All Exams >

Civil Engineering (CE) >

Foundation Engineering >

All Questions

All questions of Deep Foundation for Civil Engineering (CE) Exam

Consider the following statements:

1. Piles are provided in groups, which are connected together by a pile cap. The structure rests on top of the pile cap. The pile cap is situated below the ground level.

2. For situations where pile is subjected to upward pull, pedestal piles or under reamed piles are more suitable type of foundations.

Which of these statements is/are correct?

- a)1 only

- b)2 only

- c)Both 1 and 2

- d)Neither 1 nor 2

Correct answer is option 'C'. Can you explain this answer?

Consider the following statements:

1. Piles are provided in groups, which are connected together by a pile cap. The structure rests on top of the pile cap. The pile cap is situated below the ground level.

2. For situations where pile is subjected to upward pull, pedestal piles or under reamed piles are more suitable type of foundations.

Which of these statements is/are correct?

1. Piles are provided in groups, which are connected together by a pile cap. The structure rests on top of the pile cap. The pile cap is situated below the ground level.

2. For situations where pile is subjected to upward pull, pedestal piles or under reamed piles are more suitable type of foundations.

Which of these statements is/are correct?

a)

1 only

b)

2 only

c)

Both 1 and 2

d)

Neither 1 nor 2

|

Constructing Careers answered |

Let's evaluate the statements about piles:

- Piles are provided in groups, which are connected together by a pile cap. The structure rests on top of the pile cap. The pile cap is situated below the ground level.

- This statement is correct. Piles are often used in groups and connected by a pile cap to distribute the load from the structure above. The pile cap is typically situated below the ground level to provide stability.

- For situations where a pile is subjected to an upward pull, pedestal piles or under-reamed piles are more suitable types of foundations.

- This statement is also correct. Pedestal piles and under-reamed piles are designed to resist uplift forces due to their enlarged bases, making them suitable for situations where there is an upward pull.

Therefore, the correct option is:

3. Both 1 and 2

Pile driven in deep clay deposits transfers its loads by- a)End bearing

- b)Frictional resistance

- c)Both (a) and (b)

- d)None of these

Correct answer is option 'C'. Can you explain this answer?

Pile driven in deep clay deposits transfers its loads by

a)

End bearing

b)

Frictional resistance

c)

Both (a) and (b)

d)

None of these

|

|

Zoya Sharma answered |

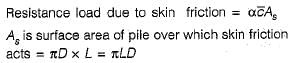

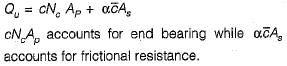

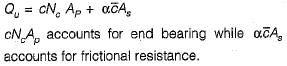

For clay deposits ultimate load of pile is given by,

A self-aligning ball bearing has a basic dynamic load rating (C10, for 106 revolutions) of 35 kN. If the equivalent radial load on the bearing is 45 kN, the expected life (in 106 revolutions) is- a)below 0.5

- b)0.5 to 0.8

- c)0.8 to 1.0

- d)above 1.0

Correct answer is option 'A'. Can you explain this answer?

A self-aligning ball bearing has a basic dynamic load rating (C10, for 106 revolutions) of 35 kN. If the equivalent radial load on the bearing is 45 kN, the expected life (in 106 revolutions) is

a)

below 0.5

b)

0.5 to 0.8

c)

0.8 to 1.0

d)

above 1.0

|

Bhaskar Rane answered |

Basic Dynamic Load Rating (C10):

- The basic dynamic load rating (C10) is a standardized rating given to bearings to indicate their load-carrying capacity.

- It represents the load, in kilonewtons (kN), that the bearing can withstand for a basic rating life of 106 revolutions.

Equivalent Radial Load:

- The equivalent radial load is the load that a bearing would experience if it were subjected to a combination of radial and axial loads.

- It is calculated based on the actual radial and axial loads acting on the bearing.

Expected Life:

- The expected life of a bearing is the number of revolutions that it is expected to complete before the first signs of fatigue occur.

- It is influenced by factors such as load, speed, lubrication, and operating conditions.

Solution:

- Given that the basic dynamic load rating (C10) of the self-aligning ball bearing is 35 kN and the equivalent radial load is 45 kN.

- The equivalent radial load exceeds the basic dynamic load rating, indicating that the bearing is subjected to a higher load than its rated capacity.

- In such cases, the bearing is expected to have a relatively short life.

Comparison of Equivalent Radial Load and Basic Dynamic Load Rating:

- If the equivalent radial load is less than or equal to the basic dynamic load rating (45 kN ≤ 35 kN), the expected life of the bearing is considered to be above 1.0 (greater than 1.0 x 106 revolutions).

- However, if the equivalent radial load exceeds the basic dynamic load rating (45 kN > 35 kN), the expected life of the bearing is significantly reduced.

- In this case, the expected life of the bearing is below 0.5 (less than 0.5 x 106 revolutions).

Conclusion:

- Based on the given information, the expected life of the self-aligning ball bearing is below 0.5 (option 'A').

- The basic dynamic load rating (C10) is a standardized rating given to bearings to indicate their load-carrying capacity.

- It represents the load, in kilonewtons (kN), that the bearing can withstand for a basic rating life of 106 revolutions.

Equivalent Radial Load:

- The equivalent radial load is the load that a bearing would experience if it were subjected to a combination of radial and axial loads.

- It is calculated based on the actual radial and axial loads acting on the bearing.

Expected Life:

- The expected life of a bearing is the number of revolutions that it is expected to complete before the first signs of fatigue occur.

- It is influenced by factors such as load, speed, lubrication, and operating conditions.

Solution:

- Given that the basic dynamic load rating (C10) of the self-aligning ball bearing is 35 kN and the equivalent radial load is 45 kN.

- The equivalent radial load exceeds the basic dynamic load rating, indicating that the bearing is subjected to a higher load than its rated capacity.

- In such cases, the bearing is expected to have a relatively short life.

Comparison of Equivalent Radial Load and Basic Dynamic Load Rating:

- If the equivalent radial load is less than or equal to the basic dynamic load rating (45 kN ≤ 35 kN), the expected life of the bearing is considered to be above 1.0 (greater than 1.0 x 106 revolutions).

- However, if the equivalent radial load exceeds the basic dynamic load rating (45 kN > 35 kN), the expected life of the bearing is significantly reduced.

- In this case, the expected life of the bearing is below 0.5 (less than 0.5 x 106 revolutions).

Conclusion:

- Based on the given information, the expected life of the self-aligning ball bearing is below 0.5 (option 'A').

The rated life of a ball bearing varies- a)Directly as the load

- b)Directly as the square of the load

- c)Directly as the cube of the load

- d)Inversely as the cube of the load

Correct answer is option 'D'. Can you explain this answer?

The rated life of a ball bearing varies

a)

Directly as the load

b)

Directly as the square of the load

c)

Directly as the cube of the load

d)

Inversely as the cube of the load

|

|

Sudhir Patel answered |

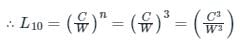

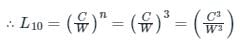

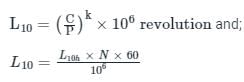

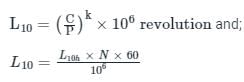

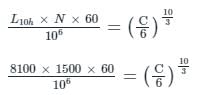

Life of a bearing is given by:

where

L10 = basic life rating in million revolutions

C = dynamic load-carrying capacity

W = equivalent dynamic load

n = constant = 3 for ball bearing and 10/3 for roller bearing

Thus, The rated life of a ball bearing varies Inversely as the cube of the load.

So, option (4) is the correct answer.

where

L10 = basic life rating in million revolutions

C = dynamic load-carrying capacity

W = equivalent dynamic load

n = constant = 3 for ball bearing and 10/3 for roller bearing

Thus, The rated life of a ball bearing varies Inversely as the cube of the load.

So, option (4) is the correct answer.

If a hammer is raised by steam and allowed to fall by gravity on top of the pile, it is called as________- a)Diesel hammer

- b)Vibratory hammer

- c)Single acting hammer

- d)Drop hammer

Correct answer is option 'C'. Can you explain this answer?

If a hammer is raised by steam and allowed to fall by gravity on top of the pile, it is called as________

a)

Diesel hammer

b)

Vibratory hammer

c)

Single acting hammer

d)

Drop hammer

|

Poulomi Khanna answered |

Single Acting Hammer

- A single acting hammer is a type of pile driving hammer that is raised by steam and allowed to fall by gravity onto the pile.

- This type of hammer is commonly used in pile driving operations in construction and civil engineering projects.

- The single acting hammer works on the principle of converting potential energy into kinetic energy to drive the pile into the ground.

- It consists of a heavy weight, usually a steel or iron hammer, which is raised to a certain height using steam power.

- The hammer is then released and allowed to fall freely onto the pile, delivering a powerful impact force.

- The impact force generated by the falling hammer drives the pile into the ground.

- The steam power is used to raise the hammer, and gravity provides the energy for the hammer to fall.

- The hammer is typically raised using a steam engine or a steam-driven winch system.

- The height to which the hammer is raised determines the potential energy it possesses.

- When the hammer is released, this potential energy is converted into kinetic energy as the hammer falls under the influence of gravity.

- The kinetic energy is transferred to the pile, causing it to penetrate the ground.

- Single acting hammers are effective in driving piles into various types of soil, including soft soils, dense soils, and even hard rock.

- They are commonly used in the construction of bridges, buildings, and other structures that require deep foundation systems.

- Single acting hammers are known for their simplicity and reliability.

- They are relatively easy to operate and maintain, making them a popular choice in pile driving operations.

- A single acting hammer is a type of pile driving hammer that is raised by steam and allowed to fall by gravity onto the pile.

- This type of hammer is commonly used in pile driving operations in construction and civil engineering projects.

- The single acting hammer works on the principle of converting potential energy into kinetic energy to drive the pile into the ground.

- It consists of a heavy weight, usually a steel or iron hammer, which is raised to a certain height using steam power.

- The hammer is then released and allowed to fall freely onto the pile, delivering a powerful impact force.

- The impact force generated by the falling hammer drives the pile into the ground.

- The steam power is used to raise the hammer, and gravity provides the energy for the hammer to fall.

- The hammer is typically raised using a steam engine or a steam-driven winch system.

- The height to which the hammer is raised determines the potential energy it possesses.

- When the hammer is released, this potential energy is converted into kinetic energy as the hammer falls under the influence of gravity.

- The kinetic energy is transferred to the pile, causing it to penetrate the ground.

- Single acting hammers are effective in driving piles into various types of soil, including soft soils, dense soils, and even hard rock.

- They are commonly used in the construction of bridges, buildings, and other structures that require deep foundation systems.

- Single acting hammers are known for their simplicity and reliability.

- They are relatively easy to operate and maintain, making them a popular choice in pile driving operations.

What is the effect of negative skin friction on the load carrying capacity of pile foundations? - a)It has no effect on the load carrying capacity

- b)It makes the load carrying capacity zero

- c)It increases the load carrying capacity

- d)It decreases the load carrying capacity

Correct answer is option 'D'. Can you explain this answer?

What is the effect of negative skin friction on the load carrying capacity of pile foundations?

a)

It has no effect on the load carrying capacity

b)

It makes the load carrying capacity zero

c)

It increases the load carrying capacity

d)

It decreases the load carrying capacity

|

|

Sanya Agarwal answered |

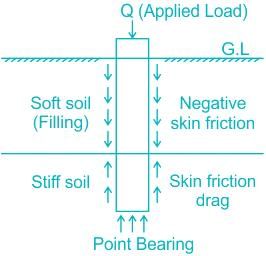

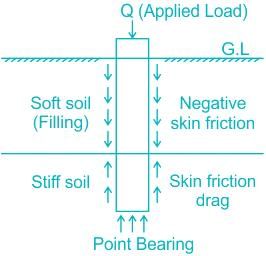

Negative skin friction: It is usually a downward shear drag acting on a pile or pile group because of the downward movement of surrounding soil relative to the piles. Such a force can exist under one of the following conditions:

- If a fill of clay soil is placed over a granular soil layer into which a pile is driven, the fill will exert a downward drag force on the pile due to consolidation.

- If a fill of granular soil is placed over a layer of soft clay, it will induce the process of consolidation in the clay layer and thus exert a downward drag on the pile.

- Lowering of the water table will increase the vertical effective stress on the soil at any depth, so it can induce negative skin friction on piles.

Now the axial capacity of a pile is the summation of the upward reaction due to bearing at the base and net upward skin frictional resistance. As the negative skin friction (acting downward) lowers the net skin resistance, it in turn reduces the axial capacity of piles.

A schematic diagram of negative skin friction on piles is shown below:

∴ Negative skin friction on a pile under vertical compressive load acts downwards and reduces the load-carrying capacity.

A schematic diagram of negative skin friction on piles is shown below:

∴ Negative skin friction on a pile under vertical compressive load acts downwards and reduces the load-carrying capacity.

Consider the following statements about the under-reamed pile in swelling soils:

1. Its bulb provides anchor against movement due to volume changes of soil.

2. It is a driven pile.

3. Its bulb diameter is 2.5 times its shaft diameter.

Which of these statements are correct?- a)1,2 and 3

- b)1 and 2 only

- c)2 and 3 only

- d)1 and 3 only

Correct answer is option 'D'. Can you explain this answer?

Consider the following statements about the under-reamed pile in swelling soils:

1. Its bulb provides anchor against movement due to volume changes of soil.

2. It is a driven pile.

3. Its bulb diameter is 2.5 times its shaft diameter.

Which of these statements are correct?

1. Its bulb provides anchor against movement due to volume changes of soil.

2. It is a driven pile.

3. Its bulb diameter is 2.5 times its shaft diameter.

Which of these statements are correct?

a)

1,2 and 3

b)

1 and 2 only

c)

2 and 3 only

d)

1 and 3 only

|

Siddharth Datta answered |

Under-reamed pile is a special type of bored pile which is provided with a bulb/pedestal at the end. The usual size of such piles are 150 to 200 mm shaft diameter, 3 to 4 m long. The diameter of under-reamed portion is usually 2 to 3 times the shaft diameter.

Based on the function, piles can be classified into ___________ types.- a)4

- b)6

- c)8

- d)3

Correct answer is option 'C'. Can you explain this answer?

Based on the function, piles can be classified into ___________ types.

a)

4

b)

6

c)

8

d)

3

|

Debolina Chavan answered |

Piles are structural elements used in civil engineering to transfer loads from a structure to the ground. They are typically long, slender columns made of materials such as concrete, steel, or timber. Piles can be classified into different types based on various criteria such as their material, shape, installation method, and load-carrying mechanism.

The given question asks about the classification of piles based on a certain function. Let's discuss the answer in detail:

Classification of Piles Based on Function:

------------------------------------------

1. Load-Bearing Piles: These piles are primarily used to transfer the loads from a structure to the ground. They are designed to carry compressive, tensile, or both types of loads. Load-bearing piles can be further classified into:

a) End-Bearing Piles: These piles transfer the load through the lower tip or end of the pile to a hard or dense layer of soil or rock beneath. They rely on the bearing capacity of the underlying stratum. Examples include driven piles and bored piles with a socket in rock.

b) Friction Piles: These piles transfer the load to the surrounding soil through skin friction along the pile shaft. They rely on the adhesion and shearing resistance between the pile surface and the soil. Examples include driven piles in cohesive soils and bored piles in cohesive or granular soils.

c) Combination Piles: These piles combine the load-bearing mechanisms of both end-bearing and friction piles. They transfer load both through the tip and the shaft. Examples include driven piles in granular soils or weak rock formations.

2. Sheet Piles: These piles are used as retaining walls to provide lateral support to excavations or to retain soil or water. They are typically made of steel, concrete, or timber and are installed vertically or at a slight inclination into the ground.

3. Compaction Piles: These piles are used to densify loose or compressible soils. They are installed by driving or vibrating into the ground to compact the surrounding soil and improve its bearing capacity.

4. Anchor Piles: These piles are used to provide lateral or uplift resistance to structures. They are installed at an angle and anchor into stable soil or rock to counteract the applied loads.

5. Tension Piles: These piles are used to resist tensile forces in structures. They are designed to transfer the applied tension loads to the ground through their embedded length.

Conclusion:

-----------

Based on the function, piles can be classified into various types such as load-bearing piles (end-bearing, friction, combination), sheet piles, compaction piles, anchor piles, and tension piles. Therefore, the correct answer to the given question is option 'C' - 8 types.

The given question asks about the classification of piles based on a certain function. Let's discuss the answer in detail:

Classification of Piles Based on Function:

------------------------------------------

1. Load-Bearing Piles: These piles are primarily used to transfer the loads from a structure to the ground. They are designed to carry compressive, tensile, or both types of loads. Load-bearing piles can be further classified into:

a) End-Bearing Piles: These piles transfer the load through the lower tip or end of the pile to a hard or dense layer of soil or rock beneath. They rely on the bearing capacity of the underlying stratum. Examples include driven piles and bored piles with a socket in rock.

b) Friction Piles: These piles transfer the load to the surrounding soil through skin friction along the pile shaft. They rely on the adhesion and shearing resistance between the pile surface and the soil. Examples include driven piles in cohesive soils and bored piles in cohesive or granular soils.

c) Combination Piles: These piles combine the load-bearing mechanisms of both end-bearing and friction piles. They transfer load both through the tip and the shaft. Examples include driven piles in granular soils or weak rock formations.

2. Sheet Piles: These piles are used as retaining walls to provide lateral support to excavations or to retain soil or water. They are typically made of steel, concrete, or timber and are installed vertically or at a slight inclination into the ground.

3. Compaction Piles: These piles are used to densify loose or compressible soils. They are installed by driving or vibrating into the ground to compact the surrounding soil and improve its bearing capacity.

4. Anchor Piles: These piles are used to provide lateral or uplift resistance to structures. They are installed at an angle and anchor into stable soil or rock to counteract the applied loads.

5. Tension Piles: These piles are used to resist tensile forces in structures. They are designed to transfer the applied tension loads to the ground through their embedded length.

Conclusion:

-----------

Based on the function, piles can be classified into various types such as load-bearing piles (end-bearing, friction, combination), sheet piles, compaction piles, anchor piles, and tension piles. Therefore, the correct answer to the given question is option 'C' - 8 types.

Which test is used for separating the load carried by the pile into the skin friction and point bearing resistance?- a)Plate load test

- b)Cyclic load test

- c)Dynamic load test

- d)Pile Integrity test

Correct answer is option 'B'. Can you explain this answer?

Which test is used for separating the load carried by the pile into the skin friction and point bearing resistance?

a)

Plate load test

b)

Cyclic load test

c)

Dynamic load test

d)

Pile Integrity test

|

|

Sanya Agarwal answered |

Plate load Test

- Plate load test is done at the site to determine the ultimate bearing capacity of soil and settlement of foundation under the loads for clayey and sandy soils.

Cyclic load Test

- It is used for separating the load carried by the pile into the skin friction and point bearing resistance.

Dynamic load Test

- Dynamic load testing with the aid of Pile Dynamic Analyzer (PDA) is a fast and reliable way to evaluate the bearing capacity of the pile.

Pile Integrity Test

- It is a non-distracted test (NDT) method that can evaluate the continuity and consistency of pile material, length, and cross-sectional area.

The piles that are used for protecting structures from ships and floating object is ____________

- a)Anchor piles

- b)Compaction piles

- c)Fender piles

- d)Batter piles

Correct answer is option 'C'. Can you explain this answer?

The piles that are used for protecting structures from ships and floating object is ____________

a)

Anchor piles

b)

Compaction piles

c)

Fender piles

d)

Batter piles

|

|

Sanya Agarwal answered |

Fender piles and dolphins are used to protect waterfront structures against the impact of ships or other floating objects.

Piles are commonly driven in to ground by means of special device called __________- a)Pile driver and Hammer

- b)Driller

- c)None of the mentioned

- d)All of the mentioned

Correct answer is option 'A'. Can you explain this answer?

Piles are commonly driven in to ground by means of special device called __________

a)

Pile driver and Hammer

b)

Driller

c)

None of the mentioned

d)

All of the mentioned

|

|

Sanvi Kapoor answered |

Piles are commonly driven by means of hammer supported by a crane or by a special device known as pile drivers.

A Factor of safety that should be adopted for finding an allowable load for a pile is _________- a)2.5 and 3

- b)4

- c)None of the mentioned

- d)All of the mentioned

Correct answer is option 'A'. Can you explain this answer?

A Factor of safety that should be adopted for finding an allowable load for a pile is _________

a)

2.5 and 3

b)

4

c)

None of the mentioned

d)

All of the mentioned

|

Aditi Sarkar answered |

The factor of safety is an important consideration in the design of any structure or foundation, including piles. It is used to ensure that the design is robust and can withstand uncertainties and variations in the loadings or material properties. In the case of piles, the factor of safety helps determine the allowable load that can be applied to the pile without causing failure or excessive settlement.

A) The factor of safety for finding an allowable load for a pile is typically recommended to be between 2.5 and 3. This means that the ultimate capacity of the pile should be at least 2.5 to 3 times the expected or design load.

Importance of Factor of Safety:

- The factor of safety takes into account uncertainties in soil properties, construction methods, and environmental conditions that can affect the performance of the pile.

- It provides a margin of safety against unexpected or unaccounted-for loads that may occur during the service life of the structure.

- It accounts for potential variations in the pile material properties, such as strength or stiffness, that may affect its load-carrying capacity.

- It considers the potential deterioration or degradation of the pile over time due to factors such as corrosion, aging, or exposure to harsh environmental conditions.

Factors Affecting the Factor of Safety:

- Soil conditions: The factor of safety may be increased for problematic soil conditions such as soft or weak soils, expansive soils, or soils with high water content.

- Design load: Higher factor of safety may be required for structures that experience dynamic or cyclic loads, such as bridges or tall buildings.

- Consequences of failure: The factor of safety may be increased for structures with significant consequences of failure, such as dams or nuclear power plants.

- Construction methods and quality control: The factor of safety may be adjusted based on the level of quality control during construction, such as pile installation methods and inspection procedures.

In summary, a factor of safety between 2.5 and 3 is recommended for finding an allowable load for a pile. This factor takes into account uncertainties, material properties, and variations in loadings or environmental conditions. It provides a margin of safety and ensures the pile can withstand expected and unexpected loads throughout its service life.

A) The factor of safety for finding an allowable load for a pile is typically recommended to be between 2.5 and 3. This means that the ultimate capacity of the pile should be at least 2.5 to 3 times the expected or design load.

Importance of Factor of Safety:

- The factor of safety takes into account uncertainties in soil properties, construction methods, and environmental conditions that can affect the performance of the pile.

- It provides a margin of safety against unexpected or unaccounted-for loads that may occur during the service life of the structure.

- It accounts for potential variations in the pile material properties, such as strength or stiffness, that may affect its load-carrying capacity.

- It considers the potential deterioration or degradation of the pile over time due to factors such as corrosion, aging, or exposure to harsh environmental conditions.

Factors Affecting the Factor of Safety:

- Soil conditions: The factor of safety may be increased for problematic soil conditions such as soft or weak soils, expansive soils, or soils with high water content.

- Design load: Higher factor of safety may be required for structures that experience dynamic or cyclic loads, such as bridges or tall buildings.

- Consequences of failure: The factor of safety may be increased for structures with significant consequences of failure, such as dams or nuclear power plants.

- Construction methods and quality control: The factor of safety may be adjusted based on the level of quality control during construction, such as pile installation methods and inspection procedures.

In summary, a factor of safety between 2.5 and 3 is recommended for finding an allowable load for a pile. This factor takes into account uncertainties, material properties, and variations in loadings or environmental conditions. It provides a margin of safety and ensures the pile can withstand expected and unexpected loads throughout its service life.

Which of the following piles is a cast-in-situ type of concrete pile?- a)Under-reamed pile

- b)Raymond standard pile

- c)Pressure pile

- d)Anchor pile

Correct answer is option 'B'. Can you explain this answer?

Which of the following piles is a cast-in-situ type of concrete pile?

a)

Under-reamed pile

b)

Raymond standard pile

c)

Pressure pile

d)

Anchor pile

|

|

Sanvi Kapoor answered |

Raymond standard pile and Raymond step-taper pile are the common types of cast-in-situ piles.

Multi-under-reamed piles are generally provided in- a)Silty soil

- b)Sandy soil

- c)Expansive clayey soil

- d)Gravelly sandy soil

Correct answer is option 'C'. Can you explain this answer?

Multi-under-reamed piles are generally provided in

a)

Silty soil

b)

Sandy soil

c)

Expansive clayey soil

d)

Gravelly sandy soil

|

Moumita Dasgupta answered |

Multi-Under-reamed Piles in Expansive Clayey Soil

Multi-under-reamed piles are a type of pile foundation that consists of a series of bored piles interconnected with a horizontal concrete beam. These piles are commonly used in areas where the soil is weak or has low bearing capacity. The under-reamed portion of the pile refers to an enlarged bulb-like shape at the bottom of the pile, which provides increased bearing capacity.

Expansive clayey soil is a type of soil that undergoes significant volume changes due to changes in moisture content. The soil swells when it absorbs water and shrinks when it dries out. This type of soil can cause significant damage to structures if not properly accounted for in the foundation design.

Multi-under-reamed piles are particularly suited for expansive clayey soil due to their ability to distribute the load over a larger area and resist the heave caused by soil volume changes. The enlarged bulb-like shape of the under-reamed portion of the pile ensures that the pile remains anchored in the soil even when the soil swells.

In addition, the interconnected nature of the pile system provides additional stability and resistance to lateral forces. The horizontal concrete beam connecting the piles helps to distribute the load evenly and prevent differential settlement.

Therefore, multi-under-reamed piles are an effective solution for building foundations in expansive clayey soil, providing a stable and durable foundation that can withstand the challenges of this type of soil.

Multi-under-reamed piles are a type of pile foundation that consists of a series of bored piles interconnected with a horizontal concrete beam. These piles are commonly used in areas where the soil is weak or has low bearing capacity. The under-reamed portion of the pile refers to an enlarged bulb-like shape at the bottom of the pile, which provides increased bearing capacity.

Expansive clayey soil is a type of soil that undergoes significant volume changes due to changes in moisture content. The soil swells when it absorbs water and shrinks when it dries out. This type of soil can cause significant damage to structures if not properly accounted for in the foundation design.

Multi-under-reamed piles are particularly suited for expansive clayey soil due to their ability to distribute the load over a larger area and resist the heave caused by soil volume changes. The enlarged bulb-like shape of the under-reamed portion of the pile ensures that the pile remains anchored in the soil even when the soil swells.

In addition, the interconnected nature of the pile system provides additional stability and resistance to lateral forces. The horizontal concrete beam connecting the piles helps to distribute the load evenly and prevent differential settlement.

Therefore, multi-under-reamed piles are an effective solution for building foundations in expansive clayey soil, providing a stable and durable foundation that can withstand the challenges of this type of soil.

The precast concrete piles are generally used for a maximum design load of about ____________- a)50 tonnes

- b)100 tonnes

- c)75 tonnes

- d)80 tonnes

Correct answer is option 'D'. Can you explain this answer?

The precast concrete piles are generally used for a maximum design load of about ____________

a)

50 tonnes

b)

100 tonnes

c)

75 tonnes

d)

80 tonnes

|

|

Sanvi Kapoor answered |

The precast concrete piles are generally used for a maximum design load of about 80 tonnes, except for large pre-stressed piles.

For pile in cohesive soil __________ is neglected for individual pile action.- a)Frictional resistance

- b)Surface area of pile

- c)Shear strength of soil

- d)All of the mentioned

Correct answer is option 'B'. Can you explain this answer?

For pile in cohesive soil __________ is neglected for individual pile action.

a)

Frictional resistance

b)

Surface area of pile

c)

Shear strength of soil

d)

All of the mentioned

|

Sreemoyee Chauhan answered |

Explanation:

In the case of cohesive soil, which is a type of soil with fine particles that stick together, the surface area of the pile is neglected for individual pile action. This means that the surface area of the pile does not play a significant role in the behavior of the pile in cohesive soil.

Reasoning:

The reason for neglecting the surface area of the pile in cohesive soil is primarily due to the nature of cohesive soil itself. Cohesive soil has the ability to develop shear strength due to the cohesive forces between its particles. These cohesive forces allow the soil to resist deformation and maintain its shape.

Frictional Resistance:

Frictional resistance refers to the resistance offered by the soil to the movement of the pile. In cohesive soil, the cohesive forces between the soil particles are much stronger than the frictional forces. Therefore, the frictional resistance is negligible compared to the cohesive forces.

Shear Strength of Soil:

Shear strength is the ability of soil to resist shear stresses. In cohesive soil, the shear strength is primarily derived from the cohesive forces between the soil particles. These cohesive forces contribute to the shear strength of the soil and allow it to resist deformation.

Surface Area of Pile:

The surface area of the pile refers to the area of contact between the pile and the surrounding soil. In cohesive soil, the cohesive forces between the soil particles dominate the behavior of the soil-pile system. The surface area of the pile is relatively small compared to the cohesive forces acting on the soil particles. Therefore, the surface area of the pile is neglected for individual pile action in cohesive soil.

Conclusion:

In cohesive soil, the behavior of the pile is primarily governed by the cohesive forces between the soil particles. The frictional resistance and surface area of the pile are negligible compared to the cohesive forces. Therefore, the surface area of the pile is neglected for individual pile action in cohesive soil.

In the case of cohesive soil, which is a type of soil with fine particles that stick together, the surface area of the pile is neglected for individual pile action. This means that the surface area of the pile does not play a significant role in the behavior of the pile in cohesive soil.

Reasoning:

The reason for neglecting the surface area of the pile in cohesive soil is primarily due to the nature of cohesive soil itself. Cohesive soil has the ability to develop shear strength due to the cohesive forces between its particles. These cohesive forces allow the soil to resist deformation and maintain its shape.

Frictional Resistance:

Frictional resistance refers to the resistance offered by the soil to the movement of the pile. In cohesive soil, the cohesive forces between the soil particles are much stronger than the frictional forces. Therefore, the frictional resistance is negligible compared to the cohesive forces.

Shear Strength of Soil:

Shear strength is the ability of soil to resist shear stresses. In cohesive soil, the shear strength is primarily derived from the cohesive forces between the soil particles. These cohesive forces contribute to the shear strength of the soil and allow it to resist deformation.

Surface Area of Pile:

The surface area of the pile refers to the area of contact between the pile and the surrounding soil. In cohesive soil, the cohesive forces between the soil particles dominate the behavior of the soil-pile system. The surface area of the pile is relatively small compared to the cohesive forces acting on the soil particles. Therefore, the surface area of the pile is neglected for individual pile action in cohesive soil.

Conclusion:

In cohesive soil, the behavior of the pile is primarily governed by the cohesive forces between the soil particles. The frictional resistance and surface area of the pile are negligible compared to the cohesive forces. Therefore, the surface area of the pile is neglected for individual pile action in cohesive soil.

The group efficiency of a pile group- a)will be always less than 100%

- b)will be always greater than 100%

- c)may be less than 100% or more than 100% depending upon other factors

- d)is more than 100% in cohesionless soil and less than 100% in cohesive soil

Correct answer is option 'D'. Can you explain this answer?

The group efficiency of a pile group

a)

will be always less than 100%

b)

will be always greater than 100%

c)

may be less than 100% or more than 100% depending upon other factors

d)

is more than 100% in cohesionless soil and less than 100% in cohesive soil

|

Tanvi Sarkar answered |

Understanding Group Efficiency of Pile Groups

The efficiency of a pile group refers to how effectively the group can support loads compared to individual piles. The concept is influenced by soil type and load distribution.

Factors Influencing Group Efficiency

- Soil Type: The behavior of pile groups varies significantly in cohesive versus cohesionless soils.

- Load Distribution: The way loads are transferred through piles affects their performance as a group.

Efficiency in Cohesionless Soils

- In cohesionless soils (like sand), pile groups can experience increased efficiency due to lateral and vertical load sharing.

- The interaction between piles allows for better redistribution of forces, often leading to a group efficiency greater than 100%.

Efficiency in Cohesive Soils

- In cohesive soils (like clay), the behavior is different. The piles may not interact as beneficially due to the stiffness of the surrounding soil.

- This can lead to a situation where the group efficiency is less than 100%, as the soil may not provide adequate support or may limit the performance of the individual piles.

Conclusion

The correct answer, option 'D', reflects the reality that:

- Group efficiency can exceed 100% in cohesionless soils due to favorable load sharing.

- Conversely, it is typically less than 100% in cohesive soils due to the restrictive nature of the soil.

Understanding these dynamics is crucial for effective pile design and performance evaluation in different soil conditions.

The efficiency of a pile group refers to how effectively the group can support loads compared to individual piles. The concept is influenced by soil type and load distribution.

Factors Influencing Group Efficiency

- Soil Type: The behavior of pile groups varies significantly in cohesive versus cohesionless soils.

- Load Distribution: The way loads are transferred through piles affects their performance as a group.

Efficiency in Cohesionless Soils

- In cohesionless soils (like sand), pile groups can experience increased efficiency due to lateral and vertical load sharing.

- The interaction between piles allows for better redistribution of forces, often leading to a group efficiency greater than 100%.

Efficiency in Cohesive Soils

- In cohesive soils (like clay), the behavior is different. The piles may not interact as beneficially due to the stiffness of the surrounding soil.

- This can lead to a situation where the group efficiency is less than 100%, as the soil may not provide adequate support or may limit the performance of the individual piles.

Conclusion

The correct answer, option 'D', reflects the reality that:

- Group efficiency can exceed 100% in cohesionless soils due to favorable load sharing.

- Conversely, it is typically less than 100% in cohesive soils due to the restrictive nature of the soil.

Understanding these dynamics is crucial for effective pile design and performance evaluation in different soil conditions.

The pile load test should be performed on __________- a)Working pile

- b)Test pile

- c)All of the mentioned

- d)None of the mentioned

Correct answer is option 'C'. Can you explain this answer?

The pile load test should be performed on __________

a)

Working pile

b)

Test pile

c)

All of the mentioned

d)

None of the mentioned

|

Sahil Chawla answered |

Introduction:

The pile load test is a crucial test conducted in the field of civil engineering to determine the load-bearing capacity and the overall performance of a pile foundation. This test is performed on both working piles and test piles.

Explanation:

a) Working pile:

- A working pile refers to a pile that is part of the actual foundation system designed to support the structure.

- These piles are installed during the construction phase and are subjected to the actual loads from the structure.

- The primary purpose of a working pile is to provide support and stability to the structure.

- The pile load test is performed on working piles to assess their load-bearing capacity and ensure that they meet the design requirements.

- It helps to verify whether the working piles are capable of safely carrying the loads imposed by the structure.

b) Test pile:

- A test pile, on the other hand, is specifically installed for the purpose of conducting load tests.

- Test piles are typically installed adjacent to the working piles and are not part of the actual foundation system.

- These piles are used to evaluate the soil conditions, determine the load-bearing capacity, and assess the performance of the pile foundation.

- The test pile is subjected to a controlled load incrementally to measure the settlement response and load capacity of the pile.

- The data obtained from the test pile is used to validate the design assumptions and to optimize the pile foundation for the structure.

c) All of the mentioned:

- The pile load test is performed on both working piles and test piles.

- It is essential to conduct the test on working piles to ensure their load-bearing capacity and performance.

- Test piles provide valuable information about the soil conditions and help in optimizing the design of the pile foundation.

- Therefore, the pile load test should be performed on both working piles and test piles to ensure the overall safety and efficiency of the pile foundation system.

Conclusion:

In conclusion, the pile load test should be performed on both working piles and test piles. This comprehensive testing approach helps validate the design assumptions, optimize the foundation system, and ensure the overall performance and safety of the pile foundation.

The pile load test is a crucial test conducted in the field of civil engineering to determine the load-bearing capacity and the overall performance of a pile foundation. This test is performed on both working piles and test piles.

Explanation:

a) Working pile:

- A working pile refers to a pile that is part of the actual foundation system designed to support the structure.

- These piles are installed during the construction phase and are subjected to the actual loads from the structure.

- The primary purpose of a working pile is to provide support and stability to the structure.

- The pile load test is performed on working piles to assess their load-bearing capacity and ensure that they meet the design requirements.

- It helps to verify whether the working piles are capable of safely carrying the loads imposed by the structure.

b) Test pile:

- A test pile, on the other hand, is specifically installed for the purpose of conducting load tests.

- Test piles are typically installed adjacent to the working piles and are not part of the actual foundation system.

- These piles are used to evaluate the soil conditions, determine the load-bearing capacity, and assess the performance of the pile foundation.

- The test pile is subjected to a controlled load incrementally to measure the settlement response and load capacity of the pile.

- The data obtained from the test pile is used to validate the design assumptions and to optimize the pile foundation for the structure.

c) All of the mentioned:

- The pile load test is performed on both working piles and test piles.

- It is essential to conduct the test on working piles to ensure their load-bearing capacity and performance.

- Test piles provide valuable information about the soil conditions and help in optimizing the design of the pile foundation.

- Therefore, the pile load test should be performed on both working piles and test piles to ensure the overall safety and efficiency of the pile foundation system.

Conclusion:

In conclusion, the pile load test should be performed on both working piles and test piles. This comprehensive testing approach helps validate the design assumptions, optimize the foundation system, and ensure the overall performance and safety of the pile foundation.

Find the dynamic load-carrying capacity of a roller bearing if the shaft rotates at 1500 rpm, the radial load acting on the bearing is 6 kN and the expected life for 90% life of the bearing is 8100 hours.- a)6 kN

- b)44 kN

- c)54000 kN

- d)60000 kN

Correct answer is option 'B'. Can you explain this answer?

Find the dynamic load-carrying capacity of a roller bearing if the shaft rotates at 1500 rpm, the radial load acting on the bearing is 6 kN and the expected life for 90% life of the bearing is 8100 hours.

a)

6 kN

b)

44 kN

c)

54000 kN

d)

60000 kN

|

|

Sudhir Patel answered |

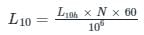

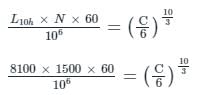

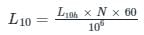

Load-life relationship:

The approximate rating of the service life of a ball or roller bearing is based on the given fundamental equation.

L10 = Rated bearing life (in million revolutions)

C = Dynamic load capacity.

P = Load acting in bearing.

k = 3 for ball bearing and k = 10/3 for the roller bearing.

The relation between life in million revolutions and life in hours is given by:

where, L10h = rated bearing life in hours and N = speed of rotation in rpm.

Calculation:

Given:

N = 1500 rpm, P = 6 kN, L10h = 8100 hours, roller bearing k = 10/3

We know that;

Combining both equations:

C = 43.34 kN

The approximate rating of the service life of a ball or roller bearing is based on the given fundamental equation.

L10 = Rated bearing life (in million revolutions)

C = Dynamic load capacity.

P = Load acting in bearing.

k = 3 for ball bearing and k = 10/3 for the roller bearing.

The relation between life in million revolutions and life in hours is given by:

where, L10h = rated bearing life in hours and N = speed of rotation in rpm.

Calculation:

Given:

N = 1500 rpm, P = 6 kN, L10h = 8100 hours, roller bearing k = 10/3

We know that;

Combining both equations:

C = 43.34 kN

In single row angular contact ball bearings, the basic static load relates to the: - a)full radial and partial axial component of the load

- b)axial component of the load

- c)full axial and partial radial component of the load

- d)radial component of the load

Correct answer is option 'A'. Can you explain this answer?

In single row angular contact ball bearings, the basic static load relates to the:

a)

full radial and partial axial component of the load

b)

axial component of the load

c)

full axial and partial radial component of the load

d)

radial component of the load

|

Nilanjan Chawla answered |

Basic Static Load in Single Row Angular Contact Ball Bearings

The basic static load in single row angular contact ball bearings refers to the load that the bearing can withstand without permanent deformation or damage. It is an important parameter to consider when selecting bearings for applications that involve static loads.

Understanding Angular Contact Ball Bearings

Angular contact ball bearings are designed to withstand combined radial and axial loads. They have raceways in the inner and outer rings that are inclined relative to the bearing axis. This design allows the bearings to support both radial and axial loads simultaneously.

Load Components in Single Row Angular Contact Ball Bearings

In single row angular contact ball bearings, the load can be divided into two components:

1. Radial Component: The radial component of the load is the force acting perpendicular to the bearing axis. It is the load that is applied to the bearing in a direction parallel to the shaft.

2. Axial Component: The axial component of the load is the force acting parallel to the bearing axis. It is the load that is applied to the bearing in a direction perpendicular to the shaft.

Relationship between Basic Static Load and Load Components

The basic static load rating of a single row angular contact ball bearing is defined as the static radial load that causes a total permanent deformation of the ball and raceway contact surfaces equal to 0.0001 of the ball diameter.

Since angular contact ball bearings are designed to withstand combined radial and axial loads, the basic static load rating takes into account both the radial and axial load components. Therefore, the correct answer is option 'A' - the full radial and partial axial component of the load.

This means that the basic static load rating indicates the maximum load that can be applied to a bearing without causing permanent deformation, taking into consideration both the radial and axial forces acting on the bearing.

By considering the full radial and partial axial component of the load, the basic static load rating provides a comprehensive measure of the bearing's load-carrying capacity and ensures that the bearing can safely withstand the anticipated loads in a static application.

The basic static load in single row angular contact ball bearings refers to the load that the bearing can withstand without permanent deformation or damage. It is an important parameter to consider when selecting bearings for applications that involve static loads.

Understanding Angular Contact Ball Bearings

Angular contact ball bearings are designed to withstand combined radial and axial loads. They have raceways in the inner and outer rings that are inclined relative to the bearing axis. This design allows the bearings to support both radial and axial loads simultaneously.

Load Components in Single Row Angular Contact Ball Bearings

In single row angular contact ball bearings, the load can be divided into two components:

1. Radial Component: The radial component of the load is the force acting perpendicular to the bearing axis. It is the load that is applied to the bearing in a direction parallel to the shaft.

2. Axial Component: The axial component of the load is the force acting parallel to the bearing axis. It is the load that is applied to the bearing in a direction perpendicular to the shaft.

Relationship between Basic Static Load and Load Components

The basic static load rating of a single row angular contact ball bearing is defined as the static radial load that causes a total permanent deformation of the ball and raceway contact surfaces equal to 0.0001 of the ball diameter.

Since angular contact ball bearings are designed to withstand combined radial and axial loads, the basic static load rating takes into account both the radial and axial load components. Therefore, the correct answer is option 'A' - the full radial and partial axial component of the load.

This means that the basic static load rating indicates the maximum load that can be applied to a bearing without causing permanent deformation, taking into consideration both the radial and axial forces acting on the bearing.

By considering the full radial and partial axial component of the load, the basic static load rating provides a comprehensive measure of the bearing's load-carrying capacity and ensures that the bearing can safely withstand the anticipated loads in a static application.

Black cotton soil is unsuitable for foundations because its- a)particles are cohesive

- b)permeability is uncertain

- c)property to undergo volumetric change

- d)bearing capacity is low

Correct answer is option 'C'. Can you explain this answer?

Black cotton soil is unsuitable for foundations because its

a)

particles are cohesive

b)

permeability is uncertain

c)

property to undergo volumetric change

d)

bearing capacity is low

|

Bijoy Mehra answered |

Why Black Cotton Soil is Unsuitable for Foundations

Black cotton soil is a type of expansive soil that is composed of clay minerals and is known to undergo volumetric changes due to changes in moisture content. It is unsuitable for foundations due to the following reasons:

1. Volumetric Changes

Black cotton soil has a high capacity to absorb moisture, which causes it to swell and expand. Conversely, when it loses moisture, it shrinks and contracts. These volumetric changes can cause significant damage to foundations, leading to cracks and settlement.

2. Low Bearing Capacity

Black cotton soil has a low bearing capacity, which means it cannot support heavy loads. This is because it is composed of small particles that are cohesive and have poor drainage properties. When a foundation is built on such soil, it can easily sink and become unstable, leading to structural damage.

3. Permeability

Black cotton soil has uncertain permeability, which means it can retain moisture for a long time. This can lead to the weakening of the soil structure, making it unsuitable for foundations.

Conclusion

In conclusion, black cotton soil is unsuitable for foundations due to its property to undergo volumetric changes, low bearing capacity, and uncertain permeability. It is important to carry out a soil investigation before building any foundation to determine the suitability of the soil for the intended purpose.

Black cotton soil is a type of expansive soil that is composed of clay minerals and is known to undergo volumetric changes due to changes in moisture content. It is unsuitable for foundations due to the following reasons:

1. Volumetric Changes

Black cotton soil has a high capacity to absorb moisture, which causes it to swell and expand. Conversely, when it loses moisture, it shrinks and contracts. These volumetric changes can cause significant damage to foundations, leading to cracks and settlement.

2. Low Bearing Capacity

Black cotton soil has a low bearing capacity, which means it cannot support heavy loads. This is because it is composed of small particles that are cohesive and have poor drainage properties. When a foundation is built on such soil, it can easily sink and become unstable, leading to structural damage.

3. Permeability

Black cotton soil has uncertain permeability, which means it can retain moisture for a long time. This can lead to the weakening of the soil structure, making it unsuitable for foundations.

Conclusion

In conclusion, black cotton soil is unsuitable for foundations due to its property to undergo volumetric changes, low bearing capacity, and uncertain permeability. It is important to carry out a soil investigation before building any foundation to determine the suitability of the soil for the intended purpose.

The result of Dutch cone penetration test can be applied to determine _________- a)Ultimate skin fraction

- b)Total ultimate point

- c)Ultimate bearing capacity

- d)None of the mentioned

Correct answer is option 'C'. Can you explain this answer?

The result of Dutch cone penetration test can be applied to determine _________

a)

Ultimate skin fraction

b)

Total ultimate point

c)

Ultimate bearing capacity

d)

None of the mentioned

|

|

Sanvi Kapoor answered |

The result of Dutch cone penetration test can be applied with sufficient accuracy to determine the ultimate bearing capacity of piles in cohesion soils.

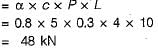

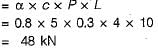

A square pile of section 30 cm x 30 cm and length 10 m penetrates a deposit of clay having c = 5 kN/m2 and the mobilizing factor α = 0.8. What is the load carried by the pile by skin friction only?- a)192 kN

- b)75 kN

- c)60 kN

- d)48 kN

Correct answer is option 'D'. Can you explain this answer?

A square pile of section 30 cm x 30 cm and length 10 m penetrates a deposit of clay having c = 5 kN/m2 and the mobilizing factor α = 0.8. What is the load carried by the pile by skin friction only?

a)

192 kN

b)

75 kN

c)

60 kN

d)

48 kN

|

Jay Sharma answered |

The load carried by skin-friction only

A cycle load test is performed to determine a pile's- a)Skin resistance

- b)Tip resistance

- c)Ultimate load capacity under repetition

- d)Skin resistance and tip resistance separately

Correct answer is option 'D'. Can you explain this answer?

A cycle load test is performed to determine a pile's

a)

Skin resistance

b)

Tip resistance

c)

Ultimate load capacity under repetition

d)

Skin resistance and tip resistance separately

|

Aniket Mehta answered |

Cycle Load Test for Piles

A cycle load test is a type of load test performed on piles to determine their ultimate load capacity under repetition. It involves applying a cyclic load to the pile and monitoring the pile's response to the load. The test is performed to assess the pile's long-term performance and to determine its resistance to fatigue failure.

Skin Resistance and Tip Resistance

During the cycle load test, the skin resistance and tip resistance of the pile are determined separately. Skin resistance is the resistance that the soil exerts on the pile shaft, while tip resistance is the resistance that the soil exerts on the pile tip. These two types of resistance are critical in determining the pile's ultimate load capacity.

Skin Resistance Testing

Skin resistance testing involves applying a cyclic load to the pile and measuring the deflection of the pile shaft. The deflection is used to calculate the skin resistance of the pile. Skin resistance testing is essential for determining the pile's capacity to resist lateral loads and bending.

Tip Resistance Testing

Tip resistance testing involves applying a cyclic load to the pile and measuring the deflection of the pile tip. The deflection is used to calculate the tip resistance of the pile. Tip resistance testing is essential for determining the pile's capacity to resist axial loads.

Conclusion

In conclusion, a cycle load test is performed to determine the ultimate load capacity of a pile under repetition. During the test, the skin resistance and tip resistance of the pile are determined separately. Skin resistance testing is essential for determining the pile's capacity to resist lateral loads and bending, while tip resistance testing is essential for determining the pile's capacity to resist axial loads.

A cycle load test is a type of load test performed on piles to determine their ultimate load capacity under repetition. It involves applying a cyclic load to the pile and monitoring the pile's response to the load. The test is performed to assess the pile's long-term performance and to determine its resistance to fatigue failure.

Skin Resistance and Tip Resistance

During the cycle load test, the skin resistance and tip resistance of the pile are determined separately. Skin resistance is the resistance that the soil exerts on the pile shaft, while tip resistance is the resistance that the soil exerts on the pile tip. These two types of resistance are critical in determining the pile's ultimate load capacity.

Skin Resistance Testing

Skin resistance testing involves applying a cyclic load to the pile and measuring the deflection of the pile shaft. The deflection is used to calculate the skin resistance of the pile. Skin resistance testing is essential for determining the pile's capacity to resist lateral loads and bending.

Tip Resistance Testing

Tip resistance testing involves applying a cyclic load to the pile and measuring the deflection of the pile tip. The deflection is used to calculate the tip resistance of the pile. Tip resistance testing is essential for determining the pile's capacity to resist axial loads.

Conclusion

In conclusion, a cycle load test is performed to determine the ultimate load capacity of a pile under repetition. During the test, the skin resistance and tip resistance of the pile are determined separately. Skin resistance testing is essential for determining the pile's capacity to resist lateral loads and bending, while tip resistance testing is essential for determining the pile's capacity to resist axial loads.

Modern pile driving method was first invented by ______- a)Romans

- b)Nasmyth

- c)Terzaghi

- d)Vitruvious

Correct answer is option 'B'. Can you explain this answer?

Modern pile driving method was first invented by ______

a)

Romans

b)

Nasmyth

c)

Terzaghi

d)

Vitruvious

|

Jaya Yadav answered |

Modern pile driving method was first invented by Nasmyth

James Nasmyth

James Nasmyth, a Scottish engineer and inventor, is credited with inventing the modern pile driving method. He was born in 1808 and is best known for his invention of the steam hammer, which revolutionized the pile driving process.

Invention of the Steam Hammer

Nasmyth's invention of the steam hammer allowed piles to be driven into the ground with much greater force and efficiency than previous methods. The steam hammer used steam power to deliver powerful blows to the pile, driving it deep into the ground quickly and effectively.

Impact on Construction Industry

The invention of the steam hammer by Nasmyth had a significant impact on the construction industry. It made pile driving faster, more efficient, and more cost-effective, allowing for the construction of larger and more complex structures.

Legacy

Nasmyth's contributions to the field of engineering, including the invention of the modern pile driving method, have had a lasting impact on the construction industry. His innovations continue to be used in construction projects around the world today.

Conclusion

In conclusion, James Nasmyth is credited with inventing the modern pile driving method through his invention of the steam hammer. His innovative approach to pile driving revolutionized the construction industry and continues to be an important technique in modern construction projects.

James Nasmyth

James Nasmyth, a Scottish engineer and inventor, is credited with inventing the modern pile driving method. He was born in 1808 and is best known for his invention of the steam hammer, which revolutionized the pile driving process.

Invention of the Steam Hammer

Nasmyth's invention of the steam hammer allowed piles to be driven into the ground with much greater force and efficiency than previous methods. The steam hammer used steam power to deliver powerful blows to the pile, driving it deep into the ground quickly and effectively.

Impact on Construction Industry

The invention of the steam hammer by Nasmyth had a significant impact on the construction industry. It made pile driving faster, more efficient, and more cost-effective, allowing for the construction of larger and more complex structures.

Legacy

Nasmyth's contributions to the field of engineering, including the invention of the modern pile driving method, have had a lasting impact on the construction industry. His innovations continue to be used in construction projects around the world today.

Conclusion

In conclusion, James Nasmyth is credited with inventing the modern pile driving method through his invention of the steam hammer. His innovative approach to pile driving revolutionized the construction industry and continues to be an important technique in modern construction projects.

In pile foundation, the skin friction and end bearing are separated by- a)Static formula

- b)Hiley's formula

- c)Engineering news formula

- d)Cyclic loading test

Correct answer is option 'D'. Can you explain this answer?

In pile foundation, the skin friction and end bearing are separated by

a)

Static formula

b)

Hiley's formula

c)

Engineering news formula

d)

Cyclic loading test

|

Sankar Rane answered |

Static formula gives the ultimate capacity of an individual pile

Hileys formula and Engineering news formula are dynamic formula to calculate the load-carrying capacity of a driven pile

In Cyclic loading test an incremental load is repeatedly applied and removed to separate skin friction and end bearing of a pile.

Hileys formula and Engineering news formula are dynamic formula to calculate the load-carrying capacity of a driven pile

In Cyclic loading test an incremental load is repeatedly applied and removed to separate skin friction and end bearing of a pile.

The settlement ratio of pile group is generally- a)less than 0.25

- b)between 0.5 and 0.75

- c)between 0.75 and 1.00

- d)more than 1.00

Correct answer is option 'D'. Can you explain this answer?

The settlement ratio of pile group is generally

a)

less than 0.25

b)

between 0.5 and 0.75

c)

between 0.75 and 1.00

d)

more than 1.00

|

Tanishq Nair answered |

The settlement of a group of piles in mnore than the settlement of a single pile even when the load on the single pile and the load on each pile of the pile group are same. This is because of the fact that the zone of influence of a pile group is much deeper than that of a single pile.

Sheet piles are commonly used as __________ in hydraulic structure.- a)Bulk heads

- b)Bearing stratum

- c)Boulders

- d)Composite piles

Correct answer is option 'A'. Can you explain this answer?

Sheet piles are commonly used as __________ in hydraulic structure.

a)

Bulk heads

b)

Bearing stratum

c)

Boulders

d)

Composite piles

|

|

Sanya Agarwal answered |

Sheet piles are commonly used as bulkheads, or as an impervious cutoff to reduce seepage and uplift under the hydraulic structure.

Immediately on driving a pile in clayey soil, it will have- a)High point resistance

- b)High skin friction

- c)Low point resistance

- d)Improvement of structure of surrounding soil

Correct answer is option 'C'. Can you explain this answer?

Immediately on driving a pile in clayey soil, it will have

a)

High point resistance

b)

High skin friction

c)

Low point resistance

d)

Improvement of structure of surrounding soil

|

Anshul Chakraborty answered |

Answer:

Clayey soil is a type of soil that is characterized by its high plasticity, low permeability, and high compressibility. When a pile is driven into clayey soil, it will experience both skin friction and point resistance. The skin friction is the resistance that occurs along the surface of the pile as it moves through the soil, while the point resistance is the resistance that occurs at the tip of the pile.

Explanation:

Low Point Resistance:

- When a pile is driven into clayey soil, it will experience low point resistance because the soil is highly compressible and cannot provide a significant amount of support to the pile.

- The clayey soil will deform and compress under the weight of the pile, which will result in a low point resistance.

- This low point resistance can make it difficult to drive the pile to a desired depth or to achieve the required load capacity.

High Skin Friction:

- On the other hand, when a pile is driven into clayey soil, it will experience high skin friction because the soil particles will adhere to the surface of the pile.

- This skin friction will provide additional support to the pile and increase its load capacity.

- However, the high skin friction can also make it difficult to drive the pile into the soil because it creates a significant amount of resistance.

Improvement of Structure of Surrounding Soil:

- As the pile is driven into the soil, it will also improve the structure of the surrounding soil by compacting it and increasing its density.

- This can be beneficial in situations where the soil is unstable or prone to settlement.

- The compacted soil will provide additional support to the pile and increase its load capacity.

Conclusion:

In conclusion, driving a pile into clayey soil will result in low point resistance, high skin friction, and improvement of the structure of the surrounding soil. These factors should be taken into consideration when designing and constructing foundations in clayey soil.

Clayey soil is a type of soil that is characterized by its high plasticity, low permeability, and high compressibility. When a pile is driven into clayey soil, it will experience both skin friction and point resistance. The skin friction is the resistance that occurs along the surface of the pile as it moves through the soil, while the point resistance is the resistance that occurs at the tip of the pile.

Explanation:

Low Point Resistance:

- When a pile is driven into clayey soil, it will experience low point resistance because the soil is highly compressible and cannot provide a significant amount of support to the pile.

- The clayey soil will deform and compress under the weight of the pile, which will result in a low point resistance.

- This low point resistance can make it difficult to drive the pile to a desired depth or to achieve the required load capacity.

High Skin Friction:

- On the other hand, when a pile is driven into clayey soil, it will experience high skin friction because the soil particles will adhere to the surface of the pile.

- This skin friction will provide additional support to the pile and increase its load capacity.

- However, the high skin friction can also make it difficult to drive the pile into the soil because it creates a significant amount of resistance.

Improvement of Structure of Surrounding Soil:

- As the pile is driven into the soil, it will also improve the structure of the surrounding soil by compacting it and increasing its density.

- This can be beneficial in situations where the soil is unstable or prone to settlement.

- The compacted soil will provide additional support to the pile and increase its load capacity.

Conclusion:

In conclusion, driving a pile into clayey soil will result in low point resistance, high skin friction, and improvement of the structure of the surrounding soil. These factors should be taken into consideration when designing and constructing foundations in clayey soil.

The art of driving piles into the ground was first established by __________- a)Greeks

- b)Romans

- c)Philippians

- d)None of the mentioned

Correct answer is option 'B'. Can you explain this answer?

The art of driving piles into the ground was first established by __________

a)

Greeks

b)

Romans

c)

Philippians

d)

None of the mentioned

|

|

Sanya Agarwal answered |

The art of driving was first well-established in Roman times and the details of such foundation were recorded by Vitruvius in 59 A.D.

The separation of Q at any stage of loading into Rp and Rf in cyclic test is based on experimental value found out by________- a)Hailey

- b)A.F. Van Weele

- c)A.M. Wellington

- d)MacArthur

Correct answer is option 'B'. Can you explain this answer?

The separation of Q at any stage of loading into Rp and Rf in cyclic test is based on experimental value found out by________

a)

Hailey

b)

A.F. Van Weele

c)

A.M. Wellington

d)

MacArthur

|

|

Sanvi Kapoor answered |

The separation of Q at any stage of loading into Rp and Rf in cyclic test is based on experimental found value of A.F. Van Weele (1957) that the load on the pile toes (1957) that the load on the pile toe (i.e. RP) increases linearly with the elastic compression of the soil.

In the Engineering News Record formula for determining the safe load, carrying capacity of a pile, the factor of safety used is- a)2.5

- b)3

- c)4

- d)6

Correct answer is option 'D'. Can you explain this answer?

In the Engineering News Record formula for determining the safe load, carrying capacity of a pile, the factor of safety used is

a)

2.5

b)

3

c)

4

d)

6

|

Kirti Sharma answered |

Determining Safe Load Carrying Capacity of a Pile

The safe load carrying capacity of a pile is an important factor in the design and construction of foundations for various structures. The Engineering News Record (ENR) formula is a widely used method for calculating the safe load carrying capacity of a pile. This formula takes into account various factors such as the pile diameter, length, soil properties, and the factor of safety.

Factor of Safety

The factor of safety is defined as the ratio of the ultimate load or the maximum load that a pile can withstand to the working load or the load that is applied during the normal operation of the structure. The factor of safety is used to ensure that the pile can safely withstand any additional loads or stresses that may be exerted on it due to various factors such as changes in soil conditions, structural modifications, or external forces such as earthquakes or wind loads.

ENR Formula

The ENR formula for determining the safe load carrying capacity of a pile is given by:

Qs = (A x S x Nc x Sc) + (A x S x Nq x Sq) + (0.5 x A x S x Nγ x γ)

Where:

Qs = Safe load carrying capacity of the pile

A = Cross-sectional area of the pile

S = Allowable bearing pressure of the soil

Nc, Nq, and Nγ = Bearing capacity factors for cohesion, angle of internal friction, and unit weight of soil, respectively

Sc, Sq, and γ = Correction factors for cohesion, angle of internal friction, and unit weight of soil, respectively.

The factor of safety used in the ENR formula is typically 6, which ensures that the pile can safely withstand any additional loads or stresses that may be exerted on it. This factor of safety is based on various factors such as the uncertainty in soil properties, the variability in structural loads, and the potential for unforeseen events such as earthquakes or extreme weather conditions.

Conclusion

The factor of safety is an important parameter in the design and construction of foundations for various structures. The ENR formula provides a comprehensive methodology for calculating the safe load carrying capacity of a pile, taking into account various factors such as the soil properties, pile dimensions, and the factor of safety. The use of a factor of safety of 6 ensures that the pile can safely withstand any additional loads or stresses that may be exerted on it.

The safe load carrying capacity of a pile is an important factor in the design and construction of foundations for various structures. The Engineering News Record (ENR) formula is a widely used method for calculating the safe load carrying capacity of a pile. This formula takes into account various factors such as the pile diameter, length, soil properties, and the factor of safety.

Factor of Safety