All Exams >

Civil Engineering (CE) >

6 Months Preparation for GATE Civil Engg >

All Questions

All questions of Mechanical Properties of Materials for Civil Engineering (CE) Exam

Limit of proportionality depends upon

- a)type of loading

- b)type of material

- c)area of cross-section

- d)all of the above

Correct answer is option 'B'. Can you explain this answer?

Limit of proportionality depends upon

a)

type of loading

b)

type of material

c)

area of cross-section

d)

all of the above

|

|

Gaurav Kapoor answered |

The material and its properties. Different materials have different limits of proportionality, which is the maximum stress a material can withstand before it no longer behaves in a linearly elastic manner. It also depends on the temperature and the strain rate.

The permanent mode of deformation of a material known as ____________- a)Plasticity

- b)Elasticity

- c)Slip deformation

- d)Twinning deformation

Correct answer is option 'A'. Can you explain this answer?

The permanent mode of deformation of a material known as ____________

a)

Plasticity

b)

Elasticity

c)

Slip deformation

d)

Twinning deformation

|

|

Sarita Yadav answered |

Plasticity is defined as the property of a material due to which it is permanently deformed due to loading. Elasticity is the temporary form of deformation. Twinning and Slip are mechanisms of Plastic deformation.

Strain is defined as ratio of- a)change in volume to original volume

- b)change in length to original length.

- c)change in cross-sectional area to original cross-sectional area

- d)any one of the above

Correct answer is option 'D'. Can you explain this answer?

Strain is defined as ratio of

a)

change in volume to original volume

b)

change in length to original length.

c)

change in cross-sectional area to original cross-sectional area

d)

any one of the above

|

|

Neha Joshi answered |

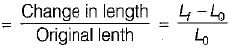

The strain is defined as the ratio of change in dimension to the original dimension.

If ‘δl’ changes in the length and ‘l’ is the original length, strain = δl/l

Important Terms:

- The ratio of change in length to the original length is called the longitudinal strain.

- The ratio of change in diameter/breadth to original diameter/breadth is called the lateral strain.

- The volumetric strain of a deformed body is defined as the ratio of the change in volume of the body to the deformation to its original volume.

- Shear strain is defined as the strain accompanying a shearing action. It is the angle in radian measure through which the body gets distorted when subjected to external shearing action.

Young's modulus is defined as the ratio of- a)volumetric stress and volumetric strain

- b)lateral stress and lateral strain

- c)longitudinal stress and lateral strain

- d)longitudinal stress and longitudinal strain

Correct answer is option 'D'. Can you explain this answer?

Young's modulus is defined as the ratio of

a)

volumetric stress and volumetric strain

b)

lateral stress and lateral strain

c)

longitudinal stress and lateral strain

d)

longitudinal stress and longitudinal strain

|

Megha Choudhury answered |

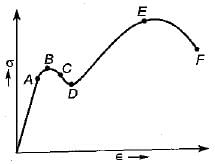

The linear relationship between stress and strain for a bar in simple tension or compression can be expressed by the equation

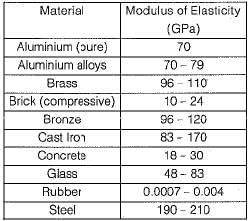

in which Eis a constant of proportionality known as modulus of elasticity for the material. The modulus of elasticity is the slope of the stress- strain diagram in the linearly elastic region and its value depends upon the particular material being used.

in which Eis a constant of proportionality known as modulus of elasticity for the material. The modulus of elasticity is the slope of the stress- strain diagram in the linearly elastic region and its value depends upon the particular material being used.

Consider the following statements about truestress-strain method/curve:

1. It is more sensitive to changes in both metallurgical and mechanical conditions.

2. It gives a more accurate picture of the ductility.

3. It can be correlated with stress-strain values in other tests like torsion, impact, combined stress tests etc.

4. It can be used for compression tests as well.Which of the above statements are correct?- a)1, 2 and 3

- b)1, 3 and 4

- c)2, 3 and 4

- d)1, 2, 3 and 4

Correct answer is option 'D'. Can you explain this answer?

Consider the following statements about truestress-strain method/curve:

1. It is more sensitive to changes in both metallurgical and mechanical conditions.

2. It gives a more accurate picture of the ductility.

3. It can be correlated with stress-strain values in other tests like torsion, impact, combined stress tests etc.

4. It can be used for compression tests as well.

1. It is more sensitive to changes in both metallurgical and mechanical conditions.

2. It gives a more accurate picture of the ductility.

3. It can be correlated with stress-strain values in other tests like torsion, impact, combined stress tests etc.

4. It can be used for compression tests as well.

Which of the above statements are correct?

a)

1, 2 and 3

b)

1, 3 and 4

c)

2, 3 and 4

d)

1, 2, 3 and 4

|

Nitya Nambiar answered |

Truestress-strain method/curve is a widely used method in materials testing to determine the mechanical behavior of a material under load. It provides valuable information about the material's strength, ductility, and other mechanical properties. Let's analyze each statement to determine their correctness:

Statement 1: It is more sensitive to changes in both metallurgical and mechanical conditions.

- This statement is correct. The truestress-strain method takes into account the instantaneous cross-sectional area of the specimen, which changes during deformation. This makes it more sensitive to changes in the material's mechanical and metallurgical conditions compared to the engineering stress-strain method.

Statement 2: It gives a more accurate picture of the ductility.

- This statement is correct. The truestress-strain curve provides a more accurate representation of the material's ductility because it considers the actual change in cross-sectional area during deformation. It accounts for the necking phenomenon that occurs in many materials under tension, which is crucial for accurately assessing the material's ability to deform before failure.

Statement 3: It can be correlated with stress-strain values in other tests like torsion, impact, combined stress tests, etc.

- This statement is correct. The truestress-strain values obtained from tensile testing can be correlated with stress-strain values obtained from other testing methods like torsion, impact, and combined stress tests. This allows for a better understanding of the material's behavior under different loading conditions and helps in predicting its performance in various applications.

Statement 4: It can be used for compression tests as well.

- This statement is correct. While the truestress-strain method is commonly used in tensile testing, it can also be applied to compression testing. The concept of truestress and truestrain can be extended to compression tests by considering the instantaneous cross-sectional area and volume changes during deformation.

In conclusion, all the given statements about the truestress-strain method/curve are correct. It is a sensitive method that provides a more accurate picture of ductility, can be correlated with other test results, and can be used for both tension and compression testing.

Statement 1: It is more sensitive to changes in both metallurgical and mechanical conditions.

- This statement is correct. The truestress-strain method takes into account the instantaneous cross-sectional area of the specimen, which changes during deformation. This makes it more sensitive to changes in the material's mechanical and metallurgical conditions compared to the engineering stress-strain method.

Statement 2: It gives a more accurate picture of the ductility.

- This statement is correct. The truestress-strain curve provides a more accurate representation of the material's ductility because it considers the actual change in cross-sectional area during deformation. It accounts for the necking phenomenon that occurs in many materials under tension, which is crucial for accurately assessing the material's ability to deform before failure.

Statement 3: It can be correlated with stress-strain values in other tests like torsion, impact, combined stress tests, etc.

- This statement is correct. The truestress-strain values obtained from tensile testing can be correlated with stress-strain values obtained from other testing methods like torsion, impact, and combined stress tests. This allows for a better understanding of the material's behavior under different loading conditions and helps in predicting its performance in various applications.

Statement 4: It can be used for compression tests as well.

- This statement is correct. While the truestress-strain method is commonly used in tensile testing, it can also be applied to compression testing. The concept of truestress and truestrain can be extended to compression tests by considering the instantaneous cross-sectional area and volume changes during deformation.

In conclusion, all the given statements about the truestress-strain method/curve are correct. It is a sensitive method that provides a more accurate picture of ductility, can be correlated with other test results, and can be used for both tension and compression testing.

The material in which large deformation is possible before the absolute failure or rupture is termed as- a)brittle

- b)elastic

- c)ductile

- d)plastic

Correct answer is option 'C'. Can you explain this answer?

The material in which large deformation is possible before the absolute failure or rupture is termed as

a)

brittle

b)

elastic

c)

ductile

d)

plastic

|

Partho Jain answered |

Explanation:

In materials science and engineering, the ability of a material to undergo large deformation without fracturing or rupturing is referred to as ductility. Ductility is an important mechanical property of materials and is often desired in applications where the material needs to undergo extensive deformation without failure.

Ductile Materials:

Ductile materials exhibit plastic deformation before failure. Plastic deformation occurs when the material is subjected to an applied load and undergoes a permanent change in shape without fracturing or rupturing. This is in contrast to brittle materials, which undergo little to no plastic deformation before failure.

Brittle Materials:

Brittle materials, such as glass or ceramic, have very limited plastic deformation capabilities. They tend to fracture or rupture at relatively low strains or stresses without undergoing any significant plastic deformation. This makes them more prone to sudden failure under applied loads.

Elastic Materials:

Elastic materials, on the other hand, exhibit reversible deformation. When an elastic material is subjected to an applied load, it deforms temporarily but returns to its original shape once the load is removed. These materials can undergo small deformations without permanent damage or failure.

Importance of Ductility:

Ductility is an important property in various engineering applications. For example, in the construction industry, materials used for structural purposes need to be ductile to withstand loads and deformations caused by earthquakes, wind, or other external forces. Ductile materials are also preferred in metal forming processes such as forging, rolling, or extrusion, where extensive plastic deformation is required.

Conclusion:

In summary, the material in which large deformation is possible before absolute failure or rupture is termed as ductile. Ductile materials can undergo significant plastic deformation without fracturing or rupturing, making them desirable for various engineering applications.

A thin mid steel wire is loaded by adding loads in equal increments till it breaks. The extensions noted with increasing loads will behave as under- a)uniform throughout

- b)first increase and then decrease

- c)increase uniformly first and then increase rapidly

- d)increase rapidly first and then uniformly

Correct answer is option 'C'. Can you explain this answer?

A thin mid steel wire is loaded by adding loads in equal increments till it breaks. The extensions noted with increasing loads will behave as under

a)

uniform throughout

b)

first increase and then decrease

c)

increase uniformly first and then increase rapidly

d)

increase rapidly first and then uniformly

|

|

Neha Joshi answered |

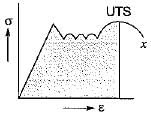

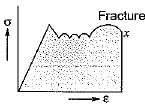

At first, the strain is proportional to strain or elongation is proportional to the load giving a straight-line relationship.

A further increase in the load after yield load will cause marked deformation in the whole volume of the metal. The maximum load which the specimen can withstand without failure is called the load at the ultimate strength.

The linear relation between the stress and strain of a material is valid until

- a)fracture stress

- b)proportional limit

- c)ultimate stress

- d)elastic limit

Correct answer is option 'D'. Can you explain this answer?

The linear relation between the stress and strain of a material is valid until

a)

fracture stress

b)

proportional limit

c)

ultimate stress

d)

elastic limit

|

|

Arshiya Dey answered |

Hooke’s law holds up to the proportional limit.

Hooke’s law in terms of stress and strain is Stress∝Strain→σ∝ε→σ=Eε

The constant of proportionality is called the elastic modulus or Young’s modulus, E. It has the same units as stress. E is a property of the material used.

Resilience of a material is considered when it is subjected to

- a)fatigue

- b)creep

- c)shock loading

- d)resonant condition

Correct answer is option 'C'. Can you explain this answer?

Resilience of a material is considered when it is subjected to

a)

fatigue

b)

creep

c)

shock loading

d)

resonant condition

|

Rutuja Deshpande answered |

It is the property of materials to absorb energy and to resist shock and impact loads. It is measured by the amount of energy absorbed per unit volume within elastic limit this property is essential for spring materials. The resilience of material should be considered when it is subjected to shock loading.

In a tensile testing experiment on a specimen of 1 cm2 area, the maximum load observed was 5 tonnes and neck area 0.25 cm2. The ultimate tensile strength of specimen is

- a)4 tonnes/cm2

- b)5 tonnes/cm2

- c)16 tonnes/cm2

- d)22 tonnes/cm2

Correct answer is option 'B'. Can you explain this answer?

In a tensile testing experiment on a specimen of 1 cm2 area, the maximum load observed was 5 tonnes and neck area 0.25 cm2. The ultimate tensile strength of specimen is

a)

4 tonnes/cm2

b)

5 tonnes/cm2

c)

16 tonnes/cm2

d)

22 tonnes/cm2

|

|

Sinjini Bose answered |

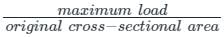

Ultimate tensile strength is corresponding to the maximum load and cross-sectional area of the specimen at the start of the test.

Ultimate tensile strength =

Area = 1 cm2 and maximum load = 5 tonnes

So ultimate tensile strength = 5 tonnes/1 cm2 = 5 tonnes/cm2

Area = 1 cm2 and maximum load = 5 tonnes

So ultimate tensile strength = 5 tonnes/1 cm2 = 5 tonnes/cm2

What are the materials which show direction dependent properties?- a)Homogeneous materials

- b)Viscoelastic materials

- c)Isotropic materials

- d)Anisotropic materials

Correct answer is option 'D'. Can you explain this answer?

What are the materials which show direction dependent properties?

a)

Homogeneous materials

b)

Viscoelastic materials

c)

Isotropic materials

d)

Anisotropic materials

|

|

Mrinalini Sharma answered |

Anisotropy is the property in which material possess different properties in different directions.

What is the phenomenon of progressive extension of the material i.e. strain increasing with the time at a constant load, called?- a)Plasticity

- b)Yielding

- c)Creeping

- d)Breaking

Correct answer is option 'C'. Can you explain this answer?

What is the phenomenon of progressive extension of the material i.e. strain increasing with the time at a constant load, called?

a)

Plasticity

b)

Yielding

c)

Creeping

d)

Breaking

|

|

Dishani Desai answered |

When metals are subjected to constant loads, metals tends to deform continuously. This continuous deformation of metals under constant loads is called as creep.

The percentage elongation of a material as - obtained from static tension test depends upon the- a)diameter of the test specimen

- b)gauge length of the specimen

- c)nature of end-grips of the testing machine

- d)geometry of the test specimen

Correct answer is option 'B'. Can you explain this answer?

The percentage elongation of a material as - obtained from static tension test depends upon the

a)

diameter of the test specimen

b)

gauge length of the specimen

c)

nature of end-grips of the testing machine

d)

geometry of the test specimen

|

|

Dipika Kulkarni answered |

Percentage elongation

where

Lo = original gauge length

Lf = final length between the gauge mark measured after fracture

since local yielding occurs before the fracture of the specimen, the percentage elongation depends upon the gauge length of the specimen.

where

Lo = original gauge length

Lf = final length between the gauge mark measured after fracture

since local yielding occurs before the fracture of the specimen, the percentage elongation depends upon the gauge length of the specimen.

The ability of a material to resist plastic deformation known as _____________- a)Tensile strength

- b)Modulus of elasticity

- c)Yield strength

- d)Impact strength

Correct answer is option 'C'. Can you explain this answer?

The ability of a material to resist plastic deformation known as _____________

a)

Tensile strength

b)

Modulus of elasticity

c)

Yield strength

d)

Impact strength

|

|

Avinash Sharma answered |

The point of stretching where it increases suddenly is known as yield strength, i.e. the region where the stretch is elastic. Tensile strength is the force needed to fracture the material. Impact strength is the capacity of a material to resist shock energy before a fracture.

Elastic limit is the point- a)up to which stress is proportional to strain

- b)at which elongation takes place without application of additional load

- c)up to which if the load is removed, original volume and shape are regained

- d)at which the toughness is maximum

Correct answer is option 'C'. Can you explain this answer?

Elastic limit is the point

a)

up to which stress is proportional to strain

b)

at which elongation takes place without application of additional load

c)

up to which if the load is removed, original volume and shape are regained

d)

at which the toughness is maximum

|

|

Sparsh Chakraborty answered |

Explanation:

The elastic limit is the point at which a material experiences permanent deformation or plasticity after being subjected to stress. It is an important concept in materials science and engineering, as it defines the maximum stress that a material can withstand without undergoing permanent deformation.

Definition:

The elastic limit is defined as the maximum stress that a material can withstand without experiencing permanent deformation. It is the point at which the material transitions from elastic behavior to plastic behavior.

Key Points:

- Stress and strain are two fundamental concepts in the study of materials behavior under applied loads.

- Stress is defined as the force per unit area, and strain is defined as the change in length per unit length.

- In the elastic region, stress is proportional to strain, which means that the material returns to its original shape and size after the stress is removed.

- The elastic limit is the point at which the stress is no longer proportional to strain.

- Beyond the elastic limit, the material undergoes permanent deformation and does not return to its original shape and size when the stress is removed.

- The elastic limit can be determined experimentally by subjecting a material to increasing levels of stress and measuring the resulting strain.

- Once the elastic limit is reached, the material starts to exhibit plastic behavior, which means that it undergoes permanent deformation even when the stress is removed.

- It is important to note that the elastic limit is different for different materials and can vary depending on factors such as temperature, strain rate, and microstructure.

- The elastic limit is an important consideration in the design and analysis of structures and components, as it defines the maximum stress that a material can withstand without undergoing permanent deformation.

- Beyond the elastic limit, the material may experience failure or fracture, depending on its strength and other mechanical properties.

Conclusion:

The elastic limit is the point at which a material undergoes permanent deformation or plasticity after being subjected to stress. It is the maximum stress that a material can withstand without experiencing permanent deformation. Beyond the elastic limit, the material does not return to its original shape and size when the stress is removed. The elastic limit is an important concept in materials science and engineering, as it defines the maximum stress that a material can withstand without undergoing permanent deformation.

The elastic limit is the point at which a material experiences permanent deformation or plasticity after being subjected to stress. It is an important concept in materials science and engineering, as it defines the maximum stress that a material can withstand without undergoing permanent deformation.

Definition:

The elastic limit is defined as the maximum stress that a material can withstand without experiencing permanent deformation. It is the point at which the material transitions from elastic behavior to plastic behavior.

Key Points:

- Stress and strain are two fundamental concepts in the study of materials behavior under applied loads.

- Stress is defined as the force per unit area, and strain is defined as the change in length per unit length.

- In the elastic region, stress is proportional to strain, which means that the material returns to its original shape and size after the stress is removed.

- The elastic limit is the point at which the stress is no longer proportional to strain.

- Beyond the elastic limit, the material undergoes permanent deformation and does not return to its original shape and size when the stress is removed.

- The elastic limit can be determined experimentally by subjecting a material to increasing levels of stress and measuring the resulting strain.

- Once the elastic limit is reached, the material starts to exhibit plastic behavior, which means that it undergoes permanent deformation even when the stress is removed.

- It is important to note that the elastic limit is different for different materials and can vary depending on factors such as temperature, strain rate, and microstructure.

- The elastic limit is an important consideration in the design and analysis of structures and components, as it defines the maximum stress that a material can withstand without undergoing permanent deformation.

- Beyond the elastic limit, the material may experience failure or fracture, depending on its strength and other mechanical properties.

Conclusion:

The elastic limit is the point at which a material undergoes permanent deformation or plasticity after being subjected to stress. It is the maximum stress that a material can withstand without experiencing permanent deformation. Beyond the elastic limit, the material does not return to its original shape and size when the stress is removed. The elastic limit is an important concept in materials science and engineering, as it defines the maximum stress that a material can withstand without undergoing permanent deformation.

Which one of the following pairs is NOT correctly matched?- a)Visco-elastic material : Small plastic zone

- b)Strain hardening material : Stiffening effect felt at some stage

- c)Orthotropic material : Different properties in three perpendi-cular directions

- d)Isotropic material : Same physical properties in all directions at a point

Correct answer is option 'A'. Can you explain this answer?

Which one of the following pairs is NOT correctly matched?

a)

Visco-elastic material : Small plastic zone

b)

Strain hardening material : Stiffening effect felt at some stage

c)

Orthotropic material : Different properties in three perpendi-cular directions

d)

Isotropic material : Same physical properties in all directions at a point

|

|

Sanya Agarwal answered |

Answer: a)Visco-elastic material : Small plastic zone

Explanation: Visco-elastic material exhibit a mixture of creep and elastic after effects at room temperature. Thus their behaviour is time-dependent. Materials with different properties in different directions are called anisotropic. Orthotropic material is a special case of an anisotropic material in three mutually perpendicular directions. However, these are symmetric about any axis.

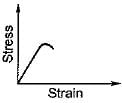

The stress-strain curve for glass during tensile test would exhibit- a)a straight line

- b)a hyperbolic curve

- c)an irregular curve

- d)a sudden break

Correct answer is option 'D'. Can you explain this answer?

The stress-strain curve for glass during tensile test would exhibit

a)

a straight line

b)

a hyperbolic curve

c)

an irregular curve

d)

a sudden break

|

|

Ruchi Ahuja answered |

Glass is a brittle material and it can’t withstand tension.

Match list - I with list - II and select the correct answer using the codes below:

List - I

A. Ductility

B. Brittleness

C. Tenacity

D. Toughness

List - II

1. Failure without warning

2. Drawn permanently over great changes of shape without rupture.

3. Absorption of energy at high stress without rupture.

4. High tensile strength

- a)A – 1, B – 2, C – 4, D - 3

- b)A – 2, B – 1, C – 4, D - 3

- c)A – 2, B – 3, C – 4, D - 1

- d)A – 1, B – 2, C – 3, D - 4

Correct answer is option 'B'. Can you explain this answer?

Match list - I with list - II and select the correct answer using the codes below:

List - I

A. Ductility

B. Brittleness

C. Tenacity

D. Toughness

List - II

1. Failure without warning

2. Drawn permanently over great changes of shape without rupture.

3. Absorption of energy at high stress without rupture.

4. High tensile strength

a)

A – 1, B – 2, C – 4, D - 3

b)

A – 2, B – 1, C – 4, D - 3

c)

A – 2, B – 3, C – 4, D - 1

d)

A – 1, B – 2, C – 3, D - 4

|

|

Rashi Chauhan answered |

Ductility is the ability of a material to withstand tensile force when it is applied upon it as it undergoes plastic deformation whereas Brittleness is the opposite of ductility as it refers to the ability of materials to break into pieces upon application of tensile force without any elongation or plastic deformation.

Tenacity is the property of a metal to resist the fracture when under the action of tensile load. it refers to the ultimate tensile strength of the material, a metal having high tenacity means it has high tensile strength.

Toughness is the ability to absorb mechanical energy up to failure.

Malleability is that property by which a metal can be drawn into a thin sheet of negligible thickness.

Plasticity is an ability of material to deform without any rupture by non-returnable way. After removing the load there are staying permanent deformations.

A wire is stretched by a force. If its length increases by 1%, what is the strain?- a)0.1

- b)0.01

- c)1

- d)10

Correct answer is option 'B'. Can you explain this answer?

A wire is stretched by a force. If its length increases by 1%, what is the strain?

a)

0.1

b)

0.01

c)

1

d)

10

|

Crack Gate answered |

If a wire is stretched by a force and its length increases by 1%, the strain can be calculated as follows:

- Strain is defined as the change in length divided by the original length.

- In this case, the change in length is 1% of the original length.

- Therefore, strain = (Change in Length) / (Original Length).

- As a decimal, 1% is equal to 0.01.

Thus, the strain is 0.01. The correct answer is B.

Which of the following best defines stress?- a)Extension per unit length

- b)Strain per unit force

- c)Force per unit area

- d)Force multiplied by area

Correct answer is option 'C'. Can you explain this answer?

Which of the following best defines stress?

a)

Extension per unit length

b)

Strain per unit force

c)

Force per unit area

d)

Force multiplied by area

|

Pk Academy answered |

Stress is best defined as the force applied per unit area. It measures how much force is distributed over a specific area and is crucial in understanding material behaviour under load. The correct definition can be summarised as follows:

- Force per unit area indicates how pressure is applied to an object.

- This concept is essential in fields such as engineering and physics.

- Understanding stress helps predict how materials will respond to external forces.

What is the unit of Young’s modulus in the SI system?- a)N/m

- b)N/m²

- c)Pa

- d)N

Correct answer is option 'C'. Can you explain this answer?

What is the unit of Young’s modulus in the SI system?

a)

N/m

b)

N/m²

c)

Pa

d)

N

|

Naina Das answered |

Understanding Young's Modulus

Young's modulus is a fundamental property of materials that measures their stiffness or resistance to deformation when subjected to tensile or compressive stress. It is defined as the ratio of stress (force per unit area) to strain (relative deformation) in the elastic region of a material’s stress-strain curve.

Unit of Young's Modulus

The correct unit of Young's modulus in the SI system is the pascal (Pa). Here's why:

- Stress Definition: Stress is defined as force (N) divided by area (m²):

- Stress = Force / Area = N / m² = Pa

- Strain Definition: Strain is dimensionless, as it is the ratio of change in length to the original length (no units).

- Therefore: Since Young's modulus is the ratio of stress (N/m² or Pa) to strain (dimensionless), it retains the unit of stress:

- Young's Modulus = Stress / Strain = (N/m²) / (dimensionless) = N/m² = Pa

Conclusion

Thus, the correct answer is option 'C', which is pascal (Pa). This unit reflects the amount of force applied over a specific area and is crucial for engineers when selecting materials for various applications, ensuring structural integrity and performance.

Young's modulus is a fundamental property of materials that measures their stiffness or resistance to deformation when subjected to tensile or compressive stress. It is defined as the ratio of stress (force per unit area) to strain (relative deformation) in the elastic region of a material’s stress-strain curve.

Unit of Young's Modulus

The correct unit of Young's modulus in the SI system is the pascal (Pa). Here's why:

- Stress Definition: Stress is defined as force (N) divided by area (m²):

- Stress = Force / Area = N / m² = Pa

- Strain Definition: Strain is dimensionless, as it is the ratio of change in length to the original length (no units).

- Therefore: Since Young's modulus is the ratio of stress (N/m² or Pa) to strain (dimensionless), it retains the unit of stress:

- Young's Modulus = Stress / Strain = (N/m²) / (dimensionless) = N/m² = Pa

Conclusion

Thus, the correct answer is option 'C', which is pascal (Pa). This unit reflects the amount of force applied over a specific area and is crucial for engineers when selecting materials for various applications, ensuring structural integrity and performance.

Creep is the gradual increase of- a)plastic strain with time at constant load

- b)elastic strain with time at constant load

- c)plastic strain with time at varying load

- d)elastic strain with time at varying load

Correct answer is option 'A'. Can you explain this answer?

Creep is the gradual increase of

a)

plastic strain with time at constant load

b)

elastic strain with time at constant load

c)

plastic strain with time at varying load

d)

elastic strain with time at varying load

|

|

Nandini Basak answered |

Creep is that property by virtue of which a metal specimen undergoes additional deformation with the passage of time under sustained loading within elastic limit. It is permanent in nature and cannot be recovered after removal of load, hence is plastic in nature.

Pick the odd one out- a)stiffness

- b)resilience

- c)endurance limit

- d)elastic strength

Correct answer is option 'C'. Can you explain this answer?

Pick the odd one out

a)

stiffness

b)

resilience

c)

endurance limit

d)

elastic strength

|

|

Kritika Joshi answered |

Except endurance limit all are elastic properties of the material in tension. Endurance limit is the fatigue property and found out by reversible cyclic loading.

The stress level, below which a material has a high probability of not failing under reversal of stress, is known as- a)elastic limit

- b)endurance limit

- c)proportional limit

- d)tolerance limit

Correct answer is option 'B'. Can you explain this answer?

The stress level, below which a material has a high probability of not failing under reversal of stress, is known as

a)

elastic limit

b)

endurance limit

c)

proportional limit

d)

tolerance limit

|

|

Soumya Basak answered |

The stress which can be withstand for some specified number of cycles is the fatigue strength of material. The stress level which can be withstand for an infinite number of cycles, without failure is called endurance limit.

Select the proper sequence

1. Proportional limit

2. Elastic limit

3. Yielding

4. Failure- a)2 ,3 , 1 , 4

- b)2, 1 , 3 , 4

- c)1, 3, 2, 4

- d)1,2, 3, 4

Correct answer is option 'D'. Can you explain this answer?

Select the proper sequence

1. Proportional limit

2. Elastic limit

3. Yielding

4. Failure

1. Proportional limit

2. Elastic limit

3. Yielding

4. Failure

a)

2 ,3 , 1 , 4

b)

2, 1 , 3 , 4

c)

1, 3, 2, 4

d)

1,2, 3, 4

|

|

Sanskriti Chakraborty answered |

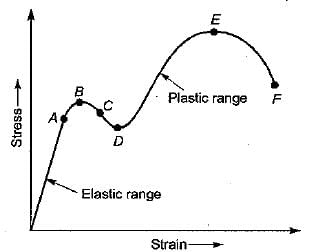

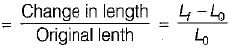

A: Proportional limit

B : Elastic limit

C : UYP

D: LYP

E: UTS

F: Rupture point

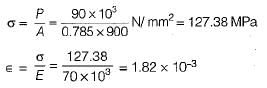

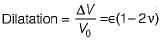

A prismatic bar of circular cross-section is loaded by tensile forces P= 90 kN. The bar has length L = 3 m and diameter d = 30 mm. If is made of aluminium with modulus of elasticity E = 70 GPa and Poisson’s ratio v = 1/3. What is the increase in volume ΔV of the bar?- a)800 mm3

- b)1000 mm3

- c)1285 mm3

- d)1412 mm3

Correct answer is option 'C'. Can you explain this answer?

A prismatic bar of circular cross-section is loaded by tensile forces P= 90 kN. The bar has length L = 3 m and diameter d = 30 mm. If is made of aluminium with modulus of elasticity E = 70 GPa and Poisson’s ratio v = 1/3. What is the increase in volume ΔV of the bar?

a)

800 mm3

b)

1000 mm3

c)

1285 mm3

d)

1412 mm3

|

Garima Kulkarni answered |

A material has identical properties in all directions, it is said to be- a)homogeneous

- b)isotropic

- c)elastic

- d)orthotropic

Correct answer is option 'B'. Can you explain this answer?

A material has identical properties in all directions, it is said to be

a)

homogeneous

b)

isotropic

c)

elastic

d)

orthotropic

|

|

Stuti Mishra answered |

Isotropy is the property in which material posses same properties any where within it.

Resilience is- a)maximum strain energy

- b)recoverable strain energy

- c)total potential energy

- d)shear strain energy (Beyond Hooke’s Law)

Correct answer is option 'B'. Can you explain this answer?

Resilience is

a)

maximum strain energy

b)

recoverable strain energy

c)

total potential energy

d)

shear strain energy (Beyond Hooke’s Law)

|

|

Niharika Iyer answered |

Resilience is the total strain energy stored in a given volume of a material within elastic limit. On removal of load this energy is released. In other words, it is the area under load deflection curve within elastic limit.

The energy absorbed in a body, when it is strained within the elastic limits, is known as

- a)resilience

- b)strain energy

- c)proof resilience

- d)modulus of resilience

Correct answer is option 'B'. Can you explain this answer?

The energy absorbed in a body, when it is strained within the elastic limits, is known as

a)

resilience

b)

strain energy

c)

proof resilience

d)

modulus of resilience

|

|

Gayatri Dasgupta answered |

Resilience can be defined as the ability of the material to absorb energy when deformed elastically and to release this energy when unloaded.

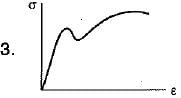

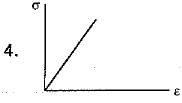

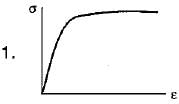

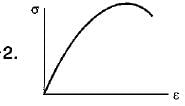

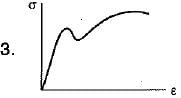

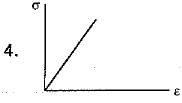

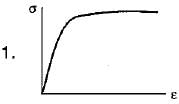

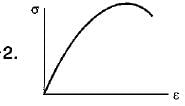

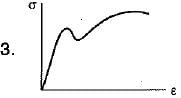

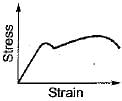

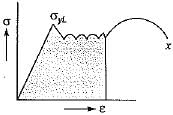

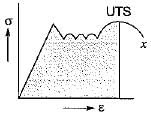

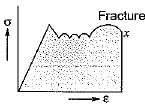

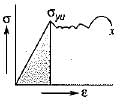

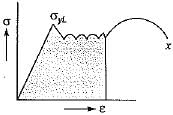

Match List-I (Materials) with List-II (Stress-Strain curves) and select the correct answer using the codes given below the lists:

List-I

A. Mild steel

B. Pure copper

C. Cast iron

D. Pure aluminium

List-II

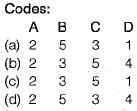

Codes:

A B C D

(a) 3 1 4 1

(b) 3 2 4 2

(c) 2 4 3 1

(d) 3 2 4 1

- a)(a)

- b)(b)

- c)(c)

- d)(d)

Correct answer is option 'D'. Can you explain this answer?

Match List-I (Materials) with List-II (Stress-Strain curves) and select the correct answer using the codes given below the lists:

List-I

A. Mild steel

B. Pure copper

C. Cast iron

D. Pure aluminium

List-II

Codes:

A B C D

(a) 3 1 4 1

(b) 3 2 4 2

(c) 2 4 3 1

(d) 3 2 4 1

List-I

A. Mild steel

B. Pure copper

C. Cast iron

D. Pure aluminium

List-II

Codes:

A B C D

(a) 3 1 4 1

(b) 3 2 4 2

(c) 2 4 3 1

(d) 3 2 4 1

a)

(a)

b)

(b)

c)

(c)

d)

(d)

|

Pathways Academy answered |

ESteel = 210 GPa

EAluminium = 70 GPa

ECopper = 130 GPa

EAluminium = 70 GPa

ECopper = 130 GPa

- Cast iron, being a brittle material, does not show any elongation, but ductile materials like mild steel, aluminium and copper elongate due to the application of tensile force.

- Both steel and copper are ductile, but copper is more ductile because it can withstand a greater strain than steel before breaking.

Bulk modulus is defined as:- a)Pressure / volume strain

- b)Stress / strain in length

- c)Volume strain / pressure

- d)Lateral strain / longitudinal strain

Correct answer is option 'A'. Can you explain this answer?

Bulk modulus is defined as:

a)

Pressure / volume strain

b)

Stress / strain in length

c)

Volume strain / pressure

d)

Lateral strain / longitudinal strain

|

Constructing Careers answered |

Bulk modulus is defined as:

- Pressure divided by volume strain. So (a) is the right option.

Which of the following statements is true about strain?- a)It has units of pressure

- b)It is equal to the applied force

- c)It is measured in N/m²

- d)It is a dimensionless quantity

Correct answer is option 'D'. Can you explain this answer?

Which of the following statements is true about strain?

a)

It has units of pressure

b)

It is equal to the applied force

c)

It is measured in N/m²

d)

It is a dimensionless quantity

|

Gate Funda answered |

Strain is a measure of deformation representing the displacement between particles in a material body. It is expressed as a ratio of change in length to the original length, making it a dimensionless quantity. Here are key points regarding strain:

- Strain has no units, as it is a ratio.

- It is not measured in N/m²; that is a unit for stress.

- Strain does not equal the applied force; it represents how much a material deforms.

Thus, the correct statement is that strain is a dimensionless quantity.

An axial residual compressive stress due to a manufacturing process is present on the outer surface of a rotating shaft subjected to bending. Under a given bending load, the fatigue life of the shaft in the presence of the residual compressive stress is- a)decreased

- b)increased or decreased, depending on the external bending load

- c)neither decreased nor increased

- d)increased

Correct answer is option 'D'. Can you explain this answer?

An axial residual compressive stress due to a manufacturing process is present on the outer surface of a rotating shaft subjected to bending. Under a given bending load, the fatigue life of the shaft in the presence of the residual compressive stress is

a)

decreased

b)

increased or decreased, depending on the external bending load

c)

neither decreased nor increased

d)

increased

|

|

Debolina Menon answered |

The presence of an axial residual compressive stress on the outer surface of a rotating shaft subjected to bending can have a significant effect on its fatigue life. In this scenario, the correct answer is option 'D', which states that the fatigue life of the shaft is increased.

Here's an explanation of why the fatigue life is increased:

1. Residual Compressive Stress:

When a rotating shaft is subjected to a manufacturing process, such as heat treatment or forging, it can result in the development of an axial residual compressive stress on the outer surface of the shaft. This compressive stress is beneficial because it counteracts the tensile stresses induced during bending.

2. Bending Load:

When a bending load is applied to the shaft, it causes both tensile and compressive stresses on different regions of the shaft. The presence of the residual compressive stress helps to offset the tensile stresses, reducing their magnitude and preventing crack initiation.

3. Crack Initiation:

Fatigue failure of a shaft occurs when cracks initiate and propagate under cyclic loading. The presence of tensile stresses is the primary cause of crack initiation. However, the residual compressive stress acts as a compressive force that opposes crack initiation and growth.

4. Increased Fatigue Life:

Due to the presence of the residual compressive stress, the tensile stresses induced during bending are reduced or neutralized. As a result, the fatigue life of the shaft is increased because the likelihood of crack initiation and propagation is minimized.

5. External Bending Load:

The answer option 'B' states that the fatigue life can be increased or decreased depending on the external bending load. This is because the magnitude of the bending load can influence the effectiveness of the residual compressive stress in counteracting the tensile stresses. If the external bending load is too high, it can overcome the beneficial effect of the residual compressive stress and decrease the fatigue life.

In conclusion, the presence of an axial residual compressive stress on the outer surface of a rotating shaft subjected to bending increases its fatigue life. This is because the residual compressive stress counteracts the tensile stresses induced during bending and reduces the likelihood of crack initiation and propagation. However, the effectiveness of the residual compressive stress can be influenced by the magnitude of the external bending load.

Here's an explanation of why the fatigue life is increased:

1. Residual Compressive Stress:

When a rotating shaft is subjected to a manufacturing process, such as heat treatment or forging, it can result in the development of an axial residual compressive stress on the outer surface of the shaft. This compressive stress is beneficial because it counteracts the tensile stresses induced during bending.

2. Bending Load:

When a bending load is applied to the shaft, it causes both tensile and compressive stresses on different regions of the shaft. The presence of the residual compressive stress helps to offset the tensile stresses, reducing their magnitude and preventing crack initiation.

3. Crack Initiation:

Fatigue failure of a shaft occurs when cracks initiate and propagate under cyclic loading. The presence of tensile stresses is the primary cause of crack initiation. However, the residual compressive stress acts as a compressive force that opposes crack initiation and growth.

4. Increased Fatigue Life:

Due to the presence of the residual compressive stress, the tensile stresses induced during bending are reduced or neutralized. As a result, the fatigue life of the shaft is increased because the likelihood of crack initiation and propagation is minimized.

5. External Bending Load:

The answer option 'B' states that the fatigue life can be increased or decreased depending on the external bending load. This is because the magnitude of the bending load can influence the effectiveness of the residual compressive stress in counteracting the tensile stresses. If the external bending load is too high, it can overcome the beneficial effect of the residual compressive stress and decrease the fatigue life.

In conclusion, the presence of an axial residual compressive stress on the outer surface of a rotating shaft subjected to bending increases its fatigue life. This is because the residual compressive stress counteracts the tensile stresses induced during bending and reduces the likelihood of crack initiation and propagation. However, the effectiveness of the residual compressive stress can be influenced by the magnitude of the external bending load.

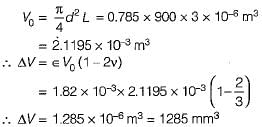

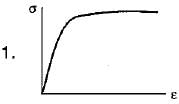

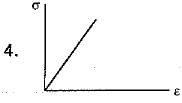

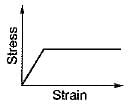

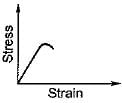

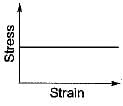

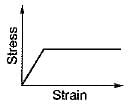

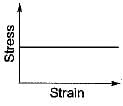

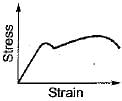

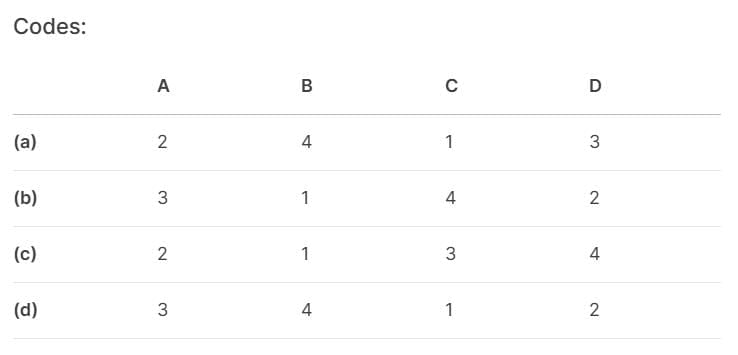

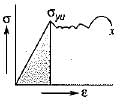

The stress-strain curve for an ideally plastic materia! is- a)

- b)

- c)

- d)

Correct answer is option 'C'. Can you explain this answer?

The stress-strain curve for an ideally plastic materia! is

a)

b)

c)

d)

|

Sai Sarkar answered |

In plastic design the stress-strain curve is bilinear as shown in figure

(a). However, the stress-strain curve for ideal plastic materials is as shown in figure (c). Figure (b) shows stress- strain curve for brittle materials. Figure (d) shows stress-strain curve for ductile materials.

(a). However, the stress-strain curve for ideal plastic materials is as shown in figure (c). Figure (b) shows stress- strain curve for brittle materials. Figure (d) shows stress-strain curve for ductile materials.

A material capable of absorbing large amount of energy before fracture is known as- a)shock proof

- b)toughness

- c)fatigue energy

- d)plasticity

Correct answer is option 'B'. Can you explain this answer?

A material capable of absorbing large amount of energy before fracture is known as

a)

shock proof

b)

toughness

c)

fatigue energy

d)

plasticity

|

Akanksha Mehta answered |

**Toughness: A Material's Ability to Absorb Energy**

**Introduction:**

When it comes to mechanical engineering, one of the most important properties of a material is its ability to withstand large amounts of energy before fracturing. This property is known as toughness. Toughness is the ability of a material to absorb energy and deform plastically before fracturing. In other words, it is a measure of a material's resistance to fracture when subjected to an impact or load.

**Explanation:**

Toughness is a combination of strength and ductility. Strength refers to a material's ability to resist deformation under load, while ductility refers to a material's ability to deform plastically before fracturing. A material with high toughness can absorb a significant amount of energy before it breaks.

When a material is subjected to an impact or load, it undergoes deformation. The energy absorbed during this deformation is stored internally within the material. If the material is unable to absorb this energy and deform plastically, it will fracture. However, if the material is tough, it can deform and absorb the energy, preventing fracture.

**Importance of Toughness:**

Toughness is a critical property for materials used in various applications. For example, in structural engineering, toughness is crucial for materials used in building structures, bridges, and other infrastructure. These materials need to be able to withstand impacts, loads, and vibrations without fracturing.

Toughness is also important in the field of materials science, where it plays a significant role in the development of new materials. By understanding the factors that contribute to toughness, researchers and engineers can design materials with improved mechanical properties.

**Conclusion:**

In conclusion, toughness is a material's ability to absorb energy and deform plastically before fracturing. It is a combination of strength and ductility and is essential for materials used in various applications. A material with high toughness can withstand impacts, loads, and vibrations without fracturing, making it a desirable property in mechanical engineering.

**Introduction:**

When it comes to mechanical engineering, one of the most important properties of a material is its ability to withstand large amounts of energy before fracturing. This property is known as toughness. Toughness is the ability of a material to absorb energy and deform plastically before fracturing. In other words, it is a measure of a material's resistance to fracture when subjected to an impact or load.

**Explanation:**

Toughness is a combination of strength and ductility. Strength refers to a material's ability to resist deformation under load, while ductility refers to a material's ability to deform plastically before fracturing. A material with high toughness can absorb a significant amount of energy before it breaks.

When a material is subjected to an impact or load, it undergoes deformation. The energy absorbed during this deformation is stored internally within the material. If the material is unable to absorb this energy and deform plastically, it will fracture. However, if the material is tough, it can deform and absorb the energy, preventing fracture.

**Importance of Toughness:**

Toughness is a critical property for materials used in various applications. For example, in structural engineering, toughness is crucial for materials used in building structures, bridges, and other infrastructure. These materials need to be able to withstand impacts, loads, and vibrations without fracturing.

Toughness is also important in the field of materials science, where it plays a significant role in the development of new materials. By understanding the factors that contribute to toughness, researchers and engineers can design materials with improved mechanical properties.

**Conclusion:**

In conclusion, toughness is a material's ability to absorb energy and deform plastically before fracturing. It is a combination of strength and ductility and is essential for materials used in various applications. A material with high toughness can withstand impacts, loads, and vibrations without fracturing, making it a desirable property in mechanical engineering.

In the elastic limit, which law is followed by solids under tensile stress?- a)Pascal’s law

- b)Newton’s law

- c)Hooke’s law

- d)Bernoulli’s principle

Correct answer is option 'C'. Can you explain this answer?

In the elastic limit, which law is followed by solids under tensile stress?

a)

Pascal’s law

b)

Newton’s law

c)

Hooke’s law

d)

Bernoulli’s principle

|

Telecom Tuners answered |

Hooke’s law describes the behaviour of solids under tensile stress within the elastic limit. It states that the strain in a material is proportional to the applied stress, provided the material's elastic limit is not exceeded. This can be summarised as:

- Stress is the force applied per unit area.

- Strain is the deformation experienced by the material.

- In simple terms, as you stretch a solid, it stretches proportionally up to a certain point.

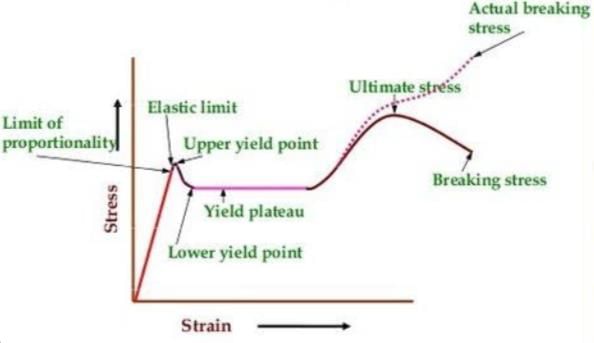

The following statements are associated with the stress-strain diagram for steel. - For small values of the strain, the relationship is linear (straight line), and the stress is proportional to the strain. This behavior is valid until the stress reaches the proportional limit.

- If the stress exceeds the proportional limit, the strain begins to increase more rapidly, and the slope of the curve decreases.

- a)1 and 2 are correct

- b)1 and 2 are wrong

- c)1 correct and 2 wrong

- d)1 wrong and 2 correct

Correct answer is option 'A'. Can you explain this answer?

The following statements are associated with the stress-strain diagram for steel.

- For small values of the strain, the relationship is linear (straight line), and the stress is proportional to the strain. This behavior is valid until the stress reaches the proportional limit.

- If the stress exceeds the proportional limit, the strain begins to increase more rapidly, and the slope of the curve decreases.

a)

1 and 2 are correct

b)

1 and 2 are wrong

c)

1 correct and 2 wrong

d)

1 wrong and 2 correct

|

Pk Academy answered |

The stress-strain diagram for steel is a graphical representation of the relationship between stress and strain during the deformation of steel. The diagram typically shows stress on the y-axis and strain on the x-axis.

Statement 1 is correct because, for small values of strain, the relationship between stress and strain is linear, and stress is proportional to strain. This behavior is known as Hooke’s Law, and it is valid until the stress reaches the proportional limit. The proportional limit is the point beyond which the relationship between stress and strain is no longer linear.

Statement 2 is also correct because, if the stress exceeds the proportional limit, the strain begins to increase more rapidly, and the slope of the curve decreases. This behavior is due to the onset of plastic deformation, which causes the steel to permanently deform even after the stress is removed. The stress at which plastic deformation begins is known as the yield strength, and it is typically higher than the proportional limit.

Therefore, both statements 1 and 2 are correct.

Proof resilience per unit volume of a material is known as .- a)resilience

- b)modulus of elasticity

- c)modulus of resilience

- d)toughness

Correct answer is option 'C'. Can you explain this answer?

Proof resilience per unit volume of a material is known as .

a)

resilience

b)

modulus of elasticity

c)

modulus of resilience

d)

toughness

|

Anmol Roy answered |

Modulus of resilience is the correct answer.

The modulus of resilience is a material property that measures its ability to absorb energy without undergoing permanent deformation. It is defined as the amount of energy per unit volume that a material can absorb in the elastic range without failure. In other words, it quantifies the material's ability to store elastic energy and recover its original shape after being deformed.

The modulus of resilience is an important parameter in designing materials that are subject to impact or shock loading. It helps engineers understand how much energy a material can absorb before it fractures or undergoes plastic deformation. This information is crucial in selecting materials for applications where high impact resistance is required, such as in the construction of safety equipment, automotive components, and structural elements.

The modulus of resilience can be calculated using the stress-strain curve of a material. It is represented by the area under the stress-strain curve within the elastic limit. The elastic limit is the maximum stress that a material can withstand without experiencing permanent deformation.

To calculate the modulus of resilience, the stress-strain curve is divided into two regions: the elastic region and the plastic region. In the elastic region, the material behaves elastically, meaning it deforms under stress but returns to its original shape when the stress is removed. The energy absorbed in the elastic region is proportional to the area under the stress-strain curve.

The modulus of resilience is given by the equation:

Resilience = (1/2) * Stress * Strain

where Stress is the yield strength of the material and Strain is the strain at the elastic limit.

In conclusion, the modulus of resilience per unit volume of a material is a measure of its ability to absorb energy without undergoing permanent deformation. It is an important property for materials subjected to impact or shock loading and is calculated using the stress-strain curve of the material.

The modulus of resilience is a material property that measures its ability to absorb energy without undergoing permanent deformation. It is defined as the amount of energy per unit volume that a material can absorb in the elastic range without failure. In other words, it quantifies the material's ability to store elastic energy and recover its original shape after being deformed.

The modulus of resilience is an important parameter in designing materials that are subject to impact or shock loading. It helps engineers understand how much energy a material can absorb before it fractures or undergoes plastic deformation. This information is crucial in selecting materials for applications where high impact resistance is required, such as in the construction of safety equipment, automotive components, and structural elements.

The modulus of resilience can be calculated using the stress-strain curve of a material. It is represented by the area under the stress-strain curve within the elastic limit. The elastic limit is the maximum stress that a material can withstand without experiencing permanent deformation.

To calculate the modulus of resilience, the stress-strain curve is divided into two regions: the elastic region and the plastic region. In the elastic region, the material behaves elastically, meaning it deforms under stress but returns to its original shape when the stress is removed. The energy absorbed in the elastic region is proportional to the area under the stress-strain curve.

The modulus of resilience is given by the equation:

Resilience = (1/2) * Stress * Strain

where Stress is the yield strength of the material and Strain is the strain at the elastic limit.

In conclusion, the modulus of resilience per unit volume of a material is a measure of its ability to absorb energy without undergoing permanent deformation. It is an important property for materials subjected to impact or shock loading and is calculated using the stress-strain curve of the material.

Which of the following has no unit?- a)Bulk modulus

- b)Kinematic viscosity

- c)Surface tension

- d)Strain

Correct answer is option 'D'. Can you explain this answer?

Which of the following has no unit?

a)

Bulk modulus

b)

Kinematic viscosity

c)

Surface tension

d)

Strain

|

Gate Funda answered |

Explanation:

- Bulk modulus: The unit of bulk modulus is Pascal (Pa) which is a measure of a substance's resistance to compression.

- Kinematic viscosity: The unit of kinematic viscosity is square meters per second (m^2/s) which represents the fluid's resistance to flow.

- Surface tension: The unit of surface tension is Newton per meter (N/m) which is the force acting on the surface of a liquid.

- Strain: Strain is a dimensionless quantity as it is the ratio of the change in dimension to the original dimension of a material. It has no unit.

Therefore, among the given options, Strain is the quantity that has no unit.

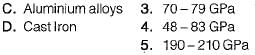

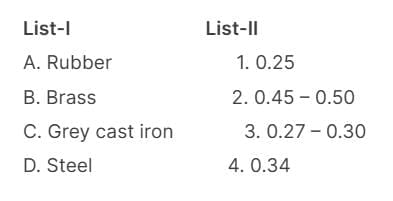

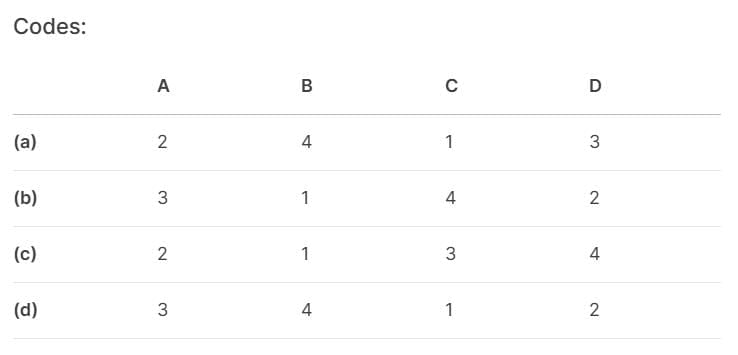

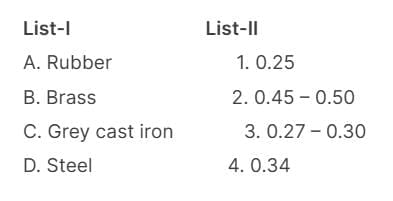

Match List-1 (Materia!) with List-ll (Poisson’s Ratio)

- a)a

- b)b

- c)c

- d)d

Correct answer is option 'A'. Can you explain this answer?

Match List-1 (Materia!) with List-ll (Poisson’s Ratio)

a)

a

b)

b

c)

c

d)

d

|

Gate Funda answered |

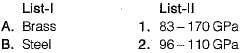

To match List-I (Materials) with List-II (Poisson's Ratio), it's essential to know typical values for each material:

- Rubber: Poisson's ratio is typically around 0.5.

- Brass: Ranges from 0.34 to 0.36.

- Grey cast iron: Around 0.25 - 0.30.

- Steel: Approximately 0.27 - 0.30.

This corresponds to the code (a) 2 4 1 3

Thus option A is correct.

In a stress-strain curve, the point at which permanent deformation starts is known as:- a)Breaking point

- b)Yield point

- c)Elastic limit

- d)Proportional limit

Correct answer is option 'B'. Can you explain this answer?

In a stress-strain curve, the point at which permanent deformation starts is known as:

a)

Breaking point

b)

Yield point

c)

Elastic limit

d)

Proportional limit

|

Telecom Tuners answered |

The point at which permanent deformation begins in a stress-strain curve is called the yield point. This is where the material starts to change shape irreversibly. Understanding this term is crucial for materials science and engineering.

Toughness for mild steel under uniaxial tensile loading is given by the shaded portion of the stress-strain diagram as shown in- a)

- b)

- c)

- d)

Correct answer is option 'D'. Can you explain this answer?

Toughness for mild steel under uniaxial tensile loading is given by the shaded portion of the stress-strain diagram as shown in

a)

b)

c)

d)

|

|

Sinjini Bose answered |

Toughness is the ability of material to absorb the energy upto fracture point, i.e. toughness of material is the total area under stress-strain curve.

Coaxing is the method of increasing- a)strength by reversible cycling

- b)creep by heat treatment

- c)fatigue resistance by over-stressing the metal by successively increasing loadings

- d)hardness by surface treatment

Correct answer is option 'C'. Can you explain this answer?

Coaxing is the method of increasing

a)

strength by reversible cycling

b)

creep by heat treatment

c)

fatigue resistance by over-stressing the metal by successively increasing loadings

d)

hardness by surface treatment

|

Varun Banerjee answered |

Coaxing in Mechanical Engineering

Coaxing is a process of increasing the fatigue resistance of metals by over-stressing them through successively increasing loadings. This process is also known as strain cycling or strain pulsing.

Working of Coaxing

When a metal is subjected to repeated loading and unloading, it experiences cyclic stresses that can lead to fatigue failure. However, when the metal is subjected to coaxing, it undergoes a different type of cyclic loading that helps to increase its fatigue resistance.

The process of coaxing involves subjecting the metal to a series of cyclic loads that increase in amplitude. Each cycle of loading and unloading causes the metal to deform slightly, which leads to the formation of dislocations in the crystal structure of the metal. These dislocations act as barriers to the propagation of cracks, which helps to increase the fatigue resistance of the metal.

Benefits of Coaxing

Coaxing is a useful process for improving the fatigue resistance of metals, especially in applications where cyclic loading is common. By subjecting metals to coaxing, it is possible to increase their fatigue strength by up to 50%.

Coaxing is a cost-effective process that can be applied to a wide range of metals, including aluminum, titanium, and steel. It is also a relatively simple process that can be carried out using standard equipment and techniques.

Conclusion

In conclusion, coaxing is a valuable process for improving the fatigue resistance of metals in mechanical engineering applications. By subjecting metals to a series of cyclic loads, it is possible to increase their fatigue strength and extend their service life.

Coaxing is a process of increasing the fatigue resistance of metals by over-stressing them through successively increasing loadings. This process is also known as strain cycling or strain pulsing.

Working of Coaxing

When a metal is subjected to repeated loading and unloading, it experiences cyclic stresses that can lead to fatigue failure. However, when the metal is subjected to coaxing, it undergoes a different type of cyclic loading that helps to increase its fatigue resistance.

The process of coaxing involves subjecting the metal to a series of cyclic loads that increase in amplitude. Each cycle of loading and unloading causes the metal to deform slightly, which leads to the formation of dislocations in the crystal structure of the metal. These dislocations act as barriers to the propagation of cracks, which helps to increase the fatigue resistance of the metal.

Benefits of Coaxing

Coaxing is a useful process for improving the fatigue resistance of metals, especially in applications where cyclic loading is common. By subjecting metals to coaxing, it is possible to increase their fatigue strength by up to 50%.

Coaxing is a cost-effective process that can be applied to a wide range of metals, including aluminum, titanium, and steel. It is also a relatively simple process that can be carried out using standard equipment and techniques.

Conclusion

In conclusion, coaxing is a valuable process for improving the fatigue resistance of metals in mechanical engineering applications. By subjecting metals to a series of cyclic loads, it is possible to increase their fatigue strength and extend their service life.

Poisson’s ratio is defined as:- a)Longitudinal strain / lateral strain

- b)Young’s modulus / stress

- c)Bulk modulus / shear modulus

- d)Lateral strain / longitudinal strain

Correct answer is option 'D'. Can you explain this answer?

Poisson’s ratio is defined as:

a)

Longitudinal strain / lateral strain

b)

Young’s modulus / stress

c)

Bulk modulus / shear modulus

d)

Lateral strain / longitudinal strain

|

Pk Academy answered |

Poisson’s ratio is defined as the ratio of:

- Lateral strain to longitudinal strain.

This means that when a material is stretched, the amount it contracts in the perpendicular direction (lateral strain) compared to the amount it stretches in the direction of the applied force (longitudinal strain) gives us the Poisson’s ratio.

Modular ratio of two materials is the ratio of- a)linear stress to linear strain

- b)shear stress to shear strain

- c)their modulus of elasticities

- d)their modulus of rigidities

Correct answer is option 'C'. Can you explain this answer?

Modular ratio of two materials is the ratio of

a)

linear stress to linear strain

b)

shear stress to shear strain

c)

their modulus of elasticities

d)

their modulus of rigidities

|

|

Keerthana Joshi answered |

The correct answer is option 'C' - the modular ratio of two materials is the ratio of their modulus of elasticities.

Explanation:

Modular ratio is a term commonly used in engineering mechanics and materials science to compare the stiffness or rigidity of two different materials. It is defined as the ratio of the modulus of elasticity of one material to the modulus of elasticity of the other material.

The modulus of elasticity, also known as Young's modulus, is a measure of a material's stiffness or ability to resist deformation under an applied load. It quantifies the relationship between stress and strain in a material. When a material is subjected to an external force or stress, it undergoes deformation or strain. The modulus of elasticity relates the stress to the resulting strain in the material.

In the context of the question, the modular ratio compares the stiffness or rigidity of two materials. It tells us how much stiffer or more rigid one material is compared to the other.

For example, let's consider two materials A and B with modulus of elasticities E_A and E_B, respectively. The modular ratio R_AB can be calculated as:

R_AB = E_A / E_B

If the modulus of elasticity of material A is higher than that of material B, the modular ratio R_AB will be greater than 1, indicating that material A is stiffer or more rigid than material B. On the other hand, if the modulus of elasticity of material A is lower than that of material B, the modular ratio R_AB will be less than 1, indicating that material A is less stiff or less rigid than material B.

In summary, the modular ratio of two materials is a measure of their relative stiffness or rigidity, and it is defined as the ratio of their modulus of elasticities.

Explanation:

Modular ratio is a term commonly used in engineering mechanics and materials science to compare the stiffness or rigidity of two different materials. It is defined as the ratio of the modulus of elasticity of one material to the modulus of elasticity of the other material.

The modulus of elasticity, also known as Young's modulus, is a measure of a material's stiffness or ability to resist deformation under an applied load. It quantifies the relationship between stress and strain in a material. When a material is subjected to an external force or stress, it undergoes deformation or strain. The modulus of elasticity relates the stress to the resulting strain in the material.

In the context of the question, the modular ratio compares the stiffness or rigidity of two materials. It tells us how much stiffer or more rigid one material is compared to the other.

For example, let's consider two materials A and B with modulus of elasticities E_A and E_B, respectively. The modular ratio R_AB can be calculated as:

R_AB = E_A / E_B

If the modulus of elasticity of material A is higher than that of material B, the modular ratio R_AB will be greater than 1, indicating that material A is stiffer or more rigid than material B. On the other hand, if the modulus of elasticity of material A is lower than that of material B, the modular ratio R_AB will be less than 1, indicating that material A is less stiff or less rigid than material B.

In summary, the modular ratio of two materials is a measure of their relative stiffness or rigidity, and it is defined as the ratio of their modulus of elasticities.

The impact strength of a material is an index of its- a)hardness

- b)toughness

- c)resistance to corrosion

- d)resistance to failure under reversal of stresses

Correct answer is option 'B'. Can you explain this answer?

The impact strength of a material is an index of its

a)

hardness

b)

toughness

c)

resistance to corrosion

d)

resistance to failure under reversal of stresses

|

|

Nayanika Yadav answered |

Explanation:

The impact strength of a material is an index of its toughness. It is the ability of a material to absorb energy during deformation without fracturing. When a force is applied to a material, it undergoes deformation. The amount of energy required to deform the material depends on its properties such as its structure, composition, and strength. Toughness is an important property for materials that are subjected to impact loads, such as in the case of machine parts or structures.

Impact Strength:

Impact strength is the ability of a material to resist sudden and severe loads. It is the capacity of a material to absorb energy during impact without fracturing. Impact strength is an essential property for materials that are subjected to impact loads. The impact strength of a material is usually measured by the Izod or Charpy impact test.

Toughness:

Toughness is the ability of a material to resist fracture under the action of a sudden and severe load. It is the capacity of a material to absorb energy during deformation without fracturing. Toughness is a crucial property for materials that are subjected to impact loads. Toughness is usually measured by the Charpy or Izod impact test.

Conclusion:

The impact strength of a material is an essential property that determines its resistance to sudden and severe loads. Toughness is an important property that determines the ability of a material to resist fracture under impact loads. The impact strength of a material is an index of its toughness. Therefore, the correct answer is option 'B,' toughness.

The impact strength of a material is an index of its toughness. It is the ability of a material to absorb energy during deformation without fracturing. When a force is applied to a material, it undergoes deformation. The amount of energy required to deform the material depends on its properties such as its structure, composition, and strength. Toughness is an important property for materials that are subjected to impact loads, such as in the case of machine parts or structures.

Impact Strength:

Impact strength is the ability of a material to resist sudden and severe loads. It is the capacity of a material to absorb energy during impact without fracturing. Impact strength is an essential property for materials that are subjected to impact loads. The impact strength of a material is usually measured by the Izod or Charpy impact test.

Toughness:

Toughness is the ability of a material to resist fracture under the action of a sudden and severe load. It is the capacity of a material to absorb energy during deformation without fracturing. Toughness is a crucial property for materials that are subjected to impact loads. Toughness is usually measured by the Charpy or Izod impact test.

Conclusion:

The impact strength of a material is an essential property that determines its resistance to sudden and severe loads. Toughness is an important property that determines the ability of a material to resist fracture under impact loads. The impact strength of a material is an index of its toughness. Therefore, the correct answer is option 'B,' toughness.

Chapter doubts & questions for Mechanical Properties of Materials - 6 Months Preparation for GATE Civil Engg 2025 is part of Civil Engineering (CE) exam preparation. The chapters have been prepared according to the Civil Engineering (CE) exam syllabus. The Chapter doubts & questions, notes, tests & MCQs are made for Civil Engineering (CE) 2025 Exam. Find important definitions, questions, notes, meanings, examples, exercises, MCQs and online tests here.

Chapter doubts & questions of Mechanical Properties of Materials - 6 Months Preparation for GATE Civil Engg in English & Hindi are available as part of Civil Engineering (CE) exam.

Download more important topics, notes, lectures and mock test series for Civil Engineering (CE) Exam by signing up for free.

6 Months Preparation for GATE Civil Engg

488 videos|1261 docs|878 tests

|

Contact Support

Our team is online on weekdays between 10 AM - 7 PM

Typical reply within 3 hours

|

Free Exam Preparation

at your Fingertips!

Access Free Study Material - Test Series, Structured Courses, Free Videos & Study Notes and Prepare for Your Exam With Ease

Join the 10M+ students on EduRev

Join the 10M+ students on EduRev

|

|

Create your account for free

OR

Forgot Password

OR

Signup to see your scores

go up

within 7 days!