Mechanical Engineering Exam > Mechanical Engineering Questions > Cold shut is a defect in casting due to[PI 20...

Start Learning for Free

Cold shut is a defect in casting due to

[PI 2006]

- a)sand sliding from the cope surface

- b)internal voids or surface depression due to excessive gas trapped

- c)discontinuity resulting from hundred contraction

- d)two streams of material that are too cold to fuse properly

Correct answer is option 'A'. Can you explain this answer?

| FREE This question is part of | Download PDF Attempt this Test |

Verified Answer

Cold shut is a defect in casting due to[PI 2006]a)sand sliding from th...

Most Upvoted Answer

Cold shut is a defect in casting due to[PI 2006]a)sand sliding from th...

Answer:

Cold shut is a defect in casting due to sand sliding from the cope surface.

Explanation:

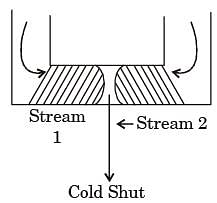

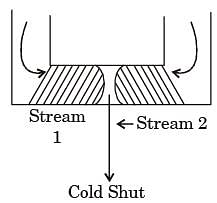

Cold shut is a common defect in casting that occurs when the molten metal does not properly fuse together during solidification. This results in a discontinuity or incomplete fusion in the casting, which weakens the structure and compromises its integrity.

Causes of cold shut:

There are several factors that can lead to the formation of cold shuts in castings. However, in this specific question, the correct answer is option 'A', which states that cold shut is a defect in casting due to sand sliding from the cope surface.

Explanation of option A:

When molten metal is poured into a mold, it comes into contact with the sand surface of the mold cavity. The sand acts as a refractory material, providing insulation and preventing the molten metal from solidifying too quickly. However, during the solidification process, the weight and pressure of the molten metal can cause the sand to shift or slide from the cope surface (the top surface of the mold). This movement of sand can result in a lack of contact between the molten metal streams, leading to incomplete fusion and the formation of cold shuts.

Other causes of cold shut:

While the correct answer for this particular question is option 'A', it is important to note that cold shuts can also be caused by other factors such as:

- Internal voids or surface depressions due to excessive gas trapped: If there is excessive gas trapped in the molten metal, it can create voids or depressions in the casting, leading to cold shuts.

- Discontinuity resulting from hundred contraction: During the solidification process, metal undergoes contraction as it cools and solidifies. If there is a significant difference in the cooling rates or the rate of solidification between different sections of the casting, it can result in a discontinuity and the formation of cold shuts.

- Two streams of material that are too cold to fuse properly: If two streams of molten metal come into contact with each other but are too cold to fuse properly, a cold shut can occur.

In conclusion, cold shut is a defect in casting that occurs when the molten metal does not properly fuse together during solidification. In this specific question, the correct answer is option 'A', which explains that cold shut is a defect in casting due to sand sliding from the cope surface.

Cold shut is a defect in casting due to sand sliding from the cope surface.

Explanation:

Cold shut is a common defect in casting that occurs when the molten metal does not properly fuse together during solidification. This results in a discontinuity or incomplete fusion in the casting, which weakens the structure and compromises its integrity.

Causes of cold shut:

There are several factors that can lead to the formation of cold shuts in castings. However, in this specific question, the correct answer is option 'A', which states that cold shut is a defect in casting due to sand sliding from the cope surface.

Explanation of option A:

When molten metal is poured into a mold, it comes into contact with the sand surface of the mold cavity. The sand acts as a refractory material, providing insulation and preventing the molten metal from solidifying too quickly. However, during the solidification process, the weight and pressure of the molten metal can cause the sand to shift or slide from the cope surface (the top surface of the mold). This movement of sand can result in a lack of contact between the molten metal streams, leading to incomplete fusion and the formation of cold shuts.

Other causes of cold shut:

While the correct answer for this particular question is option 'A', it is important to note that cold shuts can also be caused by other factors such as:

- Internal voids or surface depressions due to excessive gas trapped: If there is excessive gas trapped in the molten metal, it can create voids or depressions in the casting, leading to cold shuts.

- Discontinuity resulting from hundred contraction: During the solidification process, metal undergoes contraction as it cools and solidifies. If there is a significant difference in the cooling rates or the rate of solidification between different sections of the casting, it can result in a discontinuity and the formation of cold shuts.

- Two streams of material that are too cold to fuse properly: If two streams of molten metal come into contact with each other but are too cold to fuse properly, a cold shut can occur.

In conclusion, cold shut is a defect in casting that occurs when the molten metal does not properly fuse together during solidification. In this specific question, the correct answer is option 'A', which explains that cold shut is a defect in casting due to sand sliding from the cope surface.

Free Test

FREE

| Start Free Test |

Community Answer

Cold shut is a defect in casting due to[PI 2006]a)sand sliding from th...

Attention Mechanical Engineering Students!

To make sure you are not studying endlessly, EduRev has designed Mechanical Engineering study material, with Structured Courses, Videos, & Test Series. Plus get personalized analysis, doubt solving and improvement plans to achieve a great score in Mechanical Engineering.

|

Explore Courses for Mechanical Engineering exam

|

|

Similar Mechanical Engineering Doubts

Cold shut is a defect in casting due to[PI 2006]a)sand sliding from the cope surfaceb)internal voids or surface depression due to excessive gas trappedc)discontinuity resulting from hundred contractiond)two streams of material that are too cold to fuse properlyCorrect answer is option 'A'. Can you explain this answer?

Question Description

Cold shut is a defect in casting due to[PI 2006]a)sand sliding from the cope surfaceb)internal voids or surface depression due to excessive gas trappedc)discontinuity resulting from hundred contractiond)two streams of material that are too cold to fuse properlyCorrect answer is option 'A'. Can you explain this answer? for Mechanical Engineering 2024 is part of Mechanical Engineering preparation. The Question and answers have been prepared according to the Mechanical Engineering exam syllabus. Information about Cold shut is a defect in casting due to[PI 2006]a)sand sliding from the cope surfaceb)internal voids or surface depression due to excessive gas trappedc)discontinuity resulting from hundred contractiond)two streams of material that are too cold to fuse properlyCorrect answer is option 'A'. Can you explain this answer? covers all topics & solutions for Mechanical Engineering 2024 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for Cold shut is a defect in casting due to[PI 2006]a)sand sliding from the cope surfaceb)internal voids or surface depression due to excessive gas trappedc)discontinuity resulting from hundred contractiond)two streams of material that are too cold to fuse properlyCorrect answer is option 'A'. Can you explain this answer?.

Cold shut is a defect in casting due to[PI 2006]a)sand sliding from the cope surfaceb)internal voids or surface depression due to excessive gas trappedc)discontinuity resulting from hundred contractiond)two streams of material that are too cold to fuse properlyCorrect answer is option 'A'. Can you explain this answer? for Mechanical Engineering 2024 is part of Mechanical Engineering preparation. The Question and answers have been prepared according to the Mechanical Engineering exam syllabus. Information about Cold shut is a defect in casting due to[PI 2006]a)sand sliding from the cope surfaceb)internal voids or surface depression due to excessive gas trappedc)discontinuity resulting from hundred contractiond)two streams of material that are too cold to fuse properlyCorrect answer is option 'A'. Can you explain this answer? covers all topics & solutions for Mechanical Engineering 2024 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for Cold shut is a defect in casting due to[PI 2006]a)sand sliding from the cope surfaceb)internal voids or surface depression due to excessive gas trappedc)discontinuity resulting from hundred contractiond)two streams of material that are too cold to fuse properlyCorrect answer is option 'A'. Can you explain this answer?.

Solutions for Cold shut is a defect in casting due to[PI 2006]a)sand sliding from the cope surfaceb)internal voids or surface depression due to excessive gas trappedc)discontinuity resulting from hundred contractiond)two streams of material that are too cold to fuse properlyCorrect answer is option 'A'. Can you explain this answer? in English & in Hindi are available as part of our courses for Mechanical Engineering.

Download more important topics, notes, lectures and mock test series for Mechanical Engineering Exam by signing up for free.

Here you can find the meaning of Cold shut is a defect in casting due to[PI 2006]a)sand sliding from the cope surfaceb)internal voids or surface depression due to excessive gas trappedc)discontinuity resulting from hundred contractiond)two streams of material that are too cold to fuse properlyCorrect answer is option 'A'. Can you explain this answer? defined & explained in the simplest way possible. Besides giving the explanation of

Cold shut is a defect in casting due to[PI 2006]a)sand sliding from the cope surfaceb)internal voids or surface depression due to excessive gas trappedc)discontinuity resulting from hundred contractiond)two streams of material that are too cold to fuse properlyCorrect answer is option 'A'. Can you explain this answer?, a detailed solution for Cold shut is a defect in casting due to[PI 2006]a)sand sliding from the cope surfaceb)internal voids or surface depression due to excessive gas trappedc)discontinuity resulting from hundred contractiond)two streams of material that are too cold to fuse properlyCorrect answer is option 'A'. Can you explain this answer? has been provided alongside types of Cold shut is a defect in casting due to[PI 2006]a)sand sliding from the cope surfaceb)internal voids or surface depression due to excessive gas trappedc)discontinuity resulting from hundred contractiond)two streams of material that are too cold to fuse properlyCorrect answer is option 'A'. Can you explain this answer? theory, EduRev gives you an

ample number of questions to practice Cold shut is a defect in casting due to[PI 2006]a)sand sliding from the cope surfaceb)internal voids or surface depression due to excessive gas trappedc)discontinuity resulting from hundred contractiond)two streams of material that are too cold to fuse properlyCorrect answer is option 'A'. Can you explain this answer? tests, examples and also practice Mechanical Engineering tests.

|

Explore Courses for Mechanical Engineering exam

|

|

Suggested Free Tests

Signup for Free!

Signup to see your scores go up within 7 days! Learn & Practice with 1000+ FREE Notes, Videos & Tests.