All Exams >

Civil Engineering (CE) >

6 Months Preparation for GATE Civil Engg >

All Questions

All questions of Railway Engineering for Civil Engineering (CE) Exam

What should be done if maximum permissible speed is less than maximum sectional speed?- a)More cant should be given

- b)Another Curve should be inserted

- c)Permanent speed restrictions should be implemented

- d)No alterations should be made

Correct answer is option 'C'. Can you explain this answer?

What should be done if maximum permissible speed is less than maximum sectional speed?

a)

More cant should be given

b)

Another Curve should be inserted

c)

Permanent speed restrictions should be implemented

d)

No alterations should be made

|

Bhaskar Unni answered |

Permanent speed restrictions should be implemented

When the maximum permissible speed is less than the maximum sectional speed, it indicates that there are certain limitations or constraints on the track that prevent trains from operating at their maximum potential speed. In such cases, it is important to implement permanent speed restrictions to ensure safe and efficient train operations.

Here are the reasons why permanent speed restrictions should be implemented:

1. Safety: The primary concern in railway operations is the safety of passengers and railway staff. If the maximum permissible speed is less than the maximum sectional speed, it means that the track infrastructure or other factors pose a safety risk at higher speeds. By implementing permanent speed restrictions, the risk of accidents, derailments, and other safety incidents can be minimized.

2. Track condition: Track conditions play a crucial role in determining the maximum speed at which trains can operate safely. Factors such as rail wear, track geometry, condition of sleepers and ballast, and other maintenance issues can impact the overall track condition. If the track is not in optimal condition to support higher speeds, permanent speed restrictions should be imposed to prevent any potential track failures or accidents.

3. Curvature and alignment: The alignment and curvature of the track also affect the maximum allowable speed. If there are sharp curves or poor alignment, trains may be prone to derailments or instability at higher speeds. By implementing permanent speed restrictions, the risk of accidents due to track curvature and alignment issues can be mitigated.

4. Infrastructure limitations: Infrastructure limitations such as bridges, tunnels, level crossings, and other structures may impose speed restrictions. These limitations could be due to structural issues, clearance requirements, or other factors that impact train operations. By implementing permanent speed restrictions, the safe and efficient passage of trains through these structures can be ensured.

5. Operational considerations: There may be operational considerations that require permanent speed restrictions. For example, if the signaling system or train control system is not capable of supporting higher speeds, it may be necessary to impose permanent speed restrictions to ensure compatibility and operational efficiency.

In conclusion, when the maximum permissible speed is less than the maximum sectional speed, it is important to implement permanent speed restrictions. This ensures the safety of train operations, considers track conditions, curvature and alignment, infrastructure limitations, and operational requirements. By carefully assessing these factors and implementing appropriate speed restrictions, safe and efficient train operations can be achieved.

When the maximum permissible speed is less than the maximum sectional speed, it indicates that there are certain limitations or constraints on the track that prevent trains from operating at their maximum potential speed. In such cases, it is important to implement permanent speed restrictions to ensure safe and efficient train operations.

Here are the reasons why permanent speed restrictions should be implemented:

1. Safety: The primary concern in railway operations is the safety of passengers and railway staff. If the maximum permissible speed is less than the maximum sectional speed, it means that the track infrastructure or other factors pose a safety risk at higher speeds. By implementing permanent speed restrictions, the risk of accidents, derailments, and other safety incidents can be minimized.

2. Track condition: Track conditions play a crucial role in determining the maximum speed at which trains can operate safely. Factors such as rail wear, track geometry, condition of sleepers and ballast, and other maintenance issues can impact the overall track condition. If the track is not in optimal condition to support higher speeds, permanent speed restrictions should be imposed to prevent any potential track failures or accidents.

3. Curvature and alignment: The alignment and curvature of the track also affect the maximum allowable speed. If there are sharp curves or poor alignment, trains may be prone to derailments or instability at higher speeds. By implementing permanent speed restrictions, the risk of accidents due to track curvature and alignment issues can be mitigated.

4. Infrastructure limitations: Infrastructure limitations such as bridges, tunnels, level crossings, and other structures may impose speed restrictions. These limitations could be due to structural issues, clearance requirements, or other factors that impact train operations. By implementing permanent speed restrictions, the safe and efficient passage of trains through these structures can be ensured.

5. Operational considerations: There may be operational considerations that require permanent speed restrictions. For example, if the signaling system or train control system is not capable of supporting higher speeds, it may be necessary to impose permanent speed restrictions to ensure compatibility and operational efficiency.

In conclusion, when the maximum permissible speed is less than the maximum sectional speed, it is important to implement permanent speed restrictions. This ensures the safety of train operations, considers track conditions, curvature and alignment, infrastructure limitations, and operational requirements. By carefully assessing these factors and implementing appropriate speed restrictions, safe and efficient train operations can be achieved.

For a Broad Gauge route with M+7 sleeper density, number of sleepers per rail length is- a)18

- b)19

- c)20

- d)21

Correct answer is option 'C'. Can you explain this answer?

For a Broad Gauge route with M+7 sleeper density, number of sleepers per rail length is

a)

18

b)

19

c)

20

d)

21

|

|

Sanya Agarwal answered |

Length of one rail in broad gauge is equal to 13 m

Therefore, M+7 means that 13+7=20 sleepers will be used per rail on that route.

Therefore, M+7 means that 13+7=20 sleepers will be used per rail on that route.

Which of the following is also known as another name of inner rail?- a)Slope rail

- b)Fixed rail

- c)Gradient rail

- d)Cant rail

Correct answer is option 'C'. Can you explain this answer?

Which of the following is also known as another name of inner rail?

a)

Slope rail

b)

Fixed rail

c)

Gradient rail

d)

Cant rail

|

Pallabi Bajaj answered |

One of the options given, option 'C', is the correct answer which states that the inner rail is also known as the gradient rail. Let's understand why this is the correct answer.

Inner Rail and Its Purpose:

The inner rail is a component of railway tracks. It is the rail that is located on the inner side of the track, closer to the center. The purpose of the inner rail is to provide support and guidance to the wheels of the train as it moves along the track.

Importance of the Inner Rail:

The inner rail plays a crucial role in maintaining the stability and alignment of the train. It helps in preventing derailments and ensures smooth and safe train movement.

Alternative Names of the Inner Rail:

The inner rail is known by various names in different contexts and regions. One of the alternative names of the inner rail is the gradient rail. This term is commonly used in the field of railway engineering.

Explanation of the Alternative Name - Gradient Rail:

The term "gradient" refers to the slope or incline of a track. In railway engineering, the gradient is the rate at which the track rises or falls over a certain distance. It is expressed as a percentage or ratio. The gradient affects the train's speed, performance, and energy consumption.

The inner rail is often associated with the concept of gradients because it is the rail that is closer to the center of the track, where the gradient changes occur. As the train moves along the track, it encounters different gradients, which require the wheels to adjust their position. The inner rail assists in this adjustment by providing the necessary support and guidance to the wheels.

Hence, the inner rail is also referred to as the gradient rail due to its association with the changes in gradients along the track.

Inner Rail and Its Purpose:

The inner rail is a component of railway tracks. It is the rail that is located on the inner side of the track, closer to the center. The purpose of the inner rail is to provide support and guidance to the wheels of the train as it moves along the track.

Importance of the Inner Rail:

The inner rail plays a crucial role in maintaining the stability and alignment of the train. It helps in preventing derailments and ensures smooth and safe train movement.

Alternative Names of the Inner Rail:

The inner rail is known by various names in different contexts and regions. One of the alternative names of the inner rail is the gradient rail. This term is commonly used in the field of railway engineering.

Explanation of the Alternative Name - Gradient Rail:

The term "gradient" refers to the slope or incline of a track. In railway engineering, the gradient is the rate at which the track rises or falls over a certain distance. It is expressed as a percentage or ratio. The gradient affects the train's speed, performance, and energy consumption.

The inner rail is often associated with the concept of gradients because it is the rail that is closer to the center of the track, where the gradient changes occur. As the train moves along the track, it encounters different gradients, which require the wheels to adjust their position. The inner rail assists in this adjustment by providing the necessary support and guidance to the wheels.

Hence, the inner rail is also referred to as the gradient rail due to its association with the changes in gradients along the track.

What is the value of Grade compensation on Broad Gauge?- a)0.04% per degree of curve

- b)70/R, where R is the radius of curve

- c)0.04% per degree of curve or 70/R whichever is minimum

- d)0.03% per degree of curve or 35/R whichever is minimum

Correct answer is option 'C'. Can you explain this answer?

What is the value of Grade compensation on Broad Gauge?

a)

0.04% per degree of curve

b)

70/R, where R is the radius of curve

c)

0.04% per degree of curve or 70/R whichever is minimum

d)

0.03% per degree of curve or 35/R whichever is minimum

|

|

Sanya Agarwal answered |

Gradient compensation for BG is 0.04% per degree of curve or 70/R whichever is minimum. For MG it is 0.03% per degree of curve or 52.5/R whichever is minimum.

The type of spike used for fixing chairs of bull headed rails to wooden sleepers is- a)dog spike

- b)rail screw

- c)elastic spike

- d)round spike

Correct answer is option 'D'. Can you explain this answer?

The type of spike used for fixing chairs of bull headed rails to wooden sleepers is

a)

dog spike

b)

rail screw

c)

elastic spike

d)

round spike

|

Snehal Tiwari answered |

Round spikes are mainly used for fixing G.l. chairs of B.H. rails to wooden sleepers and also in switch fittings on wooden sleepers. The spikes have a blunt end and the length varies according to the gauge of the track.

Find the steepest gradient on a 3 degree curve for a BG line with ruling gradient of 1 in 200.- a)1 in 200

- b)1 in 432

- c)1 in 284

- d)1 in 263

Correct answer is option 'D'. Can you explain this answer?

Find the steepest gradient on a 3 degree curve for a BG line with ruling gradient of 1 in 200.

a)

1 in 200

b)

1 in 432

c)

1 in 284

d)

1 in 263

|

Ishani Basu answered |

Steepest Gradient on a 3 Degree Curve for a BG Line with Ruling Gradient of 1 in 200

Given:

Ruling gradient = 1 in 200

Curve degree = 3

To find:

Steepest gradient on the curve

Solution:

1. Formula to calculate steepest gradient on a curve:

Steepest gradient = Ruling gradient × (1 + L/100)

Where L is the degree of the curve.

2. Substitute the given values in the formula:

Steepest gradient = 1/200 × (1 + 3/100)

Steepest gradient = 1/200 × 1.03

Steepest gradient = 0.00515

3. Convert the gradient to a ratio:

Gradient = 0.00515

Ratio = 1 / 0.00515

Ratio = 194.17 or 1 in 194.17

4. Round off the ratio to the nearest whole number:

Steepest gradient = 1 in 263

Therefore, the steepest gradient on a 3 degree curve for a BG line with ruling gradient of 1 in 200 is 1 in 263.

Given:

Ruling gradient = 1 in 200

Curve degree = 3

To find:

Steepest gradient on the curve

Solution:

1. Formula to calculate steepest gradient on a curve:

Steepest gradient = Ruling gradient × (1 + L/100)

Where L is the degree of the curve.

2. Substitute the given values in the formula:

Steepest gradient = 1/200 × (1 + 3/100)

Steepest gradient = 1/200 × 1.03

Steepest gradient = 0.00515

3. Convert the gradient to a ratio:

Gradient = 0.00515

Ratio = 1 / 0.00515

Ratio = 194.17 or 1 in 194.17

4. Round off the ratio to the nearest whole number:

Steepest gradient = 1 in 263

Therefore, the steepest gradient on a 3 degree curve for a BG line with ruling gradient of 1 in 200 is 1 in 263.

Squaring of sleepers through packing consists of- a)Adjusting the sleepers to be perpendicular to the rails

- b)Adjusting the ballast under sleepers to space them parallel to each other

- c)Cutting the edges of the sleepers to a square shape

- d)Adjusting the rails to be perpendicular to the sleepers

Correct answer is option 'B'. Can you explain this answer?

Squaring of sleepers through packing consists of

a)

Adjusting the sleepers to be perpendicular to the rails

b)

Adjusting the ballast under sleepers to space them parallel to each other

c)

Cutting the edges of the sleepers to a square shape

d)

Adjusting the rails to be perpendicular to the sleepers

|

Akash Mukherjee answered |

In through packing the sleepers are squared and brought to specified spacing at straight lengths and on curves i.e., the ballast under the sleepers is adjusted to space them parallel to each other.

What is the meaning of a gradient represented as 1 in 400?- a)A rise of 1m in 400m

- b)Rise of 400m in 1km

- c)A 400% rise in track

- d)A 1m rise in 4km

Correct answer is option 'A'. Can you explain this answer?

What is the meaning of a gradient represented as 1 in 400?

a)

A rise of 1m in 400m

b)

Rise of 400m in 1km

c)

A 400% rise in track

d)

A 1m rise in 4km

|

|

Sanya Agarwal answered |

Gradient is represented as the distance travelled for a rise or fall of 1 unit distance. 1 in 400 means a rise of 1m is recorded after travelling 400m. 1 in 400 is also represented as 0.25%.

What is Pusher gradient also known as?- a)Friction gradient

- b)Helper gradient

- c)Momentum gradient

- d)Ruling gradient

Correct answer is option 'B'. Can you explain this answer?

What is Pusher gradient also known as?

a)

Friction gradient

b)

Helper gradient

c)

Momentum gradient

d)

Ruling gradient

|

|

Sanya Agarwal answered |

Pusher gradients can sometimes be steeper than Ruling gradient. If one locomotive is not sufficient to pull the entire load, another locomotive or engine can be used. It is also known as Helper gradient.

Which gradient determines the maximum load that can be hauled by a locomotive on that section?- a)Rising gradient

- b)Falling gradient

- c)Ruling gradient

- d)Momentum gradient

Correct answer is option 'C'. Can you explain this answer?

Which gradient determines the maximum load that can be hauled by a locomotive on that section?

a)

Rising gradient

b)

Falling gradient

c)

Ruling gradient

d)

Momentum gradient

|

Jaya Yadav answered |

The correct answer is option 'C' which is the ruling gradient.

The ruling gradient is the maximum allowable gradient or slope that a locomotive can haul a maximum load on a specific section of a railway track. It is determined based on various factors such as the power of the locomotive, the weight and type of the train, and the track conditions.

Here is a detailed explanation of why the ruling gradient determines the maximum load that can be hauled by a locomotive on a section of track:

1. Definition of the ruling gradient:

- The ruling gradient is the steepest gradient or slope on a section of track over which a locomotive can haul the maximum load specified for that section.

- It is designed to ensure that a locomotive can safely and efficiently haul the maximum load without causing any damage to the equipment or compromising safety.

2. Factors influencing the ruling gradient:

- Power of the locomotive: The ruling gradient depends on the tractive effort or pulling power of the locomotive. A more powerful locomotive can handle steeper gradients.

- Weight and type of the train: The ruling gradient also considers the weight of the train and the type of cars being hauled. Heavier trains or trains with a higher proportion of loaded cars may require a less steep gradient.

- Track conditions: The ruling gradient takes into account the condition of the track, including the alignment, grade, curvature, and track maintenance. A poorly maintained track may require a less steep gradient to ensure safe operation.

3. Determining the ruling gradient:

- The ruling gradient is determined through engineering calculations and analysis. It is based on the locomotive's tractive effort, the weight and type of the train, and the track conditions.

- The calculations consider the maximum tractive effort available at the locomotive's driving wheels, the resistance offered by the train, and the gradient of the track.

- The ruling gradient is typically expressed as a percentage or ratio, indicating the rise in elevation over a given horizontal distance (e.g., 1 in 100 or 1%).

4. Importance of the ruling gradient:

- The ruling gradient is essential for ensuring the safe and efficient operation of trains on a railway network.

- It helps determine the maximum load that a locomotive can haul on a specific section of track, allowing for proper planning and scheduling of train operations.

- By adhering to the ruling gradient, the risk of locomotive stalling, excessive wear on equipment, and potential accidents due to inadequate braking or control is minimized.

In conclusion, the ruling gradient is the maximum allowable gradient on a section of track that a locomotive can haul a maximum load. It is determined based on factors such as locomotive power, train weight, and track conditions to ensure safe and efficient train operations.

The ruling gradient is the maximum allowable gradient or slope that a locomotive can haul a maximum load on a specific section of a railway track. It is determined based on various factors such as the power of the locomotive, the weight and type of the train, and the track conditions.

Here is a detailed explanation of why the ruling gradient determines the maximum load that can be hauled by a locomotive on a section of track:

1. Definition of the ruling gradient:

- The ruling gradient is the steepest gradient or slope on a section of track over which a locomotive can haul the maximum load specified for that section.

- It is designed to ensure that a locomotive can safely and efficiently haul the maximum load without causing any damage to the equipment or compromising safety.

2. Factors influencing the ruling gradient:

- Power of the locomotive: The ruling gradient depends on the tractive effort or pulling power of the locomotive. A more powerful locomotive can handle steeper gradients.

- Weight and type of the train: The ruling gradient also considers the weight of the train and the type of cars being hauled. Heavier trains or trains with a higher proportion of loaded cars may require a less steep gradient.

- Track conditions: The ruling gradient takes into account the condition of the track, including the alignment, grade, curvature, and track maintenance. A poorly maintained track may require a less steep gradient to ensure safe operation.

3. Determining the ruling gradient:

- The ruling gradient is determined through engineering calculations and analysis. It is based on the locomotive's tractive effort, the weight and type of the train, and the track conditions.

- The calculations consider the maximum tractive effort available at the locomotive's driving wheels, the resistance offered by the train, and the gradient of the track.

- The ruling gradient is typically expressed as a percentage or ratio, indicating the rise in elevation over a given horizontal distance (e.g., 1 in 100 or 1%).

4. Importance of the ruling gradient:

- The ruling gradient is essential for ensuring the safe and efficient operation of trains on a railway network.

- It helps determine the maximum load that a locomotive can haul on a specific section of track, allowing for proper planning and scheduling of train operations.

- By adhering to the ruling gradient, the risk of locomotive stalling, excessive wear on equipment, and potential accidents due to inadequate braking or control is minimized.

In conclusion, the ruling gradient is the maximum allowable gradient on a section of track that a locomotive can haul a maximum load. It is determined based on factors such as locomotive power, train weight, and track conditions to ensure safe and efficient train operations.

For taking the consideration of creep of rails the sleepers that need no anchoring arrangement- a)wooden sleeper

- b)steel sleeper

- c)cast iron sleeper

- d)concrete sleeper

Correct answer is option 'D'. Can you explain this answer?

For taking the consideration of creep of rails the sleepers that need no anchoring arrangement

a)

wooden sleeper

b)

steel sleeper

c)

cast iron sleeper

d)

concrete sleeper

|

Subham Unni answered |

Concrete sleepers are heavy in weight due to their self weight and thus, the need no anchoring.

The type of bearing plate used in all joints and on curves to give better bearing area to the rails is- a)flat mild steel bearing plate

- b)mild steel canted bearing plate

- c)cast iron anti-creep bearing plate

- d)None of the above

Correct answer is option 'B'. Can you explain this answer?

The type of bearing plate used in all joints and on curves to give better bearing area to the rails is

a)

flat mild steel bearing plate

b)

mild steel canted bearing plate

c)

cast iron anti-creep bearing plate

d)

None of the above

|

Satyam Gupta answered |

On CURVES we required variable Diameter therefore cant mean sloping plate required so should not provide flat mild steel plate

ON JOINTS we allow to some movement of rail due to thermal action so should not restrict by anticreep bearing plate

ON JOINTS we allow to some movement of rail due to thermal action so should not restrict by anticreep bearing plate

The superelevation is- a)Directly proportional to the velocity of vehicles

- b)Inversely proportional to the velocity of vehicles

- c)Directly proportional to the width of pavement

- d)Inversely proportional to the width of pavement

Correct answer is option 'A'. Can you explain this answer?

The superelevation is

a)

Directly proportional to the velocity of vehicles

b)

Inversely proportional to the velocity of vehicles

c)

Directly proportional to the width of pavement

d)

Inversely proportional to the width of pavement

|

|

Sanya Agarwal answered |

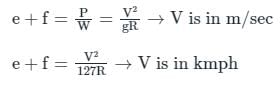

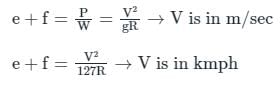

Superelevation:

It is the transverse slope to counteract the centrifugal force and to reduce the tendency of the vehicle to overturn or skid.

It is the rise of the outer edge of the pavement w.r.t inner edge on a horizontal curve thus providing a transverse slope throughout the length of the horizontal curve

It is also known as cant or banking.

Rate of Super elevation = e = tanθ = E/B

Where,

E = Total superelevated height of the outer edge

B = Width of the pavement

General equation,

where,

f = Coefficient of lateral friction = 0.15

R = Radius of horizontal curve

It can be seen that the superelevation is directly proportional to the velocity of the vehicle

Mistake point:

The rate of superelevation is inversely proportional to the width of the pavement, but the superelevation is not. Superelevation is directly proportional to the velocity of the vehicle.

It is the transverse slope to counteract the centrifugal force and to reduce the tendency of the vehicle to overturn or skid.

It is the rise of the outer edge of the pavement w.r.t inner edge on a horizontal curve thus providing a transverse slope throughout the length of the horizontal curve

It is also known as cant or banking.

Rate of Super elevation = e = tanθ = E/B

Where,

E = Total superelevated height of the outer edge

B = Width of the pavement

General equation,

where,

f = Coefficient of lateral friction = 0.15

R = Radius of horizontal curve

It can be seen that the superelevation is directly proportional to the velocity of the vehicle

Mistake point:

The rate of superelevation is inversely proportional to the width of the pavement, but the superelevation is not. Superelevation is directly proportional to the velocity of the vehicle.

What is the reason of compensation of Gradient on curves?- a)They are very difficult to design

- b)They are uneconomical

- c)Curves provide extra resistance

- d)They are dangerous

Correct answer is option 'C'. Can you explain this answer?

What is the reason of compensation of Gradient on curves?

a)

They are very difficult to design

b)

They are uneconomical

c)

Curves provide extra resistance

d)

They are dangerous

|

|

Sanvi Kapoor answered |

On curves the locomotive experiences extra resistance to its movement. Thus gradients on a curve should be flatter because more resistance can cause uncomfortable journey.

What is the definition of Superelevation?- a)Difference in height between outer and inner rail

- b)Height difference from outer rail to centre of track

- c)Height difference from inner rail to centre of track

- d)Slope at which rail is laid

Correct answer is option 'A'. Can you explain this answer?

What is the definition of Superelevation?

a)

Difference in height between outer and inner rail

b)

Height difference from outer rail to centre of track

c)

Height difference from inner rail to centre of track

d)

Slope at which rail is laid

|

Bibek Mukherjee answered |

Definition of Superelevation

Superelevation refers to the banking of a railway track or roadway at a curve, designed to counteract the lateral acceleration experienced by vehicles. It is a crucial aspect of track design in civil engineering, particularly in ensuring the safety and comfort of train operations.

Key Characteristics of Superelevation:

- Difference in Height: Superelevation is defined as the difference in height between the outer and inner rails of a track. This height difference helps to balance the forces acting on a train as it navigates a curve.

- Functionality: By raising the outer rail, superelevation allows trains to maintain higher speeds while minimizing the risk of derailment. The incline helps direct the centrifugal force downwards, enhancing stability.

- Design Considerations: The degree of superelevation is determined by factors such as curve radius, train speed, and the type of vehicles that will use the track. Proper design is essential to ensure safety and efficiency.

- Impact on Train Operations: Adequate superelevation contributes to smoother rides, reducing lateral forces on both the train and its passengers. It also helps prevent excessive wear on the rails and wheels.

Conclusion:

In summary, the correct definition of superelevation is indeed the difference in height between the outer and inner rail of a track. This design feature is vital for enhancing the safety and performance of trains while navigating curves, making it a fundamental concept in civil engineering.

Superelevation refers to the banking of a railway track or roadway at a curve, designed to counteract the lateral acceleration experienced by vehicles. It is a crucial aspect of track design in civil engineering, particularly in ensuring the safety and comfort of train operations.

Key Characteristics of Superelevation:

- Difference in Height: Superelevation is defined as the difference in height between the outer and inner rails of a track. This height difference helps to balance the forces acting on a train as it navigates a curve.

- Functionality: By raising the outer rail, superelevation allows trains to maintain higher speeds while minimizing the risk of derailment. The incline helps direct the centrifugal force downwards, enhancing stability.

- Design Considerations: The degree of superelevation is determined by factors such as curve radius, train speed, and the type of vehicles that will use the track. Proper design is essential to ensure safety and efficiency.

- Impact on Train Operations: Adequate superelevation contributes to smoother rides, reducing lateral forces on both the train and its passengers. It also helps prevent excessive wear on the rails and wheels.

Conclusion:

In summary, the correct definition of superelevation is indeed the difference in height between the outer and inner rail of a track. This design feature is vital for enhancing the safety and performance of trains while navigating curves, making it a fundamental concept in civil engineering.

Maximum value of ‘throw of switch for Broad Gauge track is- a)89 mm

- b)95 mm

- c)100 mm

- d)115 mm

Correct answer is option 'D'. Can you explain this answer?

Maximum value of ‘throw of switch for Broad Gauge track is

a)

89 mm

b)

95 mm

c)

100 mm

d)

115 mm

|

Rohan Singh answered |

Minimum value of throw of switch for broad gauge track is 95 mm. Answers (b) and (d) give minimum and maximum values of throw of switch for metre gauge track.

Consider the following statements about concrete sleepers:

1. They improve the track modulus.

2. They have good scrap value.

3. They render transportation easy.

4. They maintain the gauge quite satisfactorily.

Which of these statements are correct?- a)1 and 2

- b)2 and 3

- c)2 and 4

- d)1 and 4

Correct answer is option 'D'. Can you explain this answer?

Consider the following statements about concrete sleepers:

1. They improve the track modulus.

2. They have good scrap value.

3. They render transportation easy.

4. They maintain the gauge quite satisfactorily.

Which of these statements are correct?

1. They improve the track modulus.

2. They have good scrap value.

3. They render transportation easy.

4. They maintain the gauge quite satisfactorily.

Which of these statements are correct?

a)

1 and 2

b)

2 and 3

c)

2 and 4

d)

1 and 4

|

Rajat Sen answered |

The scrap value of concrete sleepers is nil.

The outer and inner wheels though cast monolithic, cover different distances on a curve for the same number of revolutions because of:- a)Coning of wheels

- b)Widening of gauge

- c)Tilting of rails

- d)Adzing of sleepers

Correct answer is option 'A'. Can you explain this answer?

The outer and inner wheels though cast monolithic, cover different distances on a curve for the same number of revolutions because of:

a)

Coning of wheels

b)

Widening of gauge

c)

Tilting of rails

d)

Adzing of sleepers

|

|

Sanvi Kapoor answered |

Coning of wheels:

- Inward provision of the slope of 1:20 on the wheels of the railway wagon to counteract the centrifugal force acting on the train. So, it enables the train wheels to cover different distances along the inner and outer curves simultaneously.

Purpose of coming of wheels:

- To check lateral movement of wheels.

- To avoid damage to the inner faces of rails.

- To avoid discomfort to passengers.

Hence, The outer and inner wheels though cast monolithic, cover different distances on a curve for the same number of revolutions because of coning of wheels.

Tilting of Rails:

Tilting of Rails:

- Placing the rails of a track at an inward slope of 1 in 20 is called tilting of rails.

- The main object of tilting of rails is to reduce the wear on the inside edges of rails in a track.

Adzing of sleepers

- The sleepers are cut at the rail seat to provide a slope of 1 in 20 to the rails.

- The process of cutting the wooden sleepers or casting concrete sleepers accordingly is known as adzing of sleepers.

Metal sleepers are superior to wooden sleepers with respect to- a)cost

- b)durability

- c)track circuiting

- d)fastening

Correct answer is option 'B'. Can you explain this answer?

Metal sleepers are superior to wooden sleepers with respect to

a)

cost

b)

durability

c)

track circuiting

d)

fastening

|

Prashanth Rane answered |

Introduction:

Sleepers are an essential component of railway tracks, providing support and stability to the rails. They play a crucial role in the overall performance and longevity of the track system. Metal sleepers and wooden sleepers are two common types used in railway construction. In this context, we will discuss why metal sleepers are superior to wooden sleepers in terms of durability.

Durability:

- Metal sleepers, usually made of steel or cast iron, offer superior durability compared to wooden sleepers. They have a longer lifespan and require less frequent replacement, resulting in reduced maintenance costs over time.

- Metal sleepers are highly resistant to environmental factors such as moisture, insects, and decay, which are common causes of deterioration in wooden sleepers.

- Metal sleepers have a higher load-bearing capacity and can withstand heavy loads without significant deformation or damage. This characteristic is particularly advantageous in high-traffic areas where the track experiences repetitive loading.

- Metal sleepers also exhibit excellent resistance to fire, making them a safer option compared to wooden sleepers, which are susceptible to catching fire and contributing to the spread of flames.

Cost:

- Cost is not a factor where metal sleepers outperform wooden sleepers. Metal sleepers are generally more expensive to manufacture and install compared to wooden sleepers. The initial investment for metal sleepers can be higher due to the higher cost of materials, manufacturing processes, and specialized equipment required for installation.

- However, the higher durability and longer lifespan of metal sleepers offset the initial cost difference. Over the long term, metal sleepers prove to be more cost-effective due to their reduced maintenance and replacement requirements.

Track Circuiting:

- Track circuiting refers to the electrical signaling system used to detect the presence of trains on the track.

- Metal sleepers have lower electrical resistance compared to wooden sleepers, making them more suitable for track circuiting. The lower resistance allows for better electrical continuity along the track, ensuring accurate detection of trains and preventing false signaling.

- Wooden sleepers, being non-conductive, may disrupt the electrical circuit and cause signaling issues in track circuiting systems.

Fastening:

- Fastening refers to the method used to secure the rails to the sleepers.

- Metal sleepers often have pre-drilled holes or built-in fastening systems that make rail installation quicker and more efficient. They provide a sturdy base for rail fasteners, ensuring proper alignment and reducing the risk of rail displacement.

- Wooden sleepers require additional drilling and fastening processes, which can be more time-consuming and labor-intensive.

Conclusion:

In summary, metal sleepers are superior to wooden sleepers in terms of durability. They offer enhanced resistance to environmental factors, higher load-bearing capacity, and increased fire resistance. Although metal sleepers may have a higher initial cost, their longer lifespan and reduced maintenance requirements make them more cost-effective in the long run. Metal sleepers also provide better suitability for track circuiting and offer easier rail fastening processes. Overall, metal sleepers are a preferred choice in modern railway construction due to their superior durability and performance.

Sleepers are an essential component of railway tracks, providing support and stability to the rails. They play a crucial role in the overall performance and longevity of the track system. Metal sleepers and wooden sleepers are two common types used in railway construction. In this context, we will discuss why metal sleepers are superior to wooden sleepers in terms of durability.

Durability:

- Metal sleepers, usually made of steel or cast iron, offer superior durability compared to wooden sleepers. They have a longer lifespan and require less frequent replacement, resulting in reduced maintenance costs over time.

- Metal sleepers are highly resistant to environmental factors such as moisture, insects, and decay, which are common causes of deterioration in wooden sleepers.

- Metal sleepers have a higher load-bearing capacity and can withstand heavy loads without significant deformation or damage. This characteristic is particularly advantageous in high-traffic areas where the track experiences repetitive loading.

- Metal sleepers also exhibit excellent resistance to fire, making them a safer option compared to wooden sleepers, which are susceptible to catching fire and contributing to the spread of flames.

Cost:

- Cost is not a factor where metal sleepers outperform wooden sleepers. Metal sleepers are generally more expensive to manufacture and install compared to wooden sleepers. The initial investment for metal sleepers can be higher due to the higher cost of materials, manufacturing processes, and specialized equipment required for installation.

- However, the higher durability and longer lifespan of metal sleepers offset the initial cost difference. Over the long term, metal sleepers prove to be more cost-effective due to their reduced maintenance and replacement requirements.

Track Circuiting:

- Track circuiting refers to the electrical signaling system used to detect the presence of trains on the track.

- Metal sleepers have lower electrical resistance compared to wooden sleepers, making them more suitable for track circuiting. The lower resistance allows for better electrical continuity along the track, ensuring accurate detection of trains and preventing false signaling.

- Wooden sleepers, being non-conductive, may disrupt the electrical circuit and cause signaling issues in track circuiting systems.

Fastening:

- Fastening refers to the method used to secure the rails to the sleepers.

- Metal sleepers often have pre-drilled holes or built-in fastening systems that make rail installation quicker and more efficient. They provide a sturdy base for rail fasteners, ensuring proper alignment and reducing the risk of rail displacement.

- Wooden sleepers require additional drilling and fastening processes, which can be more time-consuming and labor-intensive.

Conclusion:

In summary, metal sleepers are superior to wooden sleepers in terms of durability. They offer enhanced resistance to environmental factors, higher load-bearing capacity, and increased fire resistance. Although metal sleepers may have a higher initial cost, their longer lifespan and reduced maintenance requirements make them more cost-effective in the long run. Metal sleepers also provide better suitability for track circuiting and offer easier rail fastening processes. Overall, metal sleepers are a preferred choice in modern railway construction due to their superior durability and performance.

Which of the following is correct about Momentum gradient?- a)A falling gradient is followed by a rising gradient

- b)It is not steeper than the Ruling gradient

- c)It requires an extra engine

- d)It is very flat

Correct answer is option 'A'. Can you explain this answer?

Which of the following is correct about Momentum gradient?

a)

A falling gradient is followed by a rising gradient

b)

It is not steeper than the Ruling gradient

c)

It requires an extra engine

d)

It is very flat

|

Mahesh Nair answered |

Momentum Gradient in Civil Engineering

The momentum gradient is an important concept in civil engineering, specifically in the design of transportation systems such as railways and highways. It refers to the change in the momentum of a vehicle or train along a particular section of track or road. The momentum of a moving object is the product of its mass and velocity, and any change in momentum can affect the performance and safety of the vehicle.

Falling Gradient and Rising Gradient

The correct statement about the momentum gradient is option 'A': "A falling gradient is followed by a rising gradient." This means that when designing a track or road, there is a section where the gradient decreases or falls (i.e., the slope becomes less steep), followed by a section where the gradient increases or rises (i.e., the slope becomes steeper). This design approach is used to balance the momentum of the vehicle and ensure safe and efficient transportation.

Reasons for Falling Gradient

There are several reasons for incorporating a falling gradient in the momentum gradient design:

1. Energy Dissipation: A falling gradient allows vehicles to dissipate some of their kinetic energy, reducing the risk of excessive speeds and potential accidents.

2. Brake System Efficiency: The falling gradient provides an opportunity for vehicles to use their brakes more effectively, as the reduced slope makes it easier to control the speed and apply braking force.

3. Safety Considerations: A falling gradient allows vehicles to naturally slow down, especially if they have been traveling on a steeper gradient. This helps prevent sudden stops or collisions due to excessive speed.

Reasons for Rising Gradient

Following the falling gradient, a rising gradient is introduced to maintain the momentum of the vehicle and ensure efficient transportation. Some reasons for incorporating a rising gradient are:

1. Energy Regeneration: The rising gradient allows vehicles to regain some of the energy lost during the falling gradient section. This can be particularly beneficial for electric or hybrid vehicles, as they can regenerate energy through regenerative braking.

2. Vehicle Performance: A rising gradient helps vehicles maintain their speed and momentum, especially for heavy or loaded vehicles that may experience a decrease in speed on a level or falling gradient.

3. Overcoming Resistance: As vehicles move along a track or road, they encounter various resistances such as friction and air resistance. The rising gradient helps vehicles overcome these resistances and maintain a steady speed.

Conclusion

In summary, the momentum gradient in civil engineering involves designing a track or road with a falling gradient followed by a rising gradient. The falling gradient allows vehicles to slow down and dissipate energy, while the rising gradient helps maintain momentum and overcome resistance. This design approach ensures safe and efficient transportation.

The momentum gradient is an important concept in civil engineering, specifically in the design of transportation systems such as railways and highways. It refers to the change in the momentum of a vehicle or train along a particular section of track or road. The momentum of a moving object is the product of its mass and velocity, and any change in momentum can affect the performance and safety of the vehicle.

Falling Gradient and Rising Gradient

The correct statement about the momentum gradient is option 'A': "A falling gradient is followed by a rising gradient." This means that when designing a track or road, there is a section where the gradient decreases or falls (i.e., the slope becomes less steep), followed by a section where the gradient increases or rises (i.e., the slope becomes steeper). This design approach is used to balance the momentum of the vehicle and ensure safe and efficient transportation.

Reasons for Falling Gradient

There are several reasons for incorporating a falling gradient in the momentum gradient design:

1. Energy Dissipation: A falling gradient allows vehicles to dissipate some of their kinetic energy, reducing the risk of excessive speeds and potential accidents.

2. Brake System Efficiency: The falling gradient provides an opportunity for vehicles to use their brakes more effectively, as the reduced slope makes it easier to control the speed and apply braking force.

3. Safety Considerations: A falling gradient allows vehicles to naturally slow down, especially if they have been traveling on a steeper gradient. This helps prevent sudden stops or collisions due to excessive speed.

Reasons for Rising Gradient

Following the falling gradient, a rising gradient is introduced to maintain the momentum of the vehicle and ensure efficient transportation. Some reasons for incorporating a rising gradient are:

1. Energy Regeneration: The rising gradient allows vehicles to regain some of the energy lost during the falling gradient section. This can be particularly beneficial for electric or hybrid vehicles, as they can regenerate energy through regenerative braking.

2. Vehicle Performance: A rising gradient helps vehicles maintain their speed and momentum, especially for heavy or loaded vehicles that may experience a decrease in speed on a level or falling gradient.

3. Overcoming Resistance: As vehicles move along a track or road, they encounter various resistances such as friction and air resistance. The rising gradient helps vehicles overcome these resistances and maintain a steady speed.

Conclusion

In summary, the momentum gradient in civil engineering involves designing a track or road with a falling gradient followed by a rising gradient. The falling gradient allows vehicles to slow down and dissipate energy, while the rising gradient helps maintain momentum and overcome resistance. This design approach ensures safe and efficient transportation.

What is a gradient in which track loses elevation in direction of movement of traffic called?- a)Ruling gradient

- b)Falling gradient

- c)Rising gradient

- d)Level gradient

Correct answer is option 'B'. Can you explain this answer?

What is a gradient in which track loses elevation in direction of movement of traffic called?

a)

Ruling gradient

b)

Falling gradient

c)

Rising gradient

d)

Level gradient

|

|

Sanvi Kapoor answered |

Gradients are provided so that the rise or fall in the track’s path can be easily traversed. A down gradient also called as falling gradient is the one in which drop of elevation in the direction of movement is recorded.

Due to battering action of wheels over the end of the rails, the rails get bent down and are deflected at ends. These rails are called- a)Roaring rails

- b)Hogged rails

- c)Corrugated rails

- d)Buckled rails

Correct answer is option 'B'. Can you explain this answer?

Due to battering action of wheels over the end of the rails, the rails get bent down and are deflected at ends. These rails are called

a)

Roaring rails

b)

Hogged rails

c)

Corrugated rails

d)

Buckled rails

|

Shilpa Pillai answered |

Explanation:

When the wheels of the trains pass over the end of the rails, it causes a hammering or battering action on the rails. This results in the rails getting bent down and deflected at the ends. Such rails are called hogged rails. The term "hogged" is derived from the shape of the rails which resembles the back of a hog or pig with a raised center and sloping sides. Hogged rails are a common problem in railways and can lead to several issues such as derailments, increased wear and tear, and reduced ride quality for passengers. It is important to regularly inspect and maintain the rails to prevent hogging and ensure safe operation of trains.

Causes of Hogged Rails:

Effects of Hogged Rails:

Prevention and Maintenance:

When the wheels of the trains pass over the end of the rails, it causes a hammering or battering action on the rails. This results in the rails getting bent down and deflected at the ends. Such rails are called hogged rails. The term "hogged" is derived from the shape of the rails which resembles the back of a hog or pig with a raised center and sloping sides. Hogged rails are a common problem in railways and can lead to several issues such as derailments, increased wear and tear, and reduced ride quality for passengers. It is important to regularly inspect and maintain the rails to prevent hogging and ensure safe operation of trains.

Causes of Hogged Rails:

- High-speed trains or heavy loads that cause excessive vibrations and impact on the rails.

- Uneven distribution of load on the rails, causing some sections to bear more weight than others.

- Improper alignment of the tracks, causing the wheels to hit the ends of the rails at an angle.

- Insufficient ballast support or inadequate rail fastenings that do not hold the rails firmly in place.

Effects of Hogged Rails:

- Increased wear and tear on the rails, leading to the need for frequent replacement.

- Reduced ride quality for passengers, causing discomfort and inconvenience.

- Increased risk of derailments and accidents due to the unstable track conditions.

- Higher maintenance costs for the railway companies, as they need to regularly inspect and repair the tracks.

Prevention and Maintenance:

- Regular inspection of the tracks to identify any signs of hogging or other defects.

- Proper maintenance of the ballast and rail fastenings to ensure adequate support for the rails.

- Proper alignment of the tracks to prevent uneven distribution of load on the rails.

- Use of high-quality rails and proper installation techniques to reduce the risk of hogging and other defects.

- Implementation of speed restrictions and weight limits to reduce the impact on the rails.

Coning of wheels is provided- a)To check lateral movement of wheels

- b)To avoid damage to inner faces of rails

- c)To avoid discomfort to passengers

- d)All of the above

Correct answer is option 'D'. Can you explain this answer?

Coning of wheels is provided

a)

To check lateral movement of wheels

b)

To avoid damage to inner faces of rails

c)

To avoid discomfort to passengers

d)

All of the above

|

Samarth Ghoshal answered |

Coning of wheels is provided to:

1. Check lateral movement of wheels:

Coning of wheels refers to the gradual inclination of the tread of railway wheels. The outer diameter of the wheel is slightly larger than the inner diameter. This coning ensures that the wheels naturally tend to move towards the center of the track, reducing the possibility of lateral movement. Lateral movement of wheels can lead to derailment, which is a serious safety concern. By providing coning of wheels, the lateral stability of the train is enhanced, reducing the risk of accidents.

2. Avoid damage to inner faces of rails:

When a train is in motion, it exerts a significant amount of force on the rails. Without coning of wheels, the entire weight of the train would be concentrated on the inner faces of the rails. This concentrated force can lead to wear, deformation, and damage to the inner faces of the rails. By providing coning of wheels, the load is distributed more evenly across the rail head, reducing the potential damage and prolonging the lifespan of the rails.

3. Avoid discomfort to passengers:

Coning of wheels also helps in providing a smoother and more comfortable ride for passengers. When the wheels are coned, they naturally align with the track and follow the curvature of the rails. This reduces the lateral forces acting on the train and minimizes the vibrations and jerks experienced by the passengers. A smoother ride enhances passenger comfort and reduces fatigue during long journeys.

Conclusion:

Coning of wheels is a crucial design feature in railway systems. It serves multiple purposes, including checking lateral movement of wheels, avoiding damage to inner faces of rails, and providing a comfortable ride for passengers. By ensuring that the wheels naturally align with the track, coning enhances the safety, stability, and longevity of railway systems.

1. Check lateral movement of wheels:

Coning of wheels refers to the gradual inclination of the tread of railway wheels. The outer diameter of the wheel is slightly larger than the inner diameter. This coning ensures that the wheels naturally tend to move towards the center of the track, reducing the possibility of lateral movement. Lateral movement of wheels can lead to derailment, which is a serious safety concern. By providing coning of wheels, the lateral stability of the train is enhanced, reducing the risk of accidents.

2. Avoid damage to inner faces of rails:

When a train is in motion, it exerts a significant amount of force on the rails. Without coning of wheels, the entire weight of the train would be concentrated on the inner faces of the rails. This concentrated force can lead to wear, deformation, and damage to the inner faces of the rails. By providing coning of wheels, the load is distributed more evenly across the rail head, reducing the potential damage and prolonging the lifespan of the rails.

3. Avoid discomfort to passengers:

Coning of wheels also helps in providing a smoother and more comfortable ride for passengers. When the wheels are coned, they naturally align with the track and follow the curvature of the rails. This reduces the lateral forces acting on the train and minimizes the vibrations and jerks experienced by the passengers. A smoother ride enhances passenger comfort and reduces fatigue during long journeys.

Conclusion:

Coning of wheels is a crucial design feature in railway systems. It serves multiple purposes, including checking lateral movement of wheels, avoiding damage to inner faces of rails, and providing a comfortable ride for passengers. By ensuring that the wheels naturally align with the track, coning enhances the safety, stability, and longevity of railway systems.

Which of the following is the correct formula for equilibrium superelevation in millimetres?- a)e = GV2/254R

- b)e = GV2/381R

- c)e = GV2/127R

- d)e = GV2/96R

Correct answer is option 'C'. Can you explain this answer?

Which of the following is the correct formula for equilibrium superelevation in millimetres?

a)

e = GV2/254R

b)

e = GV2/381R

c)

e = GV2/127R

d)

e = GV2/96R

|

Ashwin Desai answered |

The correct formula for equilibrium superelevation in millimeters is:

e = GV^2 / 127R

- e: Equilibrium superelevation (in millimeters)

- G: Acceleration due to gravity (in m/s^2)

- V: Design speed of the vehicle (in km/h)

- R: Radius of the curve (in meters)

Explanation:

1. Equilibrium Superelevation:

Equilibrium superelevation is the value of superelevation that is required to balance the centrifugal force acting on a vehicle as it travels around a curved section of a road. It ensures that the vehicle maintains a stable trajectory without skidding or overturning.

2. Centrifugal Force:

Centrifugal force is the force experienced by an object moving in a curved path. In the case of a vehicle traveling on a curved road, centrifugal force pushes the vehicle outward from the curve.

3. Superelevation:

Superelevation is the banking of a road or track on a curve, where the outside edge of the road is raised higher than the inside edge. This helps counteract the centrifugal force and allows the vehicle to maintain stability while negotiating the curve.

4. Factors Affecting Equilibrium Superelevation:

The equilibrium superelevation is influenced by several factors, including the acceleration due to gravity (G), the design speed of the vehicle (V), and the radius of the curve (R).

5. Formula Derivation:

The formula for equilibrium superelevation is derived from the equation balancing the centrifugal force and the horizontal component of the gravitational force acting on the vehicle.

The horizontal component of the gravitational force is calculated as G * V^2 / R, where G is the acceleration due to gravity, V is the design speed of the vehicle, and R is the radius of the curve.

To maintain equilibrium, the centrifugal force must be equal to the horizontal component of the gravitational force. Therefore, the equilibrium superelevation (e) can be calculated by equating the two forces:

Centrifugal Force = Horizontal Component of Gravitational Force

m * V^2 / R = G * V^2 / R

Simplifying the equation gives:

m = G / R

where m is the equilibrium superelevation.

To convert the equilibrium superelevation from meters to millimeters, the formula becomes:

e = GV^2 / 127R

Hence, the correct formula for equilibrium superelevation in millimeters is e = GV^2 / 127R.

e = GV^2 / 127R

- e: Equilibrium superelevation (in millimeters)

- G: Acceleration due to gravity (in m/s^2)

- V: Design speed of the vehicle (in km/h)

- R: Radius of the curve (in meters)

Explanation:

1. Equilibrium Superelevation:

Equilibrium superelevation is the value of superelevation that is required to balance the centrifugal force acting on a vehicle as it travels around a curved section of a road. It ensures that the vehicle maintains a stable trajectory without skidding or overturning.

2. Centrifugal Force:

Centrifugal force is the force experienced by an object moving in a curved path. In the case of a vehicle traveling on a curved road, centrifugal force pushes the vehicle outward from the curve.

3. Superelevation:

Superelevation is the banking of a road or track on a curve, where the outside edge of the road is raised higher than the inside edge. This helps counteract the centrifugal force and allows the vehicle to maintain stability while negotiating the curve.

4. Factors Affecting Equilibrium Superelevation:

The equilibrium superelevation is influenced by several factors, including the acceleration due to gravity (G), the design speed of the vehicle (V), and the radius of the curve (R).

5. Formula Derivation:

The formula for equilibrium superelevation is derived from the equation balancing the centrifugal force and the horizontal component of the gravitational force acting on the vehicle.

The horizontal component of the gravitational force is calculated as G * V^2 / R, where G is the acceleration due to gravity, V is the design speed of the vehicle, and R is the radius of the curve.

To maintain equilibrium, the centrifugal force must be equal to the horizontal component of the gravitational force. Therefore, the equilibrium superelevation (e) can be calculated by equating the two forces:

Centrifugal Force = Horizontal Component of Gravitational Force

m * V^2 / R = G * V^2 / R

Simplifying the equation gives:

m = G / R

where m is the equilibrium superelevation.

To convert the equilibrium superelevation from meters to millimeters, the formula becomes:

e = GV^2 / 127R

Hence, the correct formula for equilibrium superelevation in millimeters is e = GV^2 / 127R.

What would be the result without coning of wheels?- a)Trains would have travelled slower

- b)The flange would have touched the rail

- c)Carrying capacity of the train would have reduced

- d)Passengers would feel more comfortable

Correct answer is option 'B'. Can you explain this answer?

What would be the result without coning of wheels?

a)

Trains would have travelled slower

b)

The flange would have touched the rail

c)

Carrying capacity of the train would have reduced

d)

Passengers would feel more comfortable

|

Sameer Verma answered |

Explanation:

Coning of Wheels:

- Coning of wheels is the process of sloping the wheels on a railroad or tram to ensure that they are perpendicular to the rails.

- This design feature helps in maintaining the alignment of the train on the tracks.

Flange touching the rail:

- If coning of wheels is not implemented and the wheels are not sloped, there is a high chance of the flange of the wheels touching the rail.

- This contact between the flange and the rail can cause friction and resistance, leading to increased wear and tear on both the wheels and the track.

Effects of flange touching the rail:

- The flange touching the rail can cause derailment of the train.

- It can also increase the rolling resistance, making the train slower and less efficient.

- Moreover, it can result in a bumpy ride for passengers, reducing comfort levels during the journey.

Conclusion:

- Therefore, without coning of wheels, the flange of the wheels would have touched the rail, leading to various negative consequences such as derailment, increased wear and tear, slower speeds, and reduced comfort for passengers.

- Coning of wheels is a crucial design feature in the railway industry to ensure smooth and safe operations of trains.

Coning of Wheels:

- Coning of wheels is the process of sloping the wheels on a railroad or tram to ensure that they are perpendicular to the rails.

- This design feature helps in maintaining the alignment of the train on the tracks.

Flange touching the rail:

- If coning of wheels is not implemented and the wheels are not sloped, there is a high chance of the flange of the wheels touching the rail.

- This contact between the flange and the rail can cause friction and resistance, leading to increased wear and tear on both the wheels and the track.

Effects of flange touching the rail:

- The flange touching the rail can cause derailment of the train.

- It can also increase the rolling resistance, making the train slower and less efficient.

- Moreover, it can result in a bumpy ride for passengers, reducing comfort levels during the journey.

Conclusion:

- Therefore, without coning of wheels, the flange of the wheels would have touched the rail, leading to various negative consequences such as derailment, increased wear and tear, slower speeds, and reduced comfort for passengers.

- Coning of wheels is a crucial design feature in the railway industry to ensure smooth and safe operations of trains.

Composite sleeper index is the index of- a)hardness and strength

- b)strength and toughness

- c)toughness and wear resistance

- d)wear resistance and hardness

Correct answer is option 'A'. Can you explain this answer?

Composite sleeper index is the index of

a)

hardness and strength

b)

strength and toughness

c)

toughness and wear resistance

d)

wear resistance and hardness

|

Hiral Sharma answered |

Composite Sleeper Index in Civil Engineering

Definition: Composite sleeper index is a term used in civil engineering to define the strength and hardness of composite materials used in sleepers.

Explanation:

Composite materials are widely used in railway sleepers because of their high strength, durability, and low maintenance cost. The composite sleeper index is an important parameter that defines the quality of the composite material used in sleepers. It is determined by two major factors:

1. Hardness: Hardness refers to the ability of the composite material to resist penetration and indentation. The higher the hardness, the more resistant the material is to wear and tear.

2. Strength: Strength refers to the ability of the composite material to withstand external loads without deformation or failure. The higher the strength, the more durable the material is.

Significance: The composite sleeper index provides a measure of the quality of the composite material used in sleepers. It is an important parameter that determines the lifespan of the sleepers and their performance under different loading conditions.

Conclusion: The composite sleeper index is an important parameter in civil engineering that defines the quality of the composite material used in sleepers. It is determined by the hardness and strength of the material and provides a measure of its durability and performance.

Definition: Composite sleeper index is a term used in civil engineering to define the strength and hardness of composite materials used in sleepers.

Explanation:

Composite materials are widely used in railway sleepers because of their high strength, durability, and low maintenance cost. The composite sleeper index is an important parameter that defines the quality of the composite material used in sleepers. It is determined by two major factors:

1. Hardness: Hardness refers to the ability of the composite material to resist penetration and indentation. The higher the hardness, the more resistant the material is to wear and tear.

2. Strength: Strength refers to the ability of the composite material to withstand external loads without deformation or failure. The higher the strength, the more durable the material is.

Significance: The composite sleeper index provides a measure of the quality of the composite material used in sleepers. It is an important parameter that determines the lifespan of the sleepers and their performance under different loading conditions.

Conclusion: The composite sleeper index is an important parameter in civil engineering that defines the quality of the composite material used in sleepers. It is determined by the hardness and strength of the material and provides a measure of its durability and performance.

Minimum depth of ballast cushion for a Board Gauge wooden sleeper of size 275 x 25 x 13 cm with 75 cm sleeper spacing is- a)15 cm

- b)20 cm

- c)25 cm

- d)30 cm

Correct answer is option 'C'. Can you explain this answer?

Minimum depth of ballast cushion for a Board Gauge wooden sleeper of size 275 x 25 x 13 cm with 75 cm sleeper spacing is

a)

15 cm

b)

20 cm

c)

25 cm

d)

30 cm

|

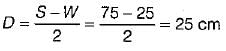

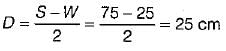

Garima Kulkarni answered |

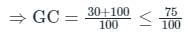

Minimum depth of ballast cushion D in terms of sleeper spacing S and width of sleeper W is given by the equation,

In a particular case, the design gradient is 1 in 25. If a horizontal curve of 100 m radius is to be introduced on this gradient, the compensated gradient on this curve is _________.- a)0.75%

- b)1.3%

- c)2.7%

- d)4%

Correct answer is option 'D'. Can you explain this answer?

In a particular case, the design gradient is 1 in 25. If a horizontal curve of 100 m radius is to be introduced on this gradient, the compensated gradient on this curve is _________.

a)

0.75%

b)

1.3%

c)

2.7%

d)

4%

|

|

Sanya Agarwal answered |

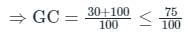

IRC Recommendations for grade compensation:

IRC gave the following guidelines for grade compensations:-

IRC gave the following guidelines for grade compensations:-

- Grade compensation is not required for grades flatter than 4% because the loss of tractive force is negligible.

- Grade compensation is

where R – radius of horizontal curve in m.

where R – radius of horizontal curve in m. - The maximum grade compensation is limited to 75/R %

Calculation:

Given:

The gradient of the Curve = (1/25) x 100 = 4%

⇒ GC = 0.75%

∴ CompensatedGradient = ((1/25) ×100)−0.75 = 4−0.75 = 3.25%

But, Compensated Gradient (C.G) should be ≥ 4 %

Since the gradient of the curve is 4 %, no grade compensation is required.

∴ C.G = 4%

Given:

The gradient of the Curve = (1/25) x 100 = 4%

⇒ GC = 0.75%

∴ CompensatedGradient = ((1/25) ×100)−0.75 = 4−0.75 = 3.25%

But, Compensated Gradient (C.G) should be ≥ 4 %

Since the gradient of the curve is 4 %, no grade compensation is required.

∴ C.G = 4%

What is the value of Slope provided to the wheels?- a)1 in 30

- b)1 in 20

- c)1 in 40

- d)1 in 15

Correct answer is option 'B'. Can you explain this answer?

What is the value of Slope provided to the wheels?

a)

1 in 30

b)

1 in 20

c)

1 in 40

d)

1 in 15

|

Sanskriti Datta answered |

The value of slope provided to the wheels is given as 1 in 20.

Explanation:

To understand the value of slope provided to the wheels, let's first understand what is meant by "1 in 20" slope.

A slope is a measure of how steep a surface is and is usually expressed as a ratio of vertical rise to horizontal run. In the case of "1 in 20" slope, it means that for every 20 units of horizontal distance traveled, there is 1 unit of vertical rise.

Now, let's discuss why option B is the correct answer.

1. Slope Measurement:

The value of slope is measured by comparing the vertical rise to the horizontal run. In this case, the slope is given as 1 in 20, which means that for every 20 units of horizontal distance, there is 1 unit of vertical rise.

2. Wheel Movement:

When a vehicle moves on a slope, the wheels experience the slope's inclination. This inclination affects the vehicle's traction and stability. The steeper the slope, the more challenging it becomes for the wheels to maintain grip and prevent slippage.

3. Optimal Slope:

To ensure safe and efficient movement, it is crucial to provide an optimal slope to the wheels. If the slope is too steep, the wheels may lose traction and result in accidents or difficulties in vehicle movement. On the other hand, if the slope is too gentle, it may not provide sufficient vertical rise to overcome obstacles or assist in vehicle control.

4. Option B: 1 in 20 Slope:

Among the given options, option B provides a slope of 1 in 20. This means that for every 20 units of horizontal distance, there is 1 unit of vertical rise. This slope strikes a balance between providing enough vertical rise for vehicle control and stability while not being overly steep to cause slippage or difficulties in movement.

Therefore, option B, which provides a slope of 1 in 20, is the correct answer.

In conclusion, the value of slope provided to the wheels is 1 in 20. This slope allows for safe and efficient movement of vehicles by providing an optimal balance between vertical rise and horizontal distance traveled.

Explanation:

To understand the value of slope provided to the wheels, let's first understand what is meant by "1 in 20" slope.

A slope is a measure of how steep a surface is and is usually expressed as a ratio of vertical rise to horizontal run. In the case of "1 in 20" slope, it means that for every 20 units of horizontal distance traveled, there is 1 unit of vertical rise.

Now, let's discuss why option B is the correct answer.

1. Slope Measurement:

The value of slope is measured by comparing the vertical rise to the horizontal run. In this case, the slope is given as 1 in 20, which means that for every 20 units of horizontal distance, there is 1 unit of vertical rise.

2. Wheel Movement:

When a vehicle moves on a slope, the wheels experience the slope's inclination. This inclination affects the vehicle's traction and stability. The steeper the slope, the more challenging it becomes for the wheels to maintain grip and prevent slippage.

3. Optimal Slope:

To ensure safe and efficient movement, it is crucial to provide an optimal slope to the wheels. If the slope is too steep, the wheels may lose traction and result in accidents or difficulties in vehicle movement. On the other hand, if the slope is too gentle, it may not provide sufficient vertical rise to overcome obstacles or assist in vehicle control.

4. Option B: 1 in 20 Slope:

Among the given options, option B provides a slope of 1 in 20. This means that for every 20 units of horizontal distance, there is 1 unit of vertical rise. This slope strikes a balance between providing enough vertical rise for vehicle control and stability while not being overly steep to cause slippage or difficulties in movement.

Therefore, option B, which provides a slope of 1 in 20, is the correct answer.

In conclusion, the value of slope provided to the wheels is 1 in 20. This slope allows for safe and efficient movement of vehicles by providing an optimal balance between vertical rise and horizontal distance traveled.

The main function of a fish plate is- a)to join the two rails together

- b)to join rails with the sleeper

- c)to allow rail to expand and contract freely

- d)None of the above

Correct answer is option 'A'. Can you explain this answer?

The main function of a fish plate is

a)

to join the two rails together

b)

to join rails with the sleeper

c)

to allow rail to expand and contract freely

d)

None of the above

|

Rounak Banerjee answered |

The rails are to be connected at their ends. This is achieved by means of a pair of fish plates per rail.The holes are drilled through the plates and the web of rails and then the fish bolts and nuts are provided in these holes.

When the bolts and nuts are tightened up, the rails are joined together and a continuous track is formed.

When the bolts and nuts are tightened up, the rails are joined together and a continuous track is formed.

Fish plate is in contact with rail at- a)web of rail

- b)fishing plane

- c)head of rail

- d)foot of rail

Correct answer is option 'B'. Can you explain this answer?

Fish plate is in contact with rail at

a)

web of rail

b)

fishing plane

c)

head of rail

d)

foot of rail

|

|

Avinash Mehta answered |

The correct answer is option 'B', fish plate is in contact with rail at the fish plane.

A fish plate, also known as a rail joint bar, is a metal plate that is used to connect the ends of two rails together in a railway track. The fish plate is placed in between the two rails, with one end of the plate in contact with the head of one rail and the other end in contact with the foot of the other rail. The point of contact between the fish plate and the rail is called the fish plane. The fish plate is bolted to the rail to secure it in place and ensure a strong and stable connection between the two rails. Fish plates are used to maintain proper alignment of the track and to distribute the load of the trains evenly across the rails.

Largest percentage of material in the rail is in its- a)head

- b)web

- c)foot

- d)heat and foot both

Correct answer is option 'A'. Can you explain this answer?

Largest percentage of material in the rail is in its

a)

head

b)

web

c)

foot

d)

heat and foot both

|

Divya Mehta answered |

The largest percentage of material in a rail is located in its head.

Explanation:

- The rail is an important component of railway tracks, which provides a stable and durable surface for train wheels to run on.

- It is typically made of steel and is designed to withstand heavy loads and constant wear and tear.

- The rail consists of three main parts: the head, the web, and the foot.