All Exams >

Electrical Engineering (EE) >

RRB JE for Electrical Engineering >

All Questions

All questions of Utilization of Electrical Energy for Electrical Engineering (EE) Exam

The process of depositing one metal over the other metal is known as:- a)Electrodeposition

- b)Electro metallization

- c)Electrofacing

- d)Anodizing

Correct answer is option 'A'. Can you explain this answer?

The process of depositing one metal over the other metal is known as:

a)

Electrodeposition

b)

Electro metallization

c)

Electrofacing

d)

Anodizing

|

Rahul Chatterjee answered |

Electrodeposition is a well-known method to produce in situ metallic coatings by the action of an electric current on a conductive material immersed in a solution containing a salt of the metal to be deposited.

When a sodium vapor lamp is switched on, initially the color is:- a)Red

- b)Pink

- c)Yellow

- d)Blue

Correct answer is option 'B'. Can you explain this answer?

When a sodium vapor lamp is switched on, initially the color is:

a)

Red

b)

Pink

c)

Yellow

d)

Blue

|

|

Samridhi Bose answered |

Initially the sodium is in the form of a sloid, deposited on the walls of inner tube. When sufficient voltage is impressed across the electrodes, the discharge starts in the inert gas (neon). It operates as a low pressure neon lamp with pink colour

In dielectric heating, the current flows through:- a)Air

- b)Dielectric

- c)Metallic conductor

- d)The ionic discharge between dielectric medium and metallic conductor

Correct answer is option 'B'. Can you explain this answer?

In dielectric heating, the current flows through:

a)

Air

b)

Dielectric

c)

Metallic conductor

d)

The ionic discharge between dielectric medium and metallic conductor

|

Partho Choudhary answered |

Upon application of an alternating electrical field, a displacement current caused by polarization and a conduction current caused by the presence of free, electrically charged particles appear in the dielectric. The flow of the total current causes the liberation of heat.

The luminous efficiency of a sodium vapour lamp is:- a)40-50 lumens/W

- b)50-100 lumens/W

- c)120-200 lumens/W

- d)10-12 lumens/W

Correct answer is option 'A'. Can you explain this answer?

The luminous efficiency of a sodium vapour lamp is:

a)

40-50 lumens/W

b)

50-100 lumens/W

c)

120-200 lumens/W

d)

10-12 lumens/W

|

|

Krish Saini answered |

Ratings of normal sodium vapour lamp:

1) The efficiency of sodium vapour lamp is lies between 40 and 50 lumens/W

2) Normally these lamps are manufactured in 45 W, 60 W, 85 W and 140 W ratings

3) The normal operating temperatures of these lamps are 300° C

4) The average value life of the sodium vapour lamp is 3000 hr and these are not affected by voltage variations

In induction heating, which of the following is of high value?- a)Frequency

- b)Current

- c)Voltage

- d)Power factor

Correct answer is option 'A'. Can you explain this answer?

In induction heating, which of the following is of high value?

a)

Frequency

b)

Current

c)

Voltage

d)

Power factor

|

|

Krish Saini answered |

The heating of the conducting materials, such as ferro magnetic and non-ferro-magnetic materials is known as induction heating

In induction heating, high frequency heating is applied to the materials

Trapezoidal speed-time curve pertains to:- a)Main line service

- b)Urban service

- c)Suburban service

- d)urban/suburban service

Correct answer is option 'A'. Can you explain this answer?

Trapezoidal speed-time curve pertains to:

a)

Main line service

b)

Urban service

c)

Suburban service

d)

urban/suburban service

|

|

Anirban Gupta answered |

Main line services: The distance between two stops is usually more than 10 km. High balancing speeds should be required. Acceleration and retardation are not so important

Urban service: The distance between two stops is very less and it is less than 1 km. It requires high average speed for frequent starting and stopping

Sub urban service: The distance between two stops is between 1 km and 8 km. This service requires rapid acceleration and retardation as frequent starting and stopping is required

In main line service, free running period is more. Hence Trapezoidal speed-time curve pertains to main line service

In electric discharge lamps, for stabilization of arc:- a)A choke is connected in series with the supply

- b)A variable resistance is connected in series the circuit

- c)A condenser is connected across the supply

- d)Any of the above

Correct answer is option 'A'. Can you explain this answer?

In electric discharge lamps, for stabilization of arc:

a)

A choke is connected in series with the supply

b)

A variable resistance is connected in series the circuit

c)

A condenser is connected across the supply

d)

Any of the above

|

|

Debanshi Iyer answered |

In electric discharge lamps, a choke is connected in series with the supply to limit the starting current and to stabilize the arc.

The process of providing an oxide film is known as:- a)Electrodeposition

- b)Electro metallization

- c)Electro facing

- d)Anodizing

Correct answer is option 'D'. Can you explain this answer?

The process of providing an oxide film is known as:

a)

Electrodeposition

b)

Electro metallization

c)

Electro facing

d)

Anodizing

|

|

Samridhi Bose answered |

Electrodeposition: It is the process by which one metal is deposited over other metal or non-metal by electrolysis

Electro metallization: It is the process by which the metal can be deposited on a conduction base for decoration and for protective purposes. Any non-conductive base is made as conductive by depositing graphite layer over it

Electro facing: It is the process of the coating of a metallic surface with a harder metal by electrodeposition

Anodizing: The process of deposition of oxide film on a metal surface is known as anodizing and oxidation

Which of the followings falls under the category of the plastic or non-fusion welding?- a)Resistance welding

- b)Electron beam welding

- c)Electro-slag welding

- d)Arc welding

Correct answer is option 'A'. Can you explain this answer?

Which of the followings falls under the category of the plastic or non-fusion welding?

a)

Resistance welding

b)

Electron beam welding

c)

Electro-slag welding

d)

Arc welding

|

|

Samridhi Bose answered |

Plastic or Non fusion welding: In this welding, the pieces of metal to be joined are heated to a plastic state and then forced together by external pressure. This procedure is used in forge welding, resistance welding, thermit welding and gas welding.

Fusion or Non pressure welding: In the fusion welding, the material at the joint is heated to a molten state and allowed to solidify. This includes gas welding, arc welding etc.

Cold welding: In this welding, the joints are produced without the application of heat but by applying pressure which results in inter-surface molecular fusion of the parts to be joined. This process is mainly used for welding nonferrous sheet metal.

An auto-transformer used with a sodium vapour lamp should have:- a)High step-up ratio

- b)High step-down ratio

- c)High leakage reactance

- d)High resistance

Correct answer is option 'C'. Can you explain this answer?

An auto-transformer used with a sodium vapour lamp should have:

a)

High step-up ratio

b)

High step-down ratio

c)

High leakage reactance

d)

High resistance

|

Hiral Sharma answered |

To start sodium vapour lamp, 380 - 450 V of striking voltage required for 40 - 100 W lamps. These voltages can be obtained from a high reactance transformer or an auto transformer.

The type of drive used for a paper mill requiring a constant speed operation and the flexibility of control is:- a)Group drive

- b)Multi-motor drive

- c)Individual or multi-motor drive

- d)Individual drive

Correct answer is option 'C'. Can you explain this answer?

The type of drive used for a paper mill requiring a constant speed operation and the flexibility of control is:

a)

Group drive

b)

Multi-motor drive

c)

Individual or multi-motor drive

d)

Individual drive

|

|

Abhay Khanna answered |

Group drives: Electric drive that is used to drive two or more than two machines from line shaft through belts and pulleys is known as group drive

Individual drive: A single electric motor is used to drive one individual machine.

Multi-motor drive: Several separate motors are provided for operating different parts of the single machine

For a paper mill requiring a constant speed operation and the flexibility of control we can use Individual or multi-motor drive

Centrifugal pumps are usually driven by:- a)DC series motors

- b)DC shunt motors

- c)Plain squirrel cage induction motors

- d)Any of the above

Correct answer is option 'C'. Can you explain this answer?

Centrifugal pumps are usually driven by:

a)

DC series motors

b)

DC shunt motors

c)

Plain squirrel cage induction motors

d)

Any of the above

|

Lekshmi Das answered |

Centrifugal pumps are used to transport fluids by the conversion of rotational kinetic energy to the hydrodynamic energy of the fluid flow. The rotational energy typically comes from an engine or electric motor. Squirrel cage induction motors are used for this purpose.

The electric arc has:- a)Linear resistance characteristic

- b)Positive resistance characteristic

- c)Negative resistance characteristic

- d)Highly inductive characteristic

Correct answer is option 'C'. Can you explain this answer?

The electric arc has:

a)

Linear resistance characteristic

b)

Positive resistance characteristic

c)

Negative resistance characteristic

d)

Highly inductive characteristic

|

|

Sandeep Saha answered |

Electric arc welding is the process of joining two metallic pieces. In this, melting of metal is obtained due to the heat developed by an arc struck between an electrode and the metal to be welded or between the two electrodes

When the supply is given across the conductors separated by some distance apart, the air gap present between the two conductors gets ionized. As the arc welding in progress, the ionization of the arc path and its surrounding area increases

The increase in ionization decreases the resistance of the path. Thus, current increases with the decrease in voltage of arc. It indicates that, arc has negative resistance characteristics

The spongy coating of electroplating speaks of:- a)Under current density

- b)Over current density

- c)Excessive electrolyte density

- d)Poorer electrolyte density

Correct answer is option 'B'. Can you explain this answer?

The spongy coating of electroplating speaks of:

a)

Under current density

b)

Over current density

c)

Excessive electrolyte density

d)

Poorer electrolyte density

|

|

Prasenjit Yadav answered |

The deposited metal is very much strong and porous. If the rate of current is high, then the nuclei are formed and at low current density, the deposits are coarse and crystalline. The spongy coating of electroplating indicates over current density.

In induction heating, the depth up to which the current will penetrate is proportional to:- a)1/(Frequency)1/2

- b)1/Frequency

- c)Frequency

- d)(Frequency)2

Correct answer is option 'A'. Can you explain this answer?

In induction heating, the depth up to which the current will penetrate is proportional to:

a)

1/(Frequency)1/2

b)

1/Frequency

c)

Frequency

d)

(Frequency)2

|

|

Anjali Choudhury answered |

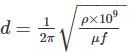

The depth of penetration of induced currents into the disc is given by:

Where, ρ is the specific resistance in Ω-cm

f is the frequency in Hz

μ is the permeability of the charge

The depth up to which the current will penetrate is inversely proportional to square of the frequency

The speed-time curve for the urban service has no:- a)Coasting period

- b)Free-running period

- c)Braking period

- d)Acceleration period

Correct answer is option 'B'. Can you explain this answer?

The speed-time curve for the urban service has no:

a)

Coasting period

b)

Free-running period

c)

Braking period

d)

Acceleration period

|

|

Anshika Khanna answered |

In urban service, there is no free running period. The distance between two stops is less about 1 km. Hence relatively short coasting and longer braking period is required.

Energy consumption in propelling the train is required for:- a)Accelerating the train mass

- b)Overcoming the gradient while moving up the gradient

- c)Overcoming the train resistance

- d)All of the above

Correct answer is option 'D'. Can you explain this answer?

Energy consumption in propelling the train is required for:

a)

Accelerating the train mass

b)

Overcoming the gradient while moving up the gradient

c)

Overcoming the train resistance

d)

All of the above

|

|

Krish Saini answered |

The energy input to the motor is called the energy consumption. This is the energy consumed by various parts of the train for its propulsion. The energy drawn from the distribution system should be equals to the energy consumed by the various parts of the train and the quantity of energy required for lighting, heating, control and braking.

This energy consumption is required for

a) Accelerating the train mass

b) Overcoming the gradient while moving up the gradient

c) Overcoming the train resistance

The dielectric loss in a dielectric is proportional to:- a)The voltage impressed on the dielectric

- b)The square of the voltage impressed on the dielectric

- c)The square root of the voltage impressed on the dielectric

- d)None of the above

Correct answer is option 'B'. Can you explain this answer?

The dielectric loss in a dielectric is proportional to:

a)

The voltage impressed on the dielectric

b)

The square of the voltage impressed on the dielectric

c)

The square root of the voltage impressed on the dielectric

d)

None of the above

|

|

Niharika Basu answered |

Dielectric loss is

PL= V2ωCδPL = V2ωCδ

Where, V is the applied voltage in V

f is the supply frequency in Hz

C is the capacitance

δ is the loss angle in radian

Dielectric loss is directly proportional to the square of the voltage impressed on the dielectric

The average speed of a train is independent of:- a)The duration of the stops

- b)The acceleration and braking retardation

- c)The distance between stops

- d)The running time

Correct answer is option 'A'. Can you explain this answer?

The average speed of a train is independent of:

a)

The duration of the stops

b)

The acceleration and braking retardation

c)

The distance between stops

d)

The running time

|

|

Alok Khanna answered |

Average Speed: It is the mean of the speeds attained by the train from start to stop, i.e. it is defined as the ratio of the distance covered by the train between two stops to the total time of run. It is denoted with Va

Average speed = distance between stops / actual time of run

Va = D/T

Where Va is the average speed of train in kmph

D is the distance between stops in km

T is the actual time in hours

Here the total time of run does not include the duration of the stops. Hence the average speed is independent of the duration of the stops.

The power factor will be maximum in case of:- a)Electric arc heating

- b)Resistance heating

- c)Induction heating

- d)Dielectric heating

Correct answer is option 'B'. Can you explain this answer?

The power factor will be maximum in case of:

a)

Electric arc heating

b)

Resistance heating

c)

Induction heating

d)

Dielectric heating

|

|

Snehal Rane answered |

The power factor will be maximum in case of resistance heating compared to any other heating method

The main drawbacks of the resistance welding are:- a)High initial as well as maintenance cost

- b)Difficult shapes and sections cannot welded

- c)Only similar metals can be welded

- d)Parent metal is affected

Correct answer is option 'A'. Can you explain this answer?

The main drawbacks of the resistance welding are:

a)

High initial as well as maintenance cost

b)

Difficult shapes and sections cannot welded

c)

Only similar metals can be welded

d)

Parent metal is affected

|

|

Debanshi Basak answered |

Drawbacks of Resistance Welding:

High Initial and Maintenance Cost:

- Resistance welding requires specialized equipment such as welding machines, transformers, and electrodes.

- These machines and equipment can be expensive to purchase and maintain, leading to high initial and maintenance costs.

- Additionally, the electrodes used in resistance welding wear out over time and need to be replaced regularly, further adding to the maintenance costs.

Difficulties in Welding Complex Shapes and Sections:

- Resistance welding is most suitable for joining simple and straight pieces of metal.

- It becomes challenging to weld complex shapes and sections, such as curved or irregularly shaped parts.

- The rigid nature of the electrodes used in resistance welding makes it difficult to accurately position and apply pressure on complex workpieces.

Limitation to Similar Metals:

- Resistance welding is primarily used for joining similar metals, such as steel to steel or aluminum to aluminum.

- It becomes challenging to weld dissimilar metals using resistance welding techniques.

- This limitation restricts the versatility of resistance welding as it cannot be used for joining different types of metals together.

Effect on Parent Metal:

- During the resistance welding process, heat is generated by passing a high electrical current through the materials being joined.

- This heat can affect the parent metal, leading to changes in its properties, such as hardness, strength, or grain structure.

- The extent of these changes depends on various factors, including the welding parameters, material properties, and the cooling process after welding.

- These alterations in the parent metal can sometimes result in undesirable effects or reduced performance of the welded joint.

Conclusion:

Resistance welding, although widely used due to its speed and efficiency, has certain drawbacks that need to be considered. The high initial and maintenance costs, difficulties in welding complex shapes and sections, limitations to similar metals, and the potential effect on the parent metal are the main drawbacks of resistance welding. Despite these limitations, resistance welding remains a popular choice for many applications in various industries.

High Initial and Maintenance Cost:

- Resistance welding requires specialized equipment such as welding machines, transformers, and electrodes.

- These machines and equipment can be expensive to purchase and maintain, leading to high initial and maintenance costs.

- Additionally, the electrodes used in resistance welding wear out over time and need to be replaced regularly, further adding to the maintenance costs.

Difficulties in Welding Complex Shapes and Sections:

- Resistance welding is most suitable for joining simple and straight pieces of metal.

- It becomes challenging to weld complex shapes and sections, such as curved or irregularly shaped parts.

- The rigid nature of the electrodes used in resistance welding makes it difficult to accurately position and apply pressure on complex workpieces.

Limitation to Similar Metals:

- Resistance welding is primarily used for joining similar metals, such as steel to steel or aluminum to aluminum.

- It becomes challenging to weld dissimilar metals using resistance welding techniques.

- This limitation restricts the versatility of resistance welding as it cannot be used for joining different types of metals together.

Effect on Parent Metal:

- During the resistance welding process, heat is generated by passing a high electrical current through the materials being joined.

- This heat can affect the parent metal, leading to changes in its properties, such as hardness, strength, or grain structure.

- The extent of these changes depends on various factors, including the welding parameters, material properties, and the cooling process after welding.

- These alterations in the parent metal can sometimes result in undesirable effects or reduced performance of the welded joint.

Conclusion:

Resistance welding, although widely used due to its speed and efficiency, has certain drawbacks that need to be considered. The high initial and maintenance costs, difficulties in welding complex shapes and sections, limitations to similar metals, and the potential effect on the parent metal are the main drawbacks of resistance welding. Despite these limitations, resistance welding remains a popular choice for many applications in various industries.

In an arc furnace, the choke is provided to:- a)Reduce the surge severity

- b)Stabilize the arc

- c)Improve the power factor

- d)All of the above

Correct answer is option 'B'. Can you explain this answer?

In an arc furnace, the choke is provided to:

a)

Reduce the surge severity

b)

Stabilize the arc

c)

Improve the power factor

d)

All of the above

|

|

Krish Saini answered |

If the high voltage is applied across an air gap, the air in the gap gets ionized under the influence of electrostatic forces and becomes conducting medium, current flows in the form of a continuous spark, known as arc. The choke is provided to stabilize this arc in arc furnaces.

For a given value of an average speed, decrease in duration of stops causes:- a)Decrease in schedule speed

- b)Increase in schedule speed

- c)Increase in crest speed

- d)Decrease in crest speed

Correct answer is option 'B'. Can you explain this answer?

For a given value of an average speed, decrease in duration of stops causes:

a)

Decrease in schedule speed

b)

Increase in schedule speed

c)

Increase in crest speed

d)

Decrease in crest speed

|

|

Anoushka Kumar answered |

Decrease in duration of stops and its effect on schedule speed

Introduction:

In transportation systems, the schedule speed represents the average speed at which a vehicle is expected to travel over a given distance. The duration of stops, such as when a vehicle halts at a station or a bus stop, directly impacts the schedule speed. In this question, we are considering the effect of decreasing the duration of stops on the schedule speed.

Explanation:

When the duration of stops is decreased, it means that vehicles spend less time stationary during their journey. This reduction in stop duration has the following effects:

1. Reduced time loss:

By decreasing the duration of stops, vehicles can spend more time in motion, resulting in reduced time loss. This means that the time spent waiting at stops is minimized, allowing vehicles to cover more distance in a given time period.

2. Increased average speed:

Since vehicles spend less time stationary and more time in motion, the average speed of the vehicle increases. The average speed is calculated by dividing the distance traveled by the total time taken. With reduced stop duration, the total time taken decreases, while the distance traveled remains the same. As a result, the average speed increases.

3. Effect on schedule speed:

The schedule speed is a predetermined speed at which a vehicle is expected to travel. It is set based on factors such as traffic conditions, road design, and passenger demand. When the duration of stops is decreased, the average speed of the vehicle increases. This means that the vehicle can cover the same distance in less time, thereby completing its journey ahead of schedule.

Therefore, the decrease in the duration of stops leads to an increase in the schedule speed. The vehicle can adhere to the schedule more efficiently, potentially allowing for improved reliability and reduced travel time for passengers.

Conclusion:

When the duration of stops is decreased, the schedule speed increases. This is due to the reduction in time loss and increased average speed resulting from less time spent stationary. The increase in schedule speed can positively impact the efficiency and reliability of transportation systems, benefiting both passengers and service providers.

Introduction:

In transportation systems, the schedule speed represents the average speed at which a vehicle is expected to travel over a given distance. The duration of stops, such as when a vehicle halts at a station or a bus stop, directly impacts the schedule speed. In this question, we are considering the effect of decreasing the duration of stops on the schedule speed.

Explanation:

When the duration of stops is decreased, it means that vehicles spend less time stationary during their journey. This reduction in stop duration has the following effects:

1. Reduced time loss:

By decreasing the duration of stops, vehicles can spend more time in motion, resulting in reduced time loss. This means that the time spent waiting at stops is minimized, allowing vehicles to cover more distance in a given time period.

2. Increased average speed:

Since vehicles spend less time stationary and more time in motion, the average speed of the vehicle increases. The average speed is calculated by dividing the distance traveled by the total time taken. With reduced stop duration, the total time taken decreases, while the distance traveled remains the same. As a result, the average speed increases.

3. Effect on schedule speed:

The schedule speed is a predetermined speed at which a vehicle is expected to travel. It is set based on factors such as traffic conditions, road design, and passenger demand. When the duration of stops is decreased, the average speed of the vehicle increases. This means that the vehicle can cover the same distance in less time, thereby completing its journey ahead of schedule.

Therefore, the decrease in the duration of stops leads to an increase in the schedule speed. The vehicle can adhere to the schedule more efficiently, potentially allowing for improved reliability and reduced travel time for passengers.

Conclusion:

When the duration of stops is decreased, the schedule speed increases. This is due to the reduction in time loss and increased average speed resulting from less time spent stationary. The increase in schedule speed can positively impact the efficiency and reliability of transportation systems, benefiting both passengers and service providers.

The solid angle subtended at the centre of a hemisphere of radius r will be:- a)2π r

- b)2π

- c)4π

- d)2π / r

Correct answer is option 'B'. Can you explain this answer?

The solid angle subtended at the centre of a hemisphere of radius r will be:

a)

2π r

b)

2π

c)

4π

d)

2π / r

|

|

Krish Saini answered |

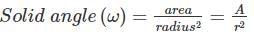

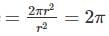

Solid angle is the angle subtended at a point in space by an area, i.e. angle enclosed in the volume formed by numerous lines lying on the surface and meeting at the point. It is usually denoted by symbol ‘ω’ and it is measured in steradian.

Area of the hemisphere = 2πr2

The solid angle subtended at the centre of a hemisphere of radius r will be

The length of arc required depends on:- a)The kind of electrode used, its coating and its diameter

- b)The magnitude of current used

- c)The position of welding

- d)All of the above

Correct answer is option 'D'. Can you explain this answer?

The length of arc required depends on:

a)

The kind of electrode used, its coating and its diameter

b)

The magnitude of current used

c)

The position of welding

d)

All of the above

|

|

Avik Iyer answered |

The length of arc required in welding depends on various factors. Let's discuss each of these factors in detail:

a) The kind of electrode used, its coating, and its diameter:

- Different types of electrodes are used for different welding processes. For example, in shielded metal arc welding (SMAW), commonly known as stick welding, electrodes with different coatings are used. The coating on the electrode helps in providing protection from the atmosphere and also influences the characteristics of the arc.

- The diameter of the electrode also affects the length of the arc. A smaller diameter electrode requires a shorter arc length, while a larger diameter electrode requires a longer arc length.

b) The magnitude of current used:

- The magnitude of current used in welding plays a crucial role in determining the length of the arc. Higher current levels generally require a longer arc length.

- The length of the arc is directly proportional to the current. As the current increases, the arc length also increases. This is because higher current levels generate more heat, and a longer arc is needed to dissipate the heat properly.

c) The position of welding:

- The position of welding, whether it is flat, horizontal, vertical, or overhead, affects the length of the arc.

- In vertical and overhead welding positions, a shorter arc length is generally preferred to prevent excessive spatter and maintain control over the molten metal.

- On the other hand, in horizontal and flat positions, a slightly longer arc length may be required to ensure proper penetration and fusion.

Considering all the factors mentioned above, the correct answer to the question is option 'D' - all of the above. The length of arc required in welding depends on the kind of electrode used, its coating, and its diameter, the magnitude of current used, as well as the position of welding. All these factors need to be taken into consideration to determine the appropriate length of the arc for a particular welding process.

a) The kind of electrode used, its coating, and its diameter:

- Different types of electrodes are used for different welding processes. For example, in shielded metal arc welding (SMAW), commonly known as stick welding, electrodes with different coatings are used. The coating on the electrode helps in providing protection from the atmosphere and also influences the characteristics of the arc.

- The diameter of the electrode also affects the length of the arc. A smaller diameter electrode requires a shorter arc length, while a larger diameter electrode requires a longer arc length.

b) The magnitude of current used:

- The magnitude of current used in welding plays a crucial role in determining the length of the arc. Higher current levels generally require a longer arc length.

- The length of the arc is directly proportional to the current. As the current increases, the arc length also increases. This is because higher current levels generate more heat, and a longer arc is needed to dissipate the heat properly.

c) The position of welding:

- The position of welding, whether it is flat, horizontal, vertical, or overhead, affects the length of the arc.

- In vertical and overhead welding positions, a shorter arc length is generally preferred to prevent excessive spatter and maintain control over the molten metal.

- On the other hand, in horizontal and flat positions, a slightly longer arc length may be required to ensure proper penetration and fusion.

Considering all the factors mentioned above, the correct answer to the question is option 'D' - all of the above. The length of arc required in welding depends on the kind of electrode used, its coating, and its diameter, the magnitude of current used, as well as the position of welding. All these factors need to be taken into consideration to determine the appropriate length of the arc for a particular welding process.

The fluorescent tube is coated form inside with a thin layer of fluorescent material in the form of powder in order to:- a)Absorb invisible ultraviolet rays and radiate visible rays

- b)Improve the appearance

- c)Reduce glare

- d)Improve life

Correct answer is option 'A'. Can you explain this answer?

The fluorescent tube is coated form inside with a thin layer of fluorescent material in the form of powder in order to:

a)

Absorb invisible ultraviolet rays and radiate visible rays

b)

Improve the appearance

c)

Reduce glare

d)

Improve life

|

|

Prasenjit Yadav answered |

The fluorescent tube is coated form inside with a thin layer of fluorescent material in the form of powder in order to absorb invisible ultraviolet rays and radiate visible rays.

The least significant electrical characteristic in the selection of the electric motor for a flour mill is:- a)Starting characteristics

- b)Braking

- c)Running characteristics

- d)Efficiency

Correct answer is option 'B'. Can you explain this answer?

The least significant electrical characteristic in the selection of the electric motor for a flour mill is:

a)

Starting characteristics

b)

Braking

c)

Running characteristics

d)

Efficiency

|

|

Nandita Kulkarni answered |

Introduction:

When selecting an electric motor for a flour mill, various electrical characteristics need to be considered. These characteristics determine the motor's performance, efficiency, and suitability for the specific application. Among these characteristics, the least significant one is the braking capability of the motor.

Explanation:

1. Starting characteristics:

Starting characteristics refer to the motor's ability to start the load attached to it. It includes parameters such as starting torque, starting current, and starting time. These characteristics are crucial in ensuring that the motor can start the flour mill efficiently and reliably. If the motor lacks sufficient starting torque or takes too long to start, it may result in operational issues and delays in the flour mill's production.

2. Running characteristics:

Running characteristics encompass the motor's performance during normal operation. These include parameters such as rated power, speed, efficiency, and load-carrying capacity. The motor should be capable of delivering the required power and maintaining the desired speed under normal operating conditions. The efficiency of the motor is also important as it affects energy consumption and operational costs.

3. Efficiency:

Efficiency is a critical factor in motor selection as it directly affects the operating costs of the flour mill. A more efficient motor utilizes electrical energy more effectively, resulting in lower energy consumption and reduced electricity bills. High-efficiency motors also produce less heat, which contributes to improved reliability and longevity.

4. Braking:

Braking capability refers to the motor's ability to decelerate or stop the load when necessary. In the context of a flour mill, braking may be required to halt the mill's operation quickly or to prevent the mill from running out of control. However, the braking characteristic is the least significant in motor selection for a flour mill because:

- Flour mills typically have external braking systems specifically designed for controlling the mill's rotation and stopping it efficiently. These systems are separate from the motor and are responsible for providing the necessary braking force.

- Electric motors used in flour mills are generally not designed to provide significant braking torque. Their primary function is to provide rotational motion to the mill, and braking is secondary.

- If the motor lacks adequate braking capability, it can be compensated by using an appropriate external braking system without compromising the motor's overall performance and suitability for the flour mill application.

Conclusion:

Among the various electrical characteristics considered when selecting an electric motor for a flour mill, the least significant one is the braking capability. Starting characteristics, running characteristics, and efficiency play more crucial roles in ensuring the motor's performance, reliability, and cost-effectiveness. Although braking capability is necessary, it can be achieved through separate external braking systems specifically designed for controlling the flour mill's operation.

When selecting an electric motor for a flour mill, various electrical characteristics need to be considered. These characteristics determine the motor's performance, efficiency, and suitability for the specific application. Among these characteristics, the least significant one is the braking capability of the motor.

Explanation:

1. Starting characteristics:

Starting characteristics refer to the motor's ability to start the load attached to it. It includes parameters such as starting torque, starting current, and starting time. These characteristics are crucial in ensuring that the motor can start the flour mill efficiently and reliably. If the motor lacks sufficient starting torque or takes too long to start, it may result in operational issues and delays in the flour mill's production.

2. Running characteristics:

Running characteristics encompass the motor's performance during normal operation. These include parameters such as rated power, speed, efficiency, and load-carrying capacity. The motor should be capable of delivering the required power and maintaining the desired speed under normal operating conditions. The efficiency of the motor is also important as it affects energy consumption and operational costs.

3. Efficiency:

Efficiency is a critical factor in motor selection as it directly affects the operating costs of the flour mill. A more efficient motor utilizes electrical energy more effectively, resulting in lower energy consumption and reduced electricity bills. High-efficiency motors also produce less heat, which contributes to improved reliability and longevity.

4. Braking:

Braking capability refers to the motor's ability to decelerate or stop the load when necessary. In the context of a flour mill, braking may be required to halt the mill's operation quickly or to prevent the mill from running out of control. However, the braking characteristic is the least significant in motor selection for a flour mill because:

- Flour mills typically have external braking systems specifically designed for controlling the mill's rotation and stopping it efficiently. These systems are separate from the motor and are responsible for providing the necessary braking force.

- Electric motors used in flour mills are generally not designed to provide significant braking torque. Their primary function is to provide rotational motion to the mill, and braking is secondary.

- If the motor lacks adequate braking capability, it can be compensated by using an appropriate external braking system without compromising the motor's overall performance and suitability for the flour mill application.

Conclusion:

Among the various electrical characteristics considered when selecting an electric motor for a flour mill, the least significant one is the braking capability. Starting characteristics, running characteristics, and efficiency play more crucial roles in ensuring the motor's performance, reliability, and cost-effectiveness. Although braking capability is necessary, it can be achieved through separate external braking systems specifically designed for controlling the flour mill's operation.

Tractive effort is required to:- a)Accelerate the train mass

- b)Overcome the train resistance (friction windage and curve resistance)

- c)Overcome the effect of gravity

- d)All of the above

Correct answer is option 'D'. Can you explain this answer?

Tractive effort is required to:

a)

Accelerate the train mass

b)

Overcome the train resistance (friction windage and curve resistance)

c)

Overcome the effect of gravity

d)

All of the above

|

|

Raghav Nambiar answered |

Understanding Tractive Effort in Trains

Tractive effort is essential for the efficient operation of trains. It is the force exerted by the train's wheels to move the train forward and is influenced by several factors. Here’s a breakdown of why tractive effort is required:

1. Accelerate the Train Mass

- Tractive effort is needed to overcome inertia when starting and to accelerate the train to the desired speed.

- The greater the mass of the train, the more tractive effort is required to achieve acceleration.

2. Overcome Train Resistance

- Trains face resistance due to friction, windage, and curve resistance.

- Friction arises between the train wheels and the track, while windage is caused by air resistance as the train moves.

- Curve resistance occurs when the train navigates turns, requiring additional force to maintain speed.

3. Overcome the Effect of Gravity

- When trains travel on inclined tracks, they must exert additional tractive effort to counteract gravitational forces.

- This is especially relevant in hilly or mountainous terrains where the gradient can significantly affect performance.

Conclusion

- Therefore, tractive effort is vital for all these functions: to accelerate the train mass, overcome resistance, and counteract gravity.

- The correct answer, "D) All of the above," reflects the comprehensive role of tractive effort in ensuring smooth and efficient train operations across varying conditions.

Tractive effort is essential for the efficient operation of trains. It is the force exerted by the train's wheels to move the train forward and is influenced by several factors. Here’s a breakdown of why tractive effort is required:

1. Accelerate the Train Mass

- Tractive effort is needed to overcome inertia when starting and to accelerate the train to the desired speed.

- The greater the mass of the train, the more tractive effort is required to achieve acceleration.

2. Overcome Train Resistance

- Trains face resistance due to friction, windage, and curve resistance.

- Friction arises between the train wheels and the track, while windage is caused by air resistance as the train moves.

- Curve resistance occurs when the train navigates turns, requiring additional force to maintain speed.

3. Overcome the Effect of Gravity

- When trains travel on inclined tracks, they must exert additional tractive effort to counteract gravitational forces.

- This is especially relevant in hilly or mountainous terrains where the gradient can significantly affect performance.

Conclusion

- Therefore, tractive effort is vital for all these functions: to accelerate the train mass, overcome resistance, and counteract gravity.

- The correct answer, "D) All of the above," reflects the comprehensive role of tractive effort in ensuring smooth and efficient train operations across varying conditions.

The light of fluorescent tube appears cooler than that from an incandescent lamp. This is due that fact that:- a)The tube consumes less power

- b)The surface area of the tube is larger than that of the incandescent lamp

- c)Tungsten is not used in the tube

- d)None of the above

Correct answer is option 'A'. Can you explain this answer?

The light of fluorescent tube appears cooler than that from an incandescent lamp. This is due that fact that:

a)

The tube consumes less power

b)

The surface area of the tube is larger than that of the incandescent lamp

c)

Tungsten is not used in the tube

d)

None of the above

|

|

Krish Saini answered |

Fluorescent lamp (electric discharge lamp) is cooler and more efficient than incandescent lamps that produces light by the fluorescence of a phosphor coating. The reason behind this is the tube consumes less power.

A substance that changes its electrical resistance when illuminated by light is called:- a)Photoconductive

- b)Photovoltaic

- c)Photoelectric

- d)None of the above

Correct answer is option 'A'. Can you explain this answer?

A substance that changes its electrical resistance when illuminated by light is called:

a)

Photoconductive

b)

Photovoltaic

c)

Photoelectric

d)

None of the above

|

|

Nayanika Kaur answered |

Photoconductivity is an optical and electrical phenomenon in which a material becomes more electrically conductive due to the absorption of electromagnetic radiation such as visible light, ultraviolet light, infrared light, or gamma radiation

Photovoltaic is a method for generating electric power by using solar cells to convert energy from the sun into a flow of electrons by the photovoltaic effect

Photoelectric effect is the emission of electrons or other free carriers when light shines on a material

The basic electrical requirement in the arc welding is that there should be: - a)High open circuit voltage

- b)No arc blow

- c)DC power supply

- d)Coated electrodes

Correct answer is option 'A'. Can you explain this answer?

The basic electrical requirement in the arc welding is that there should be:

a)

High open circuit voltage

b)

No arc blow

c)

DC power supply

d)

Coated electrodes

|

|

Krish Saini answered |

Electric arc welding is the process of joining two metallic pieces or melting of metal is obtained due to the heat developed by an arc struck between an electrode and the metal to be welded or between the two electrodes. The basic requirement in this process is high open circuit voltage to form arc between the electrodes.

The illumination of various points on a horizontal surface illuminated by the same source varies as:- a)Cos θ

- b)Cos2 θ

- c)Cos3 θ

- d)1/cos θ

Correct answer is option 'C'. Can you explain this answer?

The illumination of various points on a horizontal surface illuminated by the same source varies as:

a)

Cos θ

b)

Cos2 θ

c)

Cos3 θ

d)

1/cos θ

|

|

Anoushka Choudhury answered |

The illumination of various points on a horizontal surface illuminated by the same source varies as the cosine of the angle of incidence.

The furnaces used for cremation are:- a)Electric resistance heating

- b)Electric arc heating

- c)Dielectric heating

- d)High-frequency eddy current heating

Correct answer is option 'A'. Can you explain this answer?

The furnaces used for cremation are:

a)

Electric resistance heating

b)

Electric arc heating

c)

Dielectric heating

d)

High-frequency eddy current heating

|

|

Neha Nambiar answered |

Electric resistance heating furnace is used for cremation purpose

The speed of a train estimated taking into account the stoppage time at a station in addition to the actual running time between stops is called the:- a)Average speed

- b)Schedule speed

- c)Free-running speed

- d)Notching speed

Correct answer is option 'B'. Can you explain this answer?

The speed of a train estimated taking into account the stoppage time at a station in addition to the actual running time between stops is called the:

a)

Average speed

b)

Schedule speed

c)

Free-running speed

d)

Notching speed

|

|

Niti Tiwari answered |

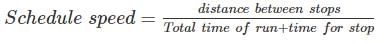

Average Speed: It is the mean of the speeds attained by the train from start to stop, i.e. it is defined as the ratio of the distance covered by the train between two stops to the total time of run. It is denoted with Va

Average speed = distance between stops/actual time of run

Va = D/T

Where Va is the average speed of train in kmph

D is the distance between stops in km

T is the actual time in hours

Schedule Speed: The ratio of the distance covered between two stops to the total time of the run including the time for stop is known as schedule speed. It is denoted with Vs

Where Ts is the schedule time in hours

The adhesive weight is the:- a)Total weight of the locomotive and the train

- b)Weight coming over the driving wheels

- c)Same as the accelerating weight

- d)None of the above

Correct answer is option 'B'. Can you explain this answer?

The adhesive weight is the:

a)

Total weight of the locomotive and the train

b)

Weight coming over the driving wheels

c)

Same as the accelerating weight

d)

None of the above

|

|

Krish Saini answered |

Adhesive weight: The total weight to be carried out on the drive in wheels of a locomotive is known as adhesive weight

Accelerating weight: It is the effective weight of train that has angular acceleration due to the rotational inertia including the dead weight of the train.

The filtration of electrolyte is necessary:- a)To remove the impurities going into the electrolyte along with the main salt.

- b)To remove the suspended salt particles and the other suspended impurities from the electrolyte.

- c)To make the agitation process more effective.

- d)Only some of the plating salts need filtration.

Correct answer is option 'B'. Can you explain this answer?

The filtration of electrolyte is necessary:

a)

To remove the impurities going into the electrolyte along with the main salt.

b)

To remove the suspended salt particles and the other suspended impurities from the electrolyte.

c)

To make the agitation process more effective.

d)

Only some of the plating salts need filtration.

|

|

Samarth Khanna answered |

The filtration of electrolyte is necessary to remove the suspended salt particles and the other suspended impurities from the electrolyte

During the resistance welding, the heat produced at the joint is proportional to:- a)Current

- b)Voltage

- c)I2R

- d)Volt-amperes

Correct answer is option 'C'. Can you explain this answer?

During the resistance welding, the heat produced at the joint is proportional to:

a)

Current

b)

Voltage

c)

I2R

d)

Volt-amperes

|

|

Parth Ghoshal answered |

Resistance welding is the process of joining two metals together by the heat produced due to the resistance offered to the flow of electric current at the junctions of two metals. The heat produced by the resistance to the flow of current is given by

H = I2R

The heat produced at the joint is proportional to I2R

The load cycle for a motor driving a power press will be:- a)Continuous

- b)Variable

- c)Intermittent and variable

- d)Continuous but periodical

Correct answer is option 'C'. Can you explain this answer?

The load cycle for a motor driving a power press will be:

a)

Continuous

b)

Variable

c)

Intermittent and variable

d)

Continuous but periodical

|

|

Akanksha Chopra answered |

Intermittent and Variable Load Cycle for a Motor Driving a Power Press

The load cycle for a motor driving a power press is categorized as intermittent and variable. This means that the motor experiences periods of operation and rest, and the load on the motor varies during its operation. Here is a detailed explanation of this answer:

Intermittent Load Cycle:

- A power press is a machine used for forming, shaping, and cutting various materials. It operates in cycles, where it performs a specific task during each cycle.

- The load on the motor driving the power press is intermittent because it is not continuously running. It starts, stops, and rests during each cycle of operation.

- During the operation of a power press, the motor needs to supply sufficient torque and power to perform the pressing task. Once the task is completed, the motor can rest until the next cycle begins.

Variable Load Cycle:

- The load on the motor driving the power press is also variable. This means that the load changes throughout the operation of the power press.

- The load can vary due to factors such as the type of material being pressed, the thickness of the material, the complexity of the shape being formed, and the speed at which the press is operating.

- For example, when a power press is forming a simple shape in a thin sheet of metal, the load on the motor may be relatively low. However, if the press is cutting a thick piece of material or forming a complex shape, the load on the motor will be higher.

Advantages of Intermittent and Variable Load Cycle:

- The intermittent and variable load cycle allows the motor to rest between cycles, reducing the overall energy consumption and heat generation.

- It also allows the motor to handle different types of tasks with varying loads, making it versatile and suitable for a range of applications.

- The motor can be designed to handle the maximum load requirements during the most demanding cycles, ensuring reliable operation and longevity.

In conclusion, the load cycle for a motor driving a power press is categorized as intermittent and variable. This classification is based on the nature of the power press operation, where the motor experiences periods of rest and the load varies during its operation.

The load cycle for a motor driving a power press is categorized as intermittent and variable. This means that the motor experiences periods of operation and rest, and the load on the motor varies during its operation. Here is a detailed explanation of this answer:

Intermittent Load Cycle:

- A power press is a machine used for forming, shaping, and cutting various materials. It operates in cycles, where it performs a specific task during each cycle.

- The load on the motor driving the power press is intermittent because it is not continuously running. It starts, stops, and rests during each cycle of operation.

- During the operation of a power press, the motor needs to supply sufficient torque and power to perform the pressing task. Once the task is completed, the motor can rest until the next cycle begins.

Variable Load Cycle:

- The load on the motor driving the power press is also variable. This means that the load changes throughout the operation of the power press.

- The load can vary due to factors such as the type of material being pressed, the thickness of the material, the complexity of the shape being formed, and the speed at which the press is operating.

- For example, when a power press is forming a simple shape in a thin sheet of metal, the load on the motor may be relatively low. However, if the press is cutting a thick piece of material or forming a complex shape, the load on the motor will be higher.

Advantages of Intermittent and Variable Load Cycle:

- The intermittent and variable load cycle allows the motor to rest between cycles, reducing the overall energy consumption and heat generation.

- It also allows the motor to handle different types of tasks with varying loads, making it versatile and suitable for a range of applications.

- The motor can be designed to handle the maximum load requirements during the most demanding cycles, ensuring reliable operation and longevity.

In conclusion, the load cycle for a motor driving a power press is categorized as intermittent and variable. This classification is based on the nature of the power press operation, where the motor experiences periods of rest and the load varies during its operation.

In the electric discharge lamps, the light is produced by:- a)The magnetic effect of current

- b)The heating effect of current

- c)Cathode ray emission

- d)The ionization in a gas or vapour

Correct answer is option 'D'. Can you explain this answer?

In the electric discharge lamps, the light is produced by:

a)

The magnetic effect of current

b)

The heating effect of current

c)

Cathode ray emission

d)

The ionization in a gas or vapour

|

|

Maulik Chatterjee answered |

In electric discharge lamps, the light is produced through the process of ionization in a gas or vapor. This phenomenon occurs due to the flow of electric current through the lamp.

Explanation:

- Electric discharge lamps, such as fluorescent lamps, neon lamps, and sodium vapor lamps, work on the principle of ionization. These lamps contain a gas or vapor-filled chamber with two electrodes, known as a cathode and an anode.

- When a high voltage is applied across the electrodes, it creates an electric field within the lamp. This electric field causes the gas or vapor molecules to become excited and gain energy.

- As the energy level of the gas or vapor molecules increases, some of the electrons in the outermost orbit of the atoms get detached from their parent atoms, creating free electrons.

- These free electrons collide with other gas or vapor molecules, causing further ionization. This process continues, leading to a chain reaction of ionization and the release of more free electrons.

- As the free electrons return to their original energy levels, they emit photons of light. This light emission occurs at specific wavelengths, depending on the type of gas or vapor present in the lamp.

- Different gases or vapors emit different colors of light. For example, neon gas emits red light, while mercury vapor emits blue or ultraviolet light.

- The photons emitted by the ionized gas or vapor create visible light, which is observed as the illumination of the lamp.

- The intensity and color of the light produced by the lamp can be controlled by varying the gas or vapor composition and the voltage applied to the electrodes.

In summary, the light in electric discharge lamps is produced through the process of ionization in a gas or vapor. The flow of electric current through the lamp causes the gas or vapor molecules to become excited and release photons of light as the electrons return to their original energy levels. This phenomenon allows electric discharge lamps to produce visible light for various applications.

Explanation:

- Electric discharge lamps, such as fluorescent lamps, neon lamps, and sodium vapor lamps, work on the principle of ionization. These lamps contain a gas or vapor-filled chamber with two electrodes, known as a cathode and an anode.

- When a high voltage is applied across the electrodes, it creates an electric field within the lamp. This electric field causes the gas or vapor molecules to become excited and gain energy.

- As the energy level of the gas or vapor molecules increases, some of the electrons in the outermost orbit of the atoms get detached from their parent atoms, creating free electrons.

- These free electrons collide with other gas or vapor molecules, causing further ionization. This process continues, leading to a chain reaction of ionization and the release of more free electrons.

- As the free electrons return to their original energy levels, they emit photons of light. This light emission occurs at specific wavelengths, depending on the type of gas or vapor present in the lamp.

- Different gases or vapors emit different colors of light. For example, neon gas emits red light, while mercury vapor emits blue or ultraviolet light.

- The photons emitted by the ionized gas or vapor create visible light, which is observed as the illumination of the lamp.

- The intensity and color of the light produced by the lamp can be controlled by varying the gas or vapor composition and the voltage applied to the electrodes.

In summary, the light in electric discharge lamps is produced through the process of ionization in a gas or vapor. The flow of electric current through the lamp causes the gas or vapor molecules to become excited and release photons of light as the electrons return to their original energy levels. This phenomenon allows electric discharge lamps to produce visible light for various applications.

The coefficient of the adhesion is the ratio of tractive effort to slip the wheels and:- a)Dead weight

- b)Accelerating weight

- c)Adhesive weight

- d)None of the above

Correct answer is option 'C'. Can you explain this answer?

The coefficient of the adhesion is the ratio of tractive effort to slip the wheels and:

a)

Dead weight

b)

Accelerating weight

c)

Adhesive weight

d)

None of the above

|

|

Mahi Bose answered |

Coefficient of adhesion (μ): It is defined as the ratio of the tractive effort (Ft) to propel the wheel of a locomotive to its adhesive weight (W).

In direct arc furnace, which of the following is of high value?- a)Current

- b)Voltage

- c)Power factor

- d)All of the above

Correct answer is option 'A'. Can you explain this answer?

In direct arc furnace, which of the following is of high value?

a)

Current

b)

Voltage

c)

Power factor

d)

All of the above

|

|

Alok Roy answered |

Introduction:

In a direct arc furnace, there are several parameters that play a crucial role in its operation. These parameters include current, voltage, and power factor. Among these, the current is considered to be of high value due to various reasons, which will be explained in detail below.

Explanation:

1. Current:

- In a direct arc furnace, current is the primary parameter that determines the amount of heat generated by the arc.

- The higher the current, the greater the heat generated, which is essential for melting and refining the materials in the furnace.

- The current also affects the melting rate and energy efficiency of the furnace. Higher current leads to faster melting and higher energy efficiency.

- Additionally, the current directly affects the electrode wear, and controlling it within the optimal range helps to minimize electrode consumption and prolong their lifespan.

- Therefore, maintaining and controlling the current in a direct arc furnace is crucial for its efficient operation and overall performance.

2. Voltage:

- While voltage is an important parameter in a direct arc furnace, it is not considered to be of high value compared to current.

- Voltage determines the arc length and stability in the furnace. Optimal voltage ensures a stable arc, which is necessary for efficient melting and refining.

- However, the voltage can be adjusted and controlled to maintain the desired arc length and stability. It does not directly affect the heat generation or energy efficiency as significantly as the current does.

3. Power Factor:

- Power factor is a measure of how effectively the current is being used in the system.

- In a direct arc furnace, power factor is important for determining the reactive power consumption and overall energy efficiency.

- While power factor optimization is important for minimizing energy losses and improving the power system's performance, it is not directly related to the value of the furnace in terms of its primary function of melting and refining.

Conclusion:

In a direct arc furnace, the current is considered to be of high value compared to voltage and power factor. It directly affects the heat generation, melting rate, energy efficiency, and electrode wear in the furnace. Controlling and maintaining the current within the optimal range is crucial for the efficient operation and performance of the furnace.

In a direct arc furnace, there are several parameters that play a crucial role in its operation. These parameters include current, voltage, and power factor. Among these, the current is considered to be of high value due to various reasons, which will be explained in detail below.

Explanation:

1. Current:

- In a direct arc furnace, current is the primary parameter that determines the amount of heat generated by the arc.

- The higher the current, the greater the heat generated, which is essential for melting and refining the materials in the furnace.

- The current also affects the melting rate and energy efficiency of the furnace. Higher current leads to faster melting and higher energy efficiency.

- Additionally, the current directly affects the electrode wear, and controlling it within the optimal range helps to minimize electrode consumption and prolong their lifespan.

- Therefore, maintaining and controlling the current in a direct arc furnace is crucial for its efficient operation and overall performance.

2. Voltage:

- While voltage is an important parameter in a direct arc furnace, it is not considered to be of high value compared to current.

- Voltage determines the arc length and stability in the furnace. Optimal voltage ensures a stable arc, which is necessary for efficient melting and refining.

- However, the voltage can be adjusted and controlled to maintain the desired arc length and stability. It does not directly affect the heat generation or energy efficiency as significantly as the current does.

3. Power Factor:

- Power factor is a measure of how effectively the current is being used in the system.

- In a direct arc furnace, power factor is important for determining the reactive power consumption and overall energy efficiency.

- While power factor optimization is important for minimizing energy losses and improving the power system's performance, it is not directly related to the value of the furnace in terms of its primary function of melting and refining.

Conclusion:

In a direct arc furnace, the current is considered to be of high value compared to voltage and power factor. It directly affects the heat generation, melting rate, energy efficiency, and electrode wear in the furnace. Controlling and maintaining the current within the optimal range is crucial for the efficient operation and performance of the furnace.

A rectifier used for welding has voltage current characteristic as:

- a)Drooping

- b)Rising

- c)Straight line

- d)Flat

Correct answer is option 'A'. Can you explain this answer?

A rectifier used for welding has voltage current characteristic as:

a)

Drooping

b)

Rising

c)

Straight line

d)

Flat

|

|

Samridhi Bose answered |

The rectifier type welders are said to combine some of the desirable arcing characteristics of the DC welding. Such as easy arc starting, with those of welding transformers such as reduced no losses. In this case, the DC voltage can be controlled by regulating the transformer output

Radiant heating is used for:- a)The malting of ferrous metals

- b)The annealing of metals

- c)The drying of paints and varnishes

- d)Any of the above

Correct answer is option 'C'. Can you explain this answer?

Radiant heating is used for:

a)

The malting of ferrous metals

b)

The annealing of metals

c)

The drying of paints and varnishes

d)

Any of the above

|

|

Krish Saini answered |

In radiant heating method, the heat energy is transferred from source (incandescent lamp) and focused upon the body to be heated up in the form of electromagnetic radiations. Normally this method is used for drying clothes in the textile industry and to dry the wet pants on an object.

The most modern method for the food processing is:- a)Induction heating

- b)Resistance heating

- c)Dielectric heating

- d)Eddy current heating

Correct answer is option 'C'. Can you explain this answer?

The most modern method for the food processing is:

a)

Induction heating

b)

Resistance heating

c)

Dielectric heating

d)

Eddy current heating

|

|

Prisha Sengupta answered |

Dielectric heating has been applied in the food processing industry:

1. Dehydrating fruits, vegetables, eggs etc.

2. Cooking food without removing the outer shells

3. Pasteurizing milk and beer inside bottles

4. Defrosting frozen foods in large bakeries and restaurants

Load equalization is desirable in the case of- a)Very large refrigeration and air-conditioning plant

- b)Rolling mills, electric hammers, presses, and reciprocating pumps

- c)Lathes, wood-working machines, paper-making machines, shapes and slotters

- d)Traveling cranes and lifts

Correct answer is option 'B'. Can you explain this answer?

Load equalization is desirable in the case of

a)

Very large refrigeration and air-conditioning plant

b)

Rolling mills, electric hammers, presses, and reciprocating pumps

c)

Lathes, wood-working machines, paper-making machines, shapes and slotters

d)

Traveling cranes and lifts

|

|

Nayanika Kaur answered |

The load fluctuations take place in many of the industrial drives such as rolling mills, electric hammers, presses, and reciprocating pumps, where the load on the motor varies widely within a span of few seconds. The sudden and peak load requires very large current from the supply results high voltage drop in the system or alternately would require very large size of cables. It is very essential to smooth out fluctuating load is known as load equalization.

In the upset butt welding:- a)The faces of the metal pieces to be joined are prepared for even contact

- b)Heating is obtained by the contact resistance of the metal pieces to be welded

- c)The voltage required is 2-8 V and the current required ranges from 50 A to several hundred amperes depending upon material and the area to be welded at a time.

- d)All of the above

Correct answer is option 'D'. Can you explain this answer?

In the upset butt welding:

a)

The faces of the metal pieces to be joined are prepared for even contact

b)

Heating is obtained by the contact resistance of the metal pieces to be welded

c)

The voltage required is 2-8 V and the current required ranges from 50 A to several hundred amperes depending upon material and the area to be welded at a time.

d)

All of the above

|

|

Nandita Bajaj answered |

In upset butt welding, the two metal parts to be welded are joined end to end and are connected across the secondary of a welding transformer

Due to the contact resistance of the metals to be welded, heating effect is generated in this welding.

The voltage required is 2-8 V and the current required ranges from 50 A to several hundred amperes depending upon material and the area to be welded at a time

Which is a process by which the purity of metal extracted from their ores can be improved?- a)Electrodeposition

- b)Refining

- c)Electroplating

- d)Anodizing

Correct answer is option 'B'. Can you explain this answer?

Which is a process by which the purity of metal extracted from their ores can be improved?

a)

Electrodeposition

b)

Refining

c)

Electroplating

d)

Anodizing

|

|

Mansi Datta answered |

Refining: It is a process by which the purity of the metal extracted from their ores can be improved

Electrodeposition: It is the process by which one metal is deposited over other metal or non-metal by electrolysis

Electro metallization: It is the process by which the metal can be deposited on a conduction base for decoration and for protective purposes. Any non-conductive base is made as conductive by depositing graphite layer over it

Anodizing: The process of deposition of oxide film on a metal surface is known as anodizing and oxidation

The electric resistance welding has the advantages of: - a)Reduced distortion, higher production rates, suitability for large quantity production and comparatively lesser skill need

- b)Heat is localized where required

- c)No filler material is required

- d)All of the above

Correct answer is option 'D'. Can you explain this answer?

The electric resistance welding has the advantages of:

a)

Reduced distortion, higher production rates, suitability for large quantity production and comparatively lesser skill need

b)

Heat is localized where required

c)

No filler material is required

d)

All of the above

|

|

Saumya Sen answered |

The advantages of electric resistance welding are

1) Welding process is rapid and simple

2) Localized heating is possible, if required

3) No need of using filler material

4) Both similar and dissimilar metals can be welded

5) Comparatively lesser skill is required

6) It can be employed for mass production

Chapter doubts & questions for Utilization of Electrical Energy - RRB JE for Electrical Engineering 2025 is part of Electrical Engineering (EE) exam preparation. The chapters have been prepared according to the Electrical Engineering (EE) exam syllabus. The Chapter doubts & questions, notes, tests & MCQs are made for Electrical Engineering (EE) 2025 Exam. Find important definitions, questions, notes, meanings, examples, exercises, MCQs and online tests here.

Chapter doubts & questions of Utilization of Electrical Energy - RRB JE for Electrical Engineering in English & Hindi are available as part of Electrical Engineering (EE) exam.

Download more important topics, notes, lectures and mock test series for Electrical Engineering (EE) Exam by signing up for free.

RRB JE for Electrical Engineering

23 videos|81 docs|32 tests

|

Contact Support

Our team is online on weekdays between 10 AM - 7 PM

Typical reply within 3 hours

|

Free Exam Preparation

at your Fingertips!

Access Free Study Material - Test Series, Structured Courses, Free Videos & Study Notes and Prepare for Your Exam With Ease

Join the 10M+ students on EduRev

Join the 10M+ students on EduRev

|

|

Create your account for free

OR

Forgot Password

OR

Signup to see your scores

go up

within 7 days!

within 7 days!

Takes less than 10 seconds to signup