unit Cost Technique is a method used to determine the optimal order quantity and reorder point for inventory management. It considers both the cost of carrying inventory and the cost of placing an order.

To solve this problem, we will use the following formula:

Total cost = Carrying cost + Ordering cost

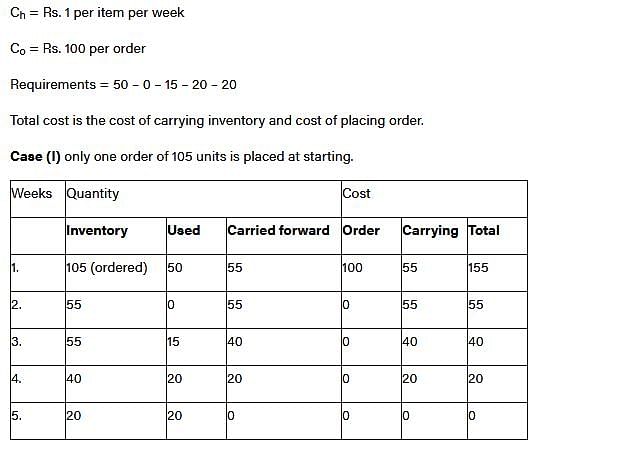

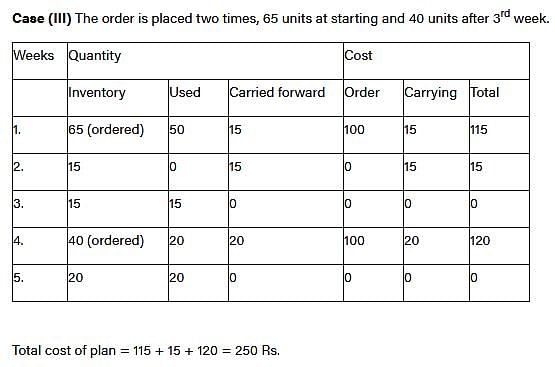

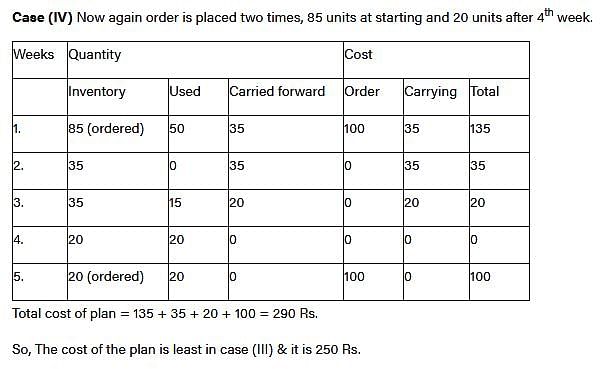

Given Data:

- Net requirements over 5 consecutive weeks: 50, 15, 20, 20

- Carrying cost per item per week: Re. 1

- Ordering cost per order: Rs. 100

- Starting inventory: 0

Calculating the Optimal Order Quantity:

To determine the optimal order quantity, we need to find the week with the highest net requirement. In this case, it is 50.

The optimal order quantity can be calculated using the formula:

Optimal Order Quantity = (Highest Net Requirement) - (Starting Inventory)

In this case, the optimal order quantity will be 50 - 0 = 50.

Calculating the Optimal Reorder Point:

The reorder point is the inventory level at which an order should be placed. It is determined by considering the lead time (time between placing an order and receiving it) and the average weekly demand.

In this case, we have 5 consecutive weeks of net requirements: 50, 15, 20, 20. The average weekly demand can be calculated by summing up these values and dividing by 5:

Average Weekly Demand = (50 + 15 + 20 + 20) / 5 = 21

The reorder point can be calculated using the formula:

Reorder Point = (Average Weekly Demand) x (Lead Time)

Since the lead time is not given in the problem, we assume it to be 1 week.

Reorder Point = 21 x 1 = 21

Calculating the Total Cost:

To calculate the total cost, we need to consider the carrying cost and the ordering cost for each week.

The carrying cost can be calculated by multiplying the carrying cost per item per week by the inventory level at the end of each week.

The ordering cost is incurred whenever an order is placed. In this case, we only place one order with the optimal order quantity.

Total Cost = (Carrying Cost Week 1 + Carrying Cost Week 2 + Carrying Cost Week 3 + Carrying Cost Week 4 + Carrying Cost Week 5) + Ordering Cost

Carrying Cost Week 1 = (Starting Inventory) x (Carrying cost per item per week) = 0 x Re. 1 = 0

Carrying Cost Week 2 = (Inventory at end of Week 1) x (Carrying cost per item per week) = 50 x Re. 1 = 50

Carrying Cost Week 3 = (Inventory at end of Week 2) x (Carrying cost per item per week) = (50 - 15) x Re. 1 = 35

Carrying Cost Week 4 = (Inventory at end of Week 3) x (Carrying cost per item per week) = (35 - 20) x Re. 1 = 15

Carrying Cost Week 5 = (Inventory at end of Week 4) x (Carrying cost per item per week) = (

The Least Unit Cost Technique is a method used to determine the optimal order quantity and reorder point for inventory management. It considers both the cost of carrying inventory and the cost of placing an order.

To solve this problem, we will use the following formula:

Total cost = Carrying cost + Ordering cost

Given Data:

- Net requirements over 5 consecutive weeks: 50, 15, 20, 20

- Carrying cost per item per week: Re. 1

- Ordering cost per order: Rs. 100

- Starting inventory: 0

Calculating the Optimal Order Quantity:

To determine the optimal order quantity, we need to find the week with the highest net requirement. In this case, it is 50.

The optimal order quantity can be calculated using the formula:

Optimal Order Quantity = (Highest Net Requirement) - (Starting Inventory)

In this case, the optimal order quantity will be 50 - 0 = 50.

Calculating the Optimal Reorder Point:

The reorder point is the inventory level at which an order should be placed. It is determined by considering the lead time (time between placing an order and receiving it) and the average weekly demand.

In this case, we have 5 consecutive weeks of net requirements: 50, 15, 20, 20. The average weekly demand can be calculated by summing up these values and dividing by 5:

Average Weekly Demand = (50 + 15 + 20 + 20) / 5 = 21

The reorder point can be calculated using the formula:

Reorder Point = (Average Weekly Demand) x (Lead Time)

Since the lead time is not given in the problem, we assume it to be 1 week.

Reorder Point = 21 x 1 = 21

Calculating the Total Cost:

To calculate the total cost, we need to consider the carrying cost and the ordering cost for each week.

The carrying cost can be calculated by multiplying the carrying cost per item per week by the inventory level at the end of each week.

The ordering cost is incurred whenever an order is placed. In this case, we only place one order with the optimal order quantity.

Total Cost = (Carrying Cost Week 1 + Carrying Cost Week 2 + Carrying Cost Week 3 + Carrying Cost Week 4 + Carrying Cost Week 5) + Ordering Cost

Carrying Cost Week 1 = (Starting Inventory) x (Carrying cost per item per week) = 0 x Re. 1 = 0

Carrying Cost Week 2 = (Inventory at end of Week 1) x (Carrying cost per item per week) = 50 x Re. 1 = 50

Carrying Cost Week 3 = (Inventory at end of Week 2) x (Carrying cost per item per week) = (50 - 15) x Re. 1 = 35

Carrying Cost Week 4 = (Inventory at end of Week 3) x (Carrying cost per item per week) = (35 - 20) x Re. 1 = 15

Carrying Cost Week 5 = (Inventory at end of Week 4) x (Carrying cost per item per week) = (

Attention Mechanical Engineering Students!

To make sure you are not studying endlessly, EduRev has designed Mechanical Engineering study material, with Structured Courses, Videos, & Test Series. Plus get personalized analysis, doubt solving and improvement plans to achieve a great score in Mechanical Engineering.

|

Explore Courses for Mechanical Engineering exam

|

|

Similar Mechanical Engineering Doubts

The net requirements of an item over 5 consecutive weeks are 50-015-20-20. The inventory carrying costs are Re. 1 per item per week and Rs. 100 per order respectively. Starting inventory is zero. Use “Least Unit Const Technique” for developing the plan. The const of the plan (in Rs.) is:a)200 b)250 c)255 d)260Correct answer is option 'B'. Can you explain this answer?

Question Description

The net requirements of an item over 5 consecutive weeks are 50-015-20-20. The inventory carrying costs are Re. 1 per item per week and Rs. 100 per order respectively. Starting inventory is zero. Use “Least Unit Const Technique” for developing the plan. The const of the plan (in Rs.) is:a)200 b)250 c)255 d)260Correct answer is option 'B'. Can you explain this answer? for Mechanical Engineering 2024 is part of Mechanical Engineering preparation. The Question and answers have been prepared according to the Mechanical Engineering exam syllabus. Information about The net requirements of an item over 5 consecutive weeks are 50-015-20-20. The inventory carrying costs are Re. 1 per item per week and Rs. 100 per order respectively. Starting inventory is zero. Use “Least Unit Const Technique” for developing the plan. The const of the plan (in Rs.) is:a)200 b)250 c)255 d)260Correct answer is option 'B'. Can you explain this answer? covers all topics & solutions for Mechanical Engineering 2024 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for The net requirements of an item over 5 consecutive weeks are 50-015-20-20. The inventory carrying costs are Re. 1 per item per week and Rs. 100 per order respectively. Starting inventory is zero. Use “Least Unit Const Technique” for developing the plan. The const of the plan (in Rs.) is:a)200 b)250 c)255 d)260Correct answer is option 'B'. Can you explain this answer?.

The net requirements of an item over 5 consecutive weeks are 50-015-20-20. The inventory carrying costs are Re. 1 per item per week and Rs. 100 per order respectively. Starting inventory is zero. Use “Least Unit Const Technique” for developing the plan. The const of the plan (in Rs.) is:a)200 b)250 c)255 d)260Correct answer is option 'B'. Can you explain this answer? for Mechanical Engineering 2024 is part of Mechanical Engineering preparation. The Question and answers have been prepared according to the Mechanical Engineering exam syllabus. Information about The net requirements of an item over 5 consecutive weeks are 50-015-20-20. The inventory carrying costs are Re. 1 per item per week and Rs. 100 per order respectively. Starting inventory is zero. Use “Least Unit Const Technique” for developing the plan. The const of the plan (in Rs.) is:a)200 b)250 c)255 d)260Correct answer is option 'B'. Can you explain this answer? covers all topics & solutions for Mechanical Engineering 2024 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for The net requirements of an item over 5 consecutive weeks are 50-015-20-20. The inventory carrying costs are Re. 1 per item per week and Rs. 100 per order respectively. Starting inventory is zero. Use “Least Unit Const Technique” for developing the plan. The const of the plan (in Rs.) is:a)200 b)250 c)255 d)260Correct answer is option 'B'. Can you explain this answer?.

Solutions for The net requirements of an item over 5 consecutive weeks are 50-015-20-20. The inventory carrying costs are Re. 1 per item per week and Rs. 100 per order respectively. Starting inventory is zero. Use “Least Unit Const Technique” for developing the plan. The const of the plan (in Rs.) is:a)200 b)250 c)255 d)260Correct answer is option 'B'. Can you explain this answer? in English & in Hindi are available as part of our courses for Mechanical Engineering.

Download more important topics, notes, lectures and mock test series for Mechanical Engineering Exam by signing up for free.

Here you can find the meaning of The net requirements of an item over 5 consecutive weeks are 50-015-20-20. The inventory carrying costs are Re. 1 per item per week and Rs. 100 per order respectively. Starting inventory is zero. Use “Least Unit Const Technique” for developing the plan. The const of the plan (in Rs.) is:a)200 b)250 c)255 d)260Correct answer is option 'B'. Can you explain this answer? defined & explained in the simplest way possible. Besides giving the explanation of

The net requirements of an item over 5 consecutive weeks are 50-015-20-20. The inventory carrying costs are Re. 1 per item per week and Rs. 100 per order respectively. Starting inventory is zero. Use “Least Unit Const Technique” for developing the plan. The const of the plan (in Rs.) is:a)200 b)250 c)255 d)260Correct answer is option 'B'. Can you explain this answer?, a detailed solution for The net requirements of an item over 5 consecutive weeks are 50-015-20-20. The inventory carrying costs are Re. 1 per item per week and Rs. 100 per order respectively. Starting inventory is zero. Use “Least Unit Const Technique” for developing the plan. The const of the plan (in Rs.) is:a)200 b)250 c)255 d)260Correct answer is option 'B'. Can you explain this answer? has been provided alongside types of The net requirements of an item over 5 consecutive weeks are 50-015-20-20. The inventory carrying costs are Re. 1 per item per week and Rs. 100 per order respectively. Starting inventory is zero. Use “Least Unit Const Technique” for developing the plan. The const of the plan (in Rs.) is:a)200 b)250 c)255 d)260Correct answer is option 'B'. Can you explain this answer? theory, EduRev gives you an

ample number of questions to practice The net requirements of an item over 5 consecutive weeks are 50-015-20-20. The inventory carrying costs are Re. 1 per item per week and Rs. 100 per order respectively. Starting inventory is zero. Use “Least Unit Const Technique” for developing the plan. The const of the plan (in Rs.) is:a)200 b)250 c)255 d)260Correct answer is option 'B'. Can you explain this answer? tests, examples and also practice Mechanical Engineering tests.

|

Explore Courses for Mechanical Engineering exam

|

|

Suggested Free Tests

Signup for Free!

Signup to see your scores go up within 7 days! Learn & Practice with 1000+ FREE Notes, Videos & Tests.