All Exams >

Mechanical Engineering >

Topicwise Question Bank for Mechanical Engineering >

All Questions

All questions of I.C Engine for Mechanical Engineering Exam

Gudgeon pin forms the link between- a)piston and big end of connecting rod

- b)piston and small end of connecing rod

- c)connecting rod and crank

- d)big end and small end

Correct answer is option 'B'. Can you explain this answer?

Gudgeon pin forms the link between

a)

piston and big end of connecting rod

b)

piston and small end of connecing rod

c)

connecting rod and crank

d)

big end and small end

|

|

Neha Joshi answered |

In internal combustion engines, the gudgeon pin (UK, wrist pin or piston pin US) connects the piston to the connecting rod, and provides a bearing for the connecting rod to pivot upon as the piston moves.

The SI engines are not supercharged due to- a)power loss

- b)heavy engine structure

- c)increased knocking

- d)drop in volumetric efficiency

Correct answer is option 'C'. Can you explain this answer?

The SI engines are not supercharged due to

a)

power loss

b)

heavy engine structure

c)

increased knocking

d)

drop in volumetric efficiency

|

|

Lavanya Menon answered |

The degree of supercharging in SI engines is limited by the knock. The increase in P and T reduces ignition delay and consequently increases the knocking tendency.

For a given compression ratio the work output of Otto cycle is- a)increases with increase in compression ratio

- b)decreases with increase in compression ratio

- c)is not affected by compression ratio

- d)none of the above

Correct answer is option 'A'. Can you explain this answer?

For a given compression ratio the work output of Otto cycle is

a)

increases with increase in compression ratio

b)

decreases with increase in compression ratio

c)

is not affected by compression ratio

d)

none of the above

|

|

Avinash Sharma answered |

As compression ratio increases, the thermal efficiency of cycle increases and for the same heat input workout put increases.

What material is used for the insulating body of a spark plug ?- a)Silica

- b)Dolomite

- c)Alumina

- d)Glass

Correct answer is option 'C'. Can you explain this answer?

What material is used for the insulating body of a spark plug ?

a)

Silica

b)

Dolomite

c)

Alumina

d)

Glass

|

|

Gaurav Kapoor answered |

Insulating Body of a Spark Plug

The insulating body of a spark plug is an essential component in an internal combustion engine. It is responsible for preventing the leakage of high voltage electrical current from the electrode to the engine block. The insulating body is made up of a high-temperature ceramic material that can withstand the extreme conditions inside an engine.

Material Used for the Insulating Body

The most commonly used material for the insulating body of a spark plug is alumina. Alumina is a ceramic material that is made up of aluminum oxide. It has excellent thermal and electrical insulation properties, making it an ideal material for use in spark plugs.

Advantages of Alumina

Alumina is a widely used material for the insulating body of a spark plug because of its numerous advantages, including:

1. High melting point: Alumina has a high melting point, which makes it resistant to high-temperature conditions inside an engine.

2. High electrical resistance: Alumina has high electrical resistance, which prevents the leakage of high voltage electrical current from the electrode to the engine block.

3. Chemical resistance: Alumina is chemically inert and is resistant to corrosion from engine fluids and gases.

4. Low thermal expansion: Alumina has a low coefficient of thermal expansion, which means it expands very little when exposed to high temperatures, reducing the risk of cracking.

Conclusion

In conclusion, the insulating body of a spark plug is typically made up of alumina, a high-temperature ceramic material with excellent electrical and thermal insulation properties. Alumina's high melting point, electrical resistance, chemical resistance, and low thermal expansion make it a suitable material for use in spark plugs.

The insulating body of a spark plug is an essential component in an internal combustion engine. It is responsible for preventing the leakage of high voltage electrical current from the electrode to the engine block. The insulating body is made up of a high-temperature ceramic material that can withstand the extreme conditions inside an engine.

Material Used for the Insulating Body

The most commonly used material for the insulating body of a spark plug is alumina. Alumina is a ceramic material that is made up of aluminum oxide. It has excellent thermal and electrical insulation properties, making it an ideal material for use in spark plugs.

Advantages of Alumina

Alumina is a widely used material for the insulating body of a spark plug because of its numerous advantages, including:

1. High melting point: Alumina has a high melting point, which makes it resistant to high-temperature conditions inside an engine.

2. High electrical resistance: Alumina has high electrical resistance, which prevents the leakage of high voltage electrical current from the electrode to the engine block.

3. Chemical resistance: Alumina is chemically inert and is resistant to corrosion from engine fluids and gases.

4. Low thermal expansion: Alumina has a low coefficient of thermal expansion, which means it expands very little when exposed to high temperatures, reducing the risk of cracking.

Conclusion

In conclusion, the insulating body of a spark plug is typically made up of alumina, a high-temperature ceramic material with excellent electrical and thermal insulation properties. Alumina's high melting point, electrical resistance, chemical resistance, and low thermal expansion make it a suitable material for use in spark plugs.

When crude oil is heated, then which one of the following hydrocarbon is given off first?- a)Gasoline

- b)Paraffin

- c)Diesel

- d)Natural gas

Correct answer is option 'D'. Can you explain this answer?

When crude oil is heated, then which one of the following hydrocarbon is given off first?

a)

Gasoline

b)

Paraffin

c)

Diesel

d)

Natural gas

|

|

Avinash Sharma answered |

Crude petroleum, as obtained from the oil wells contains gases and certain impurities such as water, solids etc. The crude oil is separated into gasoline, kerosine, fuel oil etc. by the process of fractional distillation. In the first step, the petroleum is passed through a separator in which gases are removed and a product known as natural gasoline is obtained.

Which among following additional systems is not added to simple carburettor to make a complete carburetor ?- a)Throttle valve

- b)Main metering system

- c)Economiser

- d)Choke

Correct answer is option 'A'. Can you explain this answer?

Which among following additional systems is not added to simple carburettor to make a complete carburetor ?

a)

Throttle valve

b)

Main metering system

c)

Economiser

d)

Choke

|

|

Yash Patel answered |

Following additional systems are added:

- Main metering system.

- idling system.

- Power enrichment by economiser system.

- Acceleration pump system.

- Choke.

- Throttle valve is common.

Mean effective pressure of Otto cycle is- a)inversely proportional to pressure ratio

- b)directly proportional to pressure ratio

- c)does not depend on pressure ratio

- d)proportional to square root of pressure ratio

Correct answer is option 'B'. Can you explain this answer?

Mean effective pressure of Otto cycle is

a)

inversely proportional to pressure ratio

b)

directly proportional to pressure ratio

c)

does not depend on pressure ratio

d)

proportional to square root of pressure ratio

|

|

Rhea Reddy answered |

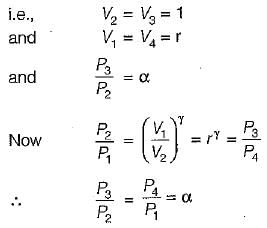

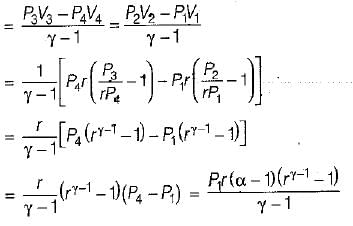

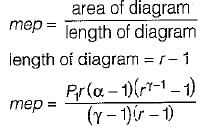

Mean effective pressure (mep) of Otto cycle: Let clearance volume be unity

Work done - area of the P-V'diagram

Hence mean effective pressure is directly proportional to pressure ratio (α) i.e., P1/P2

Valve overlap is the period in which

- a)intake valve is open while exhaust valve is closed.

- b)intake valve is closed while exhaust valve is open.

- c)the exhaust and intake cycles overlapping each other.

- d)both intake and exhaust valves are closed

Correct answer is option 'C'. Can you explain this answer?

Valve overlap is the period in which

a)

intake valve is open while exhaust valve is closed.

b)

intake valve is closed while exhaust valve is open.

c)

the exhaust and intake cycles overlapping each other.

d)

both intake and exhaust valves are closed

|

Keshav answered |

This valve timing is known as "overlap." Think of this as the exhaust and intake cycles overlapping each other. The valves are timed so the intake valve opens slightly before the piston reaches top dead center (TDC) on the exhaust stroke.

Consider the following statements for a multijet carburettor:

1. Acceleration jet is located just behind the throttle valve.

2. Main jet alone supplies petrol at normal range of engine speed.

3. It has higher volumetric efficiency.

4. it has robust design.Which of these statements are correct ?- a)1,2, 3 and 4

- b)1,2 and 3

- c)1,3 and 4

- d)2, 3, and 4

Correct answer is option 'A'. Can you explain this answer?

Consider the following statements for a multijet carburettor:

1. Acceleration jet is located just behind the throttle valve.

2. Main jet alone supplies petrol at normal range of engine speed.

3. It has higher volumetric efficiency.

4. it has robust design.

1. Acceleration jet is located just behind the throttle valve.

2. Main jet alone supplies petrol at normal range of engine speed.

3. It has higher volumetric efficiency.

4. it has robust design.

Which of these statements are correct ?

a)

1,2, 3 and 4

b)

1,2 and 3

c)

1,3 and 4

d)

2, 3, and 4

|

Ishani Basu answered |

Following are the advantages of multijet carburettors:

- Uniform quality of supply mixture.

- Higher volumetric efficiency.

- Even distribution of charge.

- Compact in its design.

Consider the following statements:

1. Petrol engines are quantity governed.

2. SI engine combustion is heteroge-neous.

3. Lean mixturer is required during idling.

4. Choke supplies rich mixture for cold starting.

5. Stoichiometric AJFratio for IC engine fuels is about 18.Which of these are correct statements ?- a)1,2, 4 and 5

- b)1 and 4

- c)1,3 and 4

- d)3 and 4

Correct answer is option 'B'. Can you explain this answer?

Consider the following statements:

1. Petrol engines are quantity governed.

2. SI engine combustion is heteroge-neous.

3. Lean mixturer is required during idling.

4. Choke supplies rich mixture for cold starting.

5. Stoichiometric AJFratio for IC engine fuels is about 18.

1. Petrol engines are quantity governed.

2. SI engine combustion is heteroge-neous.

3. Lean mixturer is required during idling.

4. Choke supplies rich mixture for cold starting.

5. Stoichiometric AJFratio for IC engine fuels is about 18.

Which of these are correct statements ?

a)

1,2, 4 and 5

b)

1 and 4

c)

1,3 and 4

d)

3 and 4

|

Sarthak Menon answered |

Combustion in SI engine is homogeneous

Rich mixture is required during idling

Stoichiometric A/F ratio for 1C engine fuels is about 15.

Rich mixture is required during idling

Stoichiometric A/F ratio for 1C engine fuels is about 15.

The delay period in a petrol engine is of the order of- a)0.001 sec

- b)0.002 sec

- c)0.01 sec

- d)0.05 sec

Correct answer is option 'B'. Can you explain this answer?

The delay period in a petrol engine is of the order of

a)

0.001 sec

b)

0.002 sec

c)

0.01 sec

d)

0.05 sec

|

|

Gaurav Kapoor answered |

The delay period is very short, about 0.002 sec. In high speed engines, this period will lead to significant crank movement.

A hot plug has- a)long insulation tip

- b)long threaded portion

- c)long path for heat dissipation

- d)is generally used in heavy duty, high speed engines

Correct answer is option 'A'. Can you explain this answer?

A hot plug has

a)

long insulation tip

b)

long threaded portion

c)

long path for heat dissipation

d)

is generally used in heavy duty, high speed engines

|

|

Ruchi Ahuja answered |

Insulator tip length is the most significant design parameter which controls the spark plug heat range or operating temperature, A hot plug generally have a long insulator tip, hence a long heat rejection path.

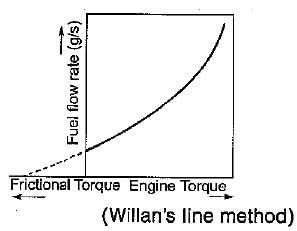

The measurement of frictional power by Willians line is applicable to- a)SI engines at a particular speed.

- b)Cl engines at a particular speed.

- c)any engine at a particular speed only.

- d)Dual fuel engines at a particular speed.

Correct answer is option 'B'. Can you explain this answer?

The measurement of frictional power by Willians line is applicable to

a)

SI engines at a particular speed.

b)

Cl engines at a particular speed.

c)

any engine at a particular speed only.

d)

Dual fuel engines at a particular speed.

|

Madhurima Banerjee answered |

Addition of TEL in gasoline is being discontinued as- a)it has bad odour

- b)it is costly

- c)decreases engine efficiency

- d)blocks the catalytic converter

Correct answer is option 'D'. Can you explain this answer?

Addition of TEL in gasoline is being discontinued as

a)

it has bad odour

b)

it is costly

c)

decreases engine efficiency

d)

blocks the catalytic converter

|

|

Sparsh Chakraborty answered |

Discontinuation of TEL in Gasoline

Introduction:

Tetraethyl lead (TEL) is an organic compound that has been widely used as an octane booster in gasoline. However, in recent years, there has been a growing concern over the health and environmental impacts of TEL. As a result, many countries have discontinued the use of TEL in gasoline. In this article, we will discuss why the addition of TEL in gasoline is being discontinued.

Blocking of Catalytic Converter:

One of the main reasons why TEL is being discontinued in gasoline is because it blocks the catalytic converter. The catalytic converter is an emission control device that reduces the amount of harmful pollutants that are emitted from the exhaust system of a vehicle. However, TEL reacts with the catalyst in the converter and forms a lead-based deposit that clogs the converter, reducing its efficiency and causing it to fail.

Health and Environmental Concerns:

TEL is also a toxic substance that can have serious health and environmental impacts. Exposure to TEL can cause neurological damage, kidney damage, reproductive issues, and even death. Additionally, TEL is a major source of lead pollution in the environment, which can lead to soil and water contamination.

Cost and Odour:

Apart from the health and environmental concerns, TEL is also costly to produce and transport. In addition, it has a distinct and unpleasant odour, which can be a nuisance for those who live near refineries or gasoline stations.

Conclusion:

In conclusion, the addition of TEL in gasoline is being discontinued mainly because it blocks the catalytic converter, poses health and environmental risks, is costly, and has an unpleasant odour. The discontinuation of TEL in gasoline is a positive step towards reducing pollution and protecting public health.

Introduction:

Tetraethyl lead (TEL) is an organic compound that has been widely used as an octane booster in gasoline. However, in recent years, there has been a growing concern over the health and environmental impacts of TEL. As a result, many countries have discontinued the use of TEL in gasoline. In this article, we will discuss why the addition of TEL in gasoline is being discontinued.

Blocking of Catalytic Converter:

One of the main reasons why TEL is being discontinued in gasoline is because it blocks the catalytic converter. The catalytic converter is an emission control device that reduces the amount of harmful pollutants that are emitted from the exhaust system of a vehicle. However, TEL reacts with the catalyst in the converter and forms a lead-based deposit that clogs the converter, reducing its efficiency and causing it to fail.

Health and Environmental Concerns:

TEL is also a toxic substance that can have serious health and environmental impacts. Exposure to TEL can cause neurological damage, kidney damage, reproductive issues, and even death. Additionally, TEL is a major source of lead pollution in the environment, which can lead to soil and water contamination.

Cost and Odour:

Apart from the health and environmental concerns, TEL is also costly to produce and transport. In addition, it has a distinct and unpleasant odour, which can be a nuisance for those who live near refineries or gasoline stations.

Conclusion:

In conclusion, the addition of TEL in gasoline is being discontinued mainly because it blocks the catalytic converter, poses health and environmental risks, is costly, and has an unpleasant odour. The discontinuation of TEL in gasoline is a positive step towards reducing pollution and protecting public health.

Blending of fuel is the process of

- a)obtaining a product of desired quality.

- b)just mixing two fuels.

- c)mixing of fuel and air for combustion.

- d)converting unstable compounds into stable ones

Correct answer is option 'B'. Can you explain this answer?

Blending of fuel is the process of

a)

obtaining a product of desired quality.

b)

just mixing two fuels.

c)

mixing of fuel and air for combustion.

d)

converting unstable compounds into stable ones

|

Anmol Roy answered |

Blending of fuel

Fuel blending is the process of combining different types or grades of fuel in order to achieve a product with specific properties or qualities. It involves mixing fuels in specific proportions to obtain a final product that meets the desired standards or requirements.

Benefits of fuel blending

Fuel blending offers several benefits, including:

1. Quality control: Blending allows for precise control over the properties of the final fuel product, ensuring that it meets the desired specifications and standards.

2. Cost optimization: By blending different fuels, it is possible to achieve a product that provides optimal performance at a lower cost. This is particularly important in industries such as transportation and power generation, where fuel costs represent a significant portion of the overall expenses.

3. Emission reduction: Blending fuels can help reduce harmful emissions by optimizing the combustion process. By adjusting the fuel composition, it is possible to achieve a cleaner and more efficient combustion, resulting in lower emissions of pollutants such as nitrogen oxides (NOx), sulfur oxides (SOx), and particulate matter (PM).

4. Availability: Fuel blending can also help overcome supply constraints by allowing the use of alternative or less expensive fuel sources. By blending different fuels, it is possible to utilize locally available resources or by-products from other industries, reducing dependence on imported fuels.

Process of fuel blending

The process of fuel blending involves several steps:

1. Fuel analysis: The first step is to analyze the properties and characteristics of the fuels that will be used in the blending process. This includes measuring parameters such as density, viscosity, flash point, sulfur content, and calorific value.

2. Formulation: Based on the desired specifications of the final product, a formulation is developed that determines the proportions of each fuel component. This formulation takes into account the desired properties, regulatory requirements, and cost considerations.

3. Mixing: The fuels are then mixed together in the prescribed proportions. This can be done using mechanical blending equipment such as tanks, pumps, and mixers. The mixing process ensures that the different fuel components are thoroughly combined to achieve a homogenous blend.

4. Quality control: After the blending process, the final fuel product is tested to ensure that it meets the desired specifications. This includes conducting tests for parameters such as density, viscosity, flash point, sulfur content, and octane or cetane number.

By following these steps, the blending process ensures that the final fuel product has the desired quality and meets the specific requirements for its intended use.

In conclusion, blending of fuel is the process of combining different fuels in specific proportions to obtain a product of desired quality. It allows for quality control, cost optimization, emission reduction, and improved availability of fuel. The process involves fuel analysis, formulation, mixing, and quality control to ensure that the final product meets the desired specifications.

Fuel blending is the process of combining different types or grades of fuel in order to achieve a product with specific properties or qualities. It involves mixing fuels in specific proportions to obtain a final product that meets the desired standards or requirements.

Benefits of fuel blending

Fuel blending offers several benefits, including:

1. Quality control: Blending allows for precise control over the properties of the final fuel product, ensuring that it meets the desired specifications and standards.

2. Cost optimization: By blending different fuels, it is possible to achieve a product that provides optimal performance at a lower cost. This is particularly important in industries such as transportation and power generation, where fuel costs represent a significant portion of the overall expenses.

3. Emission reduction: Blending fuels can help reduce harmful emissions by optimizing the combustion process. By adjusting the fuel composition, it is possible to achieve a cleaner and more efficient combustion, resulting in lower emissions of pollutants such as nitrogen oxides (NOx), sulfur oxides (SOx), and particulate matter (PM).

4. Availability: Fuel blending can also help overcome supply constraints by allowing the use of alternative or less expensive fuel sources. By blending different fuels, it is possible to utilize locally available resources or by-products from other industries, reducing dependence on imported fuels.

Process of fuel blending

The process of fuel blending involves several steps:

1. Fuel analysis: The first step is to analyze the properties and characteristics of the fuels that will be used in the blending process. This includes measuring parameters such as density, viscosity, flash point, sulfur content, and calorific value.

2. Formulation: Based on the desired specifications of the final product, a formulation is developed that determines the proportions of each fuel component. This formulation takes into account the desired properties, regulatory requirements, and cost considerations.

3. Mixing: The fuels are then mixed together in the prescribed proportions. This can be done using mechanical blending equipment such as tanks, pumps, and mixers. The mixing process ensures that the different fuel components are thoroughly combined to achieve a homogenous blend.

4. Quality control: After the blending process, the final fuel product is tested to ensure that it meets the desired specifications. This includes conducting tests for parameters such as density, viscosity, flash point, sulfur content, and octane or cetane number.

By following these steps, the blending process ensures that the final fuel product has the desired quality and meets the specific requirements for its intended use.

In conclusion, blending of fuel is the process of combining different fuels in specific proportions to obtain a product of desired quality. It allows for quality control, cost optimization, emission reduction, and improved availability of fuel. The process involves fuel analysis, formulation, mixing, and quality control to ensure that the final product meets the desired specifications.

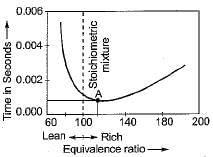

In SI engines, maximum flame speed is obtained when the equivalence ratio is between- a)1.1 and 1.2

- b)1.0 and 1.1

- c)1.2 and 1.3

- d)>1.3

Correct answer is option 'A'. Can you explain this answer?

In SI engines, maximum flame speed is obtained when the equivalence ratio is between

a)

1.1 and 1.2

b)

1.0 and 1.1

c)

1.2 and 1.3

d)

>1.3

|

|

Ayush Chawla answered |

The highest flame speed (minimum time for complete combustion) is obtained with richer mixture (Point A).

The best method of measuring speed is by- a)mechanical tachometer

- b)electrical tachometer

- c)magnetic pickup

- d)none of these

Correct answer is option 'C'. Can you explain this answer?

The best method of measuring speed is by

a)

mechanical tachometer

b)

electrical tachometer

c)

magnetic pickup

d)

none of these

|

|

Zoya Sharma answered |

Mechanical or electrical tachometer can also be used for measuring are not very accurate. For accurate and continuous measurements of speed of magnetic pick-up placed area a toothed wheel coupled to the engine shaft is used. The magnetic pick-up will produce a pulse for every revolution and a pulse counter will accurately measure the speed.

Which one of the following is NOT a necessary assumption for the air-standard Otto cycle?- a)All processes are both internally as well as externally reversible

- b)Intake and exhaust processes are constant volume heat rejection processes

- c)The combustion process is a constant volume heat addition process

- d)The working fluid is an ideal gas With constant specific heats

Correct answer is option 'B'. Can you explain this answer?

Which one of the following is NOT a necessary assumption for the air-standard Otto cycle?

a)

All processes are both internally as well as externally reversible

b)

Intake and exhaust processes are constant volume heat rejection processes

c)

The combustion process is a constant volume heat addition process

d)

The working fluid is an ideal gas With constant specific heats

|

Manasa Bose answered |

Air-standard cycle, which is based on the following assumptions:

(i) The working medium is assumed to be a perfect gas and follows the relation pV = mRT or p = ρRT.

(ii) There is no change in the mass of the working medium.

(iii) All the processes that constitute the cycle are reversible.

(iv) Heat is assumed to be supplied from a constant high temperature source and not from chemical reactions during the cycle.

(v) The working medium has constant specific heats throughout the cycle.

(i) The working medium is assumed to be a perfect gas and follows the relation pV = mRT or p = ρRT.

(ii) There is no change in the mass of the working medium.

(iii) All the processes that constitute the cycle are reversible.

(iv) Heat is assumed to be supplied from a constant high temperature source and not from chemical reactions during the cycle.

(v) The working medium has constant specific heats throughout the cycle.

Stoichiometric air-fuel ratio of petrol is roughly- a)50 : 1

- b)25 : 1

- c)15 : 1

- d)11 : 1

Correct answer is option 'C'. Can you explain this answer?

Stoichiometric air-fuel ratio of petrol is roughly

a)

50 : 1

b)

25 : 1

c)

15 : 1

d)

11 : 1

|

|

Stuti Mishra answered |

For petrol, stoichiometric air-fuel ratio is around 15 : 1.

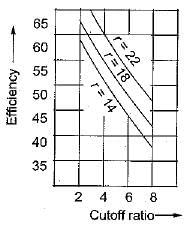

In air standard" Diesel cycle at fixed compression ratio and fixed γ,- a)thermal efficiency increases with increase in heat addition and cut-off ratio

- b)thermal efficiency decreases with increase in heat addition and cut-off ratio

- c)thermal efficiency remains the same with increase in heat addition and cut-off ratio

- d)none of the above

Correct answer is option 'B'. Can you explain this answer?

In air standard" Diesel cycle at fixed compression ratio and fixed γ,

a)

thermal efficiency increases with increase in heat addition and cut-off ratio

b)

thermal efficiency decreases with increase in heat addition and cut-off ratio

c)

thermal efficiency remains the same with increase in heat addition and cut-off ratio

d)

none of the above

|

|

Sinjini Bose answered |

With increase in heat addition for same power output efficiency of diesel engine decrease but with increase in cutoff ratio thermal efficiency decreases.

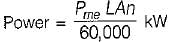

A turbocharged four-stroke direct injection diesel engine has a displacement volume of 0.0259 m3 (25.9 litres). The engine has an output of 950 kW at 2200 rpm. The mean effective pressure (in MPa) is closest to- a)2

- b)1

- c)0.2

- d)0.1

Correct answer is option 'A'. Can you explain this answer?

A turbocharged four-stroke direct injection diesel engine has a displacement volume of 0.0259 m3 (25.9 litres). The engine has an output of 950 kW at 2200 rpm. The mean effective pressure (in MPa) is closest to

a)

2

b)

1

c)

0.2

d)

0.1

|

Arnab Choudhury answered |

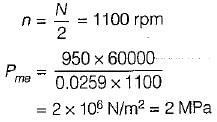

For four stroke engine

Water circulation in a thermosyphon cooling system is due to

- a)conduction currents

- b)a gear driven water pump

- c)the difference in temperature of the water.

- d)change in engine speed

Correct answer is option 'C'. Can you explain this answer?

Water circulation in a thermosyphon cooling system is due to

a)

conduction currents

b)

a gear driven water pump

c)

the difference in temperature of the water.

d)

change in engine speed

|

Gate Gurus answered |

In a thermosyphon cooling system, water circulates due to the difference in density between hot and cooled water. As the temperature of the fluid increases, its density decreases. This causes the fluid to move upward and be replaced by cooled fluid.

Cycles with lean to very lean mixture tend towards- a)practical cycles

- b)fuel-air cycles

- c)air-standard cycles

- d)none of the above

Correct answer is option 'C'. Can you explain this answer?

Cycles with lean to very lean mixture tend towards

a)

practical cycles

b)

fuel-air cycles

c)

air-standard cycles

d)

none of the above

|

|

Sagnik Choudhary answered |

As quantity of air increases, the cycle tends towards the air standard cycle since in air standard cycle working fluid is air only.

A gasoline engine working on Otto cycle consumes 8 litres of gasoline per hour and develops 28 kW. The specific gravity of gasoline. is 0.75 and its calorific value is 44000 kJ/kg. The indicated thermal efficiency of the engine is- a)45%

- b)46%

- c)38%

- d)34%

Correct answer is option 'C'. Can you explain this answer?

A gasoline engine working on Otto cycle consumes 8 litres of gasoline per hour and develops 28 kW. The specific gravity of gasoline. is 0.75 and its calorific value is 44000 kJ/kg. The indicated thermal efficiency of the engine is

a)

45%

b)

46%

c)

38%

d)

34%

|

|

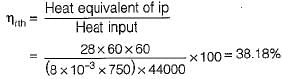

Mansi Kulkarni answered |

Consider the following parts of IC Engine:

1. Rocker arm

2. Follower

3. Cams

4. Camshaft

5. Crankshaft

Which among the above constitutes the part of valve train system?- a)1,2 and 3

- b)1, 2, 3 and 4

- c)2, 3 and 4

- d)All of the above

Correct answer is option 'B'. Can you explain this answer?

Consider the following parts of IC Engine:

1. Rocker arm

2. Follower

3. Cams

4. Camshaft

5. Crankshaft

Which among the above constitutes the part of valve train system?

1. Rocker arm

2. Follower

3. Cams

4. Camshaft

5. Crankshaft

Which among the above constitutes the part of valve train system?

a)

1,2 and 3

b)

1, 2, 3 and 4

c)

2, 3 and 4

d)

All of the above

|

|

Kajal Tiwari answered |

Valve Train System in IC Engine

The valve train system in an internal combustion engine controls the opening and closing of the engine's valves. It consists of several components, including:

1. Rocker arm: A rocker arm is a pivoting lever that allows the camshaft's motion to be transferred to the valve stem. It is usually mounted on a shaft that runs parallel to the camshaft.

2. Follower: A follower is a component that follows the contour of the camshaft's lobes. It can be in the form of a roller or a flat tappet.

3. Cams: Cams are the components that control the valve lift and duration. They have a unique shape that allows them to interact with the follower.

4. Camshaft: A camshaft is a rotating shaft that contains one or more cams. It is responsible for controlling the opening and closing of the engine's valves.

5. Crankshaft: A crankshaft is a rotating shaft that converts the reciprocating motion of the pistons into rotational motion. It is connected to the camshaft via a timing belt or chain.

Answer

The parts of the valve train system in an internal combustion engine include the rocker arm, follower, cams, and camshaft. Therefore, the correct answer is option B, i.e., 1, 2, 3, and 4. The crankshaft is not a part of the valve train system.

The valve train system in an internal combustion engine controls the opening and closing of the engine's valves. It consists of several components, including:

1. Rocker arm: A rocker arm is a pivoting lever that allows the camshaft's motion to be transferred to the valve stem. It is usually mounted on a shaft that runs parallel to the camshaft.

2. Follower: A follower is a component that follows the contour of the camshaft's lobes. It can be in the form of a roller or a flat tappet.

3. Cams: Cams are the components that control the valve lift and duration. They have a unique shape that allows them to interact with the follower.

4. Camshaft: A camshaft is a rotating shaft that contains one or more cams. It is responsible for controlling the opening and closing of the engine's valves.

5. Crankshaft: A crankshaft is a rotating shaft that converts the reciprocating motion of the pistons into rotational motion. It is connected to the camshaft via a timing belt or chain.

Answer

The parts of the valve train system in an internal combustion engine include the rocker arm, follower, cams, and camshaft. Therefore, the correct answer is option B, i.e., 1, 2, 3, and 4. The crankshaft is not a part of the valve train system.

For dual combustion cycle for fixed value of heat addition and compression ratio

- a)mep will be greater with increase in rp and decrease in rc

- b)mep will be greater with decrease in rp and decrease in rc

- c)mep remain the same with increase in rp and decrease in rc

- d)none of the above

Correct answer is option 'A'. Can you explain this answer?

For dual combustion cycle for fixed value of heat addition and compression ratio

a)

mep will be greater with increase in rp and decrease in rc

b)

mep will be greater with decrease in rp and decrease in rc

c)

mep remain the same with increase in rp and decrease in rc

d)

none of the above

|

Gate Funda answered |

Correct answer is A. mep will be greater with increase in rp and decrease in rc

The minimum number of rings in a piston are- a)two

- b)three

- c)four

- d)six

Correct answer is option 'B'. Can you explain this answer?

The minimum number of rings in a piston are

a)

two

b)

three

c)

four

d)

six

|

Sreemoyee Joshi answered |

The leakage of gases between the walls of piston and cylinder is prevented by means of three to six cast iron rings which may be square or rectangular in cross-section.

For the same indicated work per cycle, mean speed and permissible fluctuation of speed, what is the size of flywheel required for a multi-cylinder engine in comparison to a single-cylinder engine?- a)Bigger

- b)Smaller

- c)Same

- d)Depends on thermal efficiency of the engine

Correct answer is option 'B'. Can you explain this answer?

For the same indicated work per cycle, mean speed and permissible fluctuation of speed, what is the size of flywheel required for a multi-cylinder engine in comparison to a single-cylinder engine?

a)

Bigger

b)

Smaller

c)

Same

d)

Depends on thermal efficiency of the engine

|

Pallabi Tiwari answered |

Size of Flywheel for Multi-Cylinder Engine vs Single-Cylinder Engine

Introduction:

The flywheel is an essential component of an engine that helps in maintaining a consistent speed and reducing speed fluctuations. It stores kinetic energy during the power stroke and releases it during the non-power strokes of the engine cycle. The size of the flywheel required for an engine depends on the indicated work per cycle, mean speed, and permissible fluctuation of speed.

Explanation:

To understand why the size of the flywheel required for a multi-cylinder engine is smaller than that of a single-cylinder engine, we need to consider the following factors:

1. Indicated Work per Cycle:

The indicated work per cycle is the work done by the engine on the piston during each cycle. In a multi-cylinder engine, the power strokes of different cylinders are overlapping, which results in a smoother power delivery compared to a single-cylinder engine. As a result, the indicated work per cycle in a multi-cylinder engine is distributed over multiple power strokes, reducing the overall fluctuations in torque. This reduces the requirement of a larger flywheel to smooth out speed fluctuations.

2. Mean Speed:

The mean speed of an engine is the average speed at which it operates. In a multi-cylinder engine, the power strokes of different cylinders are phased in a way that they overlap, resulting in a more uniform torque output. This allows the engine to operate at a higher mean speed compared to a single-cylinder engine. Higher mean speed leads to increased energy storage capacity in the flywheel, allowing for a smaller flywheel size.

3. Permissible Fluctuation of Speed:

The permissible fluctuation of speed is the maximum allowable speed variation during each cycle. In a multi-cylinder engine, the overlapping power strokes of different cylinders help in reducing the speed fluctuations. The smoother power delivery reduces the need for a larger flywheel to compensate for speed variations. On the other hand, a single-cylinder engine has a more pronounced speed fluctuation, requiring a larger flywheel to maintain a consistent speed.

Conclusion:

In conclusion, the size of the flywheel required for a multi-cylinder engine is smaller compared to a single-cylinder engine. This is due to the smoother power delivery, higher mean speed, and reduced speed fluctuations in a multi-cylinder engine. The overlapping power strokes of different cylinders help in distributing the indicated work per cycle, resulting in a more uniform torque output. This allows for a smaller flywheel size to maintain a consistent speed and reduce speed fluctuations.

Introduction:

The flywheel is an essential component of an engine that helps in maintaining a consistent speed and reducing speed fluctuations. It stores kinetic energy during the power stroke and releases it during the non-power strokes of the engine cycle. The size of the flywheel required for an engine depends on the indicated work per cycle, mean speed, and permissible fluctuation of speed.

Explanation:

To understand why the size of the flywheel required for a multi-cylinder engine is smaller than that of a single-cylinder engine, we need to consider the following factors:

1. Indicated Work per Cycle:

The indicated work per cycle is the work done by the engine on the piston during each cycle. In a multi-cylinder engine, the power strokes of different cylinders are overlapping, which results in a smoother power delivery compared to a single-cylinder engine. As a result, the indicated work per cycle in a multi-cylinder engine is distributed over multiple power strokes, reducing the overall fluctuations in torque. This reduces the requirement of a larger flywheel to smooth out speed fluctuations.

2. Mean Speed:

The mean speed of an engine is the average speed at which it operates. In a multi-cylinder engine, the power strokes of different cylinders are phased in a way that they overlap, resulting in a more uniform torque output. This allows the engine to operate at a higher mean speed compared to a single-cylinder engine. Higher mean speed leads to increased energy storage capacity in the flywheel, allowing for a smaller flywheel size.

3. Permissible Fluctuation of Speed:

The permissible fluctuation of speed is the maximum allowable speed variation during each cycle. In a multi-cylinder engine, the overlapping power strokes of different cylinders help in reducing the speed fluctuations. The smoother power delivery reduces the need for a larger flywheel to compensate for speed variations. On the other hand, a single-cylinder engine has a more pronounced speed fluctuation, requiring a larger flywheel to maintain a consistent speed.

Conclusion:

In conclusion, the size of the flywheel required for a multi-cylinder engine is smaller compared to a single-cylinder engine. This is due to the smoother power delivery, higher mean speed, and reduced speed fluctuations in a multi-cylinder engine. The overlapping power strokes of different cylinders help in distributing the indicated work per cycle, resulting in a more uniform torque output. This allows for a smaller flywheel size to maintain a consistent speed and reduce speed fluctuations.

Main advantage of a two-stroke engine over four-stroke engine is- a)more uniform torque on the crankshaft

- b)more power output for the cylinder of same dimensions

- c)absence of valves

- d)all of the above

Correct answer is option 'D'. Can you explain this answer?

Main advantage of a two-stroke engine over four-stroke engine is

a)

more uniform torque on the crankshaft

b)

more power output for the cylinder of same dimensions

c)

absence of valves

d)

all of the above

|

Bhargavi Sarkar answered |

Advantages of two-stroke engine over four-stroke engine are

1. Low cost

2. More uniform torque and hence lighter flywheel is needed

3. Because of one power stroke for one revolution, power produced for same size of engine is more

4. Light weight and simplicity due to the absence of valve mechanism.

1. Low cost

2. More uniform torque and hence lighter flywheel is needed

3. Because of one power stroke for one revolution, power produced for same size of engine is more

4. Light weight and simplicity due to the absence of valve mechanism.

All of the following parameters reduce knocking tendency in a compression ignition engine, except- a)high inlet pressure and temperature

- b)higher compression ratio

- c)large engine size

- d)early injection of fuel

Correct answer is option 'D'. Can you explain this answer?

All of the following parameters reduce knocking tendency in a compression ignition engine, except

a)

high inlet pressure and temperature

b)

higher compression ratio

c)

large engine size

d)

early injection of fuel

|

|

Aman Ghosh answered |

The delay period increases with increase in injection advance which favour knocking tendency.

An engine produces 10 kW brake power while working with a brake thermal efficiency of 30%. If the calorific value of the fuel used is 40,000 kJ/kg then what is the fuel consumption?- a)1.5 kg/hour

- b)3.0 kg/hour

- c)0.3 kg/hour

- d)1.0 kg/hou

Correct answer is option 'B'. Can you explain this answer?

An engine produces 10 kW brake power while working with a brake thermal efficiency of 30%. If the calorific value of the fuel used is 40,000 kJ/kg then what is the fuel consumption?

a)

1.5 kg/hour

b)

3.0 kg/hour

c)

0.3 kg/hour

d)

1.0 kg/hou

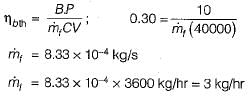

|

Prerna Menon answered |

When the mixture is lean- a)efficiency is less

- b)power output is less

- c)maximum temperature and pressure are higher

- d)power output is high

Correct answer is option 'B'. Can you explain this answer?

When the mixture is lean

a)

efficiency is less

b)

power output is less

c)

maximum temperature and pressure are higher

d)

power output is high

|

Pankaj Kapoor answered |

Explanation:

When the mixture is lean, it means that the air-fuel ratio is higher, i.e., there is more air compared to fuel in the mixture. This has several implications on the combustion process and the performance of the engine.

1. Efficiency:

When the mixture is lean, the combustion process becomes less efficient. This is because there is not enough fuel available for complete combustion. In a stoichiometric mixture (the ideal air-fuel ratio for complete combustion), all the fuel is burned completely with the available oxygen, resulting in maximum energy release. However, in a lean mixture, some of the fuel remains unburned due to insufficient oxygen. This incomplete combustion leads to lower energy release and, therefore, lower efficiency.

2. Power Output:

The power output of an engine is directly related to the energy released during combustion. As mentioned earlier, a lean mixture results in incomplete combustion and lower energy release. Consequently, the power output of the engine is reduced when the mixture is lean.

3. Maximum Temperature and Pressure:

In a lean mixture, the maximum temperature and pressure during combustion are higher compared to a stoichiometric mixture. This is because the excess air in the mixture tends to increase the combustion temperature. However, it is important to note that although the maximum temperature and pressure may be higher, the overall energy release and power output are still lower due to incomplete combustion.

Therefore, when the mixture is lean:

- The efficiency of the combustion process is reduced.

- The power output of the engine is decreased.

- The maximum temperature and pressure during combustion may be higher, but this does not compensate for the lower energy release and power output.

Hence, the correct answer is option B: Power output is less.

When the mixture is lean, it means that the air-fuel ratio is higher, i.e., there is more air compared to fuel in the mixture. This has several implications on the combustion process and the performance of the engine.

1. Efficiency:

When the mixture is lean, the combustion process becomes less efficient. This is because there is not enough fuel available for complete combustion. In a stoichiometric mixture (the ideal air-fuel ratio for complete combustion), all the fuel is burned completely with the available oxygen, resulting in maximum energy release. However, in a lean mixture, some of the fuel remains unburned due to insufficient oxygen. This incomplete combustion leads to lower energy release and, therefore, lower efficiency.

2. Power Output:

The power output of an engine is directly related to the energy released during combustion. As mentioned earlier, a lean mixture results in incomplete combustion and lower energy release. Consequently, the power output of the engine is reduced when the mixture is lean.

3. Maximum Temperature and Pressure:

In a lean mixture, the maximum temperature and pressure during combustion are higher compared to a stoichiometric mixture. This is because the excess air in the mixture tends to increase the combustion temperature. However, it is important to note that although the maximum temperature and pressure may be higher, the overall energy release and power output are still lower due to incomplete combustion.

Therefore, when the mixture is lean:

- The efficiency of the combustion process is reduced.

- The power output of the engine is decreased.

- The maximum temperature and pressure during combustion may be higher, but this does not compensate for the lower energy release and power output.

Hence, the correct answer is option B: Power output is less.

Compression ratio in case of SI engine is in the range of- a)6-10

- b)10-15

- c)16-25

- d)25-40

Correct answer is option 'A'. Can you explain this answer?

Compression ratio in case of SI engine is in the range of

a)

6-10

b)

10-15

c)

16-25

d)

25-40

|

|

Priyanka Tiwari answered |

Compression ratio in SI engine refers to the ratio of the maximum volume of the combustion chamber (when the piston is at the bottom dead center) to the minimum volume of the combustion chamber (when the piston is at the top dead center). It is an important parameter that affects the engine's performance, efficiency, and power output.

The compression ratio is typically expressed as a single number and can vary depending on the specific engine design and application. However, in general, the compression ratio in SI engines falls within the range of 6-10.

Here is a detailed explanation of why the compression ratio in SI engines is in the range of 6-10:

1. Combustion Efficiency:

- A higher compression ratio leads to better combustion efficiency. As the compression ratio increases, the air-fuel mixture is compressed to a smaller volume, resulting in higher pressure and temperature before ignition.

- This higher pressure and temperature promote better fuel atomization, mixing, and more complete combustion, leading to improved thermal efficiency and reduced emissions.

2. Knocking and Detonation:

- However, increasing the compression ratio beyond a certain limit can lead to knocking and detonation. Knocking is an undesirable phenomenon that occurs when the air-fuel mixture ignites prematurely due to high pressure and temperature.

- Knocking can cause engine damage and reduce efficiency. Therefore, the compression ratio is limited to a range where knocking is minimized.

3. Octane Rating of Fuel:

- The octane rating of the fuel used in SI engines also influences the compression ratio. The octane rating is a measure of its resistance to knocking.

- Higher octane fuels can withstand higher compression ratios without knocking. Conversely, lower octane fuels require lower compression ratios to prevent knocking.

- In most countries, the commonly available gasoline has an octane rating that is suitable for compression ratios in the range of 6-10.

4. Engine Design and Materials:

- The compression ratio is also influenced by the engine design and materials used. Factors such as piston design, cylinder head shape, combustion chamber geometry, and materials with higher resistance to heat and pressure play a role in determining the optimal compression ratio for a given engine design.

In conclusion, the compression ratio in SI engines is typically in the range of 6-10. This range strikes a balance between achieving better combustion efficiency while minimizing knocking and detonation issues. It is also influenced by the octane rating of the fuel and the engine design and materials.

The compression ratio is typically expressed as a single number and can vary depending on the specific engine design and application. However, in general, the compression ratio in SI engines falls within the range of 6-10.

Here is a detailed explanation of why the compression ratio in SI engines is in the range of 6-10:

1. Combustion Efficiency:

- A higher compression ratio leads to better combustion efficiency. As the compression ratio increases, the air-fuel mixture is compressed to a smaller volume, resulting in higher pressure and temperature before ignition.

- This higher pressure and temperature promote better fuel atomization, mixing, and more complete combustion, leading to improved thermal efficiency and reduced emissions.

2. Knocking and Detonation:

- However, increasing the compression ratio beyond a certain limit can lead to knocking and detonation. Knocking is an undesirable phenomenon that occurs when the air-fuel mixture ignites prematurely due to high pressure and temperature.

- Knocking can cause engine damage and reduce efficiency. Therefore, the compression ratio is limited to a range where knocking is minimized.

3. Octane Rating of Fuel:

- The octane rating of the fuel used in SI engines also influences the compression ratio. The octane rating is a measure of its resistance to knocking.

- Higher octane fuels can withstand higher compression ratios without knocking. Conversely, lower octane fuels require lower compression ratios to prevent knocking.

- In most countries, the commonly available gasoline has an octane rating that is suitable for compression ratios in the range of 6-10.

4. Engine Design and Materials:

- The compression ratio is also influenced by the engine design and materials used. Factors such as piston design, cylinder head shape, combustion chamber geometry, and materials with higher resistance to heat and pressure play a role in determining the optimal compression ratio for a given engine design.

In conclusion, the compression ratio in SI engines is typically in the range of 6-10. This range strikes a balance between achieving better combustion efficiency while minimizing knocking and detonation issues. It is also influenced by the octane rating of the fuel and the engine design and materials.

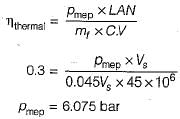

An automobile engine operates at a fuel air ratio of 0.05, volumetric efficiency of 90% and indicated thermal efficiency of 30%. Given that the calorific value of the fuel is 45 MJ/kg and the density of air at intake is 1 kg/m3, the indicated mean effective pressure for the engine is- a)6.075 bar

- b)6.75 bar

- c)67.5 bar

- d)243 bar

Correct answer is option 'A'. Can you explain this answer?

An automobile engine operates at a fuel air ratio of 0.05, volumetric efficiency of 90% and indicated thermal efficiency of 30%. Given that the calorific value of the fuel is 45 MJ/kg and the density of air at intake is 1 kg/m3, the indicated mean effective pressure for the engine is

a)

6.075 bar

b)

6.75 bar

c)

67.5 bar

d)

243 bar

|

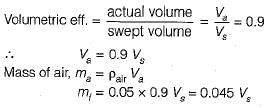

Pankaj Kapoor answered |

A two-stroke engine can be identified by- a)cooling system

- b)lubrication system

- c)absence of valves

- d)piston size

Correct answer is option 'C'. Can you explain this answer?

A two-stroke engine can be identified by

a)

cooling system

b)

lubrication system

c)

absence of valves

d)

piston size

|

Saikat Gupta answered |

A two-stroke engine can be identified by the absence of valves. Let's understand why this is the correct answer in detail.

1. Introduction:

A two-stroke engine is a type of internal combustion engine that completes a power cycle with two strokes of the piston, compared to a four-stroke engine that requires four strokes. Two-stroke engines are commonly used in applications where a compact and lightweight design is required, such as motorcycles, chainsaws, and small boats.

2. Operating Principle:

The operating principle of a two-stroke engine involves the compression, ignition, and exhaust processes within two strokes of the piston. This is achieved by combining the intake and exhaust processes in a single stroke, eliminating the need for separate intake and exhaust valves.

3. Absence of Valves:

In a four-stroke engine, the intake and exhaust processes are controlled by valves, which open and close at specific times to allow the flow of air/fuel mixture into the cylinder and the expulsion of exhaust gases. However, in a two-stroke engine, these valves are not present.

4. Port Design:

Instead of valves, a two-stroke engine uses a unique port design to control the flow of air/fuel mixture and exhaust gases. The cylinder has ports located at specific positions, which are passages for the intake and exhaust gases. These ports are uncovered and covered by the movement of the piston.

5. Piston Movement:

As the piston moves up and down in the cylinder, it uncovers and covers the ports. During the downward stroke, the piston uncovers the intake port, allowing the air/fuel mixture to enter the cylinder. Simultaneously, the exhaust port is closed. During the upward stroke, the piston covers the intake port and uncovers the exhaust port, allowing the exhaust gases to be expelled.

6. Advantages of Absence of Valves:

The absence of valves in a two-stroke engine simplifies the design and reduces the overall weight and size of the engine. It also eliminates the need for a camshaft and associated components, further enhancing compactness and reducing cost.

7. Disadvantages of Absence of Valves:

However, the absence of valves in a two-stroke engine also leads to certain disadvantages. It results in less efficient scavenging of exhaust gases, which can reduce power output and increase emissions. Additionally, the absence of valves limits the ability to control the timing and duration of the intake and exhaust processes, which can affect engine performance and efficiency.

In conclusion, the absence of valves is the key characteristic that can be used to identify a two-stroke engine. Instead of valves, a two-stroke engine uses a unique port design and the movement of the piston to control the flow of air/fuel mixture and exhaust gases.

1. Introduction:

A two-stroke engine is a type of internal combustion engine that completes a power cycle with two strokes of the piston, compared to a four-stroke engine that requires four strokes. Two-stroke engines are commonly used in applications where a compact and lightweight design is required, such as motorcycles, chainsaws, and small boats.

2. Operating Principle:

The operating principle of a two-stroke engine involves the compression, ignition, and exhaust processes within two strokes of the piston. This is achieved by combining the intake and exhaust processes in a single stroke, eliminating the need for separate intake and exhaust valves.

3. Absence of Valves:

In a four-stroke engine, the intake and exhaust processes are controlled by valves, which open and close at specific times to allow the flow of air/fuel mixture into the cylinder and the expulsion of exhaust gases. However, in a two-stroke engine, these valves are not present.

4. Port Design:

Instead of valves, a two-stroke engine uses a unique port design to control the flow of air/fuel mixture and exhaust gases. The cylinder has ports located at specific positions, which are passages for the intake and exhaust gases. These ports are uncovered and covered by the movement of the piston.

5. Piston Movement:

As the piston moves up and down in the cylinder, it uncovers and covers the ports. During the downward stroke, the piston uncovers the intake port, allowing the air/fuel mixture to enter the cylinder. Simultaneously, the exhaust port is closed. During the upward stroke, the piston covers the intake port and uncovers the exhaust port, allowing the exhaust gases to be expelled.

6. Advantages of Absence of Valves:

The absence of valves in a two-stroke engine simplifies the design and reduces the overall weight and size of the engine. It also eliminates the need for a camshaft and associated components, further enhancing compactness and reducing cost.

7. Disadvantages of Absence of Valves:

However, the absence of valves in a two-stroke engine also leads to certain disadvantages. It results in less efficient scavenging of exhaust gases, which can reduce power output and increase emissions. Additionally, the absence of valves limits the ability to control the timing and duration of the intake and exhaust processes, which can affect engine performance and efficiency.

In conclusion, the absence of valves is the key characteristic that can be used to identify a two-stroke engine. Instead of valves, a two-stroke engine uses a unique port design and the movement of the piston to control the flow of air/fuel mixture and exhaust gases.

For the following “Matching” exercise, choose the correct one from among the alternatives a, b, c and d

Group-I

1. Marine Diesel Engine

2. Air-conditioning

3. Steam power plant

4. Gas turbine power plant

Group-II

(a) Two stroke engine

(b) Four stroke engine

(c) Rotary engine

(d) Cooling and dehumidification

(e) Cooling tower

(f) Brayton cycle

(g) Rankine cycle

(h) D-slide valve- a)1-b, 2-e, 3-f, 4-h

- b)1-c, 2-f, 3-e, 4-g

- c)1 -c, 2-f, 3-g, 4-e

- d)1-a, 2-d, 3-g, 4-f

Correct answer is option 'D'. Can you explain this answer?

For the following “Matching” exercise, choose the correct one from among the alternatives a, b, c and d

Group-I

1. Marine Diesel Engine

2. Air-conditioning

3. Steam power plant

4. Gas turbine power plant

Group-II

(a) Two stroke engine

(b) Four stroke engine

(c) Rotary engine

(d) Cooling and dehumidification

(e) Cooling tower

(f) Brayton cycle

(g) Rankine cycle

(h) D-slide valve

Group-I

1. Marine Diesel Engine

2. Air-conditioning

3. Steam power plant

4. Gas turbine power plant

Group-II

(a) Two stroke engine

(b) Four stroke engine

(c) Rotary engine

(d) Cooling and dehumidification

(e) Cooling tower

(f) Brayton cycle

(g) Rankine cycle

(h) D-slide valve

a)

1-b, 2-e, 3-f, 4-h

b)

1-c, 2-f, 3-e, 4-g

c)

1 -c, 2-f, 3-g, 4-e

d)

1-a, 2-d, 3-g, 4-f

|

Abhay Kapoor answered |

Two stroke engine ⇒ used in marine diesel engine.

Air conditioning ⇒ Cooling and dehumidification is done.

Steam power plant ⇒ Based on Rankine cycle.

Gas turbine power plant ⇒ Based on Brayton cycle

Air conditioning ⇒ Cooling and dehumidification is done.

Steam power plant ⇒ Based on Rankine cycle.

Gas turbine power plant ⇒ Based on Brayton cycle

An engine using octane air mixture has N2, O2, CO2, CO and H2O as constituents in the exhaust gas. Which one of the following can be conceded?- a)Supply mixture is stoichiometric

- b)Supply mixture has incomplete combustion

- c)Supply mixture is rich

- d)Supply mixture is lean

Correct answer is option 'B'. Can you explain this answer?

An engine using octane air mixture has N2, O2, CO2, CO and H2O as constituents in the exhaust gas. Which one of the following can be conceded?

a)

Supply mixture is stoichiometric

b)

Supply mixture has incomplete combustion

c)

Supply mixture is rich

d)

Supply mixture is lean

|

|

Anmol Saini answered |

Increase of O2 and CO in flue gas analysis indicated incomplete combustion.

The function of a distributor in an automobile is to- a)inject fuel at appropriate time

- b)regulate power

- c)time the spark

- d)even charge distribution to all cylinder

Correct answer is option 'C'. Can you explain this answer?

The function of a distributor in an automobile is to

a)

inject fuel at appropriate time

b)

regulate power

c)

time the spark

d)

even charge distribution to all cylinder

|

|

Sagnik Choudhary answered |

The distributor in an automobile plays a crucial role in the ignition system. Its main function is to time the spark that ignites the fuel-air mixture in the engine cylinders. This timing is essential for the efficient operation of the engine.

Timing the Spark:

The distributor consists of several components, including a rotor and a cap with multiple contacts. As the engine rotates, the distributor rotor spins inside the cap, making contact with each contact point in a specific sequence. Each contact point is connected to a spark plug in one of the engine cylinders.

The distributor is driven by the engine's camshaft or timing belt, which ensures that the rotor rotates at half the speed of the engine. This rotational motion of the rotor is synchronized with the engine's piston movements.

When the piston is at the top of its compression stroke, the distributor rotor aligns with the contact point for the corresponding cylinder. At this moment, an electrical current is sent from the ignition coil to the rotor, and as the rotor passes the contact point, the current is transferred to the spark plug, creating a spark that ignites the fuel-air mixture in the cylinder.

Importance of Timing:

Timing the spark accurately is crucial for the engine's performance. If the spark occurs too early, it can cause knocking or pinging, which can damage the engine. On the other hand, if the spark occurs too late, it can result in poor combustion, reduced power output, and increased emissions.

The distributor is equipped with a timing advance mechanism that adjusts the spark timing based on the engine speed and load. This allows for optimum performance under different operating conditions.

Conclusion:

In summary, the function of the distributor in an automobile is to time the spark that ignites the fuel-air mixture in the engine cylinders. It ensures that the spark occurs at the correct moment during the engine's combustion cycle, leading to efficient and smooth engine operation.

Timing the Spark:

The distributor consists of several components, including a rotor and a cap with multiple contacts. As the engine rotates, the distributor rotor spins inside the cap, making contact with each contact point in a specific sequence. Each contact point is connected to a spark plug in one of the engine cylinders.

The distributor is driven by the engine's camshaft or timing belt, which ensures that the rotor rotates at half the speed of the engine. This rotational motion of the rotor is synchronized with the engine's piston movements.

When the piston is at the top of its compression stroke, the distributor rotor aligns with the contact point for the corresponding cylinder. At this moment, an electrical current is sent from the ignition coil to the rotor, and as the rotor passes the contact point, the current is transferred to the spark plug, creating a spark that ignites the fuel-air mixture in the cylinder.

Importance of Timing:

Timing the spark accurately is crucial for the engine's performance. If the spark occurs too early, it can cause knocking or pinging, which can damage the engine. On the other hand, if the spark occurs too late, it can result in poor combustion, reduced power output, and increased emissions.

The distributor is equipped with a timing advance mechanism that adjusts the spark timing based on the engine speed and load. This allows for optimum performance under different operating conditions.

Conclusion:

In summary, the function of the distributor in an automobile is to time the spark that ignites the fuel-air mixture in the engine cylinders. It ensures that the spark occurs at the correct moment during the engine's combustion cycle, leading to efficient and smooth engine operation.

The overhead valve engine is superior to a side valve or an L-head engine at high compression ratios. Which of the following characteristics of this type of valve arrangement is not favourable?- a)Lesser heat loss due to less surface to volume ratio.

- b)Shorter flame travel length.

- c)Higher volumetric efficiency from valve lifts.

- d)Localised thermal failures of the cylinder block

Correct answer is option 'D'. Can you explain this answer?

The overhead valve engine is superior to a side valve or an L-head engine at high compression ratios. Which of the following characteristics of this type of valve arrangement is not favourable?

a)

Lesser heat loss due to less surface to volume ratio.

b)

Shorter flame travel length.

c)

Higher volumetric efficiency from valve lifts.

d)

Localised thermal failures of the cylinder block

|

Sreemoyee Joshi answered |

Introduction:

The overhead valve (OHV) engine is a type of internal combustion engine that has the valves located in the cylinder head above the combustion chamber. This valve arrangement offers several advantages over the side valve or L-head engines, especially at high compression ratios. However, there is one characteristic of the OHV engine that is not favorable when compared to the other two types of engines.

Explanation:

The correct answer is option 'D' - Localised thermal failures of the cylinder block. Let's understand why this characteristic is not favorable in detail:

1. Lesser heat loss due to less surface to volume ratio:

- The OHV engine has a relatively smaller surface area compared to the side valve or L-head engines.

- This results in lesser heat loss to the surrounding environment since there is less surface area for heat transfer.

- It allows the engine to maintain higher temperatures within the combustion chamber, leading to better combustion efficiency and power output.

2. Shorter flame travel length:

- In the OHV engine, the spark plug is located closer to the combustion chamber, resulting in a shorter flame travel distance.

- This reduces the time taken for the flame to propagate across the combustion chamber, leading to faster and more efficient combustion.

- It improves the overall engine performance and fuel efficiency.

3. Higher volumetric efficiency from valve lifts:

- The OHV engine has the valves located in the cylinder head, allowing for higher valve lifts.

- Higher valve lifts enable better airflow into and out of the combustion chamber, improving the engine's volumetric efficiency.

- It results in better power output and overall performance.

4. Localised thermal failures of the cylinder block:

- The characteristic that is not favorable in the OHV engine is the potential for localized thermal failures of the cylinder block.

- Due to the positioning of the valves in the cylinder head, the combustion chamber is subjected to higher temperatures.

- These high temperatures can result in localized overheating and thermal stress on the cylinder block, leading to potential failures.

- This issue can be addressed through proper cooling and heat management techniques, but it is still a disadvantage compared to the other types of engines.

Conclusion:

In conclusion, the overhead valve (OHV) engine offers several advantages over the side valve or L-head engines at high compression ratios. It has lesser heat loss, shorter flame travel length, and higher volumetric efficiency. However, one characteristic that is not favorable is the potential for localized thermal failures of the cylinder block due to the higher temperatures in the combustion chamber.

The overhead valve (OHV) engine is a type of internal combustion engine that has the valves located in the cylinder head above the combustion chamber. This valve arrangement offers several advantages over the side valve or L-head engines, especially at high compression ratios. However, there is one characteristic of the OHV engine that is not favorable when compared to the other two types of engines.

Explanation:

The correct answer is option 'D' - Localised thermal failures of the cylinder block. Let's understand why this characteristic is not favorable in detail:

1. Lesser heat loss due to less surface to volume ratio:

- The OHV engine has a relatively smaller surface area compared to the side valve or L-head engines.

- This results in lesser heat loss to the surrounding environment since there is less surface area for heat transfer.

- It allows the engine to maintain higher temperatures within the combustion chamber, leading to better combustion efficiency and power output.

2. Shorter flame travel length:

- In the OHV engine, the spark plug is located closer to the combustion chamber, resulting in a shorter flame travel distance.

- This reduces the time taken for the flame to propagate across the combustion chamber, leading to faster and more efficient combustion.

- It improves the overall engine performance and fuel efficiency.

3. Higher volumetric efficiency from valve lifts:

- The OHV engine has the valves located in the cylinder head, allowing for higher valve lifts.

- Higher valve lifts enable better airflow into and out of the combustion chamber, improving the engine's volumetric efficiency.

- It results in better power output and overall performance.

4. Localised thermal failures of the cylinder block:

- The characteristic that is not favorable in the OHV engine is the potential for localized thermal failures of the cylinder block.

- Due to the positioning of the valves in the cylinder head, the combustion chamber is subjected to higher temperatures.

- These high temperatures can result in localized overheating and thermal stress on the cylinder block, leading to potential failures.

- This issue can be addressed through proper cooling and heat management techniques, but it is still a disadvantage compared to the other types of engines.

Conclusion:

In conclusion, the overhead valve (OHV) engine offers several advantages over the side valve or L-head engines at high compression ratios. It has lesser heat loss, shorter flame travel length, and higher volumetric efficiency. However, one characteristic that is not favorable is the potential for localized thermal failures of the cylinder block due to the higher temperatures in the combustion chamber.

The method of determination of indicated power of multi-cylinder SI engine is by the use of- a)morse test

- b)prony brake test

- c)fanno line test

- d)heat balance test

Correct answer is option 'A'. Can you explain this answer?

The method of determination of indicated power of multi-cylinder SI engine is by the use of

a)

morse test

b)

prony brake test

c)

fanno line test

d)

heat balance test

|

|

Arshiya Dey answered |

Understanding Indicated Power in Multi-Cylinder SI Engines

Indicated Power (IP) is a crucial measure of an engine's performance, representing the power produced by combustion before any losses due to friction or other factors. For multi-cylinder Spark Ignition (SI) engines, a common method to determine IP is the Morse Test.

What is the Morse Test?

- The Morse Test involves running the engine with one or more cylinders disabled while measuring the power output.

- By comparing the power output of the full engine to that of the engine with one cylinder cut out, the indicated power can be accurately calculated.

How Does the Morse Test Work?

- Setup: The engine operates normally, and measurements of power are taken.

- Cylinder Deactivation: One cylinder is deactivated, and the engine is allowed to run. Power is again measured.

- Calculation: The difference in power output enables the calculation of the indicated power for the engine.

Advantages of the Morse Test

- Accuracy: It provides a direct measure of indicated power without needing complex instrumentation.

- Simplicity: The test can be performed with relatively simple equipment, making it accessible for many testing facilities.

- Applicability: Suitable for multi-cylinder engines, allowing for accurate assessments across various configurations.

Other Methods Explained

- Prony Brake Test: Measures brake power, not indicated power, by assessing the resistance to rotation.

- Fanno Line Test: Related to compressible flow, not directly applicable to indicated power.

- Heat Balance Test: Focuses on energy balance rather than directly measuring indicated power.

In summary, the Morse Test is the preferred method for determining the indicated power of multi-cylinder SI engines due to its accuracy, simplicity, and direct applicability.