All questions of Solids for Grade 9 Exam

Material is said to be ductile if- a)a large amount of plastic deformation takes place between the elastic limit and the fracture point

- b)fracture occurs soon after the elastic limit is passed

- c)material cross section is not significantly reduced at failure

- d)material breaks suddenly at little elongation

Correct answer is option 'A'. Can you explain this answer?

Material is said to be ductile if

a)

a large amount of plastic deformation takes place between the elastic limit and the fracture point

b)

fracture occurs soon after the elastic limit is passed

c)

material cross section is not significantly reduced at failure

d)

material breaks suddenly at little elongation

|

|

Nandini Iyer answered |

A ductile material is one that can withstand a large amount of plastic deformation between the elastic limit and the fracture point.

A material that breaks suddenly when elongated or fracture occurs in it soon after the elastic limit is crossed is called a brittle material.

A ductile material that exhibits extra elongation or deformation and does not fracture is also referred as superplastic material.

A material that breaks suddenly when elongated or fracture occurs in it soon after the elastic limit is crossed is called a brittle material.

A ductile material that exhibits extra elongation or deformation and does not fracture is also referred as superplastic material.

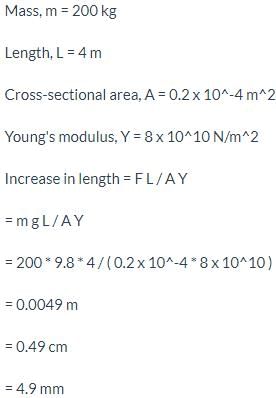

A 200-kg load is hung on a wire with a length of 4.00 m, a cross-sectional area of 0.200 × 10−4 m2, and a Young’s modulus of 8.00 × 1010N/ m2. What is its increase in length?- a)4.80 mm

- b)4.90 mm

- c)4.80 mm2.4.90 mm

- d)80 mm2.4.90 mm3.

Correct answer is option 'C'. Can you explain this answer?

A 200-kg load is hung on a wire with a length of 4.00 m, a cross-sectional area of 0.200 × 10−4 m2, and a Young’s modulus of 8.00 × 1010N/ m2. What is its increase in length?

a)

4.80 mm

b)

4.90 mm

c)

4.80 mm2.4.90 mm

d)

80 mm2.4.90 mm3.

|

|

Jyoti Sengupta answered |

You hang a flood lamp from the end of a vertical steel wire. The flood lamp stretches the wire 0.18 mm and the stress is proportional to the strain. How much would it have stretched if the wire had the same length but twice the diameter?- a)0.065 mm

- b)0.055 mm

- c)0.045 mm

- d)0.075 mm

Correct answer is option 'C'. Can you explain this answer?

You hang a flood lamp from the end of a vertical steel wire. The flood lamp stretches the wire 0.18 mm and the stress is proportional to the strain. How much would it have stretched if the wire had the same length but twice the diameter?

a)

0.065 mm

b)

0.055 mm

c)

0.045 mm

d)

0.075 mm

|

|

Pritam Kapoor answered |

Given:

- The flood lamp stretches the wire by 0.18 mm

- The stress is proportional to the strain

To find:

- How much would it have stretched if the wire had the same length but twice the diameter

Let's begin by understanding the given information.

Stress is defined as the force per unit area and is denoted by the symbol σ (sigma). Mathematically, stress is given by:

σ = F / A

where F is the force applied and A is the area over which the force is applied.

Strain is defined as the change in length per unit length and is denoted by the symbol ε (epsilon). Mathematically, strain is given by:

ε = ΔL / L

where ΔL is the change in length and L is the original length.

From the given information, we know that the stress is proportional to the strain. This can be expressed mathematically as:

σ ∝ ε

or

σ = kε

where k is a constant of proportionality.

Now, let's apply this information to the problem at hand.

When the flood lamp is hung from the wire, it exerts a force on the wire which causes it to stretch. Let's assume that the original diameter of the wire is d and the original length is L.

From the given information, we know that the stress is proportional to the strain. Therefore, we can write:

σ = kε

where σ is the stress, k is a constant of proportionality, and ε is the strain.

The stress can be calculated using the formula:

σ = F / A

where F is the force applied and A is the cross-sectional area of the wire.

The force applied is the weight of the flood lamp, which can be calculated using the formula:

F = mg

where m is the mass of the flood lamp and g is the acceleration due to gravity.

The cross-sectional area of the wire can be calculated using the formula:

A = πd^2 / 4

where d is the diameter of the wire.

Therefore, we can write:

σ = (mg) / (πd^2 / 4)

The strain can be calculated using the formula:

ε = ΔL / L

where ΔL is the change in length and L is the original length.

From the given information, we know that the flood lamp stretches the wire by 0.18 mm. Therefore, we can write:

ε = 0.18 / L

Now, let's combine the equations for stress and strain:

σ = kε

σ = (mg) / (πd^2 / 4)

ε = 0.18 / L

Substituting the values of σ and ε, we get:

(mg) / (πd^2 / 4) = k (0.18 / L)

Simplifying, we get:

k = (mgL) / (0.18πd^2)

Now, let's use this value of k to calculate the change in length when the diameter of the wire is doubled.

When the diameter of the wire is doubled, the cross-sectional area of the wire becomes 4 times the original area. Therefore, the new diameter is 2d and the new cross-sectional area is:

A' = π(2d)^2 / 4 = 4πd^2

Using the same formula for stress,

- The flood lamp stretches the wire by 0.18 mm

- The stress is proportional to the strain

To find:

- How much would it have stretched if the wire had the same length but twice the diameter

Let's begin by understanding the given information.

Stress is defined as the force per unit area and is denoted by the symbol σ (sigma). Mathematically, stress is given by:

σ = F / A

where F is the force applied and A is the area over which the force is applied.

Strain is defined as the change in length per unit length and is denoted by the symbol ε (epsilon). Mathematically, strain is given by:

ε = ΔL / L

where ΔL is the change in length and L is the original length.

From the given information, we know that the stress is proportional to the strain. This can be expressed mathematically as:

σ ∝ ε

or

σ = kε

where k is a constant of proportionality.

Now, let's apply this information to the problem at hand.

When the flood lamp is hung from the wire, it exerts a force on the wire which causes it to stretch. Let's assume that the original diameter of the wire is d and the original length is L.

From the given information, we know that the stress is proportional to the strain. Therefore, we can write:

σ = kε

where σ is the stress, k is a constant of proportionality, and ε is the strain.

The stress can be calculated using the formula:

σ = F / A

where F is the force applied and A is the cross-sectional area of the wire.

The force applied is the weight of the flood lamp, which can be calculated using the formula:

F = mg

where m is the mass of the flood lamp and g is the acceleration due to gravity.

The cross-sectional area of the wire can be calculated using the formula:

A = πd^2 / 4

where d is the diameter of the wire.

Therefore, we can write:

σ = (mg) / (πd^2 / 4)

The strain can be calculated using the formula:

ε = ΔL / L

where ΔL is the change in length and L is the original length.

From the given information, we know that the flood lamp stretches the wire by 0.18 mm. Therefore, we can write:

ε = 0.18 / L

Now, let's combine the equations for stress and strain:

σ = kε

σ = (mg) / (πd^2 / 4)

ε = 0.18 / L

Substituting the values of σ and ε, we get:

(mg) / (πd^2 / 4) = k (0.18 / L)

Simplifying, we get:

k = (mgL) / (0.18πd^2)

Now, let's use this value of k to calculate the change in length when the diameter of the wire is doubled.

When the diameter of the wire is doubled, the cross-sectional area of the wire becomes 4 times the original area. Therefore, the new diameter is 2d and the new cross-sectional area is:

A' = π(2d)^2 / 4 = 4πd^2

Using the same formula for stress,

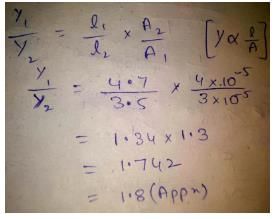

A steel wire of length 4.7 m and cross-sectional area 3.0 × 10−5 m2 stretches by the same amount as a copper wire of length 3.5 m and cross-sectional area of 4.0 × 10−5 m2 under a given load. What is the ratio of the Young’s modulus of steel to that of copper?- a)1.2

- b)1.6

- c)1.8

- d)2.0

Correct answer is option 'C'. Can you explain this answer?

A steel wire of length 4.7 m and cross-sectional area 3.0 × 10−5 m2 stretches by the same amount as a copper wire of length 3.5 m and cross-sectional area of 4.0 × 10−5 m2 under a given load. What is the ratio of the Young’s modulus of steel to that of copper?

a)

1.2

b)

1.6

c)

1.8

d)

2.0

|

|

Krishna Iyer answered |

What diameter should a 10-m-long steel wire have if we do not want it to stretch more than 0.5 cm under a tension of 940 N? Take Young's modulus of steel as 20 × 1010 Pa- a)3.2 mm

- b)3.0 mm

- c)3.4 mm

- d)3.6 mm

Correct answer is option 'C'. Can you explain this answer?

What diameter should a 10-m-long steel wire have if we do not want it to stretch more than 0.5 cm under a tension of 940 N? Take Young's modulus of steel as 20 × 1010 Pa

a)

3.2 mm

b)

3.0 mm

c)

3.4 mm

d)

3.6 mm

|

|

Rajesh Gupta answered |

Y=F x l/A x Δ l

Δ l=0.5cm=0.5x10-2m, l=10M, F=940N

Y=20x1010pa

20x1010=940x10/πr2x0.5x10-10

πr2=94x100/5x10-3x2x1011=94x102/10x108

r2=94/π x 10-7 =2.99 x 10-6

r2 ≅3x10-6

r=1.13x10-10 m

diameter=2r=3.6mm

Δ l=0.5cm=0.5x10-2m, l=10M, F=940N

Y=20x1010pa

20x1010=940x10/πr2x0.5x10-10

πr2=94x100/5x10-3x2x1011=94x102/10x108

r2=94/π x 10-7 =2.99 x 10-6

r2 ≅3x10-6

r=1.13x10-10 m

diameter=2r=3.6mm

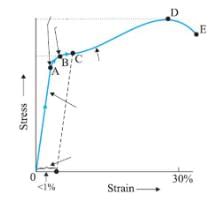

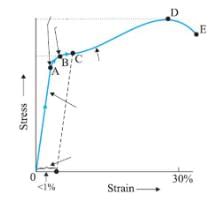

With reference to figure the elastic zone is

- a)BC

- b)CD

- c)AB

- d)OA

Correct answer is option 'D'. Can you explain this answer?

With reference to figure the elastic zone is

a)

BC

b)

CD

c)

AB

d)

OA

|

|

Hansa Sharma answered |

Hooke’s law: a law stating that the strain in a solid is proportional to the applied stress within the elastic limit of that solid.

In the OA line Hooke’s law is valid because stress is directly proportional to strain.

In the OA line Hooke’s law is valid because stress is directly proportional to strain.

You hang a flood lamp from the end of a vertical steel wire. The flood lamp stretches the wire 0.18 mm and the stress is proportional to the strain. How much would it have stretched if the wire were twice as long?- a)0.36 mm

- b)0.34 mm

- c)0.38 mm

- d)0.40 mm

Correct answer is option 'A'. Can you explain this answer?

You hang a flood lamp from the end of a vertical steel wire. The flood lamp stretches the wire 0.18 mm and the stress is proportional to the strain. How much would it have stretched if the wire were twice as long?

a)

0.36 mm

b)

0.34 mm

c)

0.38 mm

d)

0.40 mm

|

|

Rajesh Gupta answered |

F/A = e/L

F/A = 0.18/l ( let the length be l)

F/A = x/2l

0.18/L = x/2l

0.18×2l = xl

0.36l = xl

x = 0.36

F/A = 0.18/l ( let the length be l)

F/A = x/2l

0.18/L = x/2l

0.18×2l = xl

0.36l = xl

x = 0.36

The S.I unit of stress is- a)Watt

- b)Joule

- c)Pascal

- d)Newton

Correct answer is option 'C'. Can you explain this answer?

The S.I unit of stress is

a)

Watt

b)

Joule

c)

Pascal

d)

Newton

|

|

Krishna Iyer answered |

Stress has its own SI unit called the Pascal. 1 Pascal (Pa) is equal to 1 N/m2. In imperial units stress is measured in pound force per square inch which is often shortened to "psi". The dimension of stress is same as that of pressure.

Elasticity is the property of a body, by virtue of which- a)it remains in original size and shape when the force is applied

- b)it changes size and shape when the force is applied and stays in that shape when applied force is removed

- c)it tends to regain its original size and shape when the applied force is removed

- d)it is distorted or stretches without the application of force

Correct answer is option 'C'. Can you explain this answer?

Elasticity is the property of a body, by virtue of which

a)

it remains in original size and shape when the force is applied

b)

it changes size and shape when the force is applied and stays in that shape when applied force is removed

c)

it tends to regain its original size and shape when the applied force is removed

d)

it is distorted or stretches without the application of force

|

|

Suraj Raj answered |

A

According to Hooke’s law- a)For small deformations the stress and strain are inversely proportional to each other

- b)For small deformations the stress is proportional to square of strain

- c)For large deformations the stress and strain are proportional to each other

- d)For small deformations the stress and strain are proportional to each other

Correct answer is option 'D'. Can you explain this answer?

According to Hooke’s law

a)

For small deformations the stress and strain are inversely proportional to each other

b)

For small deformations the stress is proportional to square of strain

c)

For large deformations the stress and strain are proportional to each other

d)

For small deformations the stress and strain are proportional to each other

|

|

Krishna Iyer answered |

Hook’s Law states that for small deformations the stress and strain are proportional to each other.

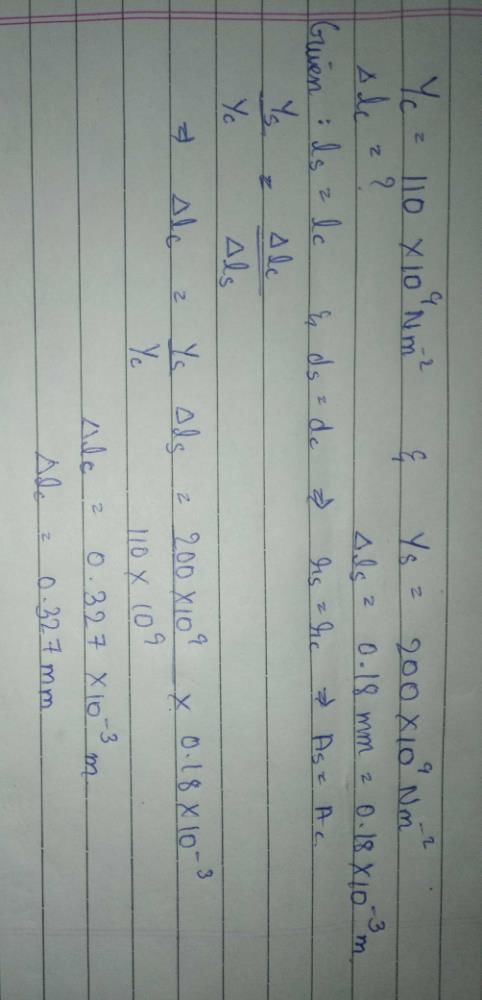

Two strips of metal are riveted together at their ends by four rivets, each of diameter 6.0 mm. What is the maximum tension that can be exerted by the riveted strip if the shearing stress on the rivet is not to exceed 6.9 × 107Pa? Assume that each rivet is to carry one quarter of the load.- a)749 kN

- b)856 kN

- c)652 N

- d)None of these

Correct answer is option 'D'. Can you explain this answer?

Two strips of metal are riveted together at their ends by four rivets, each of diameter 6.0 mm. What is the maximum tension that can be exerted by the riveted strip if the shearing stress on the rivet is not to exceed 6.9 × 107Pa? Assume that each rivet is to carry one quarter of the load.

a)

749 kN

b)

856 kN

c)

652 N

d)

None of these

|

|

Sanchita Mukherjee answered |

A steel rod 2.0 m long has a cross-sectional area of 0.30 cm2. It is hung by one end from a support, and a 550-kg milling machine is hung from its other end. Determine the elongation. Take Young's modulus of steel as 20 × 1010 Pa- a)2.0 mm

- b)1.6 mm

- c)2.2 mm

- d)1.8 mm

Correct answer is option 'D'. Can you explain this answer?

A steel rod 2.0 m long has a cross-sectional area of 0.30 cm2. It is hung by one end from a support, and a 550-kg milling machine is hung from its other end. Determine the elongation. Take Young's modulus of steel as 20 × 1010 Pa

a)

2.0 mm

b)

1.6 mm

c)

2.2 mm

d)

1.8 mm

|

|

Gaurav Kumar answered |

σ=Stress and ε=strain

σ=F/A= (550kg) × (9.81m/s2)3×10-5m2/=0.18GPA

ε=Δl/l0=σ/Υ=0.18×109/200×109=9×10-4

Δl=εl0= (9×10-4) (2m) = 0.0018m=1.8mm

σ=F/A= (550kg) × (9.81m/s2)3×10-5m2/=0.18GPA

ε=Δl/l0=σ/Υ=0.18×109/200×109=9×10-4

Δl=εl0= (9×10-4) (2m) = 0.0018m=1.8mm

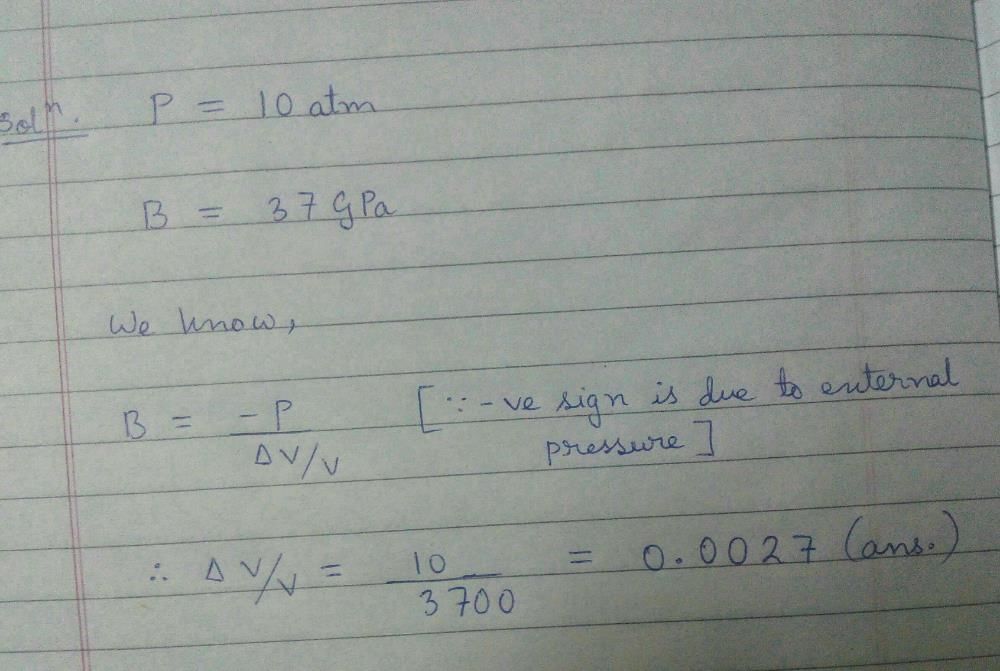

volume strain is defined- a)as the change in volume ΔV

- b)as the ratio of change in volume (ΔV) to the original volume V

- c)as the ratio of change in volume (ΔV) to thrice the original volume V

- d)as the ratio of change in volume (ΔV) to twice the original volume V

Correct answer is option 'B'. Can you explain this answer?

volume strain is defined

a)

as the change in volume ΔV

b)

as the ratio of change in volume (ΔV) to the original volume V

c)

as the ratio of change in volume (ΔV) to thrice the original volume V

d)

as the ratio of change in volume (ΔV) to twice the original volume V

|

|

Ameya Unni answered |

Understanding Volume Strain

Volume strain is an important concept in mechanics and materials science that describes how a material deforms when subjected to external forces.

Definition of Volume Strain

- Volume strain is defined specifically as the ratio of the change in volume (ΔV) to the original volume (V0) of a material.

- Mathematically, it can be expressed as: Volume Strain = ΔV / V0.

Why Option B is Correct

- Change in Volume (ΔV): This represents the difference between the final volume after deformation and the initial volume before deformation.

- Original Volume (V0): This is the volume of the material before any external forces have been applied.

- Ratio Significance: By taking the ratio of the change in volume to the original volume, we obtain a dimensionless quantity that allows for comparison across different materials and conditions.

Other Options Explained

- Option A (Change in Volume V): This does not provide a comparative metric and lacks the necessary context of the original volume.

- Option C (Thrice the Original Volume): This is an arbitrary scaling that does not conform to the standard definition of volume strain.

- Option D (Twice the Original Volume): Similar to Option C, this does not reflect the true relationship defined in mechanics.

Conclusion

In conclusion, volume strain is fundamentally about understanding how a material's volume changes relative to its original volume, which is effectively captured by Option B. This definition is crucial for engineers and scientists to assess material behavior under stress.

Volume strain is an important concept in mechanics and materials science that describes how a material deforms when subjected to external forces.

Definition of Volume Strain

- Volume strain is defined specifically as the ratio of the change in volume (ΔV) to the original volume (V0) of a material.

- Mathematically, it can be expressed as: Volume Strain = ΔV / V0.

Why Option B is Correct

- Change in Volume (ΔV): This represents the difference between the final volume after deformation and the initial volume before deformation.

- Original Volume (V0): This is the volume of the material before any external forces have been applied.

- Ratio Significance: By taking the ratio of the change in volume to the original volume, we obtain a dimensionless quantity that allows for comparison across different materials and conditions.

Other Options Explained

- Option A (Change in Volume V): This does not provide a comparative metric and lacks the necessary context of the original volume.

- Option C (Thrice the Original Volume): This is an arbitrary scaling that does not conform to the standard definition of volume strain.

- Option D (Twice the Original Volume): Similar to Option C, this does not reflect the true relationship defined in mechanics.

Conclusion

In conclusion, volume strain is fundamentally about understanding how a material's volume changes relative to its original volume, which is effectively captured by Option B. This definition is crucial for engineers and scientists to assess material behavior under stress.

Rectangular section is rarely used in beams because- a)stresses are uniform in a rectangular section

- b)more material in kilos is required

- c)stresses are always plastic in rectangular section

- d)less material in kilos is required

Correct answer is option 'B'. Can you explain this answer?

Rectangular section is rarely used in beams because

a)

stresses are uniform in a rectangular section

b)

more material in kilos is required

c)

stresses are always plastic in rectangular section

d)

less material in kilos is required

|

|

Anjali Iyer answered |

I section is generally used as a beam because of its high section modulus as it's most of the area is situated away from it's neutral axis hence it has high moment of inertia i.e high section modulus i.e high moment carrying capacity which is the major requirement for a good beam section.

A steel rod 2.0 m long has a cross-sectional area of 0.30 cm2 . It is hung by one end from a support, and a 550-kg milling machine is hung from its other end. Determine the resulting strain. Young's Modulus of Steel (Y) = 20×1010 Pa

- a)8.0 × 10−4

- b)10.0 × 10−4

- c)7.0 × 10−4

- d)9.0 × 10−4

Correct answer is option 'D'. Can you explain this answer?

A steel rod 2.0 m long has a cross-sectional area of 0.30 cm2 . It is hung by one end from a support, and a 550-kg milling machine is hung from its other end. Determine the resulting strain. Young's Modulus of Steel (Y) = 20×1010 Pa

a)

8.0 × 10−4

b)

10.0 × 10−4

c)

7.0 × 10−4

d)

9.0 × 10−4

|

|

Naina Bansal answered |

from the Hooke’s law :

ε = σ/Y = (1.8 x 10^8 Pa)/(20 x 10^10 Pa)

= 9.0 x 10^−4

Columns are loaded in- a)shear

- b)hydraulic stress

- c)tension

- d)compression

Correct answer is option 'D'. Can you explain this answer?

Columns are loaded in

a)

shear

b)

hydraulic stress

c)

tension

d)

compression

|

Madhavan Patel answered |

Alternation of generations (also known as metagenesis) is the type of life cycle that occurs in those plants and algae in the Archaeplastida and the Heterokontophyta that have distinct sexual haploid and asexual diploid stages.

Elastomers are materials- a)which can be stretched without corresponding stress

- b)which cannot be stretched to cause large strains

- c)which cannot be stretched to beyond elastic limit

- d)which can be stretched to cause large strains

Correct answer is option 'D'. Can you explain this answer?

Elastomers are materials

a)

which can be stretched without corresponding stress

b)

which cannot be stretched to cause large strains

c)

which cannot be stretched to beyond elastic limit

d)

which can be stretched to cause large strains

|

|

Rajeev Saxena answered |

An elastomer is a polymer with viscoelasticity (i. e., both viscosity and elasticity) and very weak intermolecular forces, and generally low Young's modulus and high failure strain compared with other materials. Elastomer rubber compounds are made from five to ten ingredients, each ingredient playing a specific role. Polymer is the main component, and determines heat and chemical resistance, as well as low- temperature performance. Reinforcing filler is used, typically carbon black, for strength properties.

A circular steel wire 2.00 m long must stretch no more than 0.25 cm when a tensile force of 400 N is applied to each end of the wire. What minimum diameter is required for the wire? Given that the Young's modulus for steel is Young's modulus of the material is 2.00×1011 N/m2)- a)1.4 mm

- b)10 mm

- c)1.5 mm

- d)12.4 mm

Correct answer is option 'A'. Can you explain this answer?

A circular steel wire 2.00 m long must stretch no more than 0.25 cm when a tensile force of 400 N is applied to each end of the wire. What minimum diameter is required for the wire? Given that the Young's modulus for steel is Young's modulus of the material is 2.00×1011 N/m2)

a)

1.4 mm

b)

10 mm

c)

1.5 mm

d)

12.4 mm

|

EduRev NEET answered |

A mild steel wire of length 1.0 m and cross-sectional area 0.50 × 10−2 cm2 is stretched, well within its elastic limit, horizontally between two pillars. A mass of 100 g is suspended from the mid-point of the wire. Calculate the depression at the midpoint.- a)1.1 cm

- b)1.0 cm

- c)0.9 cm

- d)1.2 cm

Correct answer is option 'A'. Can you explain this answer?

A mild steel wire of length 1.0 m and cross-sectional area 0.50 × 10−2 cm2 is stretched, well within its elastic limit, horizontally between two pillars. A mass of 100 g is suspended from the mid-point of the wire. Calculate the depression at the midpoint.

a)

1.1 cm

b)

1.0 cm

c)

0.9 cm

d)

1.2 cm

|

|

Siddharth Mehra answered |

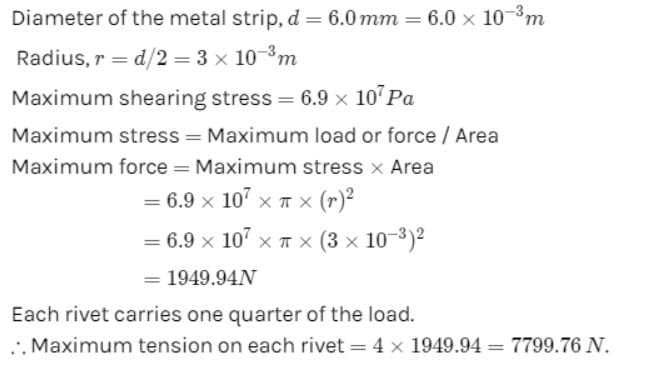

You hang a flood lamp from the end of a vertical steel wire. The flood lamp stretches the wire 0.18 mm and the stress is proportional to the strain. How much would it have stretched for a copper wire of the original length and diameter?- a)0.39 mm

- b)0.37 mm

- c)0.33 mm

- d)0.18 mm

Correct answer is option 'C'. Can you explain this answer?

You hang a flood lamp from the end of a vertical steel wire. The flood lamp stretches the wire 0.18 mm and the stress is proportional to the strain. How much would it have stretched for a copper wire of the original length and diameter?

a)

0.39 mm

b)

0.37 mm

c)

0.33 mm

d)

0.18 mm

|

|

Darshan Nagesh answered |

When a solid is deformed,- a)the atoms or molecules do not move from their equilibrium position

- b)only the atoms or molecules at some points move from their equilibrium position

- c)only the atoms or molecules of the surface move from their equilibrium position

- d)all the atoms or molecules are displaced from their equilibrium positions causing a change in inter atomic (or intermolecular) distances.

Correct answer is option 'D'. Can you explain this answer?

When a solid is deformed,

a)

the atoms or molecules do not move from their equilibrium position

b)

only the atoms or molecules at some points move from their equilibrium position

c)

only the atoms or molecules of the surface move from their equilibrium position

d)

all the atoms or molecules are displaced from their equilibrium positions causing a change in inter atomic (or intermolecular) distances.

|

Sravya Banerjee answered |

Explanation:External force permanently distubed the equilibrium position of the interatomic ( or intermolecular ) forces between the particles of solid bodies.

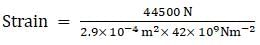

A piece of copper having a rectangular cross-section of 15.2 mm × 19.1 mm is pulled in tension with 44,500 N force, producing only elastic deformation. Calculate the resulting strain? Take Young's modulus of copper as 42 × 109Pa

- a)3.65 × 10-8

- b)3.65 × 10-3

- c)3.65 × 10-9

- d)3.65 × 10-2

Correct answer is option 'B'. Can you explain this answer?

A piece of copper having a rectangular cross-section of 15.2 mm × 19.1 mm is pulled in tension with 44,500 N force, producing only elastic deformation. Calculate the resulting strain? Take Young's modulus of copper as 42 × 10

9

Paa)

3.65 × 10-8

b)

3.65 × 10-3

c)

3.65 × 10-9

d)

3.65 × 10-2

|

|

Anjana Sharma answered |

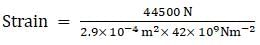

Given Data,

Length of the piece of copper = l = 19.1 mm = 19.1 × 10-3m

Breadth of the piece of copper = b = 15.2 mm = 15.2× 10-3m

Tension force applied on the piece of cooper, F = 44500N

Area of rectangular cross section of copper piece,

Area = l× b

⇒ Area = (19.1 × 10-3m) × (15.2× 10-3m)

⇒ Area = 2.9 × 10-4 m2

Modulus of elasticity of copper from standard list, η = 42× 109 N/m2

By definition, Modulus of elasticity, η = stress/strain

⇒ Strain = F/Aη

⇒ Strain = 3.65 × 10-3

Hence, the resulting strain is 3.65 × 10-3

Length of the piece of copper = l = 19.1 mm = 19.1 × 10-3m

Breadth of the piece of copper = b = 15.2 mm = 15.2× 10-3m

Tension force applied on the piece of cooper, F = 44500N

Area of rectangular cross section of copper piece,

Area = l× b

⇒ Area = (19.1 × 10-3m) × (15.2× 10-3m)

⇒ Area = 2.9 × 10-4 m2

Modulus of elasticity of copper from standard list, η = 42× 109 N/m2

By definition, Modulus of elasticity, η = stress/strain

⇒ Strain = F/Aη

⇒ Strain = 3.65 × 10-3

Hence, the resulting strain is 3.65 × 10-3

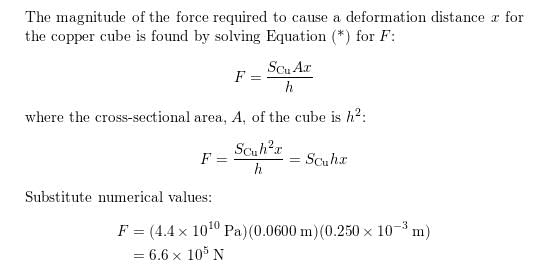

A lead cube measures 6.00 cm on each side. The bottom face is held in place by very strong glue to a flat horizontal surface, while a horizontal force F is applied to the upper face parallel to one of the edges. How large must F be to cause the cube to deform by 0.250 mm? (Shear modulus of lead = 0.6 × 1010Pa)- a)7.0 * 105 N

- b)6* 105 N

- c)6.6 * 105 N

- d)5.6 * 105 N

Correct answer is option 'C'. Can you explain this answer?

A lead cube measures 6.00 cm on each side. The bottom face is held in place by very strong glue to a flat horizontal surface, while a horizontal force F is applied to the upper face parallel to one of the edges. How large must F be to cause the cube to deform by 0.250 mm? (Shear modulus of lead = 0.6 × 1010Pa)

a)

7.0 * 105 N

b)

6* 105 N

c)

6.6 * 105 N

d)

5.6 * 105 N

|

|

Sanchita Mukherjee answered |

The importance of the elastic behavior of materials is- a)that it is useful in making springs

- b)that it enables a safe and sound design of bridges, buildings, machinery parts.

- c)that it is useful in building sling shots

- d)that it gives methods for understanding materials

Correct answer is option 'B'. Can you explain this answer?

The importance of the elastic behavior of materials is

a)

that it is useful in making springs

b)

that it enables a safe and sound design of bridges, buildings, machinery parts.

c)

that it is useful in building sling shots

d)

that it gives methods for understanding materials

|

Puja Das answered |

Explanation:More the elastic a material is , more it has the property to regain its original position which is required in construction works.

Shear modulus or modulus of rigidity is- a)the ratio of shearing stress to the corresponding lateral strain

- b)the ratio of shearing stress to the corresponding shearing strain

- c)the ratio of longitudinal stress to the corresponding shearing strain

- d)the ratio of shearing strain to the corresponding shearing stress

Correct answer is option 'B'. Can you explain this answer?

Shear modulus or modulus of rigidity is

a)

the ratio of shearing stress to the corresponding lateral strain

b)

the ratio of shearing stress to the corresponding shearing strain

c)

the ratio of longitudinal stress to the corresponding shearing strain

d)

the ratio of shearing strain to the corresponding shearing stress

|

|

Ameya Choudhury answered |

Shear modulus or modulus of rigidity is the ratio of shearing stress to the corresponding shearing strain, by the definition of shear modulus.

In constructing a large mobile, an artist hangs an aluminum sphere of mass 6.0 kg from a vertical steel wire 0.50 m long and 2.5 × 10−3 cm2in cross-sectional area. On the bottom of the sphere he attaches a similar steel wire, from which he hangs a brass cube of mass 10.0 kg. Compute the elongation.- a)3.7 mm upper, 1.0 mm lower

- b)3.4 mm upper, 1.0 mm lower

- c)3.5 mm upper, 1.1 mm lower

- d)1.6 mm upper, 1.0 mm lower

Correct answer is option 'D'. Can you explain this answer?

In constructing a large mobile, an artist hangs an aluminum sphere of mass 6.0 kg from a vertical steel wire 0.50 m long and 2.5 × 10−3 cm2in cross-sectional area. On the bottom of the sphere he attaches a similar steel wire, from which he hangs a brass cube of mass 10.0 kg. Compute the elongation.

a)

3.7 mm upper, 1.0 mm lower

b)

3.4 mm upper, 1.0 mm lower

c)

3.5 mm upper, 1.1 mm lower

d)

1.6 mm upper, 1.0 mm lower

|

|

Muskaan Kumar answered |

Hence 1.6 mm upper, 1.0 mm lower is correct.

Stress is- a)force per unit length

- b)force per unit area

- c)total applied force

- d)three point average of forces

Correct answer is option 'B'. Can you explain this answer?

Stress is

a)

force per unit length

b)

force per unit area

c)

total applied force

d)

three point average of forces

|

|

Yash Unni answered |

The Explanation:

Stress is defined as the force per unit area. It is a measure of how much force is being applied to a given area. Stress can be experienced by objects or materials when an external force is applied to them.

Force per Unit Area:

Stress is calculated by dividing the force applied on an object or material by the area over which the force is applied. It represents the intensity of the force distributed over the surface area. The formula for stress is:

Stress = Force / Area

Types of Stress:

There are different types of stress based on the type of forces applied. Some of the common types of stress include:

1. Tensile Stress: This type of stress occurs when a material is being stretched or pulled apart. It is represented by a positive value.

2. Compressive Stress: This type of stress occurs when a material is being compressed or pushed together. It is represented by a negative value.

3. Shear Stress: This type of stress occurs when a material is being subjected to forces parallel to its surface.

4. Bending Stress: This type of stress occurs when a material is being bent or subjected to bending forces.

Significance of Stress:

Stress is an important concept in engineering and materials science. It helps engineers and scientists understand how materials behave under different conditions and forces. By studying stress, they can design structures and materials that can withstand the expected forces and loads.

Measurement of Stress:

Stress can be measured using different instruments such as strain gauges, load cells, and pressure sensors. These instruments measure the applied force and the area over which the force is distributed.

Relation to Option 'B':

Option 'B' states that stress is the force per unit area, which is the correct definition of stress. Stress is not the force per unit length (Option 'A'), total applied force (Option 'C'), or the three-point average of forces (Option 'D).

In conclusion, stress is the force per unit area and is an important concept in engineering and materials science. It helps in understanding how materials respond to external forces and is measured using various instruments.

Stress is defined as the force per unit area. It is a measure of how much force is being applied to a given area. Stress can be experienced by objects or materials when an external force is applied to them.

Force per Unit Area:

Stress is calculated by dividing the force applied on an object or material by the area over which the force is applied. It represents the intensity of the force distributed over the surface area. The formula for stress is:

Stress = Force / Area

Types of Stress:

There are different types of stress based on the type of forces applied. Some of the common types of stress include:

1. Tensile Stress: This type of stress occurs when a material is being stretched or pulled apart. It is represented by a positive value.

2. Compressive Stress: This type of stress occurs when a material is being compressed or pushed together. It is represented by a negative value.

3. Shear Stress: This type of stress occurs when a material is being subjected to forces parallel to its surface.

4. Bending Stress: This type of stress occurs when a material is being bent or subjected to bending forces.

Significance of Stress:

Stress is an important concept in engineering and materials science. It helps engineers and scientists understand how materials behave under different conditions and forces. By studying stress, they can design structures and materials that can withstand the expected forces and loads.

Measurement of Stress:

Stress can be measured using different instruments such as strain gauges, load cells, and pressure sensors. These instruments measure the applied force and the area over which the force is distributed.

Relation to Option 'B':

Option 'B' states that stress is the force per unit area, which is the correct definition of stress. Stress is not the force per unit length (Option 'A'), total applied force (Option 'C'), or the three-point average of forces (Option 'D).

In conclusion, stress is the force per unit area and is an important concept in engineering and materials science. It helps in understanding how materials respond to external forces and is measured using various instruments.

Chapter doubts & questions for Solids - Physics 2025 is part of Grade 9 exam preparation. The chapters have been prepared according to the Grade 9 exam syllabus. The Chapter doubts & questions, notes, tests & MCQs are made for Grade 9 2025 Exam. Find important definitions, questions, notes, meanings, examples, exercises, MCQs and online tests here.

Chapter doubts & questions of Solids - Physics in English & Hindi are available as part of Grade 9 exam.

Download more important topics, notes, lectures and mock test series for Grade 9 Exam by signing up for free.

Physics

307 videos|482 docs|202 tests

|

Contact Support

Our team is online on weekdays between 10 AM - 7 PM

Typical reply within 3 hours

|

Free Exam Preparation

at your Fingertips!

Access Free Study Material - Test Series, Structured Courses, Free Videos & Study Notes and Prepare for Your Exam With Ease

Join the 10M+ students on EduRev

Join the 10M+ students on EduRev

|

|

Create your account for free

OR

Forgot Password

OR

Signup on EduRev and stay on top of your study goals

10M+ students crushing their study goals daily