All Exams >

Mechanical Engineering >

SSC JE Mechanical Mock Test Series 2026 >

All Questions

All questions of IC Engine for Mechanical Engineering Exam

The three way catalytic converter cannot control the following emission- a)PM emission

- b)HC emission

- c)CO emission

- d)NOx emission

Correct answer is option 'A'. Can you explain this answer?

The three way catalytic converter cannot control the following emission

a)

PM emission

b)

HC emission

c)

CO emission

d)

NOx emission

|

|

Sagarika Dey answered |

Catalytic converters are called three way converters because it reduces the concentration of CO, HC and NOx in the exhaust (three concentrations).

Orsat apparatus is used to determine products of- a)All constituents of fuel combustion by mass

- b)All constituents of fuel combustion by volume

- c)Only dry constituents of combustion by mass

- d)Only dry constituents of combustion by volume

Correct answer is option 'D'. Can you explain this answer?

Orsat apparatus is used to determine products of

a)

All constituents of fuel combustion by mass

b)

All constituents of fuel combustion by volume

c)

Only dry constituents of combustion by mass

d)

Only dry constituents of combustion by volume

|

|

Neha Joshi answered |

Orsat apparatus is used to analyse the combustion products. It measure the volume fractions of CO2 and O2 in a sample of dry combustion products from the continuous combustion unit.

The indicator on an engine is used to determine:- a)IHP and Mean indicative pressure

- b)BHP

- c)Speed

- d)Temperature

Correct answer is option 'A'. Can you explain this answer?

The indicator on an engine is used to determine:

a)

IHP and Mean indicative pressure

b)

BHP

c)

Speed

d)

Temperature

|

|

Yash Patel answered |

The device which measures the variations of the pressure in the cylinder over a part or full cycle is called an indicator and the plot of such information obtained is called an indicator diagram. This shows the mean effective pressure and indicated horse power.

Engine of different cylinder dimensions, power and speed are compared on the basis of- a)Maximum pressure

- b)Fuel consumption

- c)Mean effective pressure

- d)Unit power

Correct answer is option 'C'. Can you explain this answer?

Engine of different cylinder dimensions, power and speed are compared on the basis of

a)

Maximum pressure

b)

Fuel consumption

c)

Mean effective pressure

d)

Unit power

|

Shivani Choudhury answered |

For any particular engine, operating at a given speed and power output, there will be a specific mean effective pressure, mep. This mep is used as a basis to compare the performance.

The intake charge in a diesel engine consist of- a)Air alone

- b)Air + lubricating oil

- c)Air + fuel

- d)Air + fuel + lubricating oil

Correct answer is option 'A'. Can you explain this answer?

The intake charge in a diesel engine consist of

a)

Air alone

b)

Air + lubricating oil

c)

Air + fuel

d)

Air + fuel + lubricating oil

|

Priyanka Shah answered |

In diesel engine intake is only air. The air is compressed and then the fuel is injected to the high pressure and temperature compressed air.

Mean effective pressure at a given compression ratio is maximum when the air-fuel ratio is- a)Higher than stoichiometric

- b)Lower than stoichiometric

- c)Equal to stoichiometric

- d)None of the above

Correct answer is option 'A'. Can you explain this answer?

Mean effective pressure at a given compression ratio is maximum when the air-fuel ratio is

a)

Higher than stoichiometric

b)

Lower than stoichiometric

c)

Equal to stoichiometric

d)

None of the above

|

|

Kalyan Chakraborty answered |

Understanding Mean Effective Pressure (MEP)

Mean Effective Pressure (MEP) is a crucial parameter in internal combustion engines, representing the average pressure in the combustion chamber throughout the power stroke. It directly influences the engine's performance and efficiency.

Impact of Air-Fuel Ratio on MEP

The air-fuel ratio (AFR) affects the combustion process within an engine, impacting the MEP significantly. Here’s how different ratios play a role:

Conclusion

In summary, MEP is maximized at higher than stoichiometric air-fuel ratios due to improved combustion efficiency, resulting in better engine performance and energy extraction. Balancing the AFR is vital for optimizing engine operation and efficiency.

Mean Effective Pressure (MEP) is a crucial parameter in internal combustion engines, representing the average pressure in the combustion chamber throughout the power stroke. It directly influences the engine's performance and efficiency.

Impact of Air-Fuel Ratio on MEP

The air-fuel ratio (AFR) affects the combustion process within an engine, impacting the MEP significantly. Here’s how different ratios play a role:

- Higher than Stoichiometric: When the AFR is higher than the stoichiometric value (the ideal ratio for complete combustion), there is an excess of air. This allows for more complete combustion, resulting in higher thermal efficiency and consequently higher MEP. The engine can extract more energy from the fuel, leading to improved performance.

- Lower than Stoichiometric: A lower AFR results in a rich mixture (more fuel than air). While this can increase power output temporarily, it leads to incomplete combustion, producing excess hydrocarbons and carbon monoxide. This inefficiency lowers the MEP due to wasted fuel and energy.

- Equal to Stoichiometric: At the stoichiometric ratio, combustion is optimal, but the energy extraction potential is not maximized compared to a richer mixture. Thus, while performance is decent, it does not reach the peak levels achievable with a higher AFR.

Conclusion

In summary, MEP is maximized at higher than stoichiometric air-fuel ratios due to improved combustion efficiency, resulting in better engine performance and energy extraction. Balancing the AFR is vital for optimizing engine operation and efficiency.

For the same peak pressure and heat input- a) ηOtto>ηDual>ηDiesel

- b) ηOtto>ηDiesel>ηDual

- c) ηDiesel>ηDual>ηOtto

- d) ηDiesel>ηOtto>ηDual

Correct answer is option 'C'. Can you explain this answer?

For the same peak pressure and heat input

a)

ηOtto>ηDual>ηDiesel

b)

ηOtto>ηDiesel>ηDual

c)

ηDiesel>ηDual>ηOtto

d)

ηDiesel>ηOtto>ηDual

|

Mahesh Nair answered |

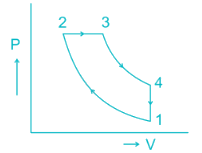

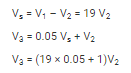

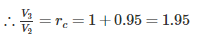

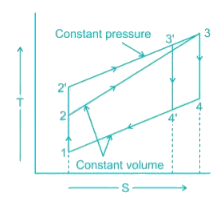

Otto cycle ⇒ 1 - 2 - 3 - 4

Diesel cycle 1 - 2’ - 3’ - 4’

It is clear from T - s diagram that the heat rejected by the Diesel cycle (area below 4’ - 1) is less than the heat rejection by the Otto cycle (area below 4 - 1); hence the diesel cycle is more efficient than Otto cycle for the condition of same maximum pressure heat input. The dual cycle efficiency lies between the Otto and Diesel cycle.

An ideal gas with heat capacity ratio of 2 is used in an ideal Otto-cycle which operates between minimum and maximum temperatures of 200 K and 1800 K. What is the compression ratio of the cycle for maximum work output?- a)1.5

- b)2

- c)3

- d)4

Correct answer is option 'C'. Can you explain this answer?

An ideal gas with heat capacity ratio of 2 is used in an ideal Otto-cycle which operates between minimum and maximum temperatures of 200 K and 1800 K. What is the compression ratio of the cycle for maximum work output?

a)

1.5

b)

2

c)

3

d)

4

|

|

Asha Basu answered |

To find the compression ratio of the ideal Otto cycle for maximum work output, we need to consider the heat capacity ratio (γ) of the gas and the given minimum and maximum temperatures.

Given:

Heat capacity ratio (γ) = 2

Minimum temperature (T1) = 200 K

Maximum temperature (T3) = 1800 K

The compression ratio (r) is given by the equation:

r = (V1/V2) = (T3/T2)^(1/(γ-1))

where V1 and V2 are the initial and final volumes of the gas, and T2 is the temperature at the end of the adiabatic compression process.

To find the compression ratio, we need to determine the value of T2. To do this, we can use the equation for adiabatic process:

T1/T2 = (V2/V1)^(γ-1)

Rearranging the equation, we get:

T2 = T1 * (V2/V1)^(γ-1)

Now we can substitute the given values to find T2:

T2 = 200 K * (V2/V1)^(2-1)

Next, we substitute the values of T1, T2, and T3 into the equation for the compression ratio:

r = (1800 K / T2)^(1/(γ-1))

Substituting the value of T2, we have:

r = (1800 K / (200 K * (V2/V1)))^(1/(γ-1))

Simplifying further:

r = (9 / (V2/V1))^(1/(γ-1))

Since the work output of the Otto cycle is maximum when the compression ratio is maximum, we need to find the maximum value of r.

As the heat capacity ratio (γ) is given as 2, the maximum value of r is obtained when the ratio of V2/V1 is minimum. In other words, V2 should be as small as possible compared to V1.

Therefore, the compression ratio for maximum work output is when V2 = V1/3, which gives:

r = (9 / (1/3))^(1/(2-1)) = 3

Hence, the correct answer is option C) 3.

Given:

Heat capacity ratio (γ) = 2

Minimum temperature (T1) = 200 K

Maximum temperature (T3) = 1800 K

The compression ratio (r) is given by the equation:

r = (V1/V2) = (T3/T2)^(1/(γ-1))

where V1 and V2 are the initial and final volumes of the gas, and T2 is the temperature at the end of the adiabatic compression process.

To find the compression ratio, we need to determine the value of T2. To do this, we can use the equation for adiabatic process:

T1/T2 = (V2/V1)^(γ-1)

Rearranging the equation, we get:

T2 = T1 * (V2/V1)^(γ-1)

Now we can substitute the given values to find T2:

T2 = 200 K * (V2/V1)^(2-1)

Next, we substitute the values of T1, T2, and T3 into the equation for the compression ratio:

r = (1800 K / T2)^(1/(γ-1))

Substituting the value of T2, we have:

r = (1800 K / (200 K * (V2/V1)))^(1/(γ-1))

Simplifying further:

r = (9 / (V2/V1))^(1/(γ-1))

Since the work output of the Otto cycle is maximum when the compression ratio is maximum, we need to find the maximum value of r.

As the heat capacity ratio (γ) is given as 2, the maximum value of r is obtained when the ratio of V2/V1 is minimum. In other words, V2 should be as small as possible compared to V1.

Therefore, the compression ratio for maximum work output is when V2 = V1/3, which gives:

r = (9 / (1/3))^(1/(2-1)) = 3

Hence, the correct answer is option C) 3.

Exhaust gas recirculation has the disadvantage of- a)Decreasing thermal efficiency

- b)Increasing HC emission

- c)Both a and b

- d)Increasing aldehydes

Correct answer is option 'C'. Can you explain this answer?

Exhaust gas recirculation has the disadvantage of

a)

Decreasing thermal efficiency

b)

Increasing HC emission

c)

Both a and b

d)

Increasing aldehydes

|

Dipika Nambiar answered |

Although Exhaust Gas Recirculation (EGR) reduces the maximum temperature in the combustion chamber but it also lowers the overall combustion efficiency. Increase in EGR results in some cycle partial burns and in the extreme, total misfires. Thus, by using EGR to reduce NOX emissions, a costly price of increased HC emission and lower thermal efficiency must be paid.

A fuel is a mixture of 60% methane and 30% carbon mono-oxide and 10% oxygen by volume. Calculate the stoichiometric oxygen needed.- a)1.35 m3

- b)1.25 m3

- c)1 m3

- d)2 m3

Correct answer is option 'B'. Can you explain this answer?

A fuel is a mixture of 60% methane and 30% carbon mono-oxide and 10% oxygen by volume. Calculate the stoichiometric oxygen needed.

a)

1.35 m3

b)

1.25 m3

c)

1 m3

d)

2 m3

|

|

Anshul Sharma answered |

CH4 + 202 → CO2 + 2 H2O

∴ 1 m3 of methane requires 2 m3 of oxygen

∴ 0.6 m3 of methane requires 1.2 m3 of oxygen

2 CO + O2 → 2 CO2

1 m3 of CO requires 0.5 m3 of oxygen, so 0.3 m3 of CO requires 0.15 m3 of oxygen

∴ Total oxygen requires = 1.2 + 0.15 = 1.35 m3

Oxygen already present = 0.1 m3

∴ Stoichiometric oxygen needed = 1.25 m3

Octane number of gasoline is a measure of its:- a)Knocking tendency

- b)Ignition delay

- c)Ignition temperature

- d)Smoke point

Correct answer is option 'A'. Can you explain this answer?

Octane number of gasoline is a measure of its:

a)

Knocking tendency

b)

Ignition delay

c)

Ignition temperature

d)

Smoke point

|

Rahul Chatterjee answered |

An octane number is a measure of the knocking tendency of gasoline fuels in spark ignition engines. The ability of a fuel to resist auto-ignition during compression and prior to the spark ignition gives it a high octane number. Two octane tests can be performed for gasoline.

What is the number of cycles completed per second for a four stroke diesel engine running at 6000 rpm?- a)50

- b)500

- c)6000

- d)3000

Correct answer is option 'A'. Can you explain this answer?

What is the number of cycles completed per second for a four stroke diesel engine running at 6000 rpm?

a)

50

b)

500

c)

6000

d)

3000

|

Preethi Datta answered |

Engine speed = 6000 RPM.

One cycle in four stroke requires two revolutions. So Number of cycles per minute = 6000/2 = 3000 cycles.

So number of cycles per minute = 3000/60 = 50 cycles

The adiabatic flame temperature of a reaction is controlled by- a)Pressure regulation

- b)Changing the masses of reactants

- c)The amount of excess air supplied

- d)Changing the reactor volume

Correct answer is option 'C'. Can you explain this answer?

The adiabatic flame temperature of a reaction is controlled by

a)

Pressure regulation

b)

Changing the masses of reactants

c)

The amount of excess air supplied

d)

Changing the reactor volume

|

|

Kritika Joshi answered |

Adiabatic flame temperature refers to the temperature reached during a combustion reaction when no heat is exchanged with the surroundings. It is a critical parameter in the design and optimization of combustion systems. Several factors can influence the adiabatic flame temperature, including pressure regulation, reactant masses, the amount of excess air supplied, and reactor volume.

Pressure Regulation:

- Pressure regulation refers to controlling the pressure at which the combustion reaction takes place.

- Changing the pressure can affect the adiabatic flame temperature by altering the equilibrium composition of the reaction products.

- Higher pressures can favor the formation of more stable products, leading to a higher adiabatic flame temperature. Conversely, lower pressures can result in lower temperatures.

Changing the Reactant Masses:

- The masses of reactants can influence the adiabatic flame temperature by changing the stoichiometry of the reaction.

- The stoichiometry determines the amount of heat released during combustion.

- Increasing the mass of one reactant while keeping the other constant can result in more heat release, leading to a higher adiabatic flame temperature.

The Amount of Excess Air Supplied:

- Excess air refers to the amount of air supplied to the combustion process beyond the stoichiometric requirement.

- The amount of excess air affects the availability of oxygen for combustion.

- Increasing the amount of excess air can result in more complete combustion and higher adiabatic flame temperatures.

- Conversely, reducing the excess air can lead to incomplete combustion and lower temperatures.

Changing the Reactor Volume:

- The reactor volume refers to the space in which the combustion reaction occurs.

- Changing the reactor volume can influence the residence time of reactants and products.

- A larger reactor volume can allow for more complete combustion and higher adiabatic flame temperatures.

- Conversely, a smaller reactor volume can result in shorter residence times and incomplete combustion, leading to lower temperatures.

Conclusion:

Among the given options, the amount of excess air supplied (option C) is the most significant factor controlling the adiabatic flame temperature. By adjusting the amount of excess air, the availability of oxygen for combustion is regulated, resulting in variations in the completeness of combustion and consequently affecting the adiabatic flame temperature. The other options, such as pressure regulation, changing reactant masses, and reactor volume, can also have an impact on the adiabatic flame temperature but to a lesser extent compared to the amount of excess air supplied.

Pressure Regulation:

- Pressure regulation refers to controlling the pressure at which the combustion reaction takes place.

- Changing the pressure can affect the adiabatic flame temperature by altering the equilibrium composition of the reaction products.

- Higher pressures can favor the formation of more stable products, leading to a higher adiabatic flame temperature. Conversely, lower pressures can result in lower temperatures.

Changing the Reactant Masses:

- The masses of reactants can influence the adiabatic flame temperature by changing the stoichiometry of the reaction.

- The stoichiometry determines the amount of heat released during combustion.

- Increasing the mass of one reactant while keeping the other constant can result in more heat release, leading to a higher adiabatic flame temperature.

The Amount of Excess Air Supplied:

- Excess air refers to the amount of air supplied to the combustion process beyond the stoichiometric requirement.

- The amount of excess air affects the availability of oxygen for combustion.

- Increasing the amount of excess air can result in more complete combustion and higher adiabatic flame temperatures.

- Conversely, reducing the excess air can lead to incomplete combustion and lower temperatures.

Changing the Reactor Volume:

- The reactor volume refers to the space in which the combustion reaction occurs.

- Changing the reactor volume can influence the residence time of reactants and products.

- A larger reactor volume can allow for more complete combustion and higher adiabatic flame temperatures.

- Conversely, a smaller reactor volume can result in shorter residence times and incomplete combustion, leading to lower temperatures.

Conclusion:

Among the given options, the amount of excess air supplied (option C) is the most significant factor controlling the adiabatic flame temperature. By adjusting the amount of excess air, the availability of oxygen for combustion is regulated, resulting in variations in the completeness of combustion and consequently affecting the adiabatic flame temperature. The other options, such as pressure regulation, changing reactant masses, and reactor volume, can also have an impact on the adiabatic flame temperature but to a lesser extent compared to the amount of excess air supplied.

The process scavenging is relevant in- a)Four-stroke engine

- b)Two-stroke engine

- c)Petrol engine

- d)Diesel engine

Correct answer is option 'B'. Can you explain this answer?

The process scavenging is relevant in

a)

Four-stroke engine

b)

Two-stroke engine

c)

Petrol engine

d)

Diesel engine

|

|

Anu Deshpande answered |

Scavenging in Two-Stroke Engines

Scavenging is a process that is relevant in a two-stroke engine. A two-stroke engine is a type of internal combustion engine that completes one power cycle with two strokes of the piston, compared to a four-stroke engine that requires four strokes of the piston to complete one power cycle. Scavenging is an important process in a two-stroke engine as it ensures efficient fuel-air mixing and removal of exhaust gases from the cylinder.

Scavenging Process

The scavenging process in a two-stroke engine involves the following steps:

1. Exhaust Stroke: During the first stroke, known as the exhaust stroke, the piston moves upwards, compressing the fuel-air mixture in the combustion chamber. As the piston reaches the top of its stroke, the exhaust port opens, allowing the exhaust gases to escape.

2. Scavenging Stroke: In the second stroke, known as the scavenging stroke, the piston moves downwards. As it descends, it uncovers the intake port, allowing fresh fuel-air mixture to enter the combustion chamber. This process is aided by the presence of a scavenging air blower or a scavenging air pump, which helps in forcing the fresh mixture into the cylinder.

3. Scavenging Air Flow: The scavenging air flow is crucial for effective scavenging. The direction and velocity of the scavenging air flow determine the efficiency of the process. The incoming fresh mixture should effectively displace the exhaust gases and ensure thorough mixing for a complete combustion process.

4. Controlled Port Timing: The timing of the exhaust and intake ports is critical for optimal scavenging. The opening and closing of the ports should be precisely controlled to ensure efficient flow of exhaust gases out of the cylinder and the entry of fresh mixture without any overlap.

5. Efficient Combustion: The scavenging process plays a significant role in achieving efficient combustion in a two-stroke engine. Proper scavenging ensures that the combustion chamber is filled with a fresh fuel-air mixture, leading to improved power output and reduced emissions.

Conclusion

In conclusion, scavenging is a crucial process in a two-stroke engine. It involves the removal of exhaust gases and the intake of fresh fuel-air mixture. The scavenging process ensures efficient combustion, leading to improved engine performance and reduced emissions.

Scavenging is a process that is relevant in a two-stroke engine. A two-stroke engine is a type of internal combustion engine that completes one power cycle with two strokes of the piston, compared to a four-stroke engine that requires four strokes of the piston to complete one power cycle. Scavenging is an important process in a two-stroke engine as it ensures efficient fuel-air mixing and removal of exhaust gases from the cylinder.

Scavenging Process

The scavenging process in a two-stroke engine involves the following steps:

1. Exhaust Stroke: During the first stroke, known as the exhaust stroke, the piston moves upwards, compressing the fuel-air mixture in the combustion chamber. As the piston reaches the top of its stroke, the exhaust port opens, allowing the exhaust gases to escape.

2. Scavenging Stroke: In the second stroke, known as the scavenging stroke, the piston moves downwards. As it descends, it uncovers the intake port, allowing fresh fuel-air mixture to enter the combustion chamber. This process is aided by the presence of a scavenging air blower or a scavenging air pump, which helps in forcing the fresh mixture into the cylinder.

3. Scavenging Air Flow: The scavenging air flow is crucial for effective scavenging. The direction and velocity of the scavenging air flow determine the efficiency of the process. The incoming fresh mixture should effectively displace the exhaust gases and ensure thorough mixing for a complete combustion process.

4. Controlled Port Timing: The timing of the exhaust and intake ports is critical for optimal scavenging. The opening and closing of the ports should be precisely controlled to ensure efficient flow of exhaust gases out of the cylinder and the entry of fresh mixture without any overlap.

5. Efficient Combustion: The scavenging process plays a significant role in achieving efficient combustion in a two-stroke engine. Proper scavenging ensures that the combustion chamber is filled with a fresh fuel-air mixture, leading to improved power output and reduced emissions.

Conclusion

In conclusion, scavenging is a crucial process in a two-stroke engine. It involves the removal of exhaust gases and the intake of fresh fuel-air mixture. The scavenging process ensures efficient combustion, leading to improved engine performance and reduced emissions.

Knocking in spark ignition engine can be reduced by- a)Increasing the compression ratio

- b)Increasing the inlet air temperature

- c)Increasing the coolant water temperature

- d)Retarding the spark advance

Correct answer is option 'D'. Can you explain this answer?

Knocking in spark ignition engine can be reduced by

a)

Increasing the compression ratio

b)

Increasing the inlet air temperature

c)

Increasing the coolant water temperature

d)

Retarding the spark advance

|

Shalini Deshpande answered |

Factors affecting knocking in SI engine:

i) Compression ratio:- Higher compression ratio will result in higher temperature of the charge, tendency to knock will increase.

ii) Inlet air temperature:- The effect of inlet air temp is same as compression ratio. High inlet temp of the air fuel mixture will increase knocking.

iii) Advancing the spark:- Advancing the spark will result in more compression during sparking. The increase in temperature during the sparking will be higher. Hence tendency to knock will increase and so by retarding the spark, the tendency to knock will decrease.

iv) Coolant water temperature:- By increasing coolant water temperature, less heat will be carried from the engine which will increase the engine temperature. So the knocking will increase.

________ is a transmission dynamometer -- a)Hydraulic dynamometer

- b)Prony brake dynamometer

- c)Rope brake dynamometer

- d)None of the above

Correct answer is option 'D'. Can you explain this answer?

________ is a transmission dynamometer -

a)

Hydraulic dynamometer

b)

Prony brake dynamometer

c)

Rope brake dynamometer

d)

None of the above

|

|

Pritam Jain answered |

A dynamometer is a device used for measuring the torque and brake power required to operate a driven machine. It has a device to measure the frictional resistance.

Following are the two types of dynamometers, used for measuring the brake power of an engine.

1. Absorption dynamometers: The entire energy or power produced by the dynamometer is absorbed by the friction resistances of the brake and is transformed into heat, during the process of measurement.

Example: Prony brake dynamometer, Rope brake dynamometer, Hydraulic dynamometer

2. Transmission dynamometers: The energy is not wasted in friction but is used for doing work. The energy or power produced by the engine is transmitted through the dynamometer to some other machines where the power developed is suitably measured.

Example: Epicyclic-train dynamometer, Belt transmission dynamometer, Torsion dynamometer.

The compression ratio for petrol engines is:- a)3 to 6

- b)8 to 10

- c)20 to 30

- d)15 to 20

Correct answer is option 'B'. Can you explain this answer?

The compression ratio for petrol engines is:

a)

3 to 6

b)

8 to 10

c)

20 to 30

d)

15 to 20

|

Aditya Jain answered |

The normal range of compression ratio for diesel engine is 16 to 20 whereas for spark ignition engines it is 6 to 10. Due to higher compression ratios used in diesel engines the efficiency of a diesel engine is more than that of the gasoline engine.

An SI engine sometimes continues to run for a very small period even after the ignition is switched off. This phenomenon is called- a)Over burning

- b)Pull up period

- c)Dieseling

- d)Throttle sticking

Correct answer is option 'C'. Can you explain this answer?

An SI engine sometimes continues to run for a very small period even after the ignition is switched off. This phenomenon is called

a)

Over burning

b)

Pull up period

c)

Dieseling

d)

Throttle sticking

|

|

Raghav Saini answered |

Dieseling is the phenomenon in which an SI engine sometimes continues to run for a very small period even after the ignition is switched off. Dieseling may take place due to following reasons:

- Engine overheating

- Too high spark plug heat range

- High engine idling speed

- Oil entry into the cylinder

- Increase in compression ratio due to carbon deposits

- Incorrect adjustment of idle fuel-air mixture

- Sticking of throttle

- Requirement of tune up of engine

Octane number of natural gas is- a)60 - 80

- b)80 - 100

- c)> 100

- d)< 60

Correct answer is option 'C'. Can you explain this answer?

Octane number of natural gas is

a)

60 - 80

b)

80 - 100

c)

> 100

d)

< 60

|

|

Sparsh Chakraborty answered |

Octane number of natural gas is around 110 which makes it a very good SI engine fuel. Because of this high octane number the flame speed is higher and engine can operate with high compression ratio.

Detonation in the SI engine becomes severe during- a)Low load and high speed

- b)High load and high speed

- c)Low load and low speed

- d)High load and low speed

Correct answer is option 'D'. Can you explain this answer?

Detonation in the SI engine becomes severe during

a)

Low load and high speed

b)

High load and high speed

c)

Low load and low speed

d)

High load and low speed

|

|

Pritam Das answered |

Detonation in SI engine will become severe at high load and low speed because at higher loads, the temperature of cylinder and combustion chamber walls will be higher and hence temperature of the end charge will be more which increases knocking tendency in SI engine.

And at lower engine speed, longer will be the absolute time for the flame to traverse the cylinder which increases the time available for pre flame reactions hence the tendency to knock increases.

By higher octane number of SI fuel, it means that fuel has- a)Higher heating value

- b)Higher flash point

- c)Lower volatility

- d)Longer ignition delay

Correct answer is option 'D'. Can you explain this answer?

By higher octane number of SI fuel, it means that fuel has

a)

Higher heating value

b)

Higher flash point

c)

Lower volatility

d)

Longer ignition delay

|

|

Disha Nambiar answered |

Higher octane is related only to longer ignition delay which prevents knocking. High octane fuel itself don’t increase the power or enhance any other property of fuel

A gas engine has a swept volume of 200 cm3 and clearance volume 20 cm3. The mechanical efficiency is 0.9 and the volumetric efficiency 0.85. The volume of the mixture taken in per stroke will be- a)1683 cm3

- b)170 cm3

- c)180 cm3

- d)190 cm3

Correct answer is option 'B'. Can you explain this answer?

A gas engine has a swept volume of 200 cm3 and clearance volume 20 cm3. The mechanical efficiency is 0.9 and the volumetric efficiency 0.85. The volume of the mixture taken in per stroke will be

a)

1683 cm3

b)

170 cm3

c)

180 cm3

d)

190 cm3

|

|

Stuti Bajaj answered |

Volumetricefficiency=

∴ Actual intake volume = 200 × 0.85 = 170 cm3

Brake specific fuel consumption is defined as- a)Fuel consumption per hour

- b)Fuel consumption per km

- c)Fuel consumption per b.p

- d)Fuel consumption per brake power hour

Correct answer is option 'D'. Can you explain this answer?

Brake specific fuel consumption is defined as

a)

Fuel consumption per hour

b)

Fuel consumption per km

c)

Fuel consumption per b.p

d)

Fuel consumption per brake power hour

|

Dipika Nambiar answered |

The meaning of bsfc is how much fuel is consume in one hour to produce one kilowatt brake power(i.e. power available at engine shaft not power produce into engine block).

It is used to measure fuel efficiency and also to compare internal combustion engine on basis of shaft power.

Morse test is carried out to determine ______ of an engine:- a)I.H.P.

- b)F.H.P.

- c)B.H.P.

- d)Efficiency

Correct answer is option 'A'. Can you explain this answer?

Morse test is carried out to determine ______ of an engine:

a)

I.H.P.

b)

F.H.P.

c)

B.H.P.

d)

Efficiency

|

Athira Pillai answered |

Morse test is a very useful test designed for multi cylinder engines. Its primary objective is to determine the indicated power developed by each cylinder. The indicated power is the sum of break horse power plus the frictional power losses.

For CI engines, fuels most preferred are- a)Naphthalene

- b)Paraffins

- c)Olefins

- d)Aromatics

Correct answer is option 'B'. Can you explain this answer?

For CI engines, fuels most preferred are

a)

Naphthalene

b)

Paraffins

c)

Olefins

d)

Aromatics

|

|

Ashish Pillai answered |

For CI engines, the normal paraffin’s are the best fuels and aromatics are the least desirable.

For SI engines the aromatics are the best fuel and the paraffins are least desirable.

The reason for this is normal paraffins exhibit the poorest antiknock quality when used in SI engines. But the antiknock quality improves with the increasing number of carbon atoms and the compactness of the molecular structure. The aromatics offer the best resistance to knocking in SI Engines.

Which is the wrong assumption for calculation of air standard efficiency?- a)All processes are reversible

- b)Specific heat remains constant at all temperatures

- c)No account of the mechanism of heat transfer is considered

- d)Gases dissociate at higher temperatures

Correct answer is option 'D'. Can you explain this answer?

Which is the wrong assumption for calculation of air standard efficiency?

a)

All processes are reversible

b)

Specific heat remains constant at all temperatures

c)

No account of the mechanism of heat transfer is considered

d)

Gases dissociate at higher temperatures

|

Nidhi Patel answered |

To simplify analysis, the following assumptions are made for calculation of air standard efficiency:

1. The working fluid is air, which continuously circulates in a closed loop and always behaves as an ideal gas.

2. All the processes that make up the cycle are internally reversible.

3. The combustion process is replaced by a heat - addition process from an external source.

4. The exhaust process is replaced by a heat - rejection process that restores the working fluid to its initial state.

In an SI engine very high compression ratio cannot be used because- a)The engine efficiency would be unmanageably high

- b)The power required for compression would be high, so cylinders will require very thick walls

- c)Cylinder will require very thick walls

- d)Self-ignition may take place before the spark occurs

Correct answer is option 'D'. Can you explain this answer?

In an SI engine very high compression ratio cannot be used because

a)

The engine efficiency would be unmanageably high

b)

The power required for compression would be high, so cylinders will require very thick walls

c)

Cylinder will require very thick walls

d)

Self-ignition may take place before the spark occurs

|

|

Anirudh Banerjee answered |

If a very high compression ratio is used, than the petrol will reach its self to the ignition temperature before the spark and the knocking will also occur. So compression ratio of petrol engine is less.

Which gas will produce the highest efficiency in an ideal Otto cycle for same compression ratio?- a)Air

- b)Carbon dioxide

- c)Helium

- d)Oxygen

Correct answer is option 'C'. Can you explain this answer?

Which gas will produce the highest efficiency in an ideal Otto cycle for same compression ratio?

a)

Air

b)

Carbon dioxide

c)

Helium

d)

Oxygen

|

Meghana Desai answered |

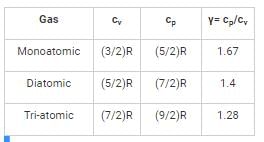

The efficiency of Otto cycle is given as η=1−(1r)γ−1η=1−(1r)γ−1

Higher the value of γ more will be the efficiency for same compression ratio. The value of γ for the different type of gases is given below

γ monoatomic > γdiatomic > γtriatomic

So out of given options Helium is mono atomic, so efficiency will be highest for Helium for a given compression ratio.

With increase in compression ratio, flame speed- a)Increases

- b)Decreases

- c)Remains the same

- d)First decreases and then increases

Correct answer is option 'A'. Can you explain this answer?

With increase in compression ratio, flame speed

a)

Increases

b)

Decreases

c)

Remains the same

d)

First decreases and then increases

|

|

Suyash Kumar answered |

Increased compression ratio reduces the clearance volume and therefore increases the density of the cylinder gases during burning. This increases the peak pressure and temperature and the total combustion duration is reduced. Thus engines having higher compression ratio have higher flame speed.

The efficiency of Diesel cycle approaches to Otto cycle efficiency when:- a)Cut-off is increased

- b)Cut-off is zero

- c)Cut-off is decreased

- d)Cut-off is constant

Correct answer is option 'B'. Can you explain this answer?

The efficiency of Diesel cycle approaches to Otto cycle efficiency when:

a)

Cut-off is increased

b)

Cut-off is zero

c)

Cut-off is decreased

d)

Cut-off is constant

|

Harsh Khanna answered |

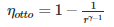

When cut off ratio (α) is equal to zero then the efficiency of Diesel cycle approaches to Otto cycle efficiency.

A four-stroke petrol engine at full load delivers 50 kW. It requires 8.5 kW to rotate it without load at the same speed. Find its mechanical efficiency (in %) at half load.- a)65

- b)75

- c)80

- d)50

Correct answer is option 'B'. Can you explain this answer?

A four-stroke petrol engine at full load delivers 50 kW. It requires 8.5 kW to rotate it without load at the same speed. Find its mechanical efficiency (in %) at half load.

a)

65

b)

75

c)

80

d)

50

|

Niharika Yadav answered |

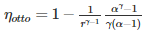

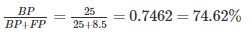

Mechanical efficiency at half load =

Pour point of fuel oil is the- a)Minimum temperature to which oil is heated in order to give off inflammable vapours in sufficient quantity to ignite momentarily when brought in contact with a flame.

- b)Temperature at which it solidifies or congeals.

- c)Indicated by 90% distillation temperature i.e., when 90% of sample oil has distilled off.

- d)Temperature at which it flows easily.

Correct answer is option 'B'. Can you explain this answer?

Pour point of fuel oil is the

a)

Minimum temperature to which oil is heated in order to give off inflammable vapours in sufficient quantity to ignite momentarily when brought in contact with a flame.

b)

Temperature at which it solidifies or congeals.

c)

Indicated by 90% distillation temperature i.e., when 90% of sample oil has distilled off.

d)

Temperature at which it flows easily.

|

|

Mansi Rane answered |

The pour point in that temperatures just about which the oil sample will not flow under certain prescribed conditions. In other words, pour point of a liquid is the temperature below which the liquid loses its flow characteristics.

A single - cylinder engine running at 1800 rpm develops a torque of 8 N - m. The indicated power of the engine is 1.8 kW. The loss due to friction power in the percentage is- a)22.6%

- b)13.1%

- c)28.5%

- d)16.22%

Correct answer is option 'D'. Can you explain this answer?

A single - cylinder engine running at 1800 rpm develops a torque of 8 N - m. The indicated power of the engine is 1.8 kW. The loss due to friction power in the percentage is

a)

22.6%

b)

13.1%

c)

28.5%

d)

16.22%

|

|

Rajat Khanna answered |

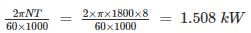

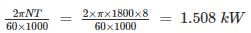

Brakepower=

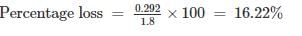

Friction power = Indicated Power – Brake Power = 1.8 - 1.508 = 0.292

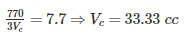

The engine of a car has three cylinder with total displacement of 770 cc. The compression ratio is 8.7. What is the clearance volume of each cylinder?- a)34.4 cc

- b)33.33 cc

- c)32.33 cc

- d)35.2 cc

Correct answer is option 'B'. Can you explain this answer?

The engine of a car has three cylinder with total displacement of 770 cc. The compression ratio is 8.7. What is the clearance volume of each cylinder?

a)

34.4 cc

b)

33.33 cc

c)

32.33 cc

d)

35.2 cc

|

Rounak Mehta answered |

Now total displaced volume for three cylinders is 770 cc. So for one cylinder the VS = 770/3 cc

The combustion in a compression ignition engine is ________.- a)heterogeneous

- b)homogeneous

- c)laminar

- d)turbulent

Correct answer is option 'A'. Can you explain this answer?

The combustion in a compression ignition engine is ________.

a)

heterogeneous

b)

homogeneous

c)

laminar

d)

turbulent

|

|

Pankaj Joshi answered |

Homogeneous compression ignition is a form of internal combustion in which air and fuel are well mixed at the point of combustion. On the other hand, in heterogenous combustion engine, the air and fuel are not mixed till the point of combustion. In CI engines or diesel engine, only air is compressed and then the fuel is injected at the last stage. So no proper mixing before combustion takes place. So the CI engines are heterogenous combustion engines.

In SI engines, maximum flame speed is obtained when the equivalence ratio is between- a)1.1 and 1.2

- b)1.0 and 1.1

- c)1.2 and 1.3

- d)Less than 1.0

Correct answer is option 'A'. Can you explain this answer?

In SI engines, maximum flame speed is obtained when the equivalence ratio is between

a)

1.1 and 1.2

b)

1.0 and 1.1

c)

1.2 and 1.3

d)

Less than 1.0

|

|

Sai Reddy answered |

The ratio of actual fuel air ratio to stoichiometric fuel air ratio is called equivalence ratio.

The highest flame velocities are obtained with somewhat richer mixture of equivalence ratio 1.1 to 1.2. When the mixture is made leaner or richer the flame speed decreases. Less thermal energy is released in case of lean mixture resulting in lower flame temperature. Very rich mixture leads to the incomplete combustion which results again in the release of less thermal energy.

Volumetric efficiency is a measure of - a)Speed

- b)Power

- c)Maximum power

- d)Breathing capacity

Correct answer is option 'D'. Can you explain this answer?

Volumetric efficiency is a measure of

a)

Speed

b)

Power

c)

Maximum power

d)

Breathing capacity

|

|

Anshul Basu answered |

Volumetric efficiency is defined as the ratio of actual volume flow rate of air into the system to the rate at which the volume is displaced by the system.

It indicates the breathing capacity of the system. It is to be noted that the utilization of the air is that determines the power output of the engine. Intake system must be designed in such a way that the engine must be able to take in as much air as possible.

The magneto in an automobile is basically a/an- a)AC generator

- b)DC generator

- c)Magnetic coil

- d)Transformer

Correct answer is option 'B'. Can you explain this answer?

The magneto in an automobile is basically a/an

a)

AC generator

b)

DC generator

c)

Magnetic coil

d)

Transformer

|

|

Nandita Chakraborty answered |

magneto is a special type of electric generator. It is mounted on the engine and replaces all the components of the coil ignition system except the spark plug. A magneto, when rotated by the engine, is capable of producing very high voltage and does not need a battery as a source of external energy.

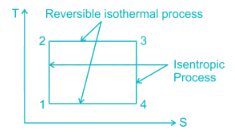

The four process of the Carnot cycles are- a)Two reversible adiabatic and two reversible isobaric process

- b)Two reversible isothermal and two reversible adiabatic process

- c)All four are isentropic processes

- d)Two reversible isochoric processes and two reversible isobaric processes

Correct answer is option 'B'. Can you explain this answer?

The four process of the Carnot cycles are

a)

Two reversible adiabatic and two reversible isobaric process

b)

Two reversible isothermal and two reversible adiabatic process

c)

All four are isentropic processes

d)

Two reversible isochoric processes and two reversible isobaric processes

|

|

Kritika Joshi answered |

Carnot cycle consists of two reversible isothermal and two isentropic process.

An SI engine sometimes continues to run for a very small period even after the ignition is switched off. This phenomenon is called- a)Over burning

- b)Pull up period

- c)Dieseling

- d)Throttle sticking

Correct answer is option 'C'. Can you explain this answer?

An SI engine sometimes continues to run for a very small period even after the ignition is switched off. This phenomenon is called

a)

Over burning

b)

Pull up period

c)

Dieseling

d)

Throttle sticking

|

Neha Mukherjee answered |

Dieseling is the phenomenon in which an SI engine sometimes continues to run for a very small period even after the ignition is switched off. Dieseling may take place due to following reasons:

- Engine overheating

- Too high spark plug heat range

- High engine idling speed

- Oil entry into the cylinder

- Increase in compression ratio due to carbon deposits

- Incorrect adjustment of idle fuel-air mixture

- Sticking of throttle

- Requirement of tune up of engine

Chapter doubts & questions for IC Engine - SSC JE Mechanical Mock Test Series 2026 2025 is part of Mechanical Engineering exam preparation. The chapters have been prepared according to the Mechanical Engineering exam syllabus. The Chapter doubts & questions, notes, tests & MCQs are made for Mechanical Engineering 2025 Exam. Find important definitions, questions, notes, meanings, examples, exercises, MCQs and online tests here.

Chapter doubts & questions of IC Engine - SSC JE Mechanical Mock Test Series 2026 in English & Hindi are available as part of Mechanical Engineering exam.

Download more important topics, notes, lectures and mock test series for Mechanical Engineering Exam by signing up for free.

SSC JE Mechanical Mock Test Series 2026

3 videos|1 docs|55 tests

|

Contact Support

Our team is online on weekdays between 10 AM - 7 PM

Typical reply within 3 hours

|

Free Exam Preparation

at your Fingertips!

Access Free Study Material - Test Series, Structured Courses, Free Videos & Study Notes and Prepare for Your Exam With Ease

Join the 10M+ students on EduRev

Join the 10M+ students on EduRev

|

|

Create your account for free

OR

Forgot Password

OR

Signup to see your scores

go up

within 7 days!

within 7 days!

Takes less than 10 seconds to signup