Mechanical Engineering Exam > Mechanical Engineering Questions > A single point cutting tool with a nose radiu...

Start Learning for Free

A single point cutting tool with a nose radius of 0.4 mm was used to turn a component in a lathe employing feed rate of 0.3 mm/rev. If the feed rate is doubled, the ideal surface roughness (peak-to-valley height) produced on the components will increase by a factor of

[PI 2003]

- a)2

- b)4

- c)8

- d)16

Correct answer is option 'B'. Can you explain this answer?

| FREE This question is part of | Download PDF Attempt this Test |

Verified Answer

A single point cutting tool with a nose radius of 0.4 mm was used to t...

Most Upvoted Answer

A single point cutting tool with a nose radius of 0.4 mm was used to t...

To understand why the ideal surface roughness produced on the components will increase by a factor of 4 when the feed rate is doubled, let's analyze the factors affecting surface roughness and how they are related to the feed rate.

Factors Affecting Surface Roughness:

1. Nose Radius: The nose radius of the cutting tool affects the depth of cut and the cutting forces. A larger nose radius will result in a smoother surface finish.

2. Feed Rate: The feed rate is the distance the cutting tool advances into the workpiece in one revolution. It directly affects the surface roughness, as a higher feed rate can lead to a rougher surface finish.

3. Depth of Cut: The depth of cut is the distance from the machined surface to the uncut material. It also influences the surface roughness, as a larger depth of cut can result in a rougher surface finish.

Effect of Feed Rate on Surface Roughness:

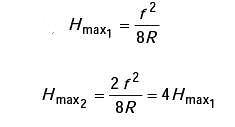

When the feed rate is doubled, the surface roughness will increase by a factor of 4. This can be understood by considering the following points:

1. Feed Rate and Depth of Cut: Increasing the feed rate while maintaining a constant depth of cut will result in a larger volume of material being removed per revolution. This increased material removal can lead to more significant variations in the machined surface, resulting in a rougher finish.

2. Feed Rate and Nose Radius: The feed rate and nose radius are inversely related when it comes to surface roughness. A larger nose radius can compensate for a higher feed rate, resulting in a smoother surface finish. However, when the feed rate is doubled, the effect of the nose radius becomes less significant, and the increased material removal dominates the surface roughness.

3. Surface Roughness Calculation: The ideal surface roughness (peak-to-valley height) is proportional to the square root of the feed rate. Therefore, when the feed rate is doubled, the ideal surface roughness will increase by a factor of √2. Since √2 ≈ 1.41, the ideal surface roughness will increase by a factor of approximately 1.41 × 1.41 = 1.99, which is approximately 2.

Hence, the ideal surface roughness will increase by a factor of 4 (2 × 2) when the feed rate is doubled. Therefore, the correct answer is option B.

Factors Affecting Surface Roughness:

1. Nose Radius: The nose radius of the cutting tool affects the depth of cut and the cutting forces. A larger nose radius will result in a smoother surface finish.

2. Feed Rate: The feed rate is the distance the cutting tool advances into the workpiece in one revolution. It directly affects the surface roughness, as a higher feed rate can lead to a rougher surface finish.

3. Depth of Cut: The depth of cut is the distance from the machined surface to the uncut material. It also influences the surface roughness, as a larger depth of cut can result in a rougher surface finish.

Effect of Feed Rate on Surface Roughness:

When the feed rate is doubled, the surface roughness will increase by a factor of 4. This can be understood by considering the following points:

1. Feed Rate and Depth of Cut: Increasing the feed rate while maintaining a constant depth of cut will result in a larger volume of material being removed per revolution. This increased material removal can lead to more significant variations in the machined surface, resulting in a rougher finish.

2. Feed Rate and Nose Radius: The feed rate and nose radius are inversely related when it comes to surface roughness. A larger nose radius can compensate for a higher feed rate, resulting in a smoother surface finish. However, when the feed rate is doubled, the effect of the nose radius becomes less significant, and the increased material removal dominates the surface roughness.

3. Surface Roughness Calculation: The ideal surface roughness (peak-to-valley height) is proportional to the square root of the feed rate. Therefore, when the feed rate is doubled, the ideal surface roughness will increase by a factor of √2. Since √2 ≈ 1.41, the ideal surface roughness will increase by a factor of approximately 1.41 × 1.41 = 1.99, which is approximately 2.

Hence, the ideal surface roughness will increase by a factor of 4 (2 × 2) when the feed rate is doubled. Therefore, the correct answer is option B.

Attention Mechanical Engineering Students!

To make sure you are not studying endlessly, EduRev has designed Mechanical Engineering study material, with Structured Courses, Videos, & Test Series. Plus get personalized analysis, doubt solving and improvement plans to achieve a great score in Mechanical Engineering.

|

Explore Courses for Mechanical Engineering exam

|

|

Similar Mechanical Engineering Doubts

A single point cutting tool with a nose radius of 0.4 mm was used to turn a component in a lathe employing feed rate of 0.3 mm/rev. If the feed rate is doubled, the ideal surface roughness (peak-to-valley height) produced on the components will increase by a factor of[PI 2003]a)2b)4c)8d)16Correct answer is option 'B'. Can you explain this answer?

Question Description

A single point cutting tool with a nose radius of 0.4 mm was used to turn a component in a lathe employing feed rate of 0.3 mm/rev. If the feed rate is doubled, the ideal surface roughness (peak-to-valley height) produced on the components will increase by a factor of[PI 2003]a)2b)4c)8d)16Correct answer is option 'B'. Can you explain this answer? for Mechanical Engineering 2024 is part of Mechanical Engineering preparation. The Question and answers have been prepared according to the Mechanical Engineering exam syllabus. Information about A single point cutting tool with a nose radius of 0.4 mm was used to turn a component in a lathe employing feed rate of 0.3 mm/rev. If the feed rate is doubled, the ideal surface roughness (peak-to-valley height) produced on the components will increase by a factor of[PI 2003]a)2b)4c)8d)16Correct answer is option 'B'. Can you explain this answer? covers all topics & solutions for Mechanical Engineering 2024 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for A single point cutting tool with a nose radius of 0.4 mm was used to turn a component in a lathe employing feed rate of 0.3 mm/rev. If the feed rate is doubled, the ideal surface roughness (peak-to-valley height) produced on the components will increase by a factor of[PI 2003]a)2b)4c)8d)16Correct answer is option 'B'. Can you explain this answer?.

A single point cutting tool with a nose radius of 0.4 mm was used to turn a component in a lathe employing feed rate of 0.3 mm/rev. If the feed rate is doubled, the ideal surface roughness (peak-to-valley height) produced on the components will increase by a factor of[PI 2003]a)2b)4c)8d)16Correct answer is option 'B'. Can you explain this answer? for Mechanical Engineering 2024 is part of Mechanical Engineering preparation. The Question and answers have been prepared according to the Mechanical Engineering exam syllabus. Information about A single point cutting tool with a nose radius of 0.4 mm was used to turn a component in a lathe employing feed rate of 0.3 mm/rev. If the feed rate is doubled, the ideal surface roughness (peak-to-valley height) produced on the components will increase by a factor of[PI 2003]a)2b)4c)8d)16Correct answer is option 'B'. Can you explain this answer? covers all topics & solutions for Mechanical Engineering 2024 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for A single point cutting tool with a nose radius of 0.4 mm was used to turn a component in a lathe employing feed rate of 0.3 mm/rev. If the feed rate is doubled, the ideal surface roughness (peak-to-valley height) produced on the components will increase by a factor of[PI 2003]a)2b)4c)8d)16Correct answer is option 'B'. Can you explain this answer?.

Solutions for A single point cutting tool with a nose radius of 0.4 mm was used to turn a component in a lathe employing feed rate of 0.3 mm/rev. If the feed rate is doubled, the ideal surface roughness (peak-to-valley height) produced on the components will increase by a factor of[PI 2003]a)2b)4c)8d)16Correct answer is option 'B'. Can you explain this answer? in English & in Hindi are available as part of our courses for Mechanical Engineering.

Download more important topics, notes, lectures and mock test series for Mechanical Engineering Exam by signing up for free.

Here you can find the meaning of A single point cutting tool with a nose radius of 0.4 mm was used to turn a component in a lathe employing feed rate of 0.3 mm/rev. If the feed rate is doubled, the ideal surface roughness (peak-to-valley height) produced on the components will increase by a factor of[PI 2003]a)2b)4c)8d)16Correct answer is option 'B'. Can you explain this answer? defined & explained in the simplest way possible. Besides giving the explanation of

A single point cutting tool with a nose radius of 0.4 mm was used to turn a component in a lathe employing feed rate of 0.3 mm/rev. If the feed rate is doubled, the ideal surface roughness (peak-to-valley height) produced on the components will increase by a factor of[PI 2003]a)2b)4c)8d)16Correct answer is option 'B'. Can you explain this answer?, a detailed solution for A single point cutting tool with a nose radius of 0.4 mm was used to turn a component in a lathe employing feed rate of 0.3 mm/rev. If the feed rate is doubled, the ideal surface roughness (peak-to-valley height) produced on the components will increase by a factor of[PI 2003]a)2b)4c)8d)16Correct answer is option 'B'. Can you explain this answer? has been provided alongside types of A single point cutting tool with a nose radius of 0.4 mm was used to turn a component in a lathe employing feed rate of 0.3 mm/rev. If the feed rate is doubled, the ideal surface roughness (peak-to-valley height) produced on the components will increase by a factor of[PI 2003]a)2b)4c)8d)16Correct answer is option 'B'. Can you explain this answer? theory, EduRev gives you an

ample number of questions to practice A single point cutting tool with a nose radius of 0.4 mm was used to turn a component in a lathe employing feed rate of 0.3 mm/rev. If the feed rate is doubled, the ideal surface roughness (peak-to-valley height) produced on the components will increase by a factor of[PI 2003]a)2b)4c)8d)16Correct answer is option 'B'. Can you explain this answer? tests, examples and also practice Mechanical Engineering tests.

|

Explore Courses for Mechanical Engineering exam

|

|

Suggested Free Tests

Signup for Free!

Signup to see your scores go up within 7 days! Learn & Practice with 1000+ FREE Notes, Videos & Tests.