UPSC Exam > UPSC Notes > Animal Husbandry & Veterinary Science Optional for UPSC > Supplementary Readings - 4

Supplementary Readings - 4 | Animal Husbandry & Veterinary Science Optional for UPSC PDF Download

Stone for Walls

- Stone is a great material for farm building walls where it's available.

- Builders familiar with stone can use it effectively.

Concrete Blocks

- Concrete blocks come in various types like solid, hollow, vibrated, or cellular.

- They can be used for load-bearing walls with thermal insulation similar to brickwork.

- Cellular blocks offer better insulation and can be used in cavity walls.

Roof Construction

- Open roofs are important for good air and light in animal buildings.

- Steel or wood trusses with felt and slates or tiles are excellent for animal habitats.

- Corrugated iron roofing is cost-effective but may make the building cold in winter and hot in summer.

Asbestos Cement Roof

- Asbestos cement roofing is non-corrosive, light, and insulating.

- It requires minimal attention and comes in corrugated sheets or flat 'slates'.

Asbestos Protected Metal

- This roofing is a combination of corrugated iron and asbestos fabric.

- It lasts long and has low maintenance costs.

Considerations for Roofing Material

- Sheeting needs truss and purlin support, while tiles and slates need a heavier structure.

- Livestock and dairy buildings may require internal lining with certain roofing materials.

Cost and Comfort

- Corrugated iron roofing is cost-effective but may affect the building's temperature.

- Asbestos cement roofing is a good balance of durability, insulation, and low maintenance.

Farm Building Tips

- Use stone for walls if available.

- Consider concrete blocks for insulation.

- Opt for trusses that allow good air and light.

- Choose roofing materials based on cost, climate, and maintenance needs.

Ideal Floor Characteristics

A good floor for animal spaces needs to be:

- Nonporous

- Easy to clean and quick-drying

- Non-slippery

- Durable and long-lasting

- Comfortable for the animals

Consideration of Expense

- Since animals are usually kept for profit, the cost of the floor is a factor to consider.

- Floors that don't absorb water and dry quickly tend to last longer.

Moisture Absorption Concerns

- Animals tend to urinate and defecate where they stand, so the floor material should not absorb moisture.

- Moisture-absorbing floors can lead to constant dampness, coldness, and unhealthy air in the building.

Health Risks of Dampness

- Damp floors and walls are major causes of illness and weakness in animals.

- They can contribute to the spread of diseases and reduce the overall health of the animals.

Slippery Floor Hazards

- Slippery floors can cause accidents, especially for horses and cattle.

- A smooth but impervious floor is harder and denser, but its smoothness can pose risks if not kept clean.

Surface Polishing and Cleanliness

- Level floors with smooth surfaces can become polished with animal movement.

- Regular cleaning is crucial to prevent surfaces from becoming too smooth and slippery.

Durability Importance

- Floors must be durable for economic and hygienic reasons.

- Poorly laid floors can wear unevenly, crack, and develop holes that collect water and dirt.

Preventing Dampness

- Ideally, the floor should be above the ground level to avoid dampness.

- If the floor must be below ground level, measures like a dry area or damp-proof course should be in place.

Drainage Challenges

- Low-level floors are harder to drain than raised ones.

- Proper drainage is essential to prevent issues associated with dampness.

Best Flooring Material

- Cement concrete is the top choice for animal house flooring.

- It's durable, less permeable, and cost-effective.

- Adding powdered carborundum makes the surface less slippery.

Question for Supplementary Readings - 4Try yourself: What is an important characteristic of a good floor for animal spaces?View Solution

Foundation Preparation

- Clear the ground to the required depth.

- Level and compact the earth for a solid base.

- Lay a 6-inch layer of hardcore (broken stones or bricks) for insulation and a proper foundation.

Insulation Importance

- Proper insulation, like using hollow terra-cotta blocks, is crucial for animal habitation floors.

- It prevents sinking and cracking of the floor.

Concrete Composition

- The concrete floor is made of one part Portland cement, four parts gravel, broken stones or bricks, and two parts sand.

- This mixture ensures a sturdy and long-lasting floor.

Suitability for Different Animals

- Cement concrete is excellent for cowsheds and piggeries but might be too slippery for horses.

- However, it's proven effective for heavy draught horses in commercial stables.

Roughening Smooth Surfaces

- Smooth and slippery concrete floors can be roughened using commercial hydrochloric acid.

- This process, devised by Scriven and Kenney, is cost-effective and can be done by farm labor.

Safety Precautions

- Workers should use rubber boots and mackintoshes when handling acid.

- Adequate ventilation is crucial due to noxious acid fumes.

Alternative Flooring Material

- Ordinary building bricks, though used in some places, are not ideal for flooring.

- They are porous and wear unevenly, making them less suitable for animal housing.

Brick Flooring

- Regular bricks are cheaper than vitrified paving bricks and less slippery.

- When used, they should be set on their edges and placed in cement for stability.

Wood Flooring Issues

- Wood is unsuitable for animal house flooring.

- Even hard-wood blocks and creosoted railway sleepers absorb water, making them inappropriate.

Cork and Plich Composition Bricks

- Composition bricks made of cork and plich are suggested for cor stalls and piggery beds.

- These bricks provide a unique combination of warmth and resiliency.

Rubber Flooring Challenges

- Rubber has been used but has limitations.

- Rubber blocks and mats can become slippery when wet and are challenging to fix securely to cement floors.

Rubber Plastic Flooring

- Rubber plastic flooring is a promising option.

- It's warm, resilient, impermeable, and durable.

- Damaged areas can be cut out and replaced with new material.

Suitability of Rubber Flooring

- Rubber flooring is not suitable for heavy-duty use in horse stables.

- However, rubber plastic flooring is recommended for dairy cattle standings.

Causes of Dampness

- Dampness in walls and floors is often due to poor construction and neglected repairs.

- Leakages from roofs, walls, or absence of damp-resisting courses contribute to dampness.

Leaky Roof Impact

- A displaced or missing slate or tile on a roof allows rainwater to soak walls.

- Regular roof inspections and prompt repairs are essential to prevent moisture damage.

Preventing Dampness

- Damp-resisting courses can be nullified if the outer ground is piled against the wall.

- Regular examination of roofs and repairs is crucial to prevent and address leaks and dampness issues.

Damaged Gutters and Rain Pipes

- Problem: Broken or clogged gutters and rain pipes can harm your building's safety.

- Impact: Water runs down walls, leading to dampness in walls and floors.

- Solution: Regularly check for cracks in rain pipes, especially near the wall, and clear any blockages.

Absence of Damp Courses

- Issue: Lack of proper damp-proof course can lead to damp walls.

- Importance: Damp-proof courses should be above ground and below the floor in new buildings.

- Action: Level the wall, remove sharp objects, and use a suitable damp-proof course like bituminous sheeting.

Retaining Walls

- Challenge: Higher ground can cause dampness in the retaining wall.

- Solution: Create a trench, lay a drain, fill with dry stones, and cover with cement concrete.

- Extra Step: Apply cement plaster or asphalt on the outer surface for added protection.

Rain Damped Walls

- Issue: Walls facing the west wind become damp during rain.

- Prevention: Build hollow walls, use cement plaster with waterproofing, or attach tiles to creosoted wood battens.

- Construction: Hollow brick walls with proper ventilation between outer and inner walls.

Galvanized Iron Ties in Walls

- Use galvanized iron ties between walls and outer casing.

- Include at least two ties per yard of work, twisted in the middle to prevent moisture transfer.

- Carefully build ties during hollow wall construction to avoid mortar dropping onto them.

Benefits of Hollow Walls

- Hollow walls offer double advantages.

- They provide a reliable method to prevent rain penetration.

- Offer better heat insulation compared to the same thickness of solid brick walls.

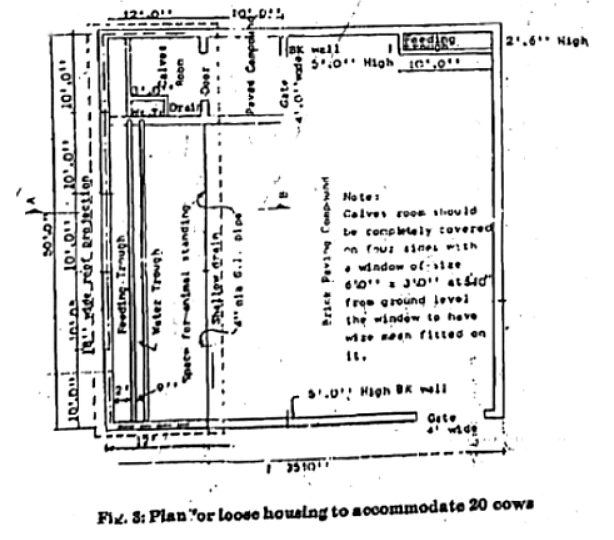

Planning Cattle Housing

- Consider details like layout, construction, and equipment for cowhouses.

- Influences animal health, milk hygiene, working costs, and labor.

- Location should have easy access to roads, pastures, dairy, and food stores.

- Ensure a sufficient water supply for milk production.

Large Herds in Cowhouses

- Common practice to house the entire milking herd in one building.

- Drawback: Diseases may spread more easily, especially in poorly ventilated buildings.

- Suggested Solution: Split large herds into self-contained units with about 50 animals each.

- Segregation is important for general health and control of contagious diseases.

Health Considerations

- Provide separate isolation boxes for calving cows and sick animals.

- Prioritize herd health and milk cleanliness in cowhouse planning.

- Emphasize the need for scrupulous care by the staff, as building expenses alone can't guarantee these outcomes.

Question for Supplementary Readings - 4Try yourself: What is the purpose of using hardcore (broken stones or bricks) in the foundation preparation for animal habitation?View Solution

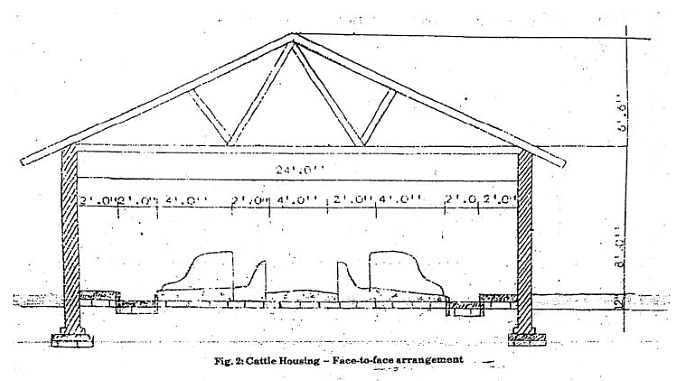

Planning and Construction of Cowhouses

- Key Considerations: Site suitability, sufficient cubic space, proper floor space proportion, efficient ventilation, lighting, and easy cleaning.

- Interior Layout: Choose between single or double rows for cow standings.

- Preference for Double-Range Cowhouses: Recommended for more than 16-20 cows, offering convenience, labor savings, and cost efficiency.

- Central Gangways: Essential for double-range cowhouses to facilitate easy cleaning and dung removal.

- Cows' Orientation: Cows should face outward with heads near fresh air inlets for optimal ventilation.

- Avoiding Respiratory Risks: Animals should not face each other to minimize the risk of respiratory infections and to facilitate effective ventilation.

Benefits of Double-Range Cowhouses

- Convenience: Easier supervision and milking.

- Labor Savings: Efficient dung removal using carts or mechanical means.

- Cost Efficiency: Maximizes floor space and reduces building costs.

Importance of Orientation

- Cows should face air inlets in walls for maximum fresh air intake.

- Ensures the health and well-being of the animals by optimizing ventilation.

Overall Objective

- Ensure a well-planned cowhouse layout to reduce labor, promote animal health, and enhance efficiency in cleaning and maintenance.

Internal Dimensions of Cowhouse

- Width:

- Single-Range Layout: Minimum dimensions - Gangway 4', dung channel 3', standing 6', manger 32" to 36", optional feeding passage 3'. Total building width 16' (or 18').

- Double-Range Layout: Similar to single-range but with a wider central gangway (5'). Total building width 27' (or 33').

- Tying Points and Manger Width:

- For side ties with narrow mangers, keep the distance from the wall or feeding passage to the dung channel under 7 feet 6 inches.

- If using wider mangers (up to 2 feet 6 inches), tie points should align with the front kerb of the manger.

- Total building width is 14 feet 6 inches (or 17 feet 6 inches) for single range, 28 feet (or 32 feet) for double range.

Length

- Cowhouse length depends on the number of standings, allowing 3 feet 6 inches for an average cow or 3 feet 3 inches for smaller breeds.

- Allocate 6 feet 6 inches or 7 feet for each double stall, and 4 feet for a single stall to accommodate cleaning and milking operations.

Height

- Inside wall height should not exceed 8 feet to avoid ventilation issues and down drafts.

- Height to ridge should be 15 feet or 16 feet for optimal cowhouse design.

Key Highlights

- Consider width, tying points, and manger width based on cowhouse layout (single or double range).

- Tailor length to accommodate the number of standings and allow space for cleaning and milking.

- Maintain a suitable height to ensure proper ventilation and avoid down drafts in the cowhouse.

Walls

- Internal cowhouse walls should have a smooth, hard finish with cement rendering, glazed tiles, or bricks.

- Maintain a height of at least 4 feet 6 inches for tiles or bricks, with the area above smoothly rendered to prevent dirt accumulation.

- Fill corners and angles with a cement filler for a complete finish.

Doors

- For a single-range cowhouse, the doorway should be 7 ft. high and a clear 4 ft. wide.

- Use a divided door with the lower part being 4 ft. high, hinged to open outwards.

- Ensure doors lie flat against the external wall when fully open to avoid hindering the passage of animals.

- In a double-range cowhouse, the doorway should be a clear 8 to 9 ft. wide.

- Options include double-hung or sliding doors, with sliding doors placed inside for weather protection.

Ventilation, Lighting, and Feeding Passages

- Refer to the 'Air, Ventilation, and Lighting' section for details on cowhouse ventilation and lighting.

- Consideration for feeding passages: Some debate exists on having a feeding passage in front of cows or having them stand close to the facing wall.

- A feeding passage is useful for yoked or similar ties, making feeding easier.

- The passage's width need not exceed 3 ft., and it should connect directly to the food-mixing room.

- Caution against wider passages being used for unintended purposes, like storing hay or as a pen for calves, which is not ideal.

Feeding Passages

- Advantages: Feeding passages allow better observation and individual attention to cows at all times.

- Consideration: Houses without feeding passages are narrower, cost less to build, and can be easily repurposed if needed.

Regional Considerations

- Note that in some parts of the U.K., particularly in Scotland, there's a preference against feeding passages.

- The reasoning behind this preference is not entirely clear, and experienced dairy farmers differ in their opinions.

Standings

- Importance of Limiting Area: The area where a cow stands and lies should be limited in length to prevent faeces and urine from soiling the floor.

- Clean Milk Production: Properly proportioned standings help avoid the cow lying on excreta, contributing to cleaner milk.

- Restriction Consideration: While limiting space may restrict backward movement, it is essential for maintaining cleanliness.

- Proper Proportions: Well-designed standings allow most excreta to fall into the dung channel behind the cows.

- Challenges of Improper Construction: If standings are not constructed well, with cows frequently soiling their udders with manure, the effort required to keep them clean becomes challenging and often unsatisfactory.

Stalls Length

- Short Stalls Issues: If stalls are too short, cows may stand with hind feet in the dung channel, causing harm to hoofs and discomfort.

- Ideal Length: The length of the standing should allow cows to stand naturally with hind legs just at the border of the rear channel.

- Tailored Length: The length varies based on cow size, ranging from 4 feet 9 inches to 5 feet 3 inches.

Feeding Passage Consideration

- If a feeding passage is present, measurements can be made from the manger.

- Length Adjustment: Varying the length can accommodate cows of different sizes by constructing back steps not parallel to the manger front.

Double Stalls

- Common Practice: Cows are typically kept in pairs in double stalls for labor efficiency and cost reduction.

- Width Consideration: Proper width prevents cows from fouling the standing or injuring each other.

- Suitable Width: For double stalls, width may range from 6 feet 6 inches for small animals to 7 feet 6 inches for larger ones.

Flooring of the Standing

- Material Choice: Use impervious, easily cleanable, non-slippery material for standing flooring.

- Ideal Surface: A uniform fall of 1 to 1.5 inches from manger to dung channel is important.

- Cement Concrete Option: Although it tends to be cold, cement concrete is cost-effective, durable, and suitable if properly finished and roughened for good foothold.

- Improved Warmth: Adding loosely packed hardcore or hollow building bricks underneath the concrete helps keep the floor warmer and drier.

Gangways and Milking Passages

- Importance of Wide Passage: A wide passage behind cows is beneficial for safety and comfort.

- Turning Comfort: Cows can turn safely, reducing the risk of slipping and falling.

- Visibility: A wider passage ensures better lighting, illuminating udders and hindquarters for efficient milking.

- Splash Prevention: A wider passage minimizes the risk of dung and urine splashing into milk pails during milking.

- Staff Efficiency: A narrow passage may lead to cramped spaces and hinder efficient work by the staff.

Milking Passage Dimensions

- Single-Range Cowhouse: Milking passage should be at least 4 feet wide with a 1-inch fall towards the dung channel.

- Double-Range Building: Central passage should be slightly cambered and no less than 8 feet wide.

- Surface Material: Flooring should be of cement concrete with a rough, non-slip surface.

- Important Detail: Fill the angle where the back wall joins the floor with a cement fillet and round out the corners for cleanliness.

Interior Drainage

- Significance: Interior drainage is crucial for cow cleanliness and overall hygiene.

- Open Channel: The drain or dung channel should be an open channel behind the standings, running the length of the building.

- Disposal: It should discharge into an open gully trap outside the building, connected to a suitable drain or disposal area.

- Environmental Consideration: Placement should avoid ditches, streams, or water sources to maintain herd health and water quality for the cowshed and dairy.

Dung Channel

- Adequate Width: The dung channel should be wide enough to hold dung and bedding without becoming overloaded.

- Recommended Dimensions: Typically, 3 feet wide with a 1-inch cross-fall away from the standing and a 1/2-inch fall per cow length.

- Uniform Depth: Maintain a uniform depth throughout the channel's length for effective drainage.

- Surface Finish: A smooth finish on the concrete surface for the first 4 inches from the edge can aid liquid drainage.

- Cross Channels Caution: Avoid cross channels unless the dung channel exceeds about 70 feet; if needed, make them about 12 inches wide with gratings.

Mangers

- Material and Design: Mangers should be made of hard, impervious, alkali-resistant materials designed for easy cleaning.

- Unsuitability of Timber: Timber is not suitable for mangers due to cleaning challenges.

- Common Types:

(i) Individual Glazed Stoneware Mangers

(ii) Continuous Concrete Mangers with High Backs - Individual Mangers:

- Dimensions: Not more than 2 feet 6 inches long, 18 inches wide, and 8 inches deep.

- Set in concrete with a raised benching at the back and sides.

- Backed by a dwarf concrete wall if there is a feeding passage to prevent food spillage.

- Horizontal rails above the dwarf wall to prevent cows from moving forward.

- Objection: Difficult to clean effectively due to design and construction challenges, especially with messy foods like wet brewers' grains.

Cleaning Challenges

- Individual mangers quickly become dirty, especially with sloppy fermentable foods.

- Cleaning is laborious and challenging, leading to less effective cleaning practices.

- Frequent and thorough cleaning is necessary but often not achieved with individual mangers.

Question for Supplementary Readings - 4Try yourself: What is the recommended layout for cow standings in a cowhouse?View Solution

The document Supplementary Readings - 4 | Animal Husbandry & Veterinary Science Optional for UPSC is a part of the UPSC Course Animal Husbandry & Veterinary Science Optional for UPSC.

All you need of UPSC at this link: UPSC

FAQs on Supplementary Readings - 4 - Animal Husbandry & Veterinary Science Optional for UPSC

| 1. What are the main causes of dampness in buildings? |  |

Ans. The main causes of dampness in buildings can include factors such as poor ventilation, water leakage, inadequate waterproofing, condensation, and rising damp.

| 2. How do galvanized iron ties in walls contribute to dampness? |  |

Ans. Galvanized iron ties in walls can contribute to dampness if they are not properly installed or maintained. Over time, these ties can corrode and create openings for water to seep in, leading to dampness issues.

| 3. What factors should be considered during the planning and construction of cowhouses to prevent dampness? |  |

Ans. To prevent dampness in cowhouses, factors such as proper drainage systems, effective waterproofing, adequate ventilation, and suitable flooring materials should be considered during the planning and construction process.

| 4. Why is ventilation important in cowhouses to prevent dampness? |  |

Ans. Ventilation is crucial in cowhouses to prevent dampness because it helps to control humidity levels, remove excess moisture, and improve air circulation. Proper ventilation can reduce the risk of condensation and dampness-related problems.

| 5. How can the internal dimensions of a cowhouse impact dampness? |  |

Ans. The internal dimensions of a cowhouse can impact dampness as inadequate space or overcrowding can lead to poor air circulation and increased humidity. It is important to ensure that the cowhouse has sufficient space for the animals and proper ventilation to prevent dampness issues.

Related Searches