Hygienic Methods of Handling of Meat | Animal Husbandry & Veterinary Science Optional for UPSC PDF Download

Spoilage of Meat and Control Measures

Overview:- Meat, like all perishable foods, is prone to spoilage caused by bacteria, moulds, and yeasts.

- These microorganisms break down proteins, fats, and carbohydrates in meat, leading to the formation of various chemical substances.

Process of Spoilage:

- When meat decomposes, it releases gaseous and foul-smelling compounds due to bacterial action.

- Enzyme activity and oxidation also contribute to the deterioration of meat.

Autolysis in Meat:

- Autolysis refers to the self-degradation of tissues facilitated by enzymes present in cells.

- Tissues with high protein synthesis and water content, like gastrointestinal mucosa and testes, exhibit faster autolytic rates.

Factors Affecting Meat Spoilage:

- The shelf-life of meat depends on its structure, pH, water content, presence of bacteria, and storage conditions.

- External factors such as temperature, moisture, oxygen availability, and nutrients influence the growth of bacteria, moulds, and yeasts on meat.

Meat Contamination:

- Meat can be contaminated by bacteria from various sources like soil, water, equipment, and personnel.

- Initially believed to be sterile, meat from healthy animals can harbor certain bacteria types, leading to spoilage or diseases if not handled properly.

Spoilage Organisms in Food

Gram-Positive Spoilage Organisms- Microorganisms like Micrococcus, Staphylococcus, Streptococcus, Lactobacillus, Bacillus (including Bacillus subtilis), Clostridium, Corynebacterium, and Unicrobacterium can cause spoilage.

- These organisms can thrive in various pressure conditions.

Gram-Negative Spoilage Organisms

- Pseudomonas, Flavobacterium, Actinobacter, Achromobacter, Alcaligenes, Halobacterium, Moraxella, Escherichia, Klebsiella, Salmonella, Shigella, and Proteus are examples of Gram-negative spoilage organisms.

Main Types of Spoilage Organisms on Chilled Fresh Meats

- These organisms, commonly found in nature, are responsible for slime formation during meat storage.

- Bacteria are pervasive and inevitably contaminate carcasses during dressing procedures.

- Chilling does not halt spoilage organism activity; however, temperatures below 2°C can delay slime formation.

Symptoms of Spoilage

- Visible signs of spoilage include color changes to grey, yellow, or green, tissue softening, foul odors, and an alkaline reaction due to ammonia formation.

- Decomposition begins post-slaughter and progresses with changes in tissue consistency and odor.

Decomposition Process

- Initial surface growth is driven by aerobic bacteria like Pseudomonas and Achromobacter.

- Anaerobic bacteria such as Clostridium sporogenes thrive in oxygen-deprived environments.

- Surface putrefaction spreads gradually through nerve and connective tissues.

Internal Decomposition in Animals

- After death, internal and external decomposition occur concurrently due to factors like high blood content and bacterial invasion.

- Bacteria like E. coli and C. perfringens invade carcasses post-mortem, leading to spoilage.

Bone Taint

- Rapid body heat dissipation in a freshly killed carcass occurs in cool, dry, and well-circulated air.

- Cooling is slower in thick carcasses or those with excess fat, risking damage to deep-seated musculature, leading to spoilage known as bone taint.

- Taint in hams, also called 'souring,' is caused by organisms like Clostridium sporogenes, Cl. putrefaciens, and Cl. putreficum.

- Moulds, favored by moisture, temperature, and organic matter, such as Aspergillus and Botrytis, can spoil meat, causing black spot, white spot, and whisker infections.

Meat Spoilage

- Serious illnesses from meat consumption are often due to Salmonella or Clostridium infections, which might not show external signs of decomposition.

- Decomposition extent is assessed by pH estimation, chemiluminescence, or a torrymeter.

- Fat decomposition can lead to rancidity due to atmospheric oxidation or microbial action, resulting in taint.

Control Measures

- Hygiene is crucial in slaughterhouses, meat stores, transport, distribution, and homes to control exogenous contamination.

- Proper chilling of carcasses, preservation methods like drying, freeze-drying, pickling, and controlling humidity are essential.

- Recent strategies include irradiation and broad-spectrum antibiotics to prevent spoilage, emphasizing careful antibiotic use for effective preservation.

Post Slaughter Physicochemical Changes in Meat and Factors

- Physical and Chemical Changes:

- Significant alterations occur in the characteristics of meat within a day or two of slaughter.

- Initially, the meat appears dark, sticky, and resistant to salt and sugar.

- As time progresses, the meat becomes lighter in color, wet but not sticky, with decreased electrical resistance.

- The rate of these changes is influenced by atmospheric temperature, glycogen levels, and pH.

- Meat from exhausted animals tends to remain dark and tough due to depleted glycogen content.

- Rigor Mortis:

- Rigor mortis is the primary post-mortem change characterized by muscle hardening and contraction.

- It affects muscles in a specific sequence, starting from the head and neck.

- Factors influencing rigor mortis include temperature, animal health, and muscular acidity.

- Rigor mortis onset is related to the depletion of glycogen and the formation of lactic acid post-death.

Key Takeaways:

- Physical and chemical changes in meat occur shortly after slaughter, influenced by temperature, glycogen levels, and pH.

- Rigor mortis is a significant post-mortem process affected by factors like temperature, animal health, and muscular acidity.

- The onset and duration of rigor mortis are linked to glycogen levels and lactic acid formation in muscles.

- Desirable meat characteristics include adequate rigor mortis and low pH levels for inhibiting bacterial growth and improving tenderness.

- Rigor Mortis and Muscular Acidity:

- Rigor mortis is closely linked to muscular acidity.

- After slaughter, lactic acid concentration in muscles increases significantly.

- Living muscle has around 0.05% lactic acid, while this can rise to 0.5-1% within 24 hours post-slaughter.

- Acidification Process:

- Flesh pH changes from neutral or slightly alkaline to acidic after slaughter.

- Acidification in cattle, pigs, and horses occurs within a few hours, influenced by environmental temperature.

- In sheep, this process might be delayed and less consistent.

- pH Levels in Slaughtered Animals:

- In freshly slaughtered cattle, flesh pH starts at about 7.0, decreasing to 5.5 in approximately 18 hours.

- Eventually, pH slightly rises due to alkaline substances from protein breakdown.

- Factors Affecting Rigor Mortis:

- Absence of rigor mortis can result from poor treatment before slaughter, such as fatigue, stress, or illness.

- Inadequate pre-slaughter care may not make the meat unsafe but can affect its quality.

- Rapid onset of rigor mortis, due to improper handling like warm storage, indicates potential spoilage.

Quality Improvement Methods

- Pre-slaughter Quality Improvement: Muscle glycogen plays a crucial role in meat quality. Its presence ensures the production of adequate lactic acid post-slaughter, resulting in low pH. This, in turn, enhances the appearance, taste, tenderness, and shelf life of the meat. Depletion of muscle glycogen, due to factors like exhaustion or excitement, can lead to a higher pH level, resulting in poor quality and increased bacterial spoilage. To maintain muscle glycogen levels, it is essential to provide pre-slaughter rest and avoid stressful conditions.

- Post-mortem Lactic Acid Levels: Feeding pigs easily digestible carbohydrates like sugar before slaughter can help achieve optimal levels of lactic acid post-mortem. Molasses has been effectively used for this purpose, leading to improved quality in bacon and ham when sucrose-fed pigs are involved.

- Pre-slaughter Tenderizing: Tenderness is a desirable characteristic of meat, and various methods are employed to enhance it artificially. Proteolytic enzymes from sources like fruits, bacteria, and fungi, along with pancreatic trypsin, are used for this purpose. Enzymes such as papain from papaya, ficin from fig, and bromelain from pineapple are commonly utilized either individually or in combination. One method involves distributing enzymes through the living animal's vascular system to ensure even distribution and controlled activity in the meat. This method results in tenderization upon cooking at an optimal temperature of 60-71°C.

Meat Tenderization and Post-Slaughter Quality Improvement

- Pre-Slaughter Tenderization

- Untreated animal carcass joints are typically 35% grillable or roastable, but this can rise to 75% with pre-slaughter tenderization.

- Quality untreated beef usually has 45% of steaks and 77% of roasts above a tenderness level of 7, while treated beef rates higher.

- Advantages of tenderization include faster uniform tenderness, no weight loss, and lower costs, but drawbacks can lead to overly tender organs and occasional adverse reactions.

- Post-Slaughter Quality Improvement

- Conditioning or tenderizing of meat occurs between 0°C and 3°C, enhancing flavor, juiciness, and tenderness without bacterial influence.

- Factors affecting meat tenderness include breed, age, nutrition, exercise, and connective tissue content.

- Autolysis and enzyme actions contribute to meat tenderness by breaking down muscle proteins and collagen fibers.

- Tissue proteinases like cathepsin aid in proteolysis, increasing meat tenderness over time.

- Commercial Ripening

- Commercial meat conditioning involves specific cooling and holding processes to enhance palatability.

- Extended storage periods, especially during sea voyages, can significantly increase the tenderness of coarse meat joints.

- Various techniques like hammering, muscle stretching, and enzyme applications can further improve meat tenderness.

- Electrical Stimulation for Tenderizing

- Electrical stimulation accelerates rigor mortis onset, improving meat tenderness rapidly after slaughter.

- Benefits include avoiding cold shortening, reducing aging times, and enhancing flavor and color.

- Strict safety measures are crucial due to high voltage usage, ensuring the quality and safety of the meat.

- Adulteration of Meat and Detection

- Differentiating meats can be challenging, especially with processed or mixed varieties, leading to potential adulteration issues.

- Unscrupulous traders exploit these challenges, resulting in various forms of adulteration and substitution in the meat industry.

Understanding Meat Adulteration and Analytical Techniques

- Substitution of Inferior Meats

- Horse meat is sometimes substituted for beef, goat for lamb, cat for rabbit, and rabbit for poultry.

- Adulteration in Comminuted Meat

- Adulteration often occurs in processed or ground meat forms.

- Modern technology enables sophisticated adulteration, posing challenges for detection.

- Challenges Faced

- High meat prices and the use of various low-quality proteins encourage adulteration.

- Complexity of processed meat products makes analysis difficult.

- Constant refinement of analytical techniques is necessary to combat fraud effectively.

- Ingredients Used in Adulteration

- Various non-meat and animal-based proteins are used to mask true meat content.

- Ingredients like vegetable proteins, soya bean cereal, and low-value animal parts are common.

- Illegal use of these "meat extenders" leads to fraudulent practices.

- Use of Additives

- Polyphosphate, sodium chloride, nitrate, and nitrites are added to meat products to retain water during cooking.

- Labeling requirements differentiate between cooked and uncooked products in terms of added water content.

- Meat Differentiation Techniques

- Chemical and biological tests are crucial for identifying inferior or fraudulent meats, especially in minced or processed forms.

- Chemical tests help distinguish meats based on specific characteristics like glycogen content or fatty acid composition.

- Methods like iodine value testing aid in differentiating between fats from various animal sources.

Meat Identification Techniques

- Iodine Value:

- Horse: 71-86%

- Ox: 38-46%

- Sheep: 35-46%

- Pig: 50-70%

- Good Lard: 66%

- Refractive Index: All liquids have specific refractive indices.

- Horse: 53.5

- Ox fat: < 40

- Pig fat: ≤ 51.9

- Biological Tests:

- Precipitin Test: Antibodies develop in the blood of an animal injected with another's blood serum.

- Complement Fixation Test: Utilizes serum complement to detect antigen-antibody reactions.

- ELISA Test (Enzyme Linked Immunosorbant Assay): Relies on antibody-antigen binding.

Precipitin Test

Example: Antibodies in a rabbit injected with horse serum detect horse proteins in a meat extract.

Complement Fixation Test

Example: Utilizes guinea-pig serum to detect antigen-antibody reactions.

ELISA Test

Example: Detects specific antigens in meat samples through antibody-antigen binding.

These tests aid in identifying meat sources and detecting adulteration. ELISA tests can identify as low as 3% adulteration and provide results in six hours.

Diagnostic kits are available for easy use, offering accurate results through color reactions measured using a spectrophotometer.

Other Identification Techniques:

- Microscopic Electrophoresis

- Chemical Procedures

- Agar-Gel Diffusion

- Gas-Liquid Chromatography

These techniques complement meat identification through various methods such as physical and chemical characteristics analysis.

- Substitution of Inferior Meat

- Horse meat is sometimes passed off as beef, goat as lamb, cat as rabbit, and rabbit as poultry.

- Adulteration commonly occurs when meat is finely ground, making detection challenging.

- Modern production methods enable sophisticated adulteration, posing health risks and analytical challenges.

- Reasons for Adulteration

- High meat prices and the availability of cheaper protein sources tempt unethical manufacturers.

- Analytical limitations sometimes hinder the accurate assessment of meat content.

- Constant refinement of analytical techniques is crucial to combat evolving fraudulent practices.

- Ingredients Used

- Various non-meat proteins and animal-based proteins are utilized to mask true meat content.

- Commonly referred to as 'meat extenders' or 'meat substitutes', these ingredients facilitate fraud.

- Examples include vegetable proteins, soya bean cereal, rind, bone protein, urea, dried blood, and plasma.

- Labeling Regulations

- Different rules apply to uncooked and cooked meat products concerning water content labeling.

- Additives like polyphosphate are used to minimize water loss during cooking.

- Products resembling raw meat must disclose actual water content, excluding fresh and frozen poultry.

- Meat Differentiation

- Chemical and biological tests are crucial to detect inferior or repugnant meat substitutions.

- Differentiating between animal fats in carcass form and processed meats can be challenging.

- Tests such as the precipitin test, complement fixation test, and ELISA test aid in identifying meat authenticity.

Regulatory Provisions in Meat Trade and Industry

- Current State of the Meat Industry in India:

- The meat industry in India is still in its early stages, with even slaughterhouses in major cities lacking scientific practices.

- Conventional methods of slaughter and meat distribution are predominantly followed.

- Importance of Regulatory Provisions:

- Regulatory provisions in the meat trade and industry in India are yet to be clearly defined and enforced.

- Emphasis should be placed on following comprehensive regulations similar to those in developed countries like Great Britain.

- Emphasis on Livestock Transport:

- Healthy animals must be transported in good condition and kept free from contamination, injury, stress, and disease during the journey.

- Slaughtering livestock near the production point is recommended to minimize long journeys and ensure animal welfare.

- Transportation Guidelines:

- Personnel responsible for livestock transport must ensure careful handling, avoiding sudden stops, fast cornering, and unnecessary delays.

- Various countries, including Great Britain, have detailed regulations for humane animal transport by road, rail, air, and sea.

- Specific Regulations:

- Orders such as the Conveyance of Live Poultry Order 1919 and Transit of Animals (General) Order 1973 lay down specific regulations for the welfare of animals during transport.

- These regulations cover aspects like suitable transport conditions, protection from injury, provision of food and water, and proper labeling of animal receptacles.

Animal Transportation Regulations Summary

Vehicle Cleansing and Disinfection

- Inspectors can issue notices to vehicle owners for non-compliance.

- Failure to cleanse vehicles can lead to local authorities carrying out the work at the owner's expense.

Loading and Offloading

- Animals should not be injured during loading/unloading.

- Use suitable ramps, lifting gear, or manual lifting for loading/unloading.

Animal Welfare During Transit

- Avoid exposure to weather and ensure adequate ventilation.

- Provide partitions of specific heights for different animals.

- Animals must have attendants during transportation.

Animal Care and Feeding

- Offer food and water at least every 12 hours during journeys.

- Unfit animals or those likely to give birth are not allowed to travel without proper authorization.

Regulations and Enforcement Challenges

- Inspectors have powers to take action for unfit animals or those likely to give birth.

- Challenges exist in enforcing regulations due to various factors in the transportation process.

International Standards

- American regulations specify minimum floor space for different animals during transport.

- Calculations are based on factors like average animal weight and vehicle load limits.

Meat Storage and Handling Regulations

- Requirements for refrigeration and storage of meat products in slaughterhouses.

- Specific temperature guidelines for different types of meat and offal.

EEC Directives on Meat Handling

- Chilling requirements for meat after post-mortem inspection.

- Specifications for cutting plants, including temperature control measures.

Poultry Handling Guidelines

- EEC directives outline cleaning and chilling procedures for poultry meat.

- Maintain specified temperatures during and after processing.

Meat Refrigeration Standards Overview

- Transport conditions for fresh meat in the Common Market

- Regulations for chilling and freezing meat

- Storage requirements for different meat products

- International standards and guidelines for meat refrigeration

Transport Conditions for Fresh Meat

- Meat transport in the Common Market must meet specific temperature standards

- Regulations apply to both intra-Community trade and imports

- Exceptions for abattoirs supplying meat for domestic consumption

Chilling and Freezing Standards

- Beef and veal carcasses designated for freezing must be chilled immediately post-slaughter

- Temperature limits for beef, veal, and pig meat

- Detailed regulations in South Africa for chilling and storage of meat

Storage Requirements

- Temperature ranges and humidity conditions for chilled meat storage

- Specific guidelines for storing offal

- Differences in regulations across countries based on operating practices

International Standards and Guidelines

- Codex Alimentarius Commission's recommendations for meat hygiene and refrigeration

- Practical points for handling meat fit for human consumption

- Guidelines for monitoring chilling and freezing processes

- Standards for meat storage in freezer stores

Conclusion

- Importance of adhering to refrigeration standards for meat safety and quality

- Continuous monitoring and adherence to international guidelines

- Ensuring proper handling and storage practices to prevent contamination

Effect Of Bacterial Growth On The Shelf-life Of Meat And Meat Products

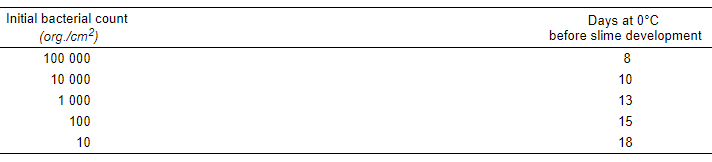

Bacterial growth significantly impacts the shelf-life of meat and meat products, with the total viable count of bacteria (TVC) being a critical measure. TVC, expressed as organisms per square centimeter (organisms/cm²) or per gram (organisms/g), dictates when meat spoils. Off-odours appear when TVC reaches 106 organisms/cm², and slime and discoloration occur at 108 organisms/cm². Factors influencing the time taken for TVC to reach these levels include initial contamination during slaughtering and processing, further contamination during storage, temperature, pH, and relative humidity.Key Points:

- Initial Contamination: Contamination during slaughtering and processing sets the initial bacterial count on the meat, affecting its shelf-life.

- Storage Conditions: Further contamination during storage, along with temperature, pH, and relative humidity, are crucial factors.

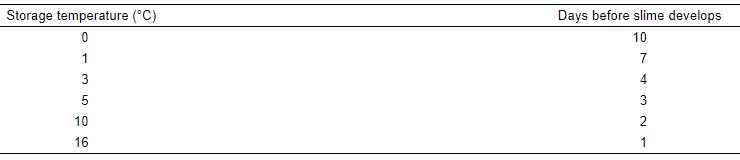

- Temperature Control: Keeping meat products cold is essential for extending shelf-life. Microbial growth accelerates at higher temperatures, with slime being a clear sign of bacterial proliferation.

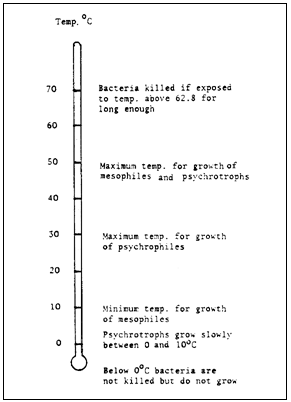

- Temperature Ranges for Bacterial Growth:

- Mesophiles: Grow between 10–45°C.

- Psychrophiles: Grow between 0–28°C.

- Psychrotrophs: Can grow between 10–45°C, with slow growth at 0–10°C.

Among these, Pseudomonas species are notable psychrotrophs capable of growing at temperatures as low as 0°C. The closer the storage temperature is to 0°C, the slower the spoilage bacteria grow, thus extending the meat's shelf-life.

TABLE 1: Effect of initial contamination on the storage life of lean beef

TABLE 1: Effect of initial contamination on the storage life of lean beef

TABLE 2: Relationship between storage temperature and slime development

TABLE 2: Relationship between storage temperature and slime development

Under ideal conditions bacteria double in number every 20 minutes. A single bacterium multiplies to over one million in less than seven hours:

Some bacteria cause product spoilage, others cause food poisoning. The former limit product shelf-life but the latter cause illness. Almost all foodpoisoning bacteria are mesophiles so refrigeration below 10°C offers good protection. Many mesophiles cause spoilage, but since meat is refrigerated most spoilage is due to psychrophiles. Storing meat at temperatures close to 0°C will inhibit the growth of pyschrotrophs. Shelf-life will be extended by avoiding contamination through good hygiene practices.

Aerobic bacteria have an absolute requirement for oxygen which limits their growth to the meat surface. Anaerobic bacteria grow within the meat as they need the absence of oxygen. Facultative anaerobes can grow slowly within oxygen but grow better in its presence. Food-poisoning bacteria are anaerobes and facultative anaerobes. The most important spoilage bacteria (Pseudomonas spp.) are aerobic.

Different types of bacteria can grow within different temperature ranges

Water is required by micro-organisms, so reducing the water available below the optimum level will prolong shelf-life. If meat is stored at a relative humidity (RH) below 95 percent, moisture will be lost from the surface. Since most spoilage bacteria, being aerobic, can grow only on the surface, this surface drying will extend the shelf-life. Moulds (fungi) are able to grow in drier conditions than bacteria, so desiccation has a selective effect on microbial growth.

Meat pH is the level of acidity in meat. Stored sugars are broken down to lactic acid. In living muscle, it is near 7.0 (above this is alkaline, below is acid). It falls to 5.4–5.6 within 24 hours. High final pH values result when animals are exhausted at slaughter, for instance because of fighting in lairage or transport. Spoilage bacteria multiply rapidly on high-pH meat and shorten the shelf-life. Exhausted animals should be rested before slaughter.

A high TVC resulting from severe contamination during slaughter or processing will shorten the shelf-life even in ideal conditions. It also indicates poor hygiene, so contamination with food-poisoning bacteria is likely.

Effect of Contamination on Sensoric Properties of Meat and Meat Products

Aerobic spoilage by bacteria and yeasts usually results in slime formation, undesirable odours, and flavours (taints). Colour changes, rancidity, tallowy or chalky flavours from the breakdown of lipids may also occur. Colour changes as a result of pigment oxidation may be grey, brown, or green discoloration. Aerobic spoilage by moulds results in a sticky surface, musty odours, alcohol flavours, and creamy, black, or green discoloration.

Anaerobic spoilage, which occurs either within the meat or on the surface in sealed containers where oxygen is absent or very limited, is marked by souring due to the production of organic acids and gases.

Food Poisoning

Food poisoning may be due to infection or intoxication. Infection is caused by the consumption of live bacteria, which multiply in the body producing characteristic symptoms. Intoxication is due to toxins in food produced by bacteria before the food was eaten. Toxins are chemical compounds which may linger in food with no microbes growing in it, and are therefore very dangerous.

- Salmonellae are facultative anaerobes which cause infectious food poisoning. Ten or 20 cells of Salmonella typhi are sufficient to cause typhoid, but 10,000 to 100,000 cells of other species may be necessary to cause an infection. Some are host-specific, affecting the animal from which the meat was produced but failing to cause infection when consumed by humans. Typical symptoms of salmonellosis include diarrhoea, fever, and vomiting. The illness may last one to 14 days after a 12 to 24-hour incubation period. Victims may excrete the bacteria for weeks after the symptoms subside. Poor personal hygiene will cause contamination of meat.

- Staphylococcus aureus is a facultative aerobe that causes intoxication. It lives in the nose, throat, hair, and skin and on animal hides. Meat is contaminated by handling and by sneezing or coughing. Minute amounts of the toxin will cause illness, which starts within one to eight hours of eating poisoned food. Nausea, vomiting, and shock may last for one to two days. On rare occasions, it is fatal. This bacterium does not produce off-odours or spoilage, so it cannot be easily checked. Refrigeration will control its growth. Cooking may destroy the bacteria but not the toxin as it is heat stable. It is particularly troublesome in cooked cured meats, normally as a result of recontamination after the curing process in subsequent handling, for instance during slicing.

- Clostridium botulinum, an anaerobe, produces the toxin botulin, one of the most poisonous substances known. This attacks the central nervous system causing death by respiratory paralysis. Dormant cells occur everywhere in the soil, fish, animals, and plants. High-moisture, low-acid, low-salt conditions at above 3°C favour growth and toxin production. Control measures must destroy spores or prevent growth and toxin formation. Botulism is usually due to undercooking processed meats. Pressure-cooking will give commercial sterility. Pasteurization (heating to 70°C) and adding salt (NaCl) and sodium nitrite (NaNO2) is used for canned ham. Refrigeration (0–10°C) is essential for vacuum-packed meats. Frozen storage prevents growth.

- Clostridium perfringens, an anaerobic bacterium, is a common cause of food poisoning but is rarely fatal. It grows well in warm meats, so it is usually found in leftover meats that have not been kept chilled and not been reheated to 70°C to kill the bacteria present. The main symptoms are diarrhoea and weakness, which last for 12 to 24 hours after an incubation period of eight to 20 hours.

FAQs on Hygienic Methods of Handling of Meat - Animal Husbandry & Veterinary Science Optional for UPSC

| 1. What are some common spoilage organisms found in meat? |  |

| 2. How can the quality of meat be improved post-slaughter? |  |

| 3. What are some regulatory provisions in the meat trade and industry? |  |

| 4. How does bacterial growth affect the shelf-life of meat and meat products? |  |

| 5. What are some hygienic methods of handling meat to prevent contamination? |  |