Chemical Engineering Exam > Chemical Engineering Questions > A counter flow, concentric tube heat exchang...

Start Learning for Free

A counter flow, concentric tube heat exchanger used for engine cooling has been in service for an extended period of time. The heat transfer surface area of the exchanger is , 5 m2 and the design value of the overall convection coefficient is 38 W/m2. During a test run, engine oil flowing at 0.1 kg/s. is cooled from 110oC 66oC by water supplied at a temperature of 25oC and a flow rate of 0.2kg/s. Calculate the fouling factor,

Rf”(m2 - K/W).

Given for engine oil c = 2166j/kg-K;

& for water c = 4178 j/kg-K

- a)0.0019 m2-K/W

- b)0.0039 m2-K/W

- c)0.0029 m2-K/W

- d)0.00 m492-K/W

Correct answer is option 'C'. Can you explain this answer?

| FREE This question is part of | Download PDF Attempt this Test |

Verified Answer

A counter flow, concentric tube heat exchanger used for engine coolin...

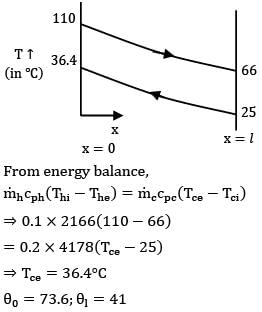

From energy balance,

mhcph(Thi - The) = mhcph(Tce - Tci)

⇒ 0.1 x 2166 x (110 - 66)

= 0.2 x 4178 (Tce - 25)

⇒ Tce = 36.4oC

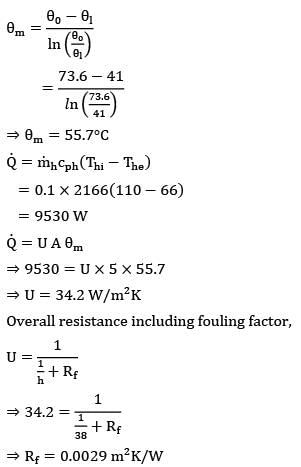

Θo = 73.6;Θ1 = 41

⇒ θm = 55.7oC

Q = mccph(Thi - Thi)

= 0.1 x 2166(110-66)

= 9530 W

Q = U A θm

⇒ 9530 = U x 5 x 55.7

⇒ U = 34.2 W/m2 K

Overall resistance including fouling factor,

⇒Rf = 0.0029 m2K/W

Most Upvoted Answer

A counter flow, concentric tube heat exchanger used for engine coolin...

Ρ = 890 kg/m3; k = 0.139 W/m-K and for water c = 4186 J/kg-K; ρ = 1000 kg/m3; k = 0.613 W/m-K.

We can use the following formula to calculate the overall heat transfer coefficient:

1/U = 1/hi + Rf + 1/ho

where hi and ho are the individual heat transfer coefficients for the oil and water sides, respectively, and Rf is the fouling factor.

We can calculate hi using the following formula:

hi = hi,oil = k oil / di

where di is the inside diameter of the oil tube. Assuming the oil tube is made of copper, we can use its thermal conductivity (k = 385 W/m-K) and the tube thickness (0.75 mm) to calculate di:

di = do - 2t = 10 mm - 2(0.75 mm) = 8.5 mm

Therefore, hi,oil = 385 W/m-K / 8.5 mm = 4548 W/m2-K

We can calculate ho using the following formula:

ho = ho,water = k water / do

where do is the outside diameter of the water tube. Assuming the water tube is made of brass, we can use its thermal conductivity (k = 121 W/m-K) and the tube thickness (1.5 mm) to calculate do:

do = di + 2t = 16 mm

Therefore, ho,water = 121 W/m-K / 16 mm = 7569 W/m2-K

Now we can use the formula for overall heat transfer coefficient to calculate Rf:

1/U = 1/hi,oil + Rf + 1/ho,water

U = 1 / (1/hi,oil + Rf + 1/ho,water)

U = 38 W/m2-K (design value)

ΔT1 = 110 - 25 = 85 K (oil inlet temperature - water inlet temperature)

ΔT2 = 66 - 25 = 41 K (oil outlet temperature - water inlet temperature)

m1 = 0.1 kg/s (oil mass flow rate)

m2 = 0.2 kg/s (water mass flow rate)

cp,oil = 2166 J/kg-K (oil specific heat)

cp,water = 4186 J/kg-K (water specific heat)

ρo = 890 kg/m3 (oil density)

ρwater = 1000 kg/m3 (water density)

Using the energy balance equation:

m1 cp,oil ΔT1 = m2 cp,water ΔT2 + UA ΔTlm

where UA is the overall heat transfer coefficient times the heat transfer surface area, and ΔTlm is the logarithmic mean temperature difference, we can solve for UA:

UA = (m1 cp,oil + m2 cp,water) ΔTlm

ΔTlm = (ΔT1 - ΔT2) / ln(ΔT1 / ΔT2)

UA = (m1 cp,oil + m2 cp,water) (ΔT1 - ΔT2) / ln(ΔT1 / ΔT2)

UA = 5 m2 (38 W/m2-K) = 190 W/K

Sub

We can use the following formula to calculate the overall heat transfer coefficient:

1/U = 1/hi + Rf + 1/ho

where hi and ho are the individual heat transfer coefficients for the oil and water sides, respectively, and Rf is the fouling factor.

We can calculate hi using the following formula:

hi = hi,oil = k oil / di

where di is the inside diameter of the oil tube. Assuming the oil tube is made of copper, we can use its thermal conductivity (k = 385 W/m-K) and the tube thickness (0.75 mm) to calculate di:

di = do - 2t = 10 mm - 2(0.75 mm) = 8.5 mm

Therefore, hi,oil = 385 W/m-K / 8.5 mm = 4548 W/m2-K

We can calculate ho using the following formula:

ho = ho,water = k water / do

where do is the outside diameter of the water tube. Assuming the water tube is made of brass, we can use its thermal conductivity (k = 121 W/m-K) and the tube thickness (1.5 mm) to calculate do:

do = di + 2t = 16 mm

Therefore, ho,water = 121 W/m-K / 16 mm = 7569 W/m2-K

Now we can use the formula for overall heat transfer coefficient to calculate Rf:

1/U = 1/hi,oil + Rf + 1/ho,water

U = 1 / (1/hi,oil + Rf + 1/ho,water)

U = 38 W/m2-K (design value)

ΔT1 = 110 - 25 = 85 K (oil inlet temperature - water inlet temperature)

ΔT2 = 66 - 25 = 41 K (oil outlet temperature - water inlet temperature)

m1 = 0.1 kg/s (oil mass flow rate)

m2 = 0.2 kg/s (water mass flow rate)

cp,oil = 2166 J/kg-K (oil specific heat)

cp,water = 4186 J/kg-K (water specific heat)

ρo = 890 kg/m3 (oil density)

ρwater = 1000 kg/m3 (water density)

Using the energy balance equation:

m1 cp,oil ΔT1 = m2 cp,water ΔT2 + UA ΔTlm

where UA is the overall heat transfer coefficient times the heat transfer surface area, and ΔTlm is the logarithmic mean temperature difference, we can solve for UA:

UA = (m1 cp,oil + m2 cp,water) ΔTlm

ΔTlm = (ΔT1 - ΔT2) / ln(ΔT1 / ΔT2)

UA = (m1 cp,oil + m2 cp,water) (ΔT1 - ΔT2) / ln(ΔT1 / ΔT2)

UA = 5 m2 (38 W/m2-K) = 190 W/K

Sub

|

Explore Courses for Chemical Engineering exam

|

|

Similar Chemical Engineering Doubts

A counter flow, concentric tube heat exchanger used for engine cooling has been in service for an extended period of time. The heat transfer surface area of the exchanger is , 5 m2 and the design value of the overall convection coefficient is 38 W/m2. During a test run, engine oil flowing at 0.1 kg/s. is cooled from 110oC 66oC by water supplied at a temperature of 25oC and a flow rate of 0.2kg/s. Calculate the fouling factor,Rf”(m2 - K/W).Given for engine oil c = 2166j/kg-K;& for water c = 4178 j/kg-Ka) 0.0019 m2-K/Wb) 0.0039 m2-K/Wc) 0.0029 m2-K/Wd) 0.00 m492-K/WCorrect answer is option 'C'. Can you explain this answer?

Question Description

A counter flow, concentric tube heat exchanger used for engine cooling has been in service for an extended period of time. The heat transfer surface area of the exchanger is , 5 m2 and the design value of the overall convection coefficient is 38 W/m2. During a test run, engine oil flowing at 0.1 kg/s. is cooled from 110oC 66oC by water supplied at a temperature of 25oC and a flow rate of 0.2kg/s. Calculate the fouling factor,Rf”(m2 - K/W).Given for engine oil c = 2166j/kg-K;& for water c = 4178 j/kg-Ka) 0.0019 m2-K/Wb) 0.0039 m2-K/Wc) 0.0029 m2-K/Wd) 0.00 m492-K/WCorrect answer is option 'C'. Can you explain this answer? for Chemical Engineering 2024 is part of Chemical Engineering preparation. The Question and answers have been prepared according to the Chemical Engineering exam syllabus. Information about A counter flow, concentric tube heat exchanger used for engine cooling has been in service for an extended period of time. The heat transfer surface area of the exchanger is , 5 m2 and the design value of the overall convection coefficient is 38 W/m2. During a test run, engine oil flowing at 0.1 kg/s. is cooled from 110oC 66oC by water supplied at a temperature of 25oC and a flow rate of 0.2kg/s. Calculate the fouling factor,Rf”(m2 - K/W).Given for engine oil c = 2166j/kg-K;& for water c = 4178 j/kg-Ka) 0.0019 m2-K/Wb) 0.0039 m2-K/Wc) 0.0029 m2-K/Wd) 0.00 m492-K/WCorrect answer is option 'C'. Can you explain this answer? covers all topics & solutions for Chemical Engineering 2024 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for A counter flow, concentric tube heat exchanger used for engine cooling has been in service for an extended period of time. The heat transfer surface area of the exchanger is , 5 m2 and the design value of the overall convection coefficient is 38 W/m2. During a test run, engine oil flowing at 0.1 kg/s. is cooled from 110oC 66oC by water supplied at a temperature of 25oC and a flow rate of 0.2kg/s. Calculate the fouling factor,Rf”(m2 - K/W).Given for engine oil c = 2166j/kg-K;& for water c = 4178 j/kg-Ka) 0.0019 m2-K/Wb) 0.0039 m2-K/Wc) 0.0029 m2-K/Wd) 0.00 m492-K/WCorrect answer is option 'C'. Can you explain this answer?.

A counter flow, concentric tube heat exchanger used for engine cooling has been in service for an extended period of time. The heat transfer surface area of the exchanger is , 5 m2 and the design value of the overall convection coefficient is 38 W/m2. During a test run, engine oil flowing at 0.1 kg/s. is cooled from 110oC 66oC by water supplied at a temperature of 25oC and a flow rate of 0.2kg/s. Calculate the fouling factor,Rf”(m2 - K/W).Given for engine oil c = 2166j/kg-K;& for water c = 4178 j/kg-Ka) 0.0019 m2-K/Wb) 0.0039 m2-K/Wc) 0.0029 m2-K/Wd) 0.00 m492-K/WCorrect answer is option 'C'. Can you explain this answer? for Chemical Engineering 2024 is part of Chemical Engineering preparation. The Question and answers have been prepared according to the Chemical Engineering exam syllabus. Information about A counter flow, concentric tube heat exchanger used for engine cooling has been in service for an extended period of time. The heat transfer surface area of the exchanger is , 5 m2 and the design value of the overall convection coefficient is 38 W/m2. During a test run, engine oil flowing at 0.1 kg/s. is cooled from 110oC 66oC by water supplied at a temperature of 25oC and a flow rate of 0.2kg/s. Calculate the fouling factor,Rf”(m2 - K/W).Given for engine oil c = 2166j/kg-K;& for water c = 4178 j/kg-Ka) 0.0019 m2-K/Wb) 0.0039 m2-K/Wc) 0.0029 m2-K/Wd) 0.00 m492-K/WCorrect answer is option 'C'. Can you explain this answer? covers all topics & solutions for Chemical Engineering 2024 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for A counter flow, concentric tube heat exchanger used for engine cooling has been in service for an extended period of time. The heat transfer surface area of the exchanger is , 5 m2 and the design value of the overall convection coefficient is 38 W/m2. During a test run, engine oil flowing at 0.1 kg/s. is cooled from 110oC 66oC by water supplied at a temperature of 25oC and a flow rate of 0.2kg/s. Calculate the fouling factor,Rf”(m2 - K/W).Given for engine oil c = 2166j/kg-K;& for water c = 4178 j/kg-Ka) 0.0019 m2-K/Wb) 0.0039 m2-K/Wc) 0.0029 m2-K/Wd) 0.00 m492-K/WCorrect answer is option 'C'. Can you explain this answer?.

Solutions for A counter flow, concentric tube heat exchanger used for engine cooling has been in service for an extended period of time. The heat transfer surface area of the exchanger is , 5 m2 and the design value of the overall convection coefficient is 38 W/m2. During a test run, engine oil flowing at 0.1 kg/s. is cooled from 110oC 66oC by water supplied at a temperature of 25oC and a flow rate of 0.2kg/s. Calculate the fouling factor,Rf”(m2 - K/W).Given for engine oil c = 2166j/kg-K;& for water c = 4178 j/kg-Ka) 0.0019 m2-K/Wb) 0.0039 m2-K/Wc) 0.0029 m2-K/Wd) 0.00 m492-K/WCorrect answer is option 'C'. Can you explain this answer? in English & in Hindi are available as part of our courses for Chemical Engineering.

Download more important topics, notes, lectures and mock test series for Chemical Engineering Exam by signing up for free.

Here you can find the meaning of A counter flow, concentric tube heat exchanger used for engine cooling has been in service for an extended period of time. The heat transfer surface area of the exchanger is , 5 m2 and the design value of the overall convection coefficient is 38 W/m2. During a test run, engine oil flowing at 0.1 kg/s. is cooled from 110oC 66oC by water supplied at a temperature of 25oC and a flow rate of 0.2kg/s. Calculate the fouling factor,Rf”(m2 - K/W).Given for engine oil c = 2166j/kg-K;& for water c = 4178 j/kg-Ka) 0.0019 m2-K/Wb) 0.0039 m2-K/Wc) 0.0029 m2-K/Wd) 0.00 m492-K/WCorrect answer is option 'C'. Can you explain this answer? defined & explained in the simplest way possible. Besides giving the explanation of

A counter flow, concentric tube heat exchanger used for engine cooling has been in service for an extended period of time. The heat transfer surface area of the exchanger is , 5 m2 and the design value of the overall convection coefficient is 38 W/m2. During a test run, engine oil flowing at 0.1 kg/s. is cooled from 110oC 66oC by water supplied at a temperature of 25oC and a flow rate of 0.2kg/s. Calculate the fouling factor,Rf”(m2 - K/W).Given for engine oil c = 2166j/kg-K;& for water c = 4178 j/kg-Ka) 0.0019 m2-K/Wb) 0.0039 m2-K/Wc) 0.0029 m2-K/Wd) 0.00 m492-K/WCorrect answer is option 'C'. Can you explain this answer?, a detailed solution for A counter flow, concentric tube heat exchanger used for engine cooling has been in service for an extended period of time. The heat transfer surface area of the exchanger is , 5 m2 and the design value of the overall convection coefficient is 38 W/m2. During a test run, engine oil flowing at 0.1 kg/s. is cooled from 110oC 66oC by water supplied at a temperature of 25oC and a flow rate of 0.2kg/s. Calculate the fouling factor,Rf”(m2 - K/W).Given for engine oil c = 2166j/kg-K;& for water c = 4178 j/kg-Ka) 0.0019 m2-K/Wb) 0.0039 m2-K/Wc) 0.0029 m2-K/Wd) 0.00 m492-K/WCorrect answer is option 'C'. Can you explain this answer? has been provided alongside types of A counter flow, concentric tube heat exchanger used for engine cooling has been in service for an extended period of time. The heat transfer surface area of the exchanger is , 5 m2 and the design value of the overall convection coefficient is 38 W/m2. During a test run, engine oil flowing at 0.1 kg/s. is cooled from 110oC 66oC by water supplied at a temperature of 25oC and a flow rate of 0.2kg/s. Calculate the fouling factor,Rf”(m2 - K/W).Given for engine oil c = 2166j/kg-K;& for water c = 4178 j/kg-Ka) 0.0019 m2-K/Wb) 0.0039 m2-K/Wc) 0.0029 m2-K/Wd) 0.00 m492-K/WCorrect answer is option 'C'. Can you explain this answer? theory, EduRev gives you an

ample number of questions to practice A counter flow, concentric tube heat exchanger used for engine cooling has been in service for an extended period of time. The heat transfer surface area of the exchanger is , 5 m2 and the design value of the overall convection coefficient is 38 W/m2. During a test run, engine oil flowing at 0.1 kg/s. is cooled from 110oC 66oC by water supplied at a temperature of 25oC and a flow rate of 0.2kg/s. Calculate the fouling factor,Rf”(m2 - K/W).Given for engine oil c = 2166j/kg-K;& for water c = 4178 j/kg-Ka) 0.0019 m2-K/Wb) 0.0039 m2-K/Wc) 0.0029 m2-K/Wd) 0.00 m492-K/WCorrect answer is option 'C'. Can you explain this answer? tests, examples and also practice Chemical Engineering tests.

|

Explore Courses for Chemical Engineering exam

|

|

Suggested Free Tests

Signup for Free!

Signup to see your scores go up within 7 days! Learn & Practice with 1000+ FREE Notes, Videos & Tests.