Civil Engineering (CE) Exam > Civil Engineering (CE) Questions > A hollow alloy tube 5m withexternal and inter...

Start Learning for Free

A hollow alloy tube 5m with external and internal diameters equal to 40mm and 25mm respectively was found to extend by 6.4mm under a tensile load of 60kN. When tube is used as column with both ends pinned, find safe compressive load for tube. (FOS = 4)

- a)392N

- b)161N

- c)2570N

- d)642.5N

Correct answer is option 'D'. Can you explain this answer?

Verified Answer

A hollow alloy tube 5m withexternal and internal diametersequal to 40m...

Most Upvoted Answer

A hollow alloy tube 5m withexternal and internal diametersequal to 40m...

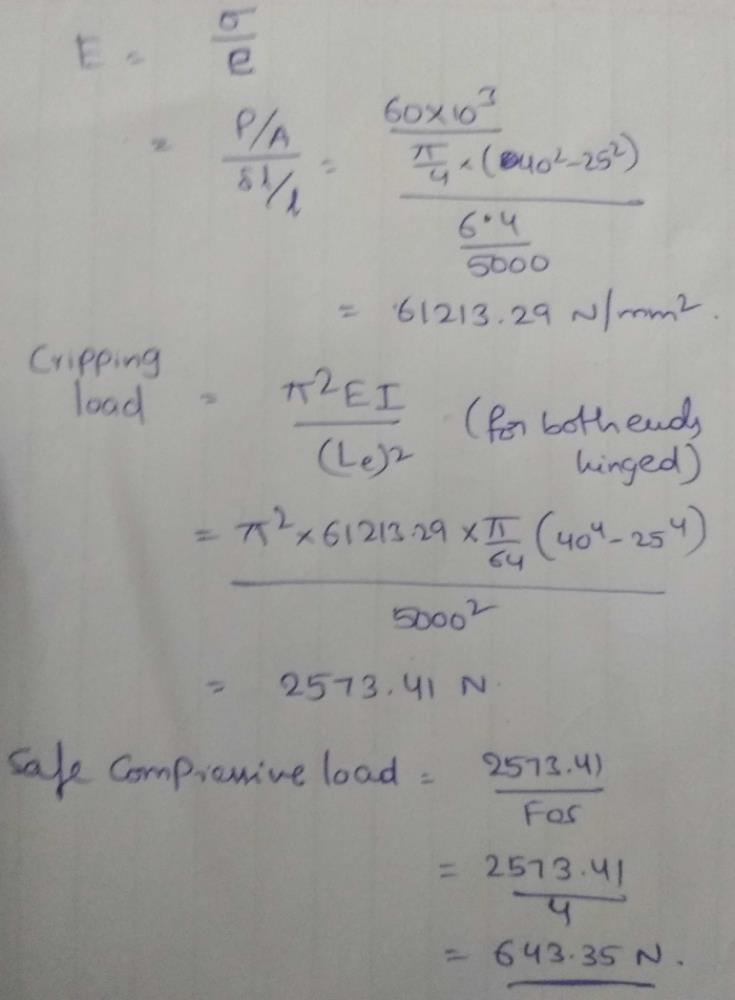

Given data:

Length of the alloy tube (L) = 5 m

External diameter (D) = 40 mm

Internal diameter (d) = 25 mm

Extension under load (ΔL) = 6.4 mm

Tensile load (P) = 60 kN

Factor of safety (FOS) = 4

To find: Safe compressive load for the tube

Formula used:

Stress in the tube under tensile load, σ = P/A

where A is the cross-sectional area of the tube.

Area of the hollow tube, A = π/4[(D^2 - d^2)]

Strain in the tube, ε = ΔL/L

Modulus of elasticity, E = σ/ε

The compressive stress can be found using Euler's formula:

Pcr = (π^2EI)/(KL)^2

where Pcr is the critical buckling load, E is the modulus of elasticity, I is the moment of inertia of the tube, K is the effective length factor, and L is the length of the tube.

Calculation:

External radius, r = D/2 = 40/2 = 20 mm = 0.02 m

Internal radius, r1 = d/2 = 25/2 = 12.5 mm = 0.0125 m

Cross-sectional area, A = π/4[(D^2 - d^2)] = π/4[(0.04^2 - 0.025^2)] = 0.00123 m^2

Stress, σ = P/A = 60 × 10^3 / 0.00123 = 48780.5 Pa

Strain, ε = ΔL/L = 6.4 × 10^-3 / 5 = 0.00128

Modulus of elasticity, E = σ/ε = 48780.5 / 0.00128 = 38126.6 MPa

Moment of inertia of the tube, I = π/64[(D^4 - d^4)] = π/64[(0.04^4 - 0.025^4)] = 3.416 × 10^-8 m^4

Effective length factor for both ends pinned, K = 1.0

Critical buckling load, Pcr = (π^2EI)/(KL)^2 = (π^2 × 38126.6 × 3.416 × 10^-8)/(1.0 × 5)^2 = 642.5 N

Safe compressive load, Psafe = Pcr/FOS = 642.5 / 4 = 160.6 N ≈ 161 N

Therefore, the safe compressive load for the tube is 161 N (approx). Hence, option (b) is the correct answer.

Length of the alloy tube (L) = 5 m

External diameter (D) = 40 mm

Internal diameter (d) = 25 mm

Extension under load (ΔL) = 6.4 mm

Tensile load (P) = 60 kN

Factor of safety (FOS) = 4

To find: Safe compressive load for the tube

Formula used:

Stress in the tube under tensile load, σ = P/A

where A is the cross-sectional area of the tube.

Area of the hollow tube, A = π/4[(D^2 - d^2)]

Strain in the tube, ε = ΔL/L

Modulus of elasticity, E = σ/ε

The compressive stress can be found using Euler's formula:

Pcr = (π^2EI)/(KL)^2

where Pcr is the critical buckling load, E is the modulus of elasticity, I is the moment of inertia of the tube, K is the effective length factor, and L is the length of the tube.

Calculation:

External radius, r = D/2 = 40/2 = 20 mm = 0.02 m

Internal radius, r1 = d/2 = 25/2 = 12.5 mm = 0.0125 m

Cross-sectional area, A = π/4[(D^2 - d^2)] = π/4[(0.04^2 - 0.025^2)] = 0.00123 m^2

Stress, σ = P/A = 60 × 10^3 / 0.00123 = 48780.5 Pa

Strain, ε = ΔL/L = 6.4 × 10^-3 / 5 = 0.00128

Modulus of elasticity, E = σ/ε = 48780.5 / 0.00128 = 38126.6 MPa

Moment of inertia of the tube, I = π/64[(D^4 - d^4)] = π/64[(0.04^4 - 0.025^4)] = 3.416 × 10^-8 m^4

Effective length factor for both ends pinned, K = 1.0

Critical buckling load, Pcr = (π^2EI)/(KL)^2 = (π^2 × 38126.6 × 3.416 × 10^-8)/(1.0 × 5)^2 = 642.5 N

Safe compressive load, Psafe = Pcr/FOS = 642.5 / 4 = 160.6 N ≈ 161 N

Therefore, the safe compressive load for the tube is 161 N (approx). Hence, option (b) is the correct answer.

Free Test

FREE

| Start Free Test |

Community Answer

A hollow alloy tube 5m withexternal and internal diametersequal to 40m...

|

Explore Courses for Civil Engineering (CE) exam

|

|

Question Description

A hollow alloy tube 5m withexternal and internal diametersequal to 40mm and 25mm respectively was found to extend by6.4mm under a tensile load of60kN. When tube is used as column with both ends pinned, find safecompressive load for tube. (FOS = 4)a)392Nb)161Nc)2570Nd)642.5NCorrect answer is option 'D'. Can you explain this answer? for Civil Engineering (CE) 2025 is part of Civil Engineering (CE) preparation. The Question and answers have been prepared according to the Civil Engineering (CE) exam syllabus. Information about A hollow alloy tube 5m withexternal and internal diametersequal to 40mm and 25mm respectively was found to extend by6.4mm under a tensile load of60kN. When tube is used as column with both ends pinned, find safecompressive load for tube. (FOS = 4)a)392Nb)161Nc)2570Nd)642.5NCorrect answer is option 'D'. Can you explain this answer? covers all topics & solutions for Civil Engineering (CE) 2025 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for A hollow alloy tube 5m withexternal and internal diametersequal to 40mm and 25mm respectively was found to extend by6.4mm under a tensile load of60kN. When tube is used as column with both ends pinned, find safecompressive load for tube. (FOS = 4)a)392Nb)161Nc)2570Nd)642.5NCorrect answer is option 'D'. Can you explain this answer?.

A hollow alloy tube 5m withexternal and internal diametersequal to 40mm and 25mm respectively was found to extend by6.4mm under a tensile load of60kN. When tube is used as column with both ends pinned, find safecompressive load for tube. (FOS = 4)a)392Nb)161Nc)2570Nd)642.5NCorrect answer is option 'D'. Can you explain this answer? for Civil Engineering (CE) 2025 is part of Civil Engineering (CE) preparation. The Question and answers have been prepared according to the Civil Engineering (CE) exam syllabus. Information about A hollow alloy tube 5m withexternal and internal diametersequal to 40mm and 25mm respectively was found to extend by6.4mm under a tensile load of60kN. When tube is used as column with both ends pinned, find safecompressive load for tube. (FOS = 4)a)392Nb)161Nc)2570Nd)642.5NCorrect answer is option 'D'. Can you explain this answer? covers all topics & solutions for Civil Engineering (CE) 2025 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for A hollow alloy tube 5m withexternal and internal diametersequal to 40mm and 25mm respectively was found to extend by6.4mm under a tensile load of60kN. When tube is used as column with both ends pinned, find safecompressive load for tube. (FOS = 4)a)392Nb)161Nc)2570Nd)642.5NCorrect answer is option 'D'. Can you explain this answer?.

Solutions for A hollow alloy tube 5m withexternal and internal diametersequal to 40mm and 25mm respectively was found to extend by6.4mm under a tensile load of60kN. When tube is used as column with both ends pinned, find safecompressive load for tube. (FOS = 4)a)392Nb)161Nc)2570Nd)642.5NCorrect answer is option 'D'. Can you explain this answer? in English & in Hindi are available as part of our courses for Civil Engineering (CE).

Download more important topics, notes, lectures and mock test series for Civil Engineering (CE) Exam by signing up for free.

Here you can find the meaning of A hollow alloy tube 5m withexternal and internal diametersequal to 40mm and 25mm respectively was found to extend by6.4mm under a tensile load of60kN. When tube is used as column with both ends pinned, find safecompressive load for tube. (FOS = 4)a)392Nb)161Nc)2570Nd)642.5NCorrect answer is option 'D'. Can you explain this answer? defined & explained in the simplest way possible. Besides giving the explanation of

A hollow alloy tube 5m withexternal and internal diametersequal to 40mm and 25mm respectively was found to extend by6.4mm under a tensile load of60kN. When tube is used as column with both ends pinned, find safecompressive load for tube. (FOS = 4)a)392Nb)161Nc)2570Nd)642.5NCorrect answer is option 'D'. Can you explain this answer?, a detailed solution for A hollow alloy tube 5m withexternal and internal diametersequal to 40mm and 25mm respectively was found to extend by6.4mm under a tensile load of60kN. When tube is used as column with both ends pinned, find safecompressive load for tube. (FOS = 4)a)392Nb)161Nc)2570Nd)642.5NCorrect answer is option 'D'. Can you explain this answer? has been provided alongside types of A hollow alloy tube 5m withexternal and internal diametersequal to 40mm and 25mm respectively was found to extend by6.4mm under a tensile load of60kN. When tube is used as column with both ends pinned, find safecompressive load for tube. (FOS = 4)a)392Nb)161Nc)2570Nd)642.5NCorrect answer is option 'D'. Can you explain this answer? theory, EduRev gives you an

ample number of questions to practice A hollow alloy tube 5m withexternal and internal diametersequal to 40mm and 25mm respectively was found to extend by6.4mm under a tensile load of60kN. When tube is used as column with both ends pinned, find safecompressive load for tube. (FOS = 4)a)392Nb)161Nc)2570Nd)642.5NCorrect answer is option 'D'. Can you explain this answer? tests, examples and also practice Civil Engineering (CE) tests.

|

Explore Courses for Civil Engineering (CE) exam

|

|

Signup for Free!

Signup to see your scores go up within 7 days! Learn & Practice with 1000+ FREE Notes, Videos & Tests.