Chemical Engineering Exam > Chemical Engineering Questions > Dry saturated steam at 10 bars and 180oC ent...

Start Learning for Free

Dry saturated steam at 10 bars and 180oC enters a condenser (counter flow heat exchanger) at the rate of 15 kg/s and leaves at 300oC . The hot gas enters at 600oC with mass flow rate of 25 kg/s. If the condenser tubes are 30 mm in diameter and 3 m long, make calculations for the heat exchange area correct upto two decimal places. Neglect the resistance offered by the metallic tubes Take the following properties for steam and gas For steam

tsat = 180oC (at 10 bar)

cps = 2.7 kj/kg - K

hs = 600 W/m2 - oC

For gas

cpg = 1kj/kg -K

hg = 250 W/m2-oC

(B) 106.0

Correct answer is between ','. Can you explain this answer?

| FREE This question is part of | Download PDF Attempt this Test |

Verified Answer

Dry saturated steam at 10 bars and 180oC enters a condenser (counter ...

From steady state flow energy equation

View all questions of this test

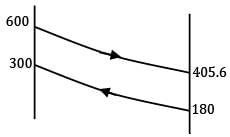

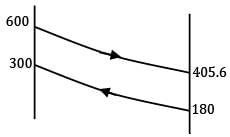

Q = mhcph (Thi - The) = mccpc(Tce - Tci)

⇒ 25 x 1 x (600 - The)

⇒ 15 x 2.7 x (300 - 180)

⇒ The = 405oC

The overall heat exchange co-efficient is given by,

1/U = 1/hg + ro/ri .1/hs

(Neglecting resistance to heat conduction through interface wall and assuming do ≅ di)

⇒ 1/U = 1/hg+ 1/hs

⇒ U = 1/250 + 1/600 = 176.47 W/m2-oC

For counter flow arrangement

ΔTi = 300oC; ΔTe = 225.6oC

∴ ΔTm = ΔTi =ΔTe/ln (ΔTi/ΔTe)

∴ Q = UA(ፀm)

⇒ mhcpg(Thi - The) = UA(ፀm)

⇒ A = 105.5 m2

Most Upvoted Answer

Dry saturated steam at 10 bars and 180oC enters a condenser (counter ...

Calculation of Heat Exchange Area

Given data:

- Mass flow rate of steam (ms) = 15 kg/s

- Inlet temperature of steam (ts1) = 180°C

- Inlet pressure of steam (ps1) = 10 bar

- Outlet temperature of steam (ts2) = 300°C

- Mass flow rate of gas (mg) = 25 kg/s

- Inlet temperature of gas (tg1) = 600°C

- Specific heat capacity of steam (cps) = 2.7 kJ/kg-K

- Specific heat capacity of gas (cpg) = 1 kJ/kg-K

- Heat transfer coefficient for steam side (hs) = 600 W/m2-°C

- Heat transfer coefficient for gas side (hg) = 250 W/m2-°C

- Tube diameter (D) = 30 mm

- Tube length (L) = 3 m

1. Calculation of Heat Transfer Rate (Q)

The heat transfer rate (Q) can be calculated using the following formula:

Q = ms * cps * (ts1 - ts2)

Q = 15 * 2.7 * (180 - 300)

Q = - 4050 kW (negative sign indicates heat is transferred from steam to gas)

2. Calculation of Log Mean Temperature Difference (LMTD)

The log mean temperature difference (LMTD) can be calculated using the following formula:

LMTD = (ΔT1 - ΔT2) / ln(ΔT1 / ΔT2)

where,

ΔT1 = ts1 - tg2

ΔT2 = ts2 - tg1

LMTD = (180 - 443.83) / ln((180 - 443.83) / (300 - 600))

LMTD = 197.51°C

3. Calculation of Overall Heat Transfer Coefficient (U)

The overall heat transfer coefficient (U) can be calculated using the following formula:

1/U = (1/hs) + (D/ln(D/d) * kg) + (1/hg)

where,

d = diameter of the tube = 30 mm

kg = thermal conductivity of the tube material = 50 W/m-K (assumed)

U = 1 / ((1/600) + ((0.03 / ln(0.03/0.0297)) * 50) + (1/250))

U = 128.64 W/m2-°C

4. Calculation of Heat Transfer Area (A)

The heat transfer area (A) can be calculated using the following formula:

Q = U * A * LMTD

A = Q / (U * LMTD)

A = -4050 / (128.64 * 197.51)

A = 1.95 m2

Therefore, the heat exchange area required is 1.95 m2.

Given data:

- Mass flow rate of steam (ms) = 15 kg/s

- Inlet temperature of steam (ts1) = 180°C

- Inlet pressure of steam (ps1) = 10 bar

- Outlet temperature of steam (ts2) = 300°C

- Mass flow rate of gas (mg) = 25 kg/s

- Inlet temperature of gas (tg1) = 600°C

- Specific heat capacity of steam (cps) = 2.7 kJ/kg-K

- Specific heat capacity of gas (cpg) = 1 kJ/kg-K

- Heat transfer coefficient for steam side (hs) = 600 W/m2-°C

- Heat transfer coefficient for gas side (hg) = 250 W/m2-°C

- Tube diameter (D) = 30 mm

- Tube length (L) = 3 m

1. Calculation of Heat Transfer Rate (Q)

The heat transfer rate (Q) can be calculated using the following formula:

Q = ms * cps * (ts1 - ts2)

Q = 15 * 2.7 * (180 - 300)

Q = - 4050 kW (negative sign indicates heat is transferred from steam to gas)

2. Calculation of Log Mean Temperature Difference (LMTD)

The log mean temperature difference (LMTD) can be calculated using the following formula:

LMTD = (ΔT1 - ΔT2) / ln(ΔT1 / ΔT2)

where,

ΔT1 = ts1 - tg2

ΔT2 = ts2 - tg1

LMTD = (180 - 443.83) / ln((180 - 443.83) / (300 - 600))

LMTD = 197.51°C

3. Calculation of Overall Heat Transfer Coefficient (U)

The overall heat transfer coefficient (U) can be calculated using the following formula:

1/U = (1/hs) + (D/ln(D/d) * kg) + (1/hg)

where,

d = diameter of the tube = 30 mm

kg = thermal conductivity of the tube material = 50 W/m-K (assumed)

U = 1 / ((1/600) + ((0.03 / ln(0.03/0.0297)) * 50) + (1/250))

U = 128.64 W/m2-°C

4. Calculation of Heat Transfer Area (A)

The heat transfer area (A) can be calculated using the following formula:

Q = U * A * LMTD

A = Q / (U * LMTD)

A = -4050 / (128.64 * 197.51)

A = 1.95 m2

Therefore, the heat exchange area required is 1.95 m2.

|

Explore Courses for Chemical Engineering exam

|

|

Similar Chemical Engineering Doubts

Dry saturated steam at 10 bars and 180oC enters a condenser (counter flow heat exchanger) at the rate of 15 kg/s and leaves at 300oC . The hot gas enters at 600oC with mass flow rate of 25 kg/s. If the condenser tubes are 30 mm in diameter and 3 m long, make calculations for the heat exchange area correct upto two decimal places. Neglect the resistance offered by the metallic tubes Take the following properties for steam and gas For steamtsat = 180oC (at 10 bar)cps = 2.7 kj/kg - Khs = 600 W/m2 - oCFor gascpg = 1kj/kg -Khg = 250 W/m2-oC(B) 106.0Correct answer is between ','. Can you explain this answer?

Question Description

Dry saturated steam at 10 bars and 180oC enters a condenser (counter flow heat exchanger) at the rate of 15 kg/s and leaves at 300oC . The hot gas enters at 600oC with mass flow rate of 25 kg/s. If the condenser tubes are 30 mm in diameter and 3 m long, make calculations for the heat exchange area correct upto two decimal places. Neglect the resistance offered by the metallic tubes Take the following properties for steam and gas For steamtsat = 180oC (at 10 bar)cps = 2.7 kj/kg - Khs = 600 W/m2 - oCFor gascpg = 1kj/kg -Khg = 250 W/m2-oC(B) 106.0Correct answer is between ','. Can you explain this answer? for Chemical Engineering 2024 is part of Chemical Engineering preparation. The Question and answers have been prepared according to the Chemical Engineering exam syllabus. Information about Dry saturated steam at 10 bars and 180oC enters a condenser (counter flow heat exchanger) at the rate of 15 kg/s and leaves at 300oC . The hot gas enters at 600oC with mass flow rate of 25 kg/s. If the condenser tubes are 30 mm in diameter and 3 m long, make calculations for the heat exchange area correct upto two decimal places. Neglect the resistance offered by the metallic tubes Take the following properties for steam and gas For steamtsat = 180oC (at 10 bar)cps = 2.7 kj/kg - Khs = 600 W/m2 - oCFor gascpg = 1kj/kg -Khg = 250 W/m2-oC(B) 106.0Correct answer is between ','. Can you explain this answer? covers all topics & solutions for Chemical Engineering 2024 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for Dry saturated steam at 10 bars and 180oC enters a condenser (counter flow heat exchanger) at the rate of 15 kg/s and leaves at 300oC . The hot gas enters at 600oC with mass flow rate of 25 kg/s. If the condenser tubes are 30 mm in diameter and 3 m long, make calculations for the heat exchange area correct upto two decimal places. Neglect the resistance offered by the metallic tubes Take the following properties for steam and gas For steamtsat = 180oC (at 10 bar)cps = 2.7 kj/kg - Khs = 600 W/m2 - oCFor gascpg = 1kj/kg -Khg = 250 W/m2-oC(B) 106.0Correct answer is between ','. Can you explain this answer?.

Dry saturated steam at 10 bars and 180oC enters a condenser (counter flow heat exchanger) at the rate of 15 kg/s and leaves at 300oC . The hot gas enters at 600oC with mass flow rate of 25 kg/s. If the condenser tubes are 30 mm in diameter and 3 m long, make calculations for the heat exchange area correct upto two decimal places. Neglect the resistance offered by the metallic tubes Take the following properties for steam and gas For steamtsat = 180oC (at 10 bar)cps = 2.7 kj/kg - Khs = 600 W/m2 - oCFor gascpg = 1kj/kg -Khg = 250 W/m2-oC(B) 106.0Correct answer is between ','. Can you explain this answer? for Chemical Engineering 2024 is part of Chemical Engineering preparation. The Question and answers have been prepared according to the Chemical Engineering exam syllabus. Information about Dry saturated steam at 10 bars and 180oC enters a condenser (counter flow heat exchanger) at the rate of 15 kg/s and leaves at 300oC . The hot gas enters at 600oC with mass flow rate of 25 kg/s. If the condenser tubes are 30 mm in diameter and 3 m long, make calculations for the heat exchange area correct upto two decimal places. Neglect the resistance offered by the metallic tubes Take the following properties for steam and gas For steamtsat = 180oC (at 10 bar)cps = 2.7 kj/kg - Khs = 600 W/m2 - oCFor gascpg = 1kj/kg -Khg = 250 W/m2-oC(B) 106.0Correct answer is between ','. Can you explain this answer? covers all topics & solutions for Chemical Engineering 2024 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for Dry saturated steam at 10 bars and 180oC enters a condenser (counter flow heat exchanger) at the rate of 15 kg/s and leaves at 300oC . The hot gas enters at 600oC with mass flow rate of 25 kg/s. If the condenser tubes are 30 mm in diameter and 3 m long, make calculations for the heat exchange area correct upto two decimal places. Neglect the resistance offered by the metallic tubes Take the following properties for steam and gas For steamtsat = 180oC (at 10 bar)cps = 2.7 kj/kg - Khs = 600 W/m2 - oCFor gascpg = 1kj/kg -Khg = 250 W/m2-oC(B) 106.0Correct answer is between ','. Can you explain this answer?.

Solutions for Dry saturated steam at 10 bars and 180oC enters a condenser (counter flow heat exchanger) at the rate of 15 kg/s and leaves at 300oC . The hot gas enters at 600oC with mass flow rate of 25 kg/s. If the condenser tubes are 30 mm in diameter and 3 m long, make calculations for the heat exchange area correct upto two decimal places. Neglect the resistance offered by the metallic tubes Take the following properties for steam and gas For steamtsat = 180oC (at 10 bar)cps = 2.7 kj/kg - Khs = 600 W/m2 - oCFor gascpg = 1kj/kg -Khg = 250 W/m2-oC(B) 106.0Correct answer is between ','. Can you explain this answer? in English & in Hindi are available as part of our courses for Chemical Engineering.

Download more important topics, notes, lectures and mock test series for Chemical Engineering Exam by signing up for free.

Here you can find the meaning of Dry saturated steam at 10 bars and 180oC enters a condenser (counter flow heat exchanger) at the rate of 15 kg/s and leaves at 300oC . The hot gas enters at 600oC with mass flow rate of 25 kg/s. If the condenser tubes are 30 mm in diameter and 3 m long, make calculations for the heat exchange area correct upto two decimal places. Neglect the resistance offered by the metallic tubes Take the following properties for steam and gas For steamtsat = 180oC (at 10 bar)cps = 2.7 kj/kg - Khs = 600 W/m2 - oCFor gascpg = 1kj/kg -Khg = 250 W/m2-oC(B) 106.0Correct answer is between ','. Can you explain this answer? defined & explained in the simplest way possible. Besides giving the explanation of

Dry saturated steam at 10 bars and 180oC enters a condenser (counter flow heat exchanger) at the rate of 15 kg/s and leaves at 300oC . The hot gas enters at 600oC with mass flow rate of 25 kg/s. If the condenser tubes are 30 mm in diameter and 3 m long, make calculations for the heat exchange area correct upto two decimal places. Neglect the resistance offered by the metallic tubes Take the following properties for steam and gas For steamtsat = 180oC (at 10 bar)cps = 2.7 kj/kg - Khs = 600 W/m2 - oCFor gascpg = 1kj/kg -Khg = 250 W/m2-oC(B) 106.0Correct answer is between ','. Can you explain this answer?, a detailed solution for Dry saturated steam at 10 bars and 180oC enters a condenser (counter flow heat exchanger) at the rate of 15 kg/s and leaves at 300oC . The hot gas enters at 600oC with mass flow rate of 25 kg/s. If the condenser tubes are 30 mm in diameter and 3 m long, make calculations for the heat exchange area correct upto two decimal places. Neglect the resistance offered by the metallic tubes Take the following properties for steam and gas For steamtsat = 180oC (at 10 bar)cps = 2.7 kj/kg - Khs = 600 W/m2 - oCFor gascpg = 1kj/kg -Khg = 250 W/m2-oC(B) 106.0Correct answer is between ','. Can you explain this answer? has been provided alongside types of Dry saturated steam at 10 bars and 180oC enters a condenser (counter flow heat exchanger) at the rate of 15 kg/s and leaves at 300oC . The hot gas enters at 600oC with mass flow rate of 25 kg/s. If the condenser tubes are 30 mm in diameter and 3 m long, make calculations for the heat exchange area correct upto two decimal places. Neglect the resistance offered by the metallic tubes Take the following properties for steam and gas For steamtsat = 180oC (at 10 bar)cps = 2.7 kj/kg - Khs = 600 W/m2 - oCFor gascpg = 1kj/kg -Khg = 250 W/m2-oC(B) 106.0Correct answer is between ','. Can you explain this answer? theory, EduRev gives you an

ample number of questions to practice Dry saturated steam at 10 bars and 180oC enters a condenser (counter flow heat exchanger) at the rate of 15 kg/s and leaves at 300oC . The hot gas enters at 600oC with mass flow rate of 25 kg/s. If the condenser tubes are 30 mm in diameter and 3 m long, make calculations for the heat exchange area correct upto two decimal places. Neglect the resistance offered by the metallic tubes Take the following properties for steam and gas For steamtsat = 180oC (at 10 bar)cps = 2.7 kj/kg - Khs = 600 W/m2 - oCFor gascpg = 1kj/kg -Khg = 250 W/m2-oC(B) 106.0Correct answer is between ','. Can you explain this answer? tests, examples and also practice Chemical Engineering tests.

|

Explore Courses for Chemical Engineering exam

|

|

Suggested Free Tests

Signup for Free!

Signup to see your scores go up within 7 days! Learn & Practice with 1000+ FREE Notes, Videos & Tests.