All Exams >

Mechanical Engineering >

Mechanical Engineering SSC JE (Technical) >

All Questions

All questions of Topic-wise Tests for Mechanical Engineering Exam

If the compression ratio of an IC engine running on otto cycle increases the efficency of the cycle- a)increases

- b)Has no effect

- c)Decreases

- d)Cannot be commented

Correct answer is option 'A'. Can you explain this answer?

If the compression ratio of an IC engine running on otto cycle increases the efficency of the cycle

a)

increases

b)

Has no effect

c)

Decreases

d)

Cannot be commented

|

Sagarika Patel answered |

In addition, as we increase the compression ratio, the increased pressure and temperature after the compression process increases the likelihood of dieseling, which describes a situation in which the fuel ignites on its own, before the ignition spark is applied.

According to chvorinov's equation, the solidification time in casting is proportional to- a)V2

- b)V

- c)1v

- d)1v2

Correct answer is option 'A'. Can you explain this answer?

According to chvorinov's equation, the solidification time in casting is proportional to

a)

V2

b)

V

c)

1v

d)

1v2

|

Shivam Sharma answered |

TS = K (V/SA)2 ts = K

K= Solidification factor

V=volume of casting

SA= surface area of casting

V=volume of casting

SA= surface area of casting

With increase in temperature of intake air, I.C. engine efficiency.- a)Decreases

- b)increases

- c)Remains same

- d)Depends on other factors.

Correct answer is option 'A'. Can you explain this answer?

With increase in temperature of intake air, I.C. engine efficiency.

a)

Decreases

b)

increases

c)

Remains same

d)

Depends on other factors.

|

|

Preeti Iyer answered |

In an ic engine intake temperature increases then the efficiency of engine is. With the increase in intake temperature, volumetric efficiency increases upto a certain level as density of air increase but increasing more temperature will decrease the efficiency.

For a pure substance, the degree of freedom forsaturated vapour and superheated vapour are- a)1 and 2

- b)1 and 1

- c)2 and 1

- d)2 and 2

Correct answer is option 'A'. Can you explain this answer?

For a pure substance, the degree of freedom forsaturated vapour and superheated vapour are

a)

1 and 2

b)

1 and 1

c)

2 and 1

d)

2 and 2

|

|

Meera Bose answered |

Degree of Freedom for Pure Substance

The degree of freedom for a pure substance can be defined as the number of independent intensive variables that can be varied without changing the number of phases in the system. For a pure substance, the degree of freedom can be determined using the Gibbs phase rule, which is given by:

F = C - P + 2

Where F is the degree of freedom, C is the number of components in the system, and P is the number of phases in the system.

Degree of Freedom for Saturated Vapor

Saturated vapor can be defined as the vapor at the saturation temperature corresponding to its pressure. The degree of freedom for saturated vapor can be determined as follows:

- For a pure substance, the number of components is one (C = 1).

- For saturated vapor, there is only one phase present (P = 1).

- Using the Gibbs phase rule, we get:

F = C - P + 2

F = 1 - 1 + 2

F = 2

Therefore, the degree of freedom for saturated vapor of a pure substance is 2.

Degree of Freedom for Superheated Vapor

Superheated vapor can be defined as the vapor at a temperature higher than its saturation temperature corresponding to its pressure. The degree of freedom for superheated vapor can be determined as follows:

- For a pure substance, the number of components is one (C = 1).

- For superheated vapor, there is only one phase present (P = 1).

- Using the Gibbs phase rule, we get:

F = C - P + 2

F = 1 - 1 + 1

F = 1

Therefore, the degree of freedom for superheated vapor of a pure substance is 1.

Conclusion

In conclusion, the correct answer to the given question is option A, which states that the degree of freedom for saturated vapor and superheated vapor of a pure substance is 1 and 2, respectively.

The degree of freedom for a pure substance can be defined as the number of independent intensive variables that can be varied without changing the number of phases in the system. For a pure substance, the degree of freedom can be determined using the Gibbs phase rule, which is given by:

F = C - P + 2

Where F is the degree of freedom, C is the number of components in the system, and P is the number of phases in the system.

Degree of Freedom for Saturated Vapor

Saturated vapor can be defined as the vapor at the saturation temperature corresponding to its pressure. The degree of freedom for saturated vapor can be determined as follows:

- For a pure substance, the number of components is one (C = 1).

- For saturated vapor, there is only one phase present (P = 1).

- Using the Gibbs phase rule, we get:

F = C - P + 2

F = 1 - 1 + 2

F = 2

Therefore, the degree of freedom for saturated vapor of a pure substance is 2.

Degree of Freedom for Superheated Vapor

Superheated vapor can be defined as the vapor at a temperature higher than its saturation temperature corresponding to its pressure. The degree of freedom for superheated vapor can be determined as follows:

- For a pure substance, the number of components is one (C = 1).

- For superheated vapor, there is only one phase present (P = 1).

- Using the Gibbs phase rule, we get:

F = C - P + 2

F = 1 - 1 + 1

F = 1

Therefore, the degree of freedom for superheated vapor of a pure substance is 1.

Conclusion

In conclusion, the correct answer to the given question is option A, which states that the degree of freedom for saturated vapor and superheated vapor of a pure substance is 1 and 2, respectively.

Which of the following is an extensive property.- a)Density

- b)Force

- c)thermal conductivity

- d)Internal Energy.

Correct answer is option 'D'. Can you explain this answer?

Which of the following is an extensive property.

a)

Density

b)

Force

c)

thermal conductivity

d)

Internal Energy.

|

Sagarika Patel answered |

Internal energy is the f(T,P) two intensive propertys…And also

Extensive proerty depend on Mass and Size(volume) of the system

Intensive proerty don't depend on Mass of the system

Ex: Take Diamond

An intensive property is a bulk property, meaning that it is a physical property of a system that does not depend on the system size or the amount of material in the system. Examples of intensive properties include temperature, T, refractive index, n, density, ρ, and hardness of an object, When a diamond is cut, the pieces maintain their intrinsic hardness (until their size reaches a few atoms thick), so hardness is independent of the size of the system.

The main purpose of chaplets is- a)To ensure directional solidification

- b)To provide efficient venting

- c)for alighting the mould boxes.

- d)To support the cores

Correct answer is option 'D'. Can you explain this answer?

The main purpose of chaplets is

a)

To ensure directional solidification

b)

To provide efficient venting

c)

for alighting the mould boxes.

d)

To support the cores

|

|

Preeti Iyer answered |

The main purpose of chaplets is to

ensure directional solidification.

pressure at a place was measured to be 1000 mm of mercury. The pressure in terms of height of water will be :-- a)1.36 m

- b)13.6 m

- c)136.0 m

- d)None

Correct answer is option 'B'. Can you explain this answer?

pressure at a place was measured to be 1000 mm of mercury. The pressure in terms of height of water will be :-

a)

1.36 m

b)

13.6 m

c)

136.0 m

d)

None

|

Diya Ahuja answered |

Pressure Conversion from Mercury to Water

Explanation:

The pressure at a place is measured to be 1000 mm of mercury. We need to convert this pressure into the height of water.

Formula:

The formula to convert pressure from mercury to water is:

h = (P × 13.6)/1000

where h is the height of water in meters, P is the pressure in mm of mercury, and 13.6 is the density ratio of mercury and water.

Calculation:

Using the above formula, we can calculate the height of water as:

h = (1000 × 13.6)/1000 = 13.6 m

Therefore, the height of water is 13.6 m.

Conclusion:

The pressure of 1000 mm of mercury is equivalent to the height of water of 13.6 m.

Explanation:

The pressure at a place is measured to be 1000 mm of mercury. We need to convert this pressure into the height of water.

Formula:

The formula to convert pressure from mercury to water is:

h = (P × 13.6)/1000

where h is the height of water in meters, P is the pressure in mm of mercury, and 13.6 is the density ratio of mercury and water.

Calculation:

Using the above formula, we can calculate the height of water as:

h = (1000 × 13.6)/1000 = 13.6 m

Therefore, the height of water is 13.6 m.

Conclusion:

The pressure of 1000 mm of mercury is equivalent to the height of water of 13.6 m.

If helium is used instead of air the efficiency of brayton cycle.- a)Remains same

- b)Decreases

- c)Increase

- d)Can't say

Correct answer is option 'C'. Can you explain this answer?

If helium is used instead of air the efficiency of brayton cycle.

a)

Remains same

b)

Decreases

c)

Increase

d)

Can't say

|

Bijoy Kapoor answered |

The Brayton cycle is a thermodynamic cycle named after George Brayton who describes the workings of a constant-pressure heat engine. The original Brayton engines used a piston compressor and piston expander, but more modern gas turbine engines and airbreathing jet engines also follow the Brayton cycle.

Two streams of liquid metal which are not hot enough to fuse properly result into a casting defect known as :-- a)cold shut

- b)sand wash

- c)swell

- d)Scab

Correct answer is option 'A'. Can you explain this answer?

Two streams of liquid metal which are not hot enough to fuse properly result into a casting defect known as :-

a)

cold shut

b)

sand wash

c)

swell

d)

Scab

|

Bijoy Kapoor answered |

The reasons of cold shut are

i) Cooling of die or loss of plasticity of the motor.

ii) Shot speed less

iii) Air vent or over flow is closed

The number of inversions of a 4 bar mechanics is- a)1

- b)3

- c)2

- d)4

Correct answer is option 'B'. Can you explain this answer?

The number of inversions of a 4 bar mechanics is

a)

1

b)

3

c)

2

d)

4

|

|

Rhea Reddy answered |

There are three inversions: 1) Beam Engine or Crank and lever mechanism. 2) Coupling rod of locomotive or double crank mechanism. 3) Watt's straight line mechanism or double lever mechanism.

Stress can be defined as :-- a)Internal Resisting force (IRF)

- b)Magnitude of IRF

- c)IRF × cross sectional area

- d)IRF × surface area

Correct answer is option 'B'. Can you explain this answer?

Stress can be defined as :-

a)

Internal Resisting force (IRF)

b)

Magnitude of IRF

c)

IRF × cross sectional area

d)

IRF × surface area

|

Baishali Bajaj answered |

Stress is a physical quantity that expresses the internal forces that neighboring particles of a continuous material exert on each other, while strain is the measure of the deformation of the material.

A liquid of specific gravity 0.7 flows with a velocity of 5 m/s. Its velocity head is near to.- a)5m

- b)0.5 m

- c)1.25 m

- d)1.5 m

Correct answer is option 'C'. Can you explain this answer?

A liquid of specific gravity 0.7 flows with a velocity of 5 m/s. Its velocity head is near to.

a)

5m

b)

0.5 m

c)

1.25 m

d)

1.5 m

|

|

Soumya Basak answered |

Velocity Head of a Liquid

Velocity head is the kinetic energy of a liquid due to its motion. It is defined as the height to which a liquid would rise if its entire kinetic energy were converted into potential energy.

Calculation

The formula for velocity head is given as:

Velocity head = (v^2) / (2g)

where v is the velocity of the liquid and g is the acceleration due to gravity.

Given that specific gravity of the liquid is 0.7 and velocity is 5 m/s.

We can calculate the velocity head using the formula as:

Velocity head = (v^2) / (2g) = (5^2) / (2 x 9.81) = 1.27 m

Therefore, the velocity head is approximately 1.25 m.

Hence, option (c) is the correct answer.

Velocity head is the kinetic energy of a liquid due to its motion. It is defined as the height to which a liquid would rise if its entire kinetic energy were converted into potential energy.

Calculation

The formula for velocity head is given as:

Velocity head = (v^2) / (2g)

where v is the velocity of the liquid and g is the acceleration due to gravity.

Given that specific gravity of the liquid is 0.7 and velocity is 5 m/s.

We can calculate the velocity head using the formula as:

Velocity head = (v^2) / (2g) = (5^2) / (2 x 9.81) = 1.27 m

Therefore, the velocity head is approximately 1.25 m.

Hence, option (c) is the correct answer.

The major difficulty during welding of aluminium is- a)high oxidation

- b)low melting point

- c)high thermal conductivity

- d)low density

Correct answer is option 'A'. Can you explain this answer?

The major difficulty during welding of aluminium is

a)

high oxidation

b)

low melting point

c)

high thermal conductivity

d)

low density

|

|

Aditya Deshmukh answered |

High affinity of aluminium with atmospheric gases increases the tendency of formation of oxides and nitrides (having density similar to that of aluminium) especially when

a) protection of weld pool is not enough,

b) proper cleaning of filler and base metal has not been done,

c) shielding gases are not pure enough and therefore making oxygen and hydrogen available to molten weld pool during welding,

d) gases are present in dissolved state in aluminium itself and tungsten inclusion while using GTA welding.

Presence of these inclusions disrupts the metallic continuity in the weld therefore these provide site for stress concentration and become a source of weakness leading to the deterioration in mechanical and corrosion performance of the weld joints

The octane number of a mixure containing 60% ISO octane and 40% n - heptane is .

- a)40

- b)100

- c)50

- d)60

Correct answer is option 'D'. Can you explain this answer?

The octane number of a mixure containing 60% ISO octane and 40% n - heptane is .

a)

40

b)

100

c)

50

d)

60

|

Anirban Khanna answered |

Octane number of fuel is the percentage of iso- octane in mixture.

In a thermal process, the pressure of a fixed mass of a gas is changed in such a manner that the gas molecules give out the heat of 30 J and work of 10 J is done on the gas. If the initial internal energy of the gas was 40 J, then the final internal energy will be?

- a)30 J

- b)20 J

- c)60 J

- d)40 J

Correct answer is option 'B'. Can you explain this answer?

In a thermal process, the pressure of a fixed mass of a gas is changed in such a manner that the gas molecules give out the heat of 30 J and work of 10 J is done on the gas. If the initial internal energy of the gas was 40 J, then the final internal energy will be?

a)

30 J

b)

20 J

c)

60 J

d)

40 J

|

Manish Aggarwal answered |

∆Q = (Uf - Ui) + ∆W

30 = Uf - 40 + 10

Uf = 60J.

30 = Uf - 40 + 10

Uf = 60J.

The process of making hollow castings of non circular shape and desired thickness of non circular shape and desired thickness by permanent mould without use of core is known as- a)die casting

- b)Slush casting

- c)Pressed casting

- d)Centrifugal casting

Correct answer is option 'B'. Can you explain this answer?

The process of making hollow castings of non circular shape and desired thickness of non circular shape and desired thickness by permanent mould without use of core is known as

a)

die casting

b)

Slush casting

c)

Pressed casting

d)

Centrifugal casting

|

|

Arshiya Dey answered |

Slush casting is a process of making hollow castings of non-circular shape and desired thickness by a permanent mould without using a core. This process is widely used in the manufacture of decorative and ornamental articles, toys, and automotive parts.

Process of Slush Casting:

1. Preparation of the mould: The mould used in slush casting is made of metal or any other suitable material. The mould is prepared in such a way that it has the desired shape and thickness of the casting.

2. Preheating the mould: The mould is preheated to a temperature slightly higher than the melting point of the material to be cast. This is done to avoid sudden solidification of the molten material when it comes in contact with the mould.

3. Pouring the material: The molten material is poured into the mould. The mould is then rotated slowly in different directions to ensure that the entire surface of the mould is coated with a thin layer of the molten material.

4. Draining the excess material: After the mould is completely coated with the molten material, the excess material is drained out of the mould. The thickness of the casting can be controlled by varying the duration of the coating process.

5. Cooling and solidification: The mould is then cooled slowly to allow the molten material to solidify. Once the casting is solidified, it is removed from the mould. The surface of the casting is then finished by grinding, polishing, or painting.

Advantages of Slush Casting:

1. The process is simple and cost-effective.

2. It is suitable for producing hollow castings of non-circular shapes and different thicknesses.

3. The process does not require the use of a core, which reduces the cost of production.

4. The surface finish of the casting is smooth and uniform.

5. The process can be automated, which increases the production rate and reduces labor costs.

Conclusion:

Slush casting is a simple and cost-effective process for producing hollow castings of non-circular shapes and different thicknesses. The process does not require the use of a core, which reduces the cost of production. The surface finish of the casting is smooth and uniform, making it suitable for decorative and ornamental articles, toys, and automotive parts.

Process of Slush Casting:

1. Preparation of the mould: The mould used in slush casting is made of metal or any other suitable material. The mould is prepared in such a way that it has the desired shape and thickness of the casting.

2. Preheating the mould: The mould is preheated to a temperature slightly higher than the melting point of the material to be cast. This is done to avoid sudden solidification of the molten material when it comes in contact with the mould.

3. Pouring the material: The molten material is poured into the mould. The mould is then rotated slowly in different directions to ensure that the entire surface of the mould is coated with a thin layer of the molten material.

4. Draining the excess material: After the mould is completely coated with the molten material, the excess material is drained out of the mould. The thickness of the casting can be controlled by varying the duration of the coating process.

5. Cooling and solidification: The mould is then cooled slowly to allow the molten material to solidify. Once the casting is solidified, it is removed from the mould. The surface of the casting is then finished by grinding, polishing, or painting.

Advantages of Slush Casting:

1. The process is simple and cost-effective.

2. It is suitable for producing hollow castings of non-circular shapes and different thicknesses.

3. The process does not require the use of a core, which reduces the cost of production.

4. The surface finish of the casting is smooth and uniform.

5. The process can be automated, which increases the production rate and reduces labor costs.

Conclusion:

Slush casting is a simple and cost-effective process for producing hollow castings of non-circular shapes and different thicknesses. The process does not require the use of a core, which reduces the cost of production. The surface finish of the casting is smooth and uniform, making it suitable for decorative and ornamental articles, toys, and automotive parts.

For a worm and worm wheel drive

1. worm has high spiral angle

2. worm wheel has high spiral angle

3. used for very high speed reduction

4. worm wheel is the driver

Which of the following is/are correct.- a)1 and 4

- b)1 and 3

- c)1, 2, 4

- d)1, 3, 4

Correct answer is option 'C'. Can you explain this answer?

For a worm and worm wheel drive

1. worm has high spiral angle

2. worm wheel has high spiral angle

3. used for very high speed reduction

4. worm wheel is the driver

Which of the following is/are correct.

1. worm has high spiral angle

2. worm wheel has high spiral angle

3. used for very high speed reduction

4. worm wheel is the driver

Which of the following is/are correct.

a)

1 and 4

b)

1 and 3

c)

1, 2, 4

d)

1, 3, 4

|

Knowledge Hub answered |

Correct Answer :- c

Explanation : The worm can be considered resembling a helical gear with a high helix angle. For extremely high helix angles, there is one continuous tooth or thread. For slightly smaller angles, there can be two, three or even more threads.

The worm wheel is similar in appearance to a spur gear the worm gear is in the form of a screw generally with a flank angle of 20°.

Self-locking means it is not possible to drive the worm using the worm wheel, and this feature is used in such things as reversing prevention systems.

A spring of length 'L' is cut into 5 equal parts if initial spring stiffness was R the final stiffness after

parallel combination of all 5 parts will be- a)R/5

- b)R

- c)5R

- d)25R

Correct answer is option 'D'. Can you explain this answer?

A spring of length 'L' is cut into 5 equal parts if initial spring stiffness was R the final stiffness after

parallel combination of all 5 parts will be

parallel combination of all 5 parts will be

a)

R/5

b)

R

c)

5R

d)

25R

|

|

Samarth Chaudhary answered |

Explanation:

When a spring is cut into equal parts, each part will have the same length, L/5. However, the cross-sectional area of each part will be smaller, since the total cross-sectional area of the spring is divided among the parts. Let us assume that the cross-sectional area of each part is A. Then, the cross-sectional area of the original spring is 5A.

When the parts are combined in parallel, the total cross-sectional area is the sum of the cross-sectional areas of the parts. Therefore, the total cross-sectional area of the combined spring is 5A+5A+5A+5A+5A=25A.

The stiffness of a spring is proportional to its cross-sectional area. Therefore, the stiffness of each part of the spring is R/A, and the stiffness of the combined spring is:

R_combined = (5R/A)+(5R/A)+(5R/A)+(5R/A)+(5R/A)

= (25R/A)

The cross-sectional area of each part is smaller than the cross-sectional area of the original spring, so A<5a. therefore,="" r_combined="">5R, which means that the final stiffness after parallel combination of all 5 parts is 25R.

Therefore, the correct answer is option D, 25R.

When a spring is cut into equal parts, each part will have the same length, L/5. However, the cross-sectional area of each part will be smaller, since the total cross-sectional area of the spring is divided among the parts. Let us assume that the cross-sectional area of each part is A. Then, the cross-sectional area of the original spring is 5A.

When the parts are combined in parallel, the total cross-sectional area is the sum of the cross-sectional areas of the parts. Therefore, the total cross-sectional area of the combined spring is 5A+5A+5A+5A+5A=25A.

The stiffness of a spring is proportional to its cross-sectional area. Therefore, the stiffness of each part of the spring is R/A, and the stiffness of the combined spring is:

R_combined = (5R/A)+(5R/A)+(5R/A)+(5R/A)+(5R/A)

= (25R/A)

The cross-sectional area of each part is smaller than the cross-sectional area of the original spring, so A<5a. therefore,="" r_combined="">5R, which means that the final stiffness after parallel combination of all 5 parts is 25R.

Therefore, the correct answer is option D, 25R.

A shaft of shear modulus 80 GPa, polar moment of inertia 80 mm4 and length 1m. What is its torsional stiffness.- a)6400 Nmm

- b)64 Nmm

- c)80 Nmm

- d)800 Nmm

Correct answer is option 'A'. Can you explain this answer?

A shaft of shear modulus 80 GPa, polar moment of inertia 80 mm4 and length 1m. What is its torsional stiffness.

a)

6400 Nmm

b)

64 Nmm

c)

80 Nmm

d)

800 Nmm

|

|

Sanskriti Chakraborty answered |

Torsional Stiffness Calculation

Given:

Shear modulus (G) = 80 GPa = 80 x 10^9 Pa

Polar moment of inertia (J) = 80 mm^4 = 80 x 10^-12 m^4

Length (L) = 1 m

Formula:

Torsional stiffness (k) = (G x J) / L

Calculation:

k = (80 x 10^9 Pa) x (80 x 10^-12 m^4) / 1 m

k = 6400 Nm/rad

Therefore, the torsional stiffness of the shaft is 6400 Nm/rad.

Given:

Shear modulus (G) = 80 GPa = 80 x 10^9 Pa

Polar moment of inertia (J) = 80 mm^4 = 80 x 10^-12 m^4

Length (L) = 1 m

Formula:

Torsional stiffness (k) = (G x J) / L

Calculation:

k = (80 x 10^9 Pa) x (80 x 10^-12 m^4) / 1 m

k = 6400 Nm/rad

Therefore, the torsional stiffness of the shaft is 6400 Nm/rad.

In CI engine the Air fuel mixure is- a)Homogenous

- b)Pure fuel mixure is

- c)Hetrogenous

- d)Homogenous and pure substance.

Correct answer is option 'C'. Can you explain this answer?

In CI engine the Air fuel mixure is

a)

Homogenous

b)

Pure fuel mixure is

c)

Hetrogenous

d)

Homogenous and pure substance.

|

Aditya Jain answered |

In a CI (Compression Ignition) engine, the air-fuel mixture is considered to be heterogeneous. Let's understand why.

Heterogeneous Mixture:

A heterogeneous mixture is one that consists of two or more different substances that are not uniformly distributed. In the case of a CI engine, the air-fuel mixture is not uniform throughout the combustion chamber. It consists of air and fuel in separate phases.

Combustion Process in CI Engine:

In a CI engine, the combustion process is initiated by the high temperature and pressure resulting from the compression of the air in the combustion chamber. Unlike in a spark-ignition engine, there is no spark plug to ignite the fuel. Instead, the fuel is injected into the combustion chamber as a fine spray or mist.

Air-Fuel Mixing:

The fuel is injected into the combustion chamber at a specific timing, pressure, and angle. It is injected in such a way that it mixes with the hot compressed air. However, due to the high pressure and short time available for mixing, the fuel does not have enough time to completely vaporize and mix uniformly with the air. As a result, the fuel exists in small droplets or particles suspended in the air.

Fuel Combustion:

When the fuel particles come into contact with the hot air, they start to vaporize and undergo combustion. The combustion process begins at the surface of the fuel droplets and gradually progresses inward. This process is known as diffusion combustion. Due to the heterogeneous nature of the air-fuel mixture, the combustion occurs at different rates and locations within the combustion chamber.

Advantages of Heterogeneous Mixture in CI Engines:

The heterogeneous nature of the air-fuel mixture in CI engines offers several advantages:

1. Improved Combustion Efficiency: The non-uniform distribution of fuel droplets in the air allows for better mixing and combustion efficiency.

2. Reduced Knocking: The uneven distribution of fuel droplets helps to reduce the likelihood of knocking, which can be detrimental to the engine's performance.

3. Lower Emissions: The heterogeneous mixture promotes more complete combustion, resulting in lower emissions of pollutants such as unburned hydrocarbons and particulate matter.

In conclusion, the air-fuel mixture in a CI engine is considered to be heterogeneous because it consists of separate phases of air and fuel. The non-uniform distribution of fuel droplets in the air allows for better combustion efficiency, reduced knocking, and lower emissions.

Heterogeneous Mixture:

A heterogeneous mixture is one that consists of two or more different substances that are not uniformly distributed. In the case of a CI engine, the air-fuel mixture is not uniform throughout the combustion chamber. It consists of air and fuel in separate phases.

Combustion Process in CI Engine:

In a CI engine, the combustion process is initiated by the high temperature and pressure resulting from the compression of the air in the combustion chamber. Unlike in a spark-ignition engine, there is no spark plug to ignite the fuel. Instead, the fuel is injected into the combustion chamber as a fine spray or mist.

Air-Fuel Mixing:

The fuel is injected into the combustion chamber at a specific timing, pressure, and angle. It is injected in such a way that it mixes with the hot compressed air. However, due to the high pressure and short time available for mixing, the fuel does not have enough time to completely vaporize and mix uniformly with the air. As a result, the fuel exists in small droplets or particles suspended in the air.

Fuel Combustion:

When the fuel particles come into contact with the hot air, they start to vaporize and undergo combustion. The combustion process begins at the surface of the fuel droplets and gradually progresses inward. This process is known as diffusion combustion. Due to the heterogeneous nature of the air-fuel mixture, the combustion occurs at different rates and locations within the combustion chamber.

Advantages of Heterogeneous Mixture in CI Engines:

The heterogeneous nature of the air-fuel mixture in CI engines offers several advantages:

1. Improved Combustion Efficiency: The non-uniform distribution of fuel droplets in the air allows for better mixing and combustion efficiency.

2. Reduced Knocking: The uneven distribution of fuel droplets helps to reduce the likelihood of knocking, which can be detrimental to the engine's performance.

3. Lower Emissions: The heterogeneous mixture promotes more complete combustion, resulting in lower emissions of pollutants such as unburned hydrocarbons and particulate matter.

In conclusion, the air-fuel mixture in a CI engine is considered to be heterogeneous because it consists of separate phases of air and fuel. The non-uniform distribution of fuel droplets in the air allows for better combustion efficiency, reduced knocking, and lower emissions.

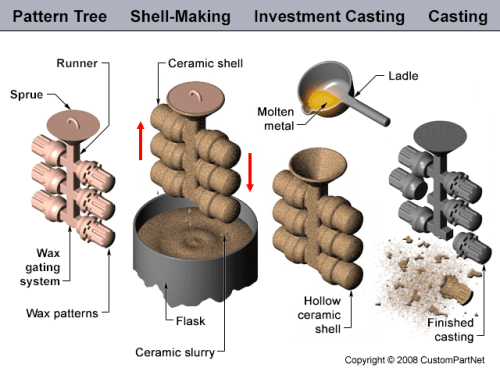

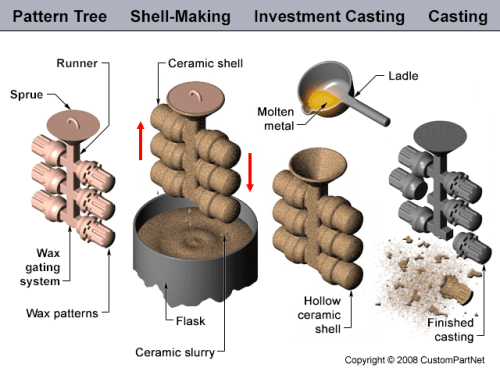

An expandable pattern is used in- a)slush casting

- b)Centrifugal casting

- c)Squeeze casting

- d)Investment casting

Correct answer is option 'D'. Can you explain this answer?

An expandable pattern is used in

a)

slush casting

b)

Centrifugal casting

c)

Squeeze casting

d)

Investment casting

|

Bijoy Kapoor answered |

Expendable pattern means designed to be used only once and then destroyed.

First law of thermodynamics provides- a)a statement that energy balance occurs when a system undergoes the change of state or the process

- b)a statement about whether the change of state or the process is at all feasible or not

- c)both a. and b.

- d)none of the above

Correct answer is option 'A'. Can you explain this answer?

First law of thermodynamics provides

a)

a statement that energy balance occurs when a system undergoes the change of state or the process

b)

a statement about whether the change of state or the process is at all feasible or not

c)

both a. and b.

d)

none of the above

|

Kaavya Sengupta answered |

The First Law of Thermodynamics states that heat is a form of energy, and thermodynamic processes are therefore subject to the principle of conservation of energy. This means that heat energy cannot be created or destroyed. It can, however, be transferred from one location to another and converted to and from other forms of energy.

A hartnell governor having equal arms is acted upon by centrifugal force of 500N and 250 N at radius of 10 cm and 5 cm respectively. The stiffness of the spring used in governor in N/cm is- a)50 N/cm

- b)100 N/cm

- c)150 N/cm

- d)None

Correct answer is option 'B'. Can you explain this answer?

A hartnell governor having equal arms is acted upon by centrifugal force of 500N and 250 N at radius of 10 cm and 5 cm respectively. The stiffness of the spring used in governor in N/cm is

a)

50 N/cm

b)

100 N/cm

c)

150 N/cm

d)

None

|

|

Stuti Mishra answered |

Solution:

Given,

Centrifugal force at radius r1 = 500 N

Centrifugal force at radius r2 = 250 N

Radius r1 = 10 cm

Radius r2 = 5 cm

Let the stiffness of the spring used in the governor be k N/cm.

The centrifugal force acting on the governor is balanced by the spring force.

Therefore, we can write the equation of equilibrium as:

k(x1 + x2) = F1 + F2

where x1 and x2 are the displacements of the arms from their mean position.

x1 = r1θ, x2 = r2θ (where θ is the angular displacement of the arms)

F1 = m1ω^2r1, F2 = m2ω^2r2

where m1 and m2 are the masses of the arms and ω is the angular velocity of the governor.

Substituting the values of x1, x2, F1, and F2 in the equation of equilibrium, we get:

k(r1 + r2)θ = m1ω^2r1 + m2ω^2r2

k = (m1ω^2r1 + m2ω^2r2)/(r1 + r2)θ

Given, m1 = m2 (equal arms)

k = 2mω^2r/(r1 + r2)θ

Substituting the given values, we get:

k = 2(1 kg)(10 rad/s)^2(10 cm)/(10 cm + 5 cm)

k = 100 N/cm

Therefore, the stiffness of the spring used in the governor is 100 N/cm. Hence, option B is the correct answer.

Given,

Centrifugal force at radius r1 = 500 N

Centrifugal force at radius r2 = 250 N

Radius r1 = 10 cm

Radius r2 = 5 cm

Let the stiffness of the spring used in the governor be k N/cm.

The centrifugal force acting on the governor is balanced by the spring force.

Therefore, we can write the equation of equilibrium as:

k(x1 + x2) = F1 + F2

where x1 and x2 are the displacements of the arms from their mean position.

x1 = r1θ, x2 = r2θ (where θ is the angular displacement of the arms)

F1 = m1ω^2r1, F2 = m2ω^2r2

where m1 and m2 are the masses of the arms and ω is the angular velocity of the governor.

Substituting the values of x1, x2, F1, and F2 in the equation of equilibrium, we get:

k(r1 + r2)θ = m1ω^2r1 + m2ω^2r2

k = (m1ω^2r1 + m2ω^2r2)/(r1 + r2)θ

Given, m1 = m2 (equal arms)

k = 2mω^2r/(r1 + r2)θ

Substituting the given values, we get:

k = 2(1 kg)(10 rad/s)^2(10 cm)/(10 cm + 5 cm)

k = 100 N/cm

Therefore, the stiffness of the spring used in the governor is 100 N/cm. Hence, option B is the correct answer.

Calculate the thrust in connecting rod, if piston effort is 200 kN and crank makes an angle of 45o from TDC. Assume obliquity ratio = 3.5- a)204.20 kN

- b)195.87 kN

- c)900.80 kN

- d) 970.02 kN

Correct answer is option 'A'. Can you explain this answer?

Calculate the thrust in connecting rod, if piston effort is 200 kN and crank makes an angle of 45o from TDC. Assume obliquity ratio = 3.5

a)

204.20 kN

b)

195.87 kN

c)

900.80 kN

d)

970.02 kN

|

|

Rajat Khanna answered |

Calculation of Thrust in Connecting Rod

Given data:

Piston effort = 200 kN

Crank angle from TDC = 45°

Obliquity ratio = 3.5

Formula used:

Thrust in connecting rod = (Piston effort / cos(θ)) × (1 + obliquity ratio × cos²(θ))

Where,

θ = Crank angle from TDC

Calculation:

θ = 45°

cos(θ) = cos(45°) = 0.707

cos²(θ) = cos²(45°) = 0.5

Thrust in connecting rod = (200 / 0.707) × (1 + 3.5 × 0.5)

Thrust in connecting rod = 204.20 kN

Therefore, the thrust in connecting rod is 204.20 kN, which is closest to option A (204.20 kN).

Given data:

Piston effort = 200 kN

Crank angle from TDC = 45°

Obliquity ratio = 3.5

Formula used:

Thrust in connecting rod = (Piston effort / cos(θ)) × (1 + obliquity ratio × cos²(θ))

Where,

θ = Crank angle from TDC

Calculation:

θ = 45°

cos(θ) = cos(45°) = 0.707

cos²(θ) = cos²(45°) = 0.5

Thrust in connecting rod = (200 / 0.707) × (1 + 3.5 × 0.5)

Thrust in connecting rod = 204.20 kN

Therefore, the thrust in connecting rod is 204.20 kN, which is closest to option A (204.20 kN).

Which of the following are welding process does not used consumable electrodes.- a)GMAW

- b)GTAW

- c)Submerged Arc Welding

- d)None of these

Correct answer is option 'B'. Can you explain this answer?

Which of the following are welding process does not used consumable electrodes.

a)

GMAW

b)

GTAW

c)

Submerged Arc Welding

d)

None of these

|

|

Tanvi Shah answered |

Non-consumable electrode methods. Gas tungsten arc welding (GTAW), or tungsten/inert-gas (TIG) welding, is a manual welding process that uses a non-consumable electrode made of tungsten, an inert or semi-inert gas mixture, and a separate filler material.

the enthalpy reading of a refrigerator are

i. at inlet to compressor → 2000 kJ/kg.

ii. at exit of compressor → 2500 kJ/kg.

iii. at exit of condenser → 500 kJ/kg.

The COP of the refrigerator is .- a)3

- b)4

- c)5

- d)6

Correct answer is option 'A'. Can you explain this answer?

the enthalpy reading of a refrigerator are

i. at inlet to compressor → 2000 kJ/kg.

ii. at exit of compressor → 2500 kJ/kg.

iii. at exit of condenser → 500 kJ/kg.

The COP of the refrigerator is .

i. at inlet to compressor → 2000 kJ/kg.

ii. at exit of compressor → 2500 kJ/kg.

iii. at exit of condenser → 500 kJ/kg.

The COP of the refrigerator is .

a)

3

b)

4

c)

5

d)

6

|

|

Raj Kumar answered |

Understanding the COP of a Refrigerator

The Coefficient of Performance (COP) is a measure of the efficiency of a refrigeration cycle. It is defined as the ratio of the heat removed from the refrigerated space (Q_in) to the work input (W) into the system.

Given Enthalpy Values

- Enthalpy at Inlet to Compressor (h1): 2000 kJ/kg

- Enthalpy at Exit of Compressor (h2): 2500 kJ/kg

- Enthalpy at Exit of Condenser (h3): 500 kJ/kg

Calculating Work Input (W)

The work done by the compressor (W) can be calculated using the enthalpy difference:

- W = h2 - h1

- W = 2500 kJ/kg - 2000 kJ/kg = 500 kJ/kg

Calculating Heat Removed (Q_in)

The heat removed from the refrigerated space can be found from the enthalpy at the exit of the condenser:

- Q_in = h1 - h3

- Q_in = 2000 kJ/kg - 500 kJ/kg = 1500 kJ/kg

Calculating COP

Now, we can determine the COP:

- COP = Q_in / W

- COP = 1500 kJ/kg / 500 kJ/kg = 3

Conclusion

The calculated COP of the refrigerator is 3, indicating that for every unit of work input, three units of heat are removed from the refrigerated space.

Hence, option A (3) is the correct answer.

The Coefficient of Performance (COP) is a measure of the efficiency of a refrigeration cycle. It is defined as the ratio of the heat removed from the refrigerated space (Q_in) to the work input (W) into the system.

Given Enthalpy Values

- Enthalpy at Inlet to Compressor (h1): 2000 kJ/kg

- Enthalpy at Exit of Compressor (h2): 2500 kJ/kg

- Enthalpy at Exit of Condenser (h3): 500 kJ/kg

Calculating Work Input (W)

The work done by the compressor (W) can be calculated using the enthalpy difference:

- W = h2 - h1

- W = 2500 kJ/kg - 2000 kJ/kg = 500 kJ/kg

Calculating Heat Removed (Q_in)

The heat removed from the refrigerated space can be found from the enthalpy at the exit of the condenser:

- Q_in = h1 - h3

- Q_in = 2000 kJ/kg - 500 kJ/kg = 1500 kJ/kg

Calculating COP

Now, we can determine the COP:

- COP = Q_in / W

- COP = 1500 kJ/kg / 500 kJ/kg = 3

Conclusion

The calculated COP of the refrigerator is 3, indicating that for every unit of work input, three units of heat are removed from the refrigerated space.

Hence, option A (3) is the correct answer.

When a gear and pinion are made of same material the design is based on.- a)Gear

- b)Both gear and pinion

- c)Pinion

- d)The one having smaller module

Correct answer is option 'C'. Can you explain this answer?

When a gear and pinion are made of same material the design is based on.

a)

Gear

b)

Both gear and pinion

c)

Pinion

d)

The one having smaller module

|

|

Sanya Agarwal answered |

-A pinion tooth is loaded and unloaded more number of times than the gear tooth. You can verify this by putting a mark on one pinion tooth and count how many times it meshes. Do the same for gear tooth and compare.

-Pinion rotates at an higher angular speed than gear. Hope you retained the marks on gear and pinion. Use them to measure revolutions per minute of each.

-Pinion has less material in the blank to sustain the same radial as well as thermal load. Smaller size => less material.

Isothermal annealing is mainly used in alloy steel to improne.- a)Machinability

- b)toughness

- c)ductility

- d)Weldability

Correct answer is option 'A'. Can you explain this answer?

Isothermal annealing is mainly used in alloy steel to improne.

a)

Machinability

b)

toughness

c)

ductility

d)

Weldability

|

|

Rajeev Sharma answered |

Isothermal annealing is primarily used for medium carbon, high carbon and some of the alloy steels to improve their machinability.

The COP of a refrigerator working on reversed carnot cycle is 4. The ratio of highest absolute temperature is lowest absolute temperature is .- a)1.5

- b)4.0

- c)1.25

- d)2

Correct answer is option 'C'. Can you explain this answer?

The COP of a refrigerator working on reversed carnot cycle is 4. The ratio of highest absolute temperature is lowest absolute temperature is .

a)

1.5

b)

4.0

c)

1.25

d)

2

|

Shalini Deshpande answered |

Solution:

Carnot cycle is a reversible cycle consisting of four processes- isothermal compression, adiabatic compression, isothermal expansion, and adiabatic expansion.

The coefficient of performance (COP) of a refrigerator working on reversed Carnot cycle is given by:

COP = T1 / (T1 - T2)

where T1 is the absolute temperature of the source (higher temperature) and T2 is the absolute temperature of the sink (lower temperature).

Given that the COP of the refrigerator is 4, we have:

4 = T1 / (T1 - T2)

Solving for T1/T2, we get:

T1/T2 = 5

Now, we need to find the ratio of T1 and T2. Let's assume that T1 is the highest absolute temperature and T2 is the lowest absolute temperature.

Therefore, we have:

T1/T2 = 5

T1 = 5T2

Substituting this in the expression for COP, we get:

4 = 5T2 / (5T2 - T2)

4 = 5T2 / 4T2

T2 = T1/5 = T1 - T1/5 = 4T1/5

Therefore, the ratio of T1 to T2 is:

T1/T2 = T1 / (4T1/5) = 5/4

Hence, the correct option is (c) 1.25.

Carnot cycle is a reversible cycle consisting of four processes- isothermal compression, adiabatic compression, isothermal expansion, and adiabatic expansion.

The coefficient of performance (COP) of a refrigerator working on reversed Carnot cycle is given by:

COP = T1 / (T1 - T2)

where T1 is the absolute temperature of the source (higher temperature) and T2 is the absolute temperature of the sink (lower temperature).

Given that the COP of the refrigerator is 4, we have:

4 = T1 / (T1 - T2)

Solving for T1/T2, we get:

T1/T2 = 5

Now, we need to find the ratio of T1 and T2. Let's assume that T1 is the highest absolute temperature and T2 is the lowest absolute temperature.

Therefore, we have:

T1/T2 = 5

T1 = 5T2

Substituting this in the expression for COP, we get:

4 = 5T2 / (5T2 - T2)

4 = 5T2 / 4T2

T2 = T1/5 = T1 - T1/5 = 4T1/5

Therefore, the ratio of T1 to T2 is:

T1/T2 = T1 / (4T1/5) = 5/4

Hence, the correct option is (c) 1.25.

A heat pump works on reversed carnot cycle.The temperature in the condenser coil is 27ºC and that in the evaporator coil is -23ºC and that in the evaporator coil is -23ºC. For work of 1.5 kW, how much heat is pumped.- a)1.5 kW

- b)6 kW

- c)3 kW

- d)9 kW

Correct answer is option 'D'. Can you explain this answer?

A heat pump works on reversed carnot cycle.The temperature in the condenser coil is 27ºC and that in the evaporator coil is -23ºC and that in the evaporator coil is -23ºC. For work of 1.5 kW, how much heat is pumped.

a)

1.5 kW

b)

6 kW

c)

3 kW

d)

9 kW

|

|

Hrishikesh Chakraborty answered |

**Explanation:**

To find the amount of heat pumped by the heat pump, we need to calculate the difference in heat transfer between the condenser and the evaporator.

The heat pump operates on the reversed Carnot cycle, which consists of four processes: isentropic compression, constant temperature heat rejection, isentropic expansion, and constant temperature heat absorption.

Given:

Temperature in the condenser coil (Tc) = 27°C

Temperature in the evaporator coil (Te) = -23°C

Work done by the heat pump (W) = 1.5 kW

We can use the Carnot efficiency equation to determine the heat transfer between the two coils:

η = 1 - (Te / Tc)

Where η is the Carnot efficiency, Te is the temperature in the evaporator coil, and Tc is the temperature in the condenser coil.

Let's calculate the Carnot efficiency:

η = 1 - (-23 / 27)

η = 1 - (-0.8519)

η = 1 + 0.8519

η = 1.8519

Now, we can use the Carnot efficiency to find the heat transfer:

Q = W / η

Q = 1.5 kW / 1.8519

Q ≈ 0.8102 kW

Therefore, the heat pumped by the heat pump is approximately 0.8102 kW.

However, none of the given options match this result. Therefore, there might be an error in the provided information or options.

To find the amount of heat pumped by the heat pump, we need to calculate the difference in heat transfer between the condenser and the evaporator.

The heat pump operates on the reversed Carnot cycle, which consists of four processes: isentropic compression, constant temperature heat rejection, isentropic expansion, and constant temperature heat absorption.

Given:

Temperature in the condenser coil (Tc) = 27°C

Temperature in the evaporator coil (Te) = -23°C

Work done by the heat pump (W) = 1.5 kW

We can use the Carnot efficiency equation to determine the heat transfer between the two coils:

η = 1 - (Te / Tc)

Where η is the Carnot efficiency, Te is the temperature in the evaporator coil, and Tc is the temperature in the condenser coil.

Let's calculate the Carnot efficiency:

η = 1 - (-23 / 27)

η = 1 - (-0.8519)

η = 1 + 0.8519

η = 1.8519

Now, we can use the Carnot efficiency to find the heat transfer:

Q = W / η

Q = 1.5 kW / 1.8519

Q ≈ 0.8102 kW

Therefore, the heat pumped by the heat pump is approximately 0.8102 kW.

However, none of the given options match this result. Therefore, there might be an error in the provided information or options.

If maximum speed is 210 rpm and minimum speed is 190 rpm then coefficient of fluctuation of speed is- a)0.01

- b)0.1

- c)0.05

- d)0.5

Correct answer is option 'B'. Can you explain this answer?

If maximum speed is 210 rpm and minimum speed is 190 rpm then coefficient of fluctuation of speed is

a)

0.01

b)

0.1

c)

0.05

d)

0.5

|

Partho Jain answered |

**Explanation:**

The coefficient of fluctuation of speed is a measure of the variation in speed of a machine or system. It is calculated by dividing the difference between the maximum and minimum speeds by the average speed.

The formula for calculating the coefficient of fluctuation of speed is:

Coefficient of fluctuation of speed = (maximum speed - minimum speed) / average speed

To calculate the coefficient of fluctuation of speed, we need to find the average speed first.

**1. Calculate the average speed:**

Average speed = (maximum speed + minimum speed) / 2

Average speed = (210 rpm + 190 rpm) / 2

Average speed = 400 rpm / 2

Average speed = 200 rpm

**2. Calculate the coefficient of fluctuation of speed:**

Coefficient of fluctuation of speed = (maximum speed - minimum speed) / average speed

Coefficient of fluctuation of speed = (210 rpm - 190 rpm) / 200 rpm

Coefficient of fluctuation of speed = 20 rpm / 200 rpm

Coefficient of fluctuation of speed = 0.1

Therefore, the coefficient of fluctuation of speed is 0.1, which corresponds to option B.

The coefficient of fluctuation of speed is a measure of the variation in speed of a machine or system. It is calculated by dividing the difference between the maximum and minimum speeds by the average speed.

The formula for calculating the coefficient of fluctuation of speed is:

Coefficient of fluctuation of speed = (maximum speed - minimum speed) / average speed

To calculate the coefficient of fluctuation of speed, we need to find the average speed first.

**1. Calculate the average speed:**

Average speed = (maximum speed + minimum speed) / 2

Average speed = (210 rpm + 190 rpm) / 2

Average speed = 400 rpm / 2

Average speed = 200 rpm

**2. Calculate the coefficient of fluctuation of speed:**

Coefficient of fluctuation of speed = (maximum speed - minimum speed) / average speed

Coefficient of fluctuation of speed = (210 rpm - 190 rpm) / 200 rpm

Coefficient of fluctuation of speed = 20 rpm / 200 rpm

Coefficient of fluctuation of speed = 0.1

Therefore, the coefficient of fluctuation of speed is 0.1, which corresponds to option B.

The gating ratio 2 : 8 : 1. for copper in gating system refers to the ratio of arae of- a)sprue : Runner : ingate

- b)Runner : Sprue: Ingate

- c)Runner : ingate: sprue

- d)Ingate : Runner : Sprue

Correct answer is option 'A'. Can you explain this answer?

The gating ratio 2 : 8 : 1. for copper in gating system refers to the ratio of arae of

a)

sprue : Runner : ingate

b)

Runner : Sprue: Ingate

c)

Runner : ingate: sprue

d)

Ingate : Runner : Sprue

|

Rahul Chatterjee answered |

The gating ratio Sprue area: Runner area: In gate area for non pressurized casting is 1:4:4. Sprue area is smallest.

Knocking in C.I. engine occurs during which stage of combustion.- a)Ist stage

- b)3rd state

- c)2nd stage

- d)4th state

Correct answer is option 'C'. Can you explain this answer?

Knocking in C.I. engine occurs during which stage of combustion.

a)

Ist stage

b)

3rd state

c)

2nd stage

d)

4th state

|

|

Keerthana Joshi answered |

Knocking in C.I. engine occurs during which stage of combustion?

The correct answer is option 'C', i.e., the 2nd stage.

Explanation:

Knocking in a C.I. (Compression Ignition) engine is the result of a rapid and uncontrolled combustion process. In a C.I. engine, fuel is injected into a compressed air mixture, and the heat generated by the compressed air ignites the fuel. Knocking can occur when the fuel ignites before the piston reaches top dead center (TDC), or when the combustion process is too rapid.

The combustion process in a C.I. engine can be divided into four stages:

1. Ignition delay period: This is the time between the start of fuel injection and the start of combustion. During this stage, the fuel is atomized and mixed with air.

2. Premixed combustion: In this stage, the fuel-air mixture ignites and burns rapidly. This is the stage where knocking can occur.

3. Diffusion combustion: This stage occurs after the premixed combustion stage and involves the burning of fuel that did not ignite during the premixed combustion stage.

4. Afterburning: This stage occurs after the diffusion combustion stage and involves the burning of unburned fuel in the exhaust gases.

During the premixed combustion stage, the fuel-air mixture burns rapidly, and the pressure and temperature inside the cylinder increase rapidly. If the pressure and temperature rise too quickly, the fuel can ignite before the piston reaches TDC, causing knocking. Therefore, the second stage of combustion is the stage where knocking can occur. To prevent knocking, the combustion process must be controlled so that the fuel ignites at the right time and at the right rate.

The correct answer is option 'C', i.e., the 2nd stage.

Explanation:

Knocking in a C.I. (Compression Ignition) engine is the result of a rapid and uncontrolled combustion process. In a C.I. engine, fuel is injected into a compressed air mixture, and the heat generated by the compressed air ignites the fuel. Knocking can occur when the fuel ignites before the piston reaches top dead center (TDC), or when the combustion process is too rapid.

The combustion process in a C.I. engine can be divided into four stages:

1. Ignition delay period: This is the time between the start of fuel injection and the start of combustion. During this stage, the fuel is atomized and mixed with air.

2. Premixed combustion: In this stage, the fuel-air mixture ignites and burns rapidly. This is the stage where knocking can occur.

3. Diffusion combustion: This stage occurs after the premixed combustion stage and involves the burning of fuel that did not ignite during the premixed combustion stage.

4. Afterburning: This stage occurs after the diffusion combustion stage and involves the burning of unburned fuel in the exhaust gases.

During the premixed combustion stage, the fuel-air mixture burns rapidly, and the pressure and temperature inside the cylinder increase rapidly. If the pressure and temperature rise too quickly, the fuel can ignite before the piston reaches TDC, causing knocking. Therefore, the second stage of combustion is the stage where knocking can occur. To prevent knocking, the combustion process must be controlled so that the fuel ignites at the right time and at the right rate.

The thermal efficiency is highest for- a)steam power plant

- b)I.C. Engine

- c)Gas power plant

- d)All has same efficiency

Correct answer is option 'A'. Can you explain this answer?

The thermal efficiency is highest for

a)

steam power plant

b)

I.C. Engine

c)

Gas power plant

d)

All has same efficiency

|

Anirban Khanna answered |

A steam/thermal power station uses heat energy generated from burning coal to produce electrical energy. This type of power station is widely used around the world.

The energy efficiency of a conventional thermal power station, considered salable energy produced as a percent of the heating value of the fuel consumed, is typically 33% to 48%. As with all heat engines, their efficiency is limited, and governed by the laws of thermodynamics.

for a refrigeration cycle the critical point shouldbe- a)As high as possible

- b)Neither too high nor too low.

- c)As low as possible

- d)Can't Say

Correct answer is option 'A'. Can you explain this answer?

for a refrigeration cycle the critical point shouldbe

a)

As high as possible

b)

Neither too high nor too low.

c)

As low as possible

d)

Can't Say

|

|

Aditya Deshmukh answered |

Critical temperature and pressure are the points on phase diagram, above which state of species can not be changed (it can neither be liquefied nor be gasified). Coolants must possess high critical temperature because high critical temperature allows high heat uptake from system. When it will operate in refrigeration system, low critical temperature or critical point can be attained, even at low heat transfer to the coolant, when it will be compressed, it will be unable for the coolant to attain its original state (because it is in supercritical condition). So, for a coolant critical point should be high and boiling point should be low.

In S.I. engines supercharging will.- a)increase Detonation

- b)No effect on detonation

- c)Decrease Detonation

- d)Cannot be predicted

Correct answer is option 'A'. Can you explain this answer?

In S.I. engines supercharging will.

a)

increase Detonation

b)

No effect on detonation

c)

Decrease Detonation

d)

Cannot be predicted

|

|

Samarth Chaudhary answered |

Understanding Supercharging in S.I. Engines

Supercharging is a method used to increase the power output of Spark Ignition (S.I.) engines by forcing more air into the combustion chamber. While it enhances performance, it can also lead to increased detonation.

What is Detonation?

- Detonation, often referred to as 'knocking', occurs when the air-fuel mixture ignites prematurely in the combustion chamber.

- This premature ignition can cause shock waves that lead to engine damage, decreased efficiency, and rough operation.

Effects of Supercharging on Detonation

- Increased Air Density: Supercharging increases the density of the air entering the engine. This allows for a greater amount of fuel to be burned.

- Higher Combustion Temperatures: The increase in air and fuel can lead to higher combustion temperatures, which significantly contributes to detonation.

- Increased Pressure: Supercharging raises the pressure within the combustion chamber, making it easier for the air-fuel mixture to ignite spontaneously.

- Higher Cylinder Pressure: The combination of increased temperature and pressure can bring the engine closer to the knock threshold, thus increasing the likelihood of detonation.

Conclusion

In summary, supercharging in S.I. engines increases detonation risk due to elevated air density, combustion temperatures, and pressures. Therefore, careful tuning and the use of high-octane fuels are essential to mitigate these effects and maintain engine reliability while harnessing the benefits of supercharging.

Supercharging is a method used to increase the power output of Spark Ignition (S.I.) engines by forcing more air into the combustion chamber. While it enhances performance, it can also lead to increased detonation.

What is Detonation?

- Detonation, often referred to as 'knocking', occurs when the air-fuel mixture ignites prematurely in the combustion chamber.

- This premature ignition can cause shock waves that lead to engine damage, decreased efficiency, and rough operation.

Effects of Supercharging on Detonation

- Increased Air Density: Supercharging increases the density of the air entering the engine. This allows for a greater amount of fuel to be burned.

- Higher Combustion Temperatures: The increase in air and fuel can lead to higher combustion temperatures, which significantly contributes to detonation.

- Increased Pressure: Supercharging raises the pressure within the combustion chamber, making it easier for the air-fuel mixture to ignite spontaneously.

- Higher Cylinder Pressure: The combination of increased temperature and pressure can bring the engine closer to the knock threshold, thus increasing the likelihood of detonation.

Conclusion

In summary, supercharging in S.I. engines increases detonation risk due to elevated air density, combustion temperatures, and pressures. Therefore, careful tuning and the use of high-octane fuels are essential to mitigate these effects and maintain engine reliability while harnessing the benefits of supercharging.

For a multiplate clutch with number of driving flange = 3 and no. of driven flange = 2 no. of contact surface is.- a)5

- b)1

- c)4

- d)3

Correct answer is option 'C'. Can you explain this answer?

For a multiplate clutch with number of driving flange = 3 and no. of driven flange = 2 no. of contact surface is.

a)

5

b)

1

c)

4

d)

3

|

Cstoppers Instructors answered |

In a multi plate clutch, number of pairs of contact surfaces (n) is equal to n1 + n2 – 1. Due to the high number of pairs of contact surfaces, the torque transmitted is higher.

n is always a whole number.

n is always a whole number.

Shell moulding can be used for.- a)producing milling cutters

- b)making gold ornaments

- c)Producing heavy and thick walled casting

- d)producing thin casting

Correct answer is option 'D'. Can you explain this answer?

Shell moulding can be used for.

a)

producing milling cutters

b)

making gold ornaments

c)

Producing heavy and thick walled casting

d)

producing thin casting

|

|

Dishani Desai answered |

Shell Moulding for Various Applications

Shell moulding is a casting process that involves the use of a resin-coated sand that is heated to create a shell-like mold. The molten metal is then poured into the mold to create the desired shape. Shell moulding is a versatile process that can be used for various applications. Here are some of the uses of shell moulding:

Producing Milling Cutters

Shell moulding is an ideal process for producing milling cutters. Milling cutters are used in the milling process to remove material from the workpiece. Shell moulding is ideal for producing milling cutters because it can produce complex shapes with high precision. The shell moulding process produces a smooth surface finish that is essential for milling cutters.

Making Gold Ornaments

Shell moulding can also be used to make gold ornaments. Gold ornaments are made by pouring molten gold into a shell-like mold. The shell moulding process produces a smooth surface finish that is perfect for gold ornaments. The shell moulding process is ideal for making intricate designs, which is essential for gold ornaments.

Producing Heavy and Thick Walled Casting

Shell moulding is ideal for producing heavy and thick-walled casting. Heavy and thick-walled casting is used in various applications, such as automotive and aerospace industries. The shell moulding process can produce large and complex shapes with high precision. The shell moulding process also produces a smooth surface finish that is essential for heavy and thick-walled casting.

Producing Thin Casting

Shell moulding can also be used to produce thin casting. Thin casting is used in various applications, such as electronic components and medical devices. The shell moulding process can produce thin casting with high precision. The shell moulding process also produces a smooth surface finish that is essential for thin casting.

Conclusion

Shell moulding is a versatile process that can be used for various applications. It is an ideal process for producing complex shapes with high precision. The shell moulding process produces a smooth surface finish that is essential for various applications. Whether you need heavy and thick-walled casting or thin casting, shell moulding is an ideal process for your needs.

Shell moulding is a casting process that involves the use of a resin-coated sand that is heated to create a shell-like mold. The molten metal is then poured into the mold to create the desired shape. Shell moulding is a versatile process that can be used for various applications. Here are some of the uses of shell moulding:

Producing Milling Cutters

Shell moulding is an ideal process for producing milling cutters. Milling cutters are used in the milling process to remove material from the workpiece. Shell moulding is ideal for producing milling cutters because it can produce complex shapes with high precision. The shell moulding process produces a smooth surface finish that is essential for milling cutters.

Making Gold Ornaments

Shell moulding can also be used to make gold ornaments. Gold ornaments are made by pouring molten gold into a shell-like mold. The shell moulding process produces a smooth surface finish that is perfect for gold ornaments. The shell moulding process is ideal for making intricate designs, which is essential for gold ornaments.

Producing Heavy and Thick Walled Casting

Shell moulding is ideal for producing heavy and thick-walled casting. Heavy and thick-walled casting is used in various applications, such as automotive and aerospace industries. The shell moulding process can produce large and complex shapes with high precision. The shell moulding process also produces a smooth surface finish that is essential for heavy and thick-walled casting.

Producing Thin Casting

Shell moulding can also be used to produce thin casting. Thin casting is used in various applications, such as electronic components and medical devices. The shell moulding process can produce thin casting with high precision. The shell moulding process also produces a smooth surface finish that is essential for thin casting.

Conclusion

Shell moulding is a versatile process that can be used for various applications. It is an ideal process for producing complex shapes with high precision. The shell moulding process produces a smooth surface finish that is essential for various applications. Whether you need heavy and thick-walled casting or thin casting, shell moulding is an ideal process for your needs.

At saturated vapour line the value of dryness fraction is- a)0

- b)0.3

- c)0.7

- d)1.0

Correct answer is option 'D'. Can you explain this answer?

At saturated vapour line the value of dryness fraction is

a)

0

b)

0.3

c)

0.7

d)

1.0

|

|

Kiran Basu answered |

Dryness Fraction at Saturated Vapour Line

The dryness fraction is a term commonly used in thermodynamics to describe the quality of steam. It represents the ratio of the mass of dry steam present in a steam-water mixture to the total mass of the mixture. The dryness fraction can range from 0 to 1, where 0 represents a completely saturated liquid and 1 represents a completely dry or saturated vapor.

Saturated Vapour Line

The saturated vapour line on a steam table represents the boundary between the saturated liquid region and the saturated vapor region. It shows the properties of steam at different temperatures and pressures when it is in equilibrium with its liquid phase. At any point on the saturated vapour line, the steam is said to be in a saturated state, meaning it has reached its maximum possible dryness fraction at that particular temperature and pressure.

Value of Dryness Fraction at Saturated Vapour Line

At the saturated vapour line, the dryness fraction is always 1.0 or 100%. This means that the steam at this point is completely dry or saturated vapor, with no liquid water present. The reason for this is that as the steam is in equilibrium with its liquid phase, it has reached its maximum possible dryness fraction at that temperature and pressure.

As we move away from the saturated vapour line towards the saturated liquid region, the dryness fraction decreases. In the saturated liquid region, the dryness fraction is 0, indicating that the steam is completely in the liquid phase with no vapor present.

Significance of Dryness Fraction

The dryness fraction is an important parameter in steam engineering as it determines the quality and usability of steam. Steam with a high dryness fraction is considered to be of good quality and is preferred in many industrial applications. It contains less moisture, which reduces the risk of corrosion, erosion, and water hammer in steam pipes and machinery.

On the other hand, steam with a low dryness fraction can cause damage to equipment and reduce the efficiency of steam-driven processes. It may also lead to excessive condensation, which can result in water hammer and other operational issues.

In conclusion, at the saturated vapour line, the dryness fraction is always 1.0 or 100%, indicating that the steam is completely dry or in a saturated vapor state.

The degree of freedom for moist air atsuperheated state is .- a)1

- b)2

- c)3

- d)0

Correct answer is option 'C'. Can you explain this answer?

The degree of freedom for moist air atsuperheated state is .

a)

1

b)

2

c)

3

d)

0

|

|

Neha Choudhury answered |

According to Gibbs Phase Rule,

Degree of freedom=C-P+2

C=No of chemical species

P=No of phases

For moist air,

C=2(Water and air),

P=1(gaseous)

DOF=2–1+2=3

DOF is minimum no of intensive properties required to describe the system

Which of the following can be used to measure velocity in open channel flow.- a)Pitot tube

- b)Bend meter

- c)Ventarimeter

- d)Current meter

Correct answer is option 'D'. Can you explain this answer?

Which of the following can be used to measure velocity in open channel flow.

a)

Pitot tube

b)

Bend meter

c)

Ventarimeter

d)

Current meter

|

Baishali Bajaj answered |

The float method (also known as the cross-sectional method) is used to measure the flow rate for larger streams and rivers. It is found by multiplying a cross sectional area of the stream by the velocity of the water.

Piston compression rings are made of which of the following- a)cast iron.

- b)Bronze

- c)Aluminium

- d)White metal

Correct answer is option 'A'. Can you explain this answer?

Piston compression rings are made of which of the following

a)

cast iron.

b)

Bronze

c)

Aluminium

d)

White metal

|

|

Rajeev Menon answered |

Piston rings are commonly made from cast iron. Cast iron retains the integrity of its original shape under heat, load, and other dynamic forces. Piston rings seal the combustion chamber, conduct heat from the piston to the cylinder wall, and return oil to the crankcase.

In diesel engine delay period means.- a)Time between spark and ignition.

- b)Time between two knocking

- c)Time between injection and ignition.

- d)Time taken for injection.

Correct answer is option 'C'. Can you explain this answer?

In diesel engine delay period means.

a)

Time between spark and ignition.

b)

Time between two knocking

c)

Time between injection and ignition.

d)

Time taken for injection.

|

Baishali Bajaj answered |

The ignition delay in a diesel engine is defined as the time interval between the start of injection and the start of combustion. This delay period consists of

(a) physical delay, wherein atomisation, vaporization and mixing of air fuel occur and

(b) of chemical delay attributed to pre-combustion reactions.

(a) physical delay, wherein atomisation, vaporization and mixing of air fuel occur and

(b) of chemical delay attributed to pre-combustion reactions.

Which of the following is a point imperfection;

1. vacency

2. frenkel defect

3. interstitialcy

4. Schottky defect- a)1 and 2 only

- b)2 and 3 only

- c)2, 3 and 4 only

- d)1, 2, 3 and 4

Correct answer is option 'D'. Can you explain this answer?

Which of the following is a point imperfection;

1. vacency

2. frenkel defect

3. interstitialcy

4. Schottky defect

1. vacency

2. frenkel defect

3. interstitialcy

4. Schottky defect

a)

1 and 2 only

b)

2 and 3 only

c)

2, 3 and 4 only

d)

1, 2, 3 and 4

|

Anjana Mukherjee answered |

**Point imperfections in crystals**

Point imperfections, also known as point defects, are structural defects that occur at specific points within the crystal lattice of a solid material. These defects can significantly alter the properties of the material. There are several types of point imperfections, including vacancies, interstitials, Frenkel defects, and Schottky defects.

**1. Vacancy**

A vacancy is a point defect that occurs when an atom or ion is missing from its lattice site. This leads to an empty space in the crystal lattice. Vacancies can occur due to thermal vibrations or impurities in the material. Vacancies can affect the density, electrical conductivity, and diffusion of atoms in the crystal.

**2. Frenkel Defect**

A Frenkel defect is a point defect that occurs when an atom or ion is displaced from its lattice site and occupies an interstitial site within the crystal lattice. This defect is usually observed in compounds with a large difference in size between the cations and anions. Frenkel defects can affect the density, electrical conductivity, and optical properties of the material.

**3. Interstitialcy**

An interstitialcy is a point defect that occurs when an extra atom or ion occupies an interstitial site within the crystal lattice. This defect can occur due to high temperatures or impurities in the material. Interstitialcies can affect the density, mechanical properties, and diffusion of atoms in the crystal.

**4. Schottky Defect**

A Schottky defect is a point defect that occurs when a pair of oppositely charged ions is missing from their lattice sites. This defect is usually observed in ionic compounds and occurs to maintain charge neutrality within the crystal lattice. Schottky defects can affect the density, electrical conductivity, and mechanical properties of the material.

**Explanation of the correct answer**

The correct answer is option 'D' because all four options (vacancy, Frenkel defect, interstitialcy, and Schottky defect) are examples of point imperfections in crystals. Each of these defects involves the disruption of the crystal lattice structure at specific points, leading to changes in the material's properties. Therefore, all four options are correct.

Point imperfections, also known as point defects, are structural defects that occur at specific points within the crystal lattice of a solid material. These defects can significantly alter the properties of the material. There are several types of point imperfections, including vacancies, interstitials, Frenkel defects, and Schottky defects.

**1. Vacancy**

A vacancy is a point defect that occurs when an atom or ion is missing from its lattice site. This leads to an empty space in the crystal lattice. Vacancies can occur due to thermal vibrations or impurities in the material. Vacancies can affect the density, electrical conductivity, and diffusion of atoms in the crystal.

**2. Frenkel Defect**

A Frenkel defect is a point defect that occurs when an atom or ion is displaced from its lattice site and occupies an interstitial site within the crystal lattice. This defect is usually observed in compounds with a large difference in size between the cations and anions. Frenkel defects can affect the density, electrical conductivity, and optical properties of the material.

**3. Interstitialcy**