All Exams >

Mechanical Engineering >

GATE Mechanical (ME) Mock Test Series 2026 >

All Questions

All questions of IC Engine for Mechanical Engineering Exam

For a heat engine operating on the Carnot cycle, the work output is ¼ th of the heat transferred to the sink. The efficiency of the engine is - a)20 %

- b)33.3 %

- c)40 %

- d)50 %

Correct answer is option 'A'. Can you explain this answer?

For a heat engine operating on the Carnot cycle, the work output is ¼ th of the heat transferred to the sink. The efficiency of the engine is

a)

20 %

b)

33.3 %

c)

40 %

d)

50 %

|

|

Tanvi Ahuja answered |

Q1->heat transferred from source to heat engine

Q2->heat transferred from heat engine to sink

So, q1 = w + q2 --(1)

Given data

w =q2 /4 - (2)

Substitute 2 in 1 you will get

q1 = q2 /4 + q2 * q1 = (5*q2) /4 --(3)

q1 = q2 /4 + q2 * q1 = (5*q2) /4 --(3)

efficiency for heat engine =1-(q2 /q1)

Now substitute 3 in above equation efficiency = 1-(4*q1/(5*q1)) = 1-(4/5) =1/5 = 0.2*10 =20%

Consider the following statements regarding Otto cycle:

1. It is not a reversible cycle.

2. Its efficiency can be improved by using a working fluid of higher value ofratio of specific heats.

3. The practical way of increasing its efficiency is to increase the compressionratio.

4. Carburetted gasoline engines working on Otto cycle can work withcompression ratios more than

Of these statements - a)1, 3 and 4 are correct

- b)1, 2 and 3 are correct

- c)1, 2 and 4 are correct

- d)2, 3 and 4 are correct

Correct answer is option 'D'. Can you explain this answer?

Consider the following statements regarding Otto cycle:

1. It is not a reversible cycle.

2. Its efficiency can be improved by using a working fluid of higher value ofratio of specific heats.

3. The practical way of increasing its efficiency is to increase the compressionratio.

4. Carburetted gasoline engines working on Otto cycle can work withcompression ratios more than

Of these statements

1. It is not a reversible cycle.

2. Its efficiency can be improved by using a working fluid of higher value ofratio of specific heats.

3. The practical way of increasing its efficiency is to increase the compressionratio.

4. Carburetted gasoline engines working on Otto cycle can work withcompression ratios more than

Of these statements

a)

1, 3 and 4 are correct

b)

1, 2 and 3 are correct

c)

1, 2 and 4 are correct

d)

2, 3 and 4 are correct

|

|

Soumya Basak answered |

Ans. (d)

Assertion (A): The C.I. engine is found to be more efficient than an S.I. engine.Reason (R): Modern C.I. engines operate on a dual-cycle, which has efficiency greaterthan the Otto cycle.- a)Both A and R are individually true and R is the correct explanation of A

- b)Both A and R are individually true but R is not the correct explanation of A

- c)A is true but R is false

- d)A is false but R is true

Correct answer is option 'B'. Can you explain this answer?

Assertion (A): The C.I. engine is found to be more efficient than an S.I. engine.Reason (R): Modern C.I. engines operate on a dual-cycle, which has efficiency greaterthan the Otto cycle.

a)

Both A and R are individually true and R is the correct explanation of A

b)

Both A and R are individually true but R is not the correct explanation of A

c)

A is true but R is false

d)

A is false but R is true

|

|

Sanya Agarwal answered |

Ans. (b)

Gudgeon pin forms the link between- a)piston and big end of connecting rod

- b)piston and small end of connecing rod

- c)connecting rod and crank

- d)big end and small end

Correct answer is option 'B'. Can you explain this answer?

Gudgeon pin forms the link between

a)

piston and big end of connecting rod

b)

piston and small end of connecing rod

c)

connecting rod and crank

d)

big end and small end

|

|

Neha Joshi answered |

In internal combustion engines, the gudgeon pin (UK, wrist pin or piston pin US) connects the piston to the connecting rod, and provides a bearing for the connecting rod to pivot upon as the piston moves.

Which one of the following cycles working within the same temperature limits has the highest work ratio? - a)Carnot cycle

- b)Joule cycle

- c)Otto cycle

- d)Rankine cycle

Correct answer is option 'D'. Can you explain this answer?

Which one of the following cycles working within the same temperature limits has the highest work ratio?

a)

Carnot cycle

b)

Joule cycle

c)

Otto cycle

d)

Rankine cycle

|

|

Kabir Verma answered |

Ans. (d) Wc is pump work in liquid state i.e. minimum

The cycle which consists of two reversible isotherms and two reversible isochores is called as- a)Rankine cycle

- b)Carnot cycle

- c)Stirling cycle

- d)Ericsson cycle

Correct answer is option 'C'. Can you explain this answer?

The cycle which consists of two reversible isotherms and two reversible isochores is called as

a)

Rankine cycle

b)

Carnot cycle

c)

Stirling cycle

d)

Ericsson cycle

|

Baishali Bajaj answered |

The Stirling cycle is a thermodynamic cycle that describes the general class of Stirling devices. This includes the original Stirling engine that was invented, developed and patented in 1816 by Robert Stirling with help from his brother, an engineer.

The ideal Otto and Diesel cycles are not totally reversible because they involve heat transfer through a finite temperature difference during the irreversible isochoric/isobaric heat-addition and heat-rejection processes. The irreversibility renders the thermal efficiency of these cycles less than that of a Carnot engine operating within the same limits of temperature. Another cycle that features isothermal heat-addition and heat-rejection processes is the Stirling cycle, which is an altered version of the Carnot cycle in which the two isentropic processes featured in the Carnot cycle are replaced by two constant-volume regeneration processes.

A diesel engine is usually more efficient than a spark ignition engine because- a)diesel being a heavier hydrocarbon, releases more heat per kg than gasoline

- b)The air standard efficiency of diesel cycle is higher than the Otto cycle, at a fixedcompression ratio

- c)The compression ratio of a diesel engine is higher than that of an SI engine

- d)Self ignition temperature of diesel is higher than that of gasoline

Correct answer is option 'C'. Can you explain this answer?

A diesel engine is usually more efficient than a spark ignition engine because

a)

diesel being a heavier hydrocarbon, releases more heat per kg than gasoline

b)

The air standard efficiency of diesel cycle is higher than the Otto cycle, at a fixedcompression ratio

c)

The compression ratio of a diesel engine is higher than that of an SI engine

d)

Self ignition temperature of diesel is higher than that of gasoline

|

|

Stuti Bajaj answered |

Ans (c)

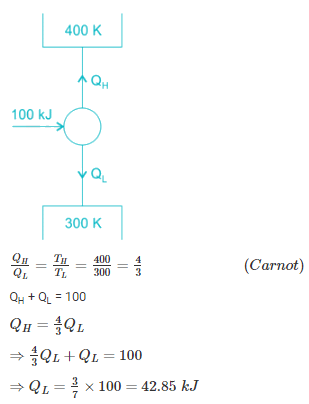

A heat transformer is a device that transfers a part of the heat, supplied to itat an intermediate temperature , to a high temperature reservoir whilerejecting the remaining part to a low temperature heat sink. In such a heattransformer, 100 kJ of heat is supplied at 350 K. The maximum amount of heatin kJ that can be transferred to 400 K, when the rest is rejected to that can betransferred to 400 K, when rest is rejected to a heat sink at 300 K is - a)12.50

- b)14.29

- c)33.33

- d)57.14

Correct answer is option 'D'. Can you explain this answer?

A heat transformer is a device that transfers a part of the heat, supplied to itat an intermediate temperature , to a high temperature reservoir whilerejecting the remaining part to a low temperature heat sink. In such a heattransformer, 100 kJ of heat is supplied at 350 K. The maximum amount of heatin kJ that can be transferred to 400 K, when the rest is rejected to that can betransferred to 400 K, when rest is rejected to a heat sink at 300 K is

a)

12.50

b)

14.29

c)

33.33

d)

57.14

|

Baishali Bajaj answered |

QH = 100 – 42.85 = 57.14 kJ

For minimizing knocking tendency is SI engine, where should the space plugbe located? - a)Near inlet valve

- b)Away from both the valves

- c)Near exhaust valve

- d)Midway between inlet and exhaust valves

Correct answer is option 'B'. Can you explain this answer?

For minimizing knocking tendency is SI engine, where should the space plugbe located?

a)

Near inlet valve

b)

Away from both the valves

c)

Near exhaust valve

d)

Midway between inlet and exhaust valves

|

|

Neha Joshi answered |

One of the fixes to engine knocking is to change the positioning of the spark plug. Since engine is a result of pre-mature burning of fuel-air mixture, the ignition mechanism must have correct spacing where the volume would be maximized. In this case, the spark plug must be placed near the exhaust valve to have greater travel distance of spark to the air-fuel mixture. This would produce less pressure to the chamber, and since the volume of the chamber is maximized, even burning of fuel-air mixture can be observed.

Assertion (A): The air standard efficiency of the diesel cycle decreases as the load is increased Reason (R): With increase of load, cut-off ratio increases. - a)Both A and R are individually true and R is the correct explanation of A

- b)Both A and R are individually true but R is not the correct explanation of A

- c)A is true but R is false

- d)A is false but R is true

Correct answer is option 'A'. Can you explain this answer?

Assertion (A): The air standard efficiency of the diesel cycle decreases as the load is increased Reason (R): With increase of load, cut-off ratio increases.

a)

Both A and R are individually true and R is the correct explanation of A

b)

Both A and R are individually true but R is not the correct explanation of A

c)

A is true but R is false

d)

A is false but R is true

|

|

Sarita Yadav answered |

Ans. (a)

For a given compression ratio the work output of Otto cycle is- a)increases with increase in compression ratio

- b)decreases with increase in compression ratio

- c)is not affected by compression ratio

- d)none of the above

Correct answer is option 'A'. Can you explain this answer?

For a given compression ratio the work output of Otto cycle is

a)

increases with increase in compression ratio

b)

decreases with increase in compression ratio

c)

is not affected by compression ratio

d)

none of the above

|

|

Avinash Sharma answered |

As compression ratio increases, the thermal efficiency of cycle increases and for the same heat input workout put increases.

In a variable speed S.I. engine, the maximum torque occurs at the maximum- a)Speed

- b)brake power

- c)Indicated power

- d)volumetric efficiency

Correct answer is option 'C'. Can you explain this answer?

In a variable speed S.I. engine, the maximum torque occurs at the maximum

a)

Speed

b)

brake power

c)

Indicated power

d)

volumetric efficiency

|

|

Pankaj Joshi answered |

Ans. (c) The torque developed by an engine is directly proportional to the indicated power.

Thus maximum torque will occur corresponding to maximum indicated power.

Thus maximum torque will occur corresponding to maximum indicated power.

For the same maximum pressure and heat input- a)The exhaust temperature of patrol is more than that of diesel engine

- b)The exhaust temperature of diesel engine is more than that of patrol engine

- c)The exhaust temperature of dual cycle engine is less than that of diesel engine

- d)The exhaust temperature of dual cycle engine is more than that of patrol engine

Correct answer is option 'A'. Can you explain this answer?

For the same maximum pressure and heat input

a)

The exhaust temperature of patrol is more than that of diesel engine

b)

The exhaust temperature of diesel engine is more than that of patrol engine

c)

The exhaust temperature of dual cycle engine is less than that of diesel engine

d)

The exhaust temperature of dual cycle engine is more than that of patrol engine

|

Anita Parida answered |

I do have d answer wid image that can explain the answer better...but here its not getting uploaded...

Consider the following statements:

Exhaust emissions of carbon monoxide from spark ignition engine is

1. mainly fuel-air mixture strength dependent

2. in the range of zero to 10%

3. measured with the help of an instrument working on the principle of nondispersiveinfra-red analysis

4. controlled by the use of a two way catalytic convertor

Which of the statements given above are correct?- a)1 and 4

- b)2 and 3

- c)1 and 3

- d)1, 2, 3 and 4

Correct answer is option 'D'. Can you explain this answer?

Consider the following statements:

Exhaust emissions of carbon monoxide from spark ignition engine is

1. mainly fuel-air mixture strength dependent

2. in the range of zero to 10%

3. measured with the help of an instrument working on the principle of nondispersiveinfra-red analysis

4. controlled by the use of a two way catalytic convertor

Which of the statements given above are correct?

Exhaust emissions of carbon monoxide from spark ignition engine is

1. mainly fuel-air mixture strength dependent

2. in the range of zero to 10%

3. measured with the help of an instrument working on the principle of nondispersiveinfra-red analysis

4. controlled by the use of a two way catalytic convertor

Which of the statements given above are correct?

a)

1 and 4

b)

2 and 3

c)

1 and 3

d)

1, 2, 3 and 4

|

|

Nandita Chakraborty answered |

Ans. (d)

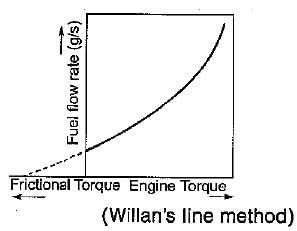

Which one of the following quantities is assumed constant for an internal combustion engine while estimating its friction power by extrapolation through Willan's line? - a)Brake thermal efficiency

- b)Indicated thermal efficiency.

- c)Mechanical efficiency

- d)Volumetric efficiency.

Correct answer is option 'B'. Can you explain this answer?

Which one of the following quantities is assumed constant for an internal combustion engine while estimating its friction power by extrapolation through Willan's line?

a)

Brake thermal efficiency

b)

Indicated thermal efficiency.

c)

Mechanical efficiency

d)

Volumetric efficiency.

|

|

Jyoti Deshpande answered |

Ans. (b)

When crude oil is heated, then which one of the following hydrocarbon is given off first?- a)Gasoline

- b)Paraffin

- c)Diesel

- d)Natural gas

Correct answer is option 'D'. Can you explain this answer?

When crude oil is heated, then which one of the following hydrocarbon is given off first?

a)

Gasoline

b)

Paraffin

c)

Diesel

d)

Natural gas

|

|

Avinash Sharma answered |

Crude petroleum, as obtained from the oil wells contains gases and certain impurities such as water, solids etc. The crude oil is separated into gasoline, kerosine, fuel oil etc. by the process of fractional distillation. In the first step, the petroleum is passed through a separator in which gases are removed and a product known as natural gasoline is obtained.

Match List I with List IT and select the correct answer using the codes given below the lists:

List I List II

(S.l. Engine problem) (Characteristic of fuel responsible for the problem)

A. Cold starting 1. Front end volatility

B. Carburetor icing 2. Mid-range volatility

C. Crankcase dilution 3. Tail end volatility

Code: A B C A B C

(a) 1 2 3 (b) 1 3 2

(c) 2 3 1 (d) 3 1 2- a)(a)

- b)(b)

- c)(c)

- d)(d)

Correct answer is option 'A'. Can you explain this answer?

Match List I with List IT and select the correct answer using the codes given below the lists:

List I List II

(S.l. Engine problem) (Characteristic of fuel responsible for the problem)

A. Cold starting 1. Front end volatility

B. Carburetor icing 2. Mid-range volatility

C. Crankcase dilution 3. Tail end volatility

Code: A B C A B C

(a) 1 2 3 (b) 1 3 2

(c) 2 3 1 (d) 3 1 2

List I List II

(S.l. Engine problem) (Characteristic of fuel responsible for the problem)

A. Cold starting 1. Front end volatility

B. Carburetor icing 2. Mid-range volatility

C. Crankcase dilution 3. Tail end volatility

Code: A B C A B C

(a) 1 2 3 (b) 1 3 2

(c) 2 3 1 (d) 3 1 2

a)

(a)

b)

(b)

c)

(c)

d)

(d)

|

Medikonda Venkata Lokesh answered |

A

Assertion (A): In SI engines, as the engine speed increases, spark is required to be advanced.Reason (R): As the engine speed increases, flame velocity increases. - a)Both A and R are individually true and R is the correct explanation of A

- b)Both A and R are individually true but R is not the correct explanation of A

- c)A is true but R is false

- d)A is false but R is true

Correct answer is option 'C'. Can you explain this answer?

Assertion (A): In SI engines, as the engine speed increases, spark is required to be advanced.Reason (R): As the engine speed increases, flame velocity increases.

a)

Both A and R are individually true and R is the correct explanation of A

b)

Both A and R are individually true but R is not the correct explanation of A

c)

A is true but R is false

d)

A is false but R is true

|

|

Kabir Verma answered |

Ans. (c)

For the same compression ratio and the same heat input, the correctsequence of the increasing order of the thermal efficiencies of the givencycles is- a)Otto, Diesel, dual

- b)Diesel, dual Otto

- c)Dual, Diesel, Otto

- d)Dual, Otto, Diesel

Correct answer is option 'B'. Can you explain this answer?

For the same compression ratio and the same heat input, the correctsequence of the increasing order of the thermal efficiencies of the givencycles is

a)

Otto, Diesel, dual

b)

Diesel, dual Otto

c)

Dual, Diesel, Otto

d)

Dual, Otto, Diesel

|

|

Aditya Chavan answered |

Ans. (b)

Which one of the following set of materials is most commonly used in catalytic converters for CI engines? - a)Platinum, palladium and rhodium

- b)Palladium, rhodium and ruthenium

- c)Rhodium, ruthenium and platinum

- d)Ruthenium, platinum and palladium

Correct answer is option 'A'. Can you explain this answer?

Which one of the following set of materials is most commonly used in catalytic converters for CI engines?

a)

Platinum, palladium and rhodium

b)

Palladium, rhodium and ruthenium

c)

Rhodium, ruthenium and platinum

d)

Ruthenium, platinum and palladium

|

|

Anshul Sharma answered |

Ans.(a)

Mean effective pressure of Otto cycle is- a)inversely proportional to pressure ratio

- b)directly proportional to pressure ratio

- c)does not depend on pressure ratio

- d)proportional to square root of pressure ratio

Correct answer is option 'B'. Can you explain this answer?

Mean effective pressure of Otto cycle is

a)

inversely proportional to pressure ratio

b)

directly proportional to pressure ratio

c)

does not depend on pressure ratio

d)

proportional to square root of pressure ratio

|

|

Rhea Reddy answered |

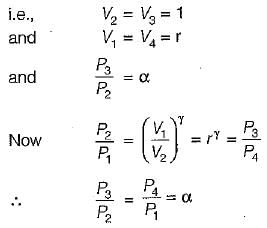

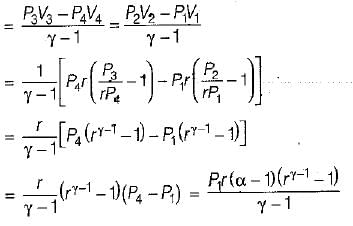

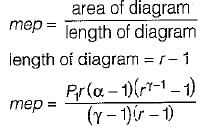

Mean effective pressure (mep) of Otto cycle: Let clearance volume be unity

Work done - area of the P-V'diagram

Hence mean effective pressure is directly proportional to pressure ratio (α) i.e., P1/P2

Which of the following symptoms shows that the combustion is necessarily complete? - a)Presence of free carbon in exhaust

- b)Presence of CO in exhaust

- c)Presence of oxygen in exhaust

- d)Presence of nitrogen in exhaust

Correct answer is option 'C'. Can you explain this answer?

Which of the following symptoms shows that the combustion is necessarily complete?

a)

Presence of free carbon in exhaust

b)

Presence of CO in exhaust

c)

Presence of oxygen in exhaust

d)

Presence of nitrogen in exhaust

|

|

Mrinalini Sharma answered |

Ans. (c)

The data given in the table refers to an engine based on Carnot cycle, whereQ1 = Heat received (kJ/min), Q2 = Heat rejected (kJ/s), W = Work output (kW)

S. No. Q1 Q2 W

1. 1500 16.80 8.20

2. 1600 17.92 8.75

3. 1700 19.03 9.30

4. 1800 20.15 9.85

If heat received by the engine is 2000 kJ/minute the work output will be,nearly,- a)9.98

- b)10.39

- c)11.54

- d)10.95

Correct answer is option 'D'. Can you explain this answer?

The data given in the table refers to an engine based on Carnot cycle, whereQ1 = Heat received (kJ/min), Q2 = Heat rejected (kJ/s), W = Work output (kW)

S. No. Q1 Q2 W

1. 1500 16.80 8.20

2. 1600 17.92 8.75

3. 1700 19.03 9.30

4. 1800 20.15 9.85

If heat received by the engine is 2000 kJ/minute the work output will be,nearly,

S. No. Q1 Q2 W

1. 1500 16.80 8.20

2. 1600 17.92 8.75

3. 1700 19.03 9.30

4. 1800 20.15 9.85

If heat received by the engine is 2000 kJ/minute the work output will be,nearly,

a)

9.98

b)

10.39

c)

11.54

d)

10.95

|

|

Muskaan Chauhan answered |

Ans. (d)

Valve overlap is the period in which

- a)intake valve is open while exhaust valve is closed.

- b)intake valve is closed while exhaust valve is open.

- c)the exhaust and intake cycles overlapping each other.

- d)both intake and exhaust valves are closed

Correct answer is option 'C'. Can you explain this answer?

Valve overlap is the period in which

a)

intake valve is open while exhaust valve is closed.

b)

intake valve is closed while exhaust valve is open.

c)

the exhaust and intake cycles overlapping each other.

d)

both intake and exhaust valves are closed

|

Keshav answered |

This valve timing is known as "overlap." Think of this as the exhaust and intake cycles overlapping each other. The valves are timed so the intake valve opens slightly before the piston reaches top dead center (TDC) on the exhaust stroke.

For a conventional S.I. engine, what is the value of fuel-air ratio in the normal operating range?- a)0.056 – 0.083

- b)0.083 – 0.56

- c)0.0056 – 0.83

- d)0.056 – 0.83

Correct answer is option 'A'. Can you explain this answer?

For a conventional S.I. engine, what is the value of fuel-air ratio in the normal operating range?

a)

0.056 – 0.083

b)

0.083 – 0.56

c)

0.0056 – 0.83

d)

0.056 – 0.83

|

|

Maulik Desai answered |

Ans. (a) (A/F) for maximum power = 12 and (A/F) for Stoichiometric = 14.5

(A/F) for maximum fuel economy = 16.

(A/F) for maximum fuel economy = 16.

In the case of a Diesel cycle, increasing the cut-off ratio will increase- a)Efficiency

- b)mean effective pressure

- c)The maximum weight

- d)the engine weight

Correct answer is option 'B'. Can you explain this answer?

In the case of a Diesel cycle, increasing the cut-off ratio will increase

a)

Efficiency

b)

mean effective pressure

c)

The maximum weight

d)

the engine weight

|

|

Bibek Das answered |

Diesel Cycle and Cut-Off Ratio

Diesel cycle is a thermodynamic cycle used in diesel engines. The cycle consists of four processes: compression, heat addition, expansion, and heat rejection. The compression and expansion processes are reversible adiabatic processes, while the heat addition and heat rejection processes are constant pressure processes.

The cut-off ratio is the ratio of the volume at which the fuel injection is cut off to the volume at the end of the compression stroke. In other words, it is the ratio of the volume of the combustion chamber at the end of the combustion process to the volume of the combustion chamber at the beginning of the combustion process.

Effect of Cut-Off Ratio on Mean Effective Pressure

The mean effective pressure (MEP) is a measure of the average pressure that acts on the piston during the power stroke of an engine. It is defined as the ratio of the work done during the power stroke to the displacement volume of the engine.

Increasing the cut-off ratio in a diesel engine increases the mean effective pressure. This is because, at higher cut-off ratios, the combustion process occurs over a smaller volume, resulting in a higher pressure and temperature in the combustion chamber. This, in turn, leads to a higher MEP.

Effect of Cut-Off Ratio on Efficiency

The efficiency of a diesel engine is the ratio of the work done by the engine to the heat supplied to the engine. The work done by the engine is the difference between the energy released during the combustion process and the energy lost due to friction and other losses.

Increasing the cut-off ratio in a diesel engine may or may not increase the efficiency, depending on the engine design and operating conditions. In general, increasing the cut-off ratio increases the temperature and pressure in the combustion chamber, which can improve the combustion efficiency and reduce the heat losses. However, at very high cut-off ratios, the combustion process may become incomplete, leading to higher emissions and lower efficiency.

Conclusion

In conclusion, increasing the cut-off ratio in a diesel engine increases the mean effective pressure, which can improve the engine performance. However, the effect of cut-off ratio on efficiency depends on various factors, and a trade-off between MEP and efficiency may need to be considered in engine design and operation.

Diesel cycle is a thermodynamic cycle used in diesel engines. The cycle consists of four processes: compression, heat addition, expansion, and heat rejection. The compression and expansion processes are reversible adiabatic processes, while the heat addition and heat rejection processes are constant pressure processes.

The cut-off ratio is the ratio of the volume at which the fuel injection is cut off to the volume at the end of the compression stroke. In other words, it is the ratio of the volume of the combustion chamber at the end of the combustion process to the volume of the combustion chamber at the beginning of the combustion process.

Effect of Cut-Off Ratio on Mean Effective Pressure

The mean effective pressure (MEP) is a measure of the average pressure that acts on the piston during the power stroke of an engine. It is defined as the ratio of the work done during the power stroke to the displacement volume of the engine.

Increasing the cut-off ratio in a diesel engine increases the mean effective pressure. This is because, at higher cut-off ratios, the combustion process occurs over a smaller volume, resulting in a higher pressure and temperature in the combustion chamber. This, in turn, leads to a higher MEP.

Effect of Cut-Off Ratio on Efficiency

The efficiency of a diesel engine is the ratio of the work done by the engine to the heat supplied to the engine. The work done by the engine is the difference between the energy released during the combustion process and the energy lost due to friction and other losses.

Increasing the cut-off ratio in a diesel engine may or may not increase the efficiency, depending on the engine design and operating conditions. In general, increasing the cut-off ratio increases the temperature and pressure in the combustion chamber, which can improve the combustion efficiency and reduce the heat losses. However, at very high cut-off ratios, the combustion process may become incomplete, leading to higher emissions and lower efficiency.

Conclusion

In conclusion, increasing the cut-off ratio in a diesel engine increases the mean effective pressure, which can improve the engine performance. However, the effect of cut-off ratio on efficiency depends on various factors, and a trade-off between MEP and efficiency may need to be considered in engine design and operation.

The method of determination of indicated power of multi-cylinder SI engineis by the use of - a)Morse test

- b)Prony brake test

- c)Motorint test

- d)Heat balance test.

Correct answer is option 'A'. Can you explain this answer?

The method of determination of indicated power of multi-cylinder SI engineis by the use of

a)

Morse test

b)

Prony brake test

c)

Motorint test

d)

Heat balance test.

|

|

Dishani Desai answered |

Ans. (a) Morse test is used to determine indicated power of multi-cylinder S.I. engine

Consider the following measures:

1. Increasing the compression ratio

2. Increasing the intake air temperature.

3. Increasing the length to diameter ratio of the cylinder.

4. Increasing the engine speed.The measures necessary to reduce the tendency to knock in CI engines wouldinclude- a)1, 2 and 3

- b)1, 2 and 4

- c)1, 3 and 4

- d)2, 3 and 4

Correct answer is option 'A'. Can you explain this answer?

Consider the following measures:

1. Increasing the compression ratio

2. Increasing the intake air temperature.

3. Increasing the length to diameter ratio of the cylinder.

4. Increasing the engine speed.The measures necessary to reduce the tendency to knock in CI engines wouldinclude

1. Increasing the compression ratio

2. Increasing the intake air temperature.

3. Increasing the length to diameter ratio of the cylinder.

4. Increasing the engine speed.The measures necessary to reduce the tendency to knock in CI engines wouldinclude

a)

1, 2 and 3

b)

1, 2 and 4

c)

1, 3 and 4

d)

2, 3 and 4

|

|

Arnav Menon answered |

Ans. (a)

A solar energy based heat engine which receives 80 kJ of heat at 100 deg Cand rejects 70 kJ of heat to the ambient at 30 deg C is to be designed. The thermal efficiency of the heat engine is- a)70%

- b)1.88%

- c)12.5%

- d)indeterminate

Correct answer is option 'C'. Can you explain this answer?

A solar energy based heat engine which receives 80 kJ of heat at 100 deg Cand rejects 70 kJ of heat to the ambient at 30 deg C is to be designed. The thermal efficiency of the heat engine is

a)

70%

b)

1.88%

c)

12.5%

d)

indeterminate

|

|

Aditya Chavan answered |

Ans. (c)

Assertion (A): The CI engine is basically more suitable for supe rcharging than the SI engine.

Reason (R): In the CI engine super charging tends to prevent diesel knocking.- a)Both A and R are individually true and R is the correct explanation of A

- b)Both A and R are individually true but R is not the correct explanation of A

- c)A is true but R is false

- d)A is false but R is true

Correct answer is option 'A'. Can you explain this answer?

Assertion (A): The CI engine is basically more suitable for supe rcharging than the SI engine.

Reason (R): In the CI engine super charging tends to prevent diesel knocking.

Reason (R): In the CI engine super charging tends to prevent diesel knocking.

a)

Both A and R are individually true and R is the correct explanation of A

b)

Both A and R are individually true but R is not the correct explanation of A

c)

A is true but R is false

d)

A is false but R is true

|

|

Raghav Saini answered |

Ans. (a)

Consider the following statements:

In a turbojet engine, thrust may be increased by

1. Increasing the jet velocity

2. Increasing the mass flow a rate of air

3. After burning of the fuel.

Of these statements- a)1 and 2 are correct

- b)2 and 3 are correct

- c)1 and 3 are correct

- d)1, 2 and 3 are correct

Correct answer is option 'D'. Can you explain this answer?

Consider the following statements:

In a turbojet engine, thrust may be increased by

1. Increasing the jet velocity

2. Increasing the mass flow a rate of air

3. After burning of the fuel.

Of these statements

In a turbojet engine, thrust may be increased by

1. Increasing the jet velocity

2. Increasing the mass flow a rate of air

3. After burning of the fuel.

Of these statements

a)

1 and 2 are correct

b)

2 and 3 are correct

c)

1 and 3 are correct

d)

1, 2 and 3 are correct

|

|

Aditya Chavan answered |

Ans. (d)

The delay period in a petrol engine is of the order of- a)0.001 sec

- b)0.002 sec

- c)0.01 sec

- d)0.05 sec

Correct answer is option 'B'. Can you explain this answer?

The delay period in a petrol engine is of the order of

a)

0.001 sec

b)

0.002 sec

c)

0.01 sec

d)

0.05 sec

|

|

Gaurav Kapoor answered |

The delay period is very short, about 0.002 sec. In high speed engines, this period will lead to significant crank movement.

Consider the following statements:

I. The performance of an S.I. engine can be improved by increasing the compression ratio.

II. Fuels of higher octane number can be employed at higher compression ratio.Of these statements- a)Both I and II are true

- b)both I and II are false

- c)I is true but II is false

- d)I is false but II is true

Correct answer is option 'D'. Can you explain this answer?

Consider the following statements:

I. The performance of an S.I. engine can be improved by increasing the compression ratio.

II. Fuels of higher octane number can be employed at higher compression ratio.Of these statements

I. The performance of an S.I. engine can be improved by increasing the compression ratio.

II. Fuels of higher octane number can be employed at higher compression ratio.Of these statements

a)

Both I and II are true

b)

both I and II are false

c)

I is true but II is false

d)

I is false but II is true

|

|

Raghav Saini answered |

Ans. (d) The performance of S.I. engine can't be improved by increasing the compression ratio because of pre-ignition and detonation.

Since high octane number tends to suppress detonation, t6 some extent fuels of higher octane number will be helpful at higher compression ratio.

Since high octane number tends to suppress detonation, t6 some extent fuels of higher octane number will be helpful at higher compression ratio.

Only rocket engines can be propelled to 'SPACE' because - a)They can generate very high thrust.

- b)They have high propulsion efficiency.

- c)These engines can work on several fuels.

- d)They are not air-beating engines.

Correct answer is option 'D'. Can you explain this answer?

Only rocket engines can be propelled to 'SPACE' because

a)

They can generate very high thrust.

b)

They have high propulsion efficiency.

c)

These engines can work on several fuels.

d)

They are not air-beating engines.

|

|

Dhruv Dasgupta answered |

Ans. (d) Rocket engines can be propelled to space because they are not air breathing

engines

engines

Alcohols are unsuitable as diesel engine fuels because - a)The cetane number of alcohol fuels is very low which prevents their ignition bycompression

- b)The cetane number of alcohol fuels is very high which prevents their ignition bycompression

- c)The cetane number of alcohol fuels is very low And high which prevents their ignition bycompression

- d)None of the above

Correct answer is option 'A'. Can you explain this answer?

Alcohols are unsuitable as diesel engine fuels because

a)

The cetane number of alcohol fuels is very low which prevents their ignition bycompression

b)

The cetane number of alcohol fuels is very high which prevents their ignition bycompression

c)

The cetane number of alcohol fuels is very low And high which prevents their ignition bycompression

d)

None of the above

|

|

Shreya Choudhury answered |

Ans. (a)

What is the flash point of a liquid fuel? - a)The temperature at which the fuel ignites spontaneously with a bang

- b)The temperature at which the fuel emits vapours at a rate which produces aninflammable mixture with air

- c)The temperature at which the fuel ignites with a clearly

- d)The temperature at which the fuel ignites without a spark

Correct answer is option 'B'. Can you explain this answer?

What is the flash point of a liquid fuel?

a)

The temperature at which the fuel ignites spontaneously with a bang

b)

The temperature at which the fuel emits vapours at a rate which produces aninflammable mixture with air

c)

The temperature at which the fuel ignites with a clearly

d)

The temperature at which the fuel ignites without a spark

|

|

Yash Das answered |

Ans. (b)

The measurement of frictional power by Willians line is applicable to- a)SI engines at a particular speed.

- b)Cl engines at a particular speed.

- c)any engine at a particular speed only.

- d)Dual fuel engines at a particular speed.

Correct answer is option 'B'. Can you explain this answer?

The measurement of frictional power by Willians line is applicable to

a)

SI engines at a particular speed.

b)

Cl engines at a particular speed.

c)

any engine at a particular speed only.

d)

Dual fuel engines at a particular speed.

|

Madhurima Banerjee answered |

Addition of TEL in gasoline is being discontinued as- a)it has bad odour

- b)it is costly

- c)decreases engine efficiency

- d)blocks the catalytic converter

Correct answer is option 'D'. Can you explain this answer?

Addition of TEL in gasoline is being discontinued as

a)

it has bad odour

b)

it is costly

c)

decreases engine efficiency

d)

blocks the catalytic converter

|

|

Sparsh Chakraborty answered |

Discontinuation of TEL in Gasoline

Introduction:

Tetraethyl lead (TEL) is an organic compound that has been widely used as an octane booster in gasoline. However, in recent years, there has been a growing concern over the health and environmental impacts of TEL. As a result, many countries have discontinued the use of TEL in gasoline. In this article, we will discuss why the addition of TEL in gasoline is being discontinued.

Blocking of Catalytic Converter:

One of the main reasons why TEL is being discontinued in gasoline is because it blocks the catalytic converter. The catalytic converter is an emission control device that reduces the amount of harmful pollutants that are emitted from the exhaust system of a vehicle. However, TEL reacts with the catalyst in the converter and forms a lead-based deposit that clogs the converter, reducing its efficiency and causing it to fail.

Health and Environmental Concerns:

TEL is also a toxic substance that can have serious health and environmental impacts. Exposure to TEL can cause neurological damage, kidney damage, reproductive issues, and even death. Additionally, TEL is a major source of lead pollution in the environment, which can lead to soil and water contamination.

Cost and Odour:

Apart from the health and environmental concerns, TEL is also costly to produce and transport. In addition, it has a distinct and unpleasant odour, which can be a nuisance for those who live near refineries or gasoline stations.

Conclusion:

In conclusion, the addition of TEL in gasoline is being discontinued mainly because it blocks the catalytic converter, poses health and environmental risks, is costly, and has an unpleasant odour. The discontinuation of TEL in gasoline is a positive step towards reducing pollution and protecting public health.

Introduction:

Tetraethyl lead (TEL) is an organic compound that has been widely used as an octane booster in gasoline. However, in recent years, there has been a growing concern over the health and environmental impacts of TEL. As a result, many countries have discontinued the use of TEL in gasoline. In this article, we will discuss why the addition of TEL in gasoline is being discontinued.

Blocking of Catalytic Converter:

One of the main reasons why TEL is being discontinued in gasoline is because it blocks the catalytic converter. The catalytic converter is an emission control device that reduces the amount of harmful pollutants that are emitted from the exhaust system of a vehicle. However, TEL reacts with the catalyst in the converter and forms a lead-based deposit that clogs the converter, reducing its efficiency and causing it to fail.

Health and Environmental Concerns:

TEL is also a toxic substance that can have serious health and environmental impacts. Exposure to TEL can cause neurological damage, kidney damage, reproductive issues, and even death. Additionally, TEL is a major source of lead pollution in the environment, which can lead to soil and water contamination.

Cost and Odour:

Apart from the health and environmental concerns, TEL is also costly to produce and transport. In addition, it has a distinct and unpleasant odour, which can be a nuisance for those who live near refineries or gasoline stations.

Conclusion:

In conclusion, the addition of TEL in gasoline is being discontinued mainly because it blocks the catalytic converter, poses health and environmental risks, is costly, and has an unpleasant odour. The discontinuation of TEL in gasoline is a positive step towards reducing pollution and protecting public health.

Blending of fuel is the process of

- a)obtaining a product of desired quality.

- b)just mixing two fuels.

- c)mixing of fuel and air for combustion.

- d)converting unstable compounds into stable ones

Correct answer is option 'B'. Can you explain this answer?

Blending of fuel is the process of

a)

obtaining a product of desired quality.

b)

just mixing two fuels.

c)

mixing of fuel and air for combustion.

d)

converting unstable compounds into stable ones

|

Anmol Roy answered |

Blending of fuel

Fuel blending is the process of combining different types or grades of fuel in order to achieve a product with specific properties or qualities. It involves mixing fuels in specific proportions to obtain a final product that meets the desired standards or requirements.

Benefits of fuel blending

Fuel blending offers several benefits, including:

1. Quality control: Blending allows for precise control over the properties of the final fuel product, ensuring that it meets the desired specifications and standards.

2. Cost optimization: By blending different fuels, it is possible to achieve a product that provides optimal performance at a lower cost. This is particularly important in industries such as transportation and power generation, where fuel costs represent a significant portion of the overall expenses.

3. Emission reduction: Blending fuels can help reduce harmful emissions by optimizing the combustion process. By adjusting the fuel composition, it is possible to achieve a cleaner and more efficient combustion, resulting in lower emissions of pollutants such as nitrogen oxides (NOx), sulfur oxides (SOx), and particulate matter (PM).

4. Availability: Fuel blending can also help overcome supply constraints by allowing the use of alternative or less expensive fuel sources. By blending different fuels, it is possible to utilize locally available resources or by-products from other industries, reducing dependence on imported fuels.

Process of fuel blending

The process of fuel blending involves several steps:

1. Fuel analysis: The first step is to analyze the properties and characteristics of the fuels that will be used in the blending process. This includes measuring parameters such as density, viscosity, flash point, sulfur content, and calorific value.

2. Formulation: Based on the desired specifications of the final product, a formulation is developed that determines the proportions of each fuel component. This formulation takes into account the desired properties, regulatory requirements, and cost considerations.

3. Mixing: The fuels are then mixed together in the prescribed proportions. This can be done using mechanical blending equipment such as tanks, pumps, and mixers. The mixing process ensures that the different fuel components are thoroughly combined to achieve a homogenous blend.

4. Quality control: After the blending process, the final fuel product is tested to ensure that it meets the desired specifications. This includes conducting tests for parameters such as density, viscosity, flash point, sulfur content, and octane or cetane number.

By following these steps, the blending process ensures that the final fuel product has the desired quality and meets the specific requirements for its intended use.

In conclusion, blending of fuel is the process of combining different fuels in specific proportions to obtain a product of desired quality. It allows for quality control, cost optimization, emission reduction, and improved availability of fuel. The process involves fuel analysis, formulation, mixing, and quality control to ensure that the final product meets the desired specifications.

Fuel blending is the process of combining different types or grades of fuel in order to achieve a product with specific properties or qualities. It involves mixing fuels in specific proportions to obtain a final product that meets the desired standards or requirements.

Benefits of fuel blending

Fuel blending offers several benefits, including:

1. Quality control: Blending allows for precise control over the properties of the final fuel product, ensuring that it meets the desired specifications and standards.

2. Cost optimization: By blending different fuels, it is possible to achieve a product that provides optimal performance at a lower cost. This is particularly important in industries such as transportation and power generation, where fuel costs represent a significant portion of the overall expenses.

3. Emission reduction: Blending fuels can help reduce harmful emissions by optimizing the combustion process. By adjusting the fuel composition, it is possible to achieve a cleaner and more efficient combustion, resulting in lower emissions of pollutants such as nitrogen oxides (NOx), sulfur oxides (SOx), and particulate matter (PM).

4. Availability: Fuel blending can also help overcome supply constraints by allowing the use of alternative or less expensive fuel sources. By blending different fuels, it is possible to utilize locally available resources or by-products from other industries, reducing dependence on imported fuels.

Process of fuel blending

The process of fuel blending involves several steps:

1. Fuel analysis: The first step is to analyze the properties and characteristics of the fuels that will be used in the blending process. This includes measuring parameters such as density, viscosity, flash point, sulfur content, and calorific value.

2. Formulation: Based on the desired specifications of the final product, a formulation is developed that determines the proportions of each fuel component. This formulation takes into account the desired properties, regulatory requirements, and cost considerations.

3. Mixing: The fuels are then mixed together in the prescribed proportions. This can be done using mechanical blending equipment such as tanks, pumps, and mixers. The mixing process ensures that the different fuel components are thoroughly combined to achieve a homogenous blend.

4. Quality control: After the blending process, the final fuel product is tested to ensure that it meets the desired specifications. This includes conducting tests for parameters such as density, viscosity, flash point, sulfur content, and octane or cetane number.

By following these steps, the blending process ensures that the final fuel product has the desired quality and meets the specific requirements for its intended use.

In conclusion, blending of fuel is the process of combining different fuels in specific proportions to obtain a product of desired quality. It allows for quality control, cost optimization, emission reduction, and improved availability of fuel. The process involves fuel analysis, formulation, mixing, and quality control to ensure that the final product meets the desired specifications.

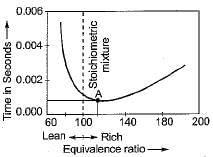

In SI engines, maximum flame speed is obtained when the equivalence ratio is between- a)1.1 and 1.2

- b)1.0 and 1.1

- c)1.2 and 1.3

- d)>1.3

Correct answer is option 'A'. Can you explain this answer?

In SI engines, maximum flame speed is obtained when the equivalence ratio is between

a)

1.1 and 1.2

b)

1.0 and 1.1

c)

1.2 and 1.3

d)

>1.3

|

|

Ayush Chawla answered |

The highest flame speed (minimum time for complete combustion) is obtained with richer mixture (Point A).

Consider the following statements:

1. In a carburettor the throttle valve is used to control the fuel supply.

2. The fuel level in the float chambers is to be about 4 to 5 mm below theorifice level of main jet.

3. An idle jet provides extra fuel during sudden acceleration.

4. A choke valve restricts the air supply to make the gas richer with fuel.

Which of the statements given above are correct?- a)2 and 4

- b)1 and 3

- c)1, 2 and 3

- d)2, 3 and 4

Correct answer is option 'A'. Can you explain this answer?

Consider the following statements:

1. In a carburettor the throttle valve is used to control the fuel supply.

2. The fuel level in the float chambers is to be about 4 to 5 mm below theorifice level of main jet.

3. An idle jet provides extra fuel during sudden acceleration.

4. A choke valve restricts the air supply to make the gas richer with fuel.

Which of the statements given above are correct?

1. In a carburettor the throttle valve is used to control the fuel supply.

2. The fuel level in the float chambers is to be about 4 to 5 mm below theorifice level of main jet.

3. An idle jet provides extra fuel during sudden acceleration.

4. A choke valve restricts the air supply to make the gas richer with fuel.

Which of the statements given above are correct?

a)

2 and 4

b)

1 and 3

c)

1, 2 and 3

d)

2, 3 and 4

|

|

Bhargavi Chauhan answered |

Ans. (a) 1 is false: In a carburetor the throttle valve is used to control the air-fuel mixture supply.

3 is false: An Idle jet provides extra-fuel during idling and low speed.

3 is false: An Idle jet provides extra-fuel during idling and low speed.

The best method of measuring speed is by- a)mechanical tachometer

- b)electrical tachometer

- c)magnetic pickup

- d)none of these

Correct answer is option 'C'. Can you explain this answer?

The best method of measuring speed is by

a)

mechanical tachometer

b)

electrical tachometer

c)

magnetic pickup

d)

none of these

|

Snehal Tiwari answered |

Understanding Speed Measurement Methods

Measuring speed accurately is crucial in various engineering applications. Among the options provided, a magnetic pickup is deemed the most effective method. Here’s why:

1. Definition of Magnetic Pickup

- A magnetic pickup is a sensor that detects the rotation of a ferromagnetic object, such as a gear or a shaft.

- It generates an electrical signal based on changes in magnetic fields as the object rotates.

2. Advantages of Magnetic Pickup

- High Accuracy: Magnetic pickups provide precise measurements, making them suitable for applications requiring exact speed readings.

- Durability: They are robust and can withstand harsh environmental conditions, including temperature fluctuations and vibrations.

- Low Maintenance: With no moving parts, magnetic pickups require minimal maintenance compared to mechanical and electrical tachometers.

3. Comparison with Other Methods

- Mechanical Tachometers: These use gears and moving parts, which can wear out over time, leading to inaccuracies.

- Electrical Tachometers: While they offer good accuracy, they can be affected by electrical noise and require calibration.

- Magnetic Pickup: Unlike the others, it is less prone to wear, thereby ensuring long-term reliability.

4. Applications

- Magnetic pickups are widely used in automotive, aerospace, and manufacturing industries for monitoring engine speed, conveyor belt speed, and more.

In conclusion, the magnetic pickup stands out as the best method for measuring speed due to its accuracy, durability, and low maintenance requirements. It is an essential tool for engineers seeking reliable and precise speed measurements in various applications.

Measuring speed accurately is crucial in various engineering applications. Among the options provided, a magnetic pickup is deemed the most effective method. Here’s why:

1. Definition of Magnetic Pickup

- A magnetic pickup is a sensor that detects the rotation of a ferromagnetic object, such as a gear or a shaft.

- It generates an electrical signal based on changes in magnetic fields as the object rotates.

2. Advantages of Magnetic Pickup

- High Accuracy: Magnetic pickups provide precise measurements, making them suitable for applications requiring exact speed readings.

- Durability: They are robust and can withstand harsh environmental conditions, including temperature fluctuations and vibrations.

- Low Maintenance: With no moving parts, magnetic pickups require minimal maintenance compared to mechanical and electrical tachometers.

3. Comparison with Other Methods

- Mechanical Tachometers: These use gears and moving parts, which can wear out over time, leading to inaccuracies.

- Electrical Tachometers: While they offer good accuracy, they can be affected by electrical noise and require calibration.

- Magnetic Pickup: Unlike the others, it is less prone to wear, thereby ensuring long-term reliability.

4. Applications

- Magnetic pickups are widely used in automotive, aerospace, and manufacturing industries for monitoring engine speed, conveyor belt speed, and more.

In conclusion, the magnetic pickup stands out as the best method for measuring speed due to its accuracy, durability, and low maintenance requirements. It is an essential tool for engineers seeking reliable and precise speed measurements in various applications.

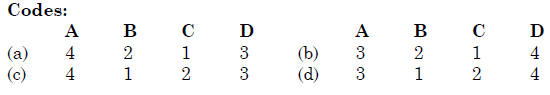

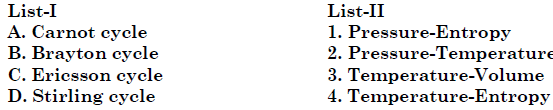

Match List-l (Gas Cycles) with List-ll (Thermodynamic co-ordinates) and select the correct answer using the codes given below the lists:

- a)(a)

- b)(b)

- c)(c)

- d)(d)

Correct answer is option 'C'. Can you explain this answer?

Match List-l (Gas Cycles) with List-ll (Thermodynamic co-ordinates) and select the correct answer using the codes given below the lists:

a)

(a)

b)

(b)

c)

(c)

d)

(d)

|

Dilip Sahani answered |

Carnot cycle-2 isntropic and 2 isothermalBrayton cycle- 2 isobaric &2 isentropicEricsson cycle-2 isobaric & 2 isothermalStirling cycle-2 isochoric & 2 isothermal

Chapter doubts & questions for IC Engine - GATE Mechanical (ME) Mock Test Series 2026 2025 is part of Mechanical Engineering exam preparation. The chapters have been prepared according to the Mechanical Engineering exam syllabus. The Chapter doubts & questions, notes, tests & MCQs are made for Mechanical Engineering 2025 Exam. Find important definitions, questions, notes, meanings, examples, exercises, MCQs and online tests here.

Chapter doubts & questions of IC Engine - GATE Mechanical (ME) Mock Test Series 2026 in English & Hindi are available as part of Mechanical Engineering exam.

Download more important topics, notes, lectures and mock test series for Mechanical Engineering Exam by signing up for free.

GATE Mechanical (ME) Mock Test Series 2026

30 docs|220 tests

|

Contact Support

Our team is online on weekdays between 10 AM - 7 PM

Typical reply within 3 hours

|

Free Exam Preparation

at your Fingertips!

Access Free Study Material - Test Series, Structured Courses, Free Videos & Study Notes and Prepare for Your Exam With Ease

Join the 10M+ students on EduRev

Join the 10M+ students on EduRev

|

|

Create your account for free

OR

Forgot Password

OR

Signup to see your scores

go up

within 7 days!

within 7 days!

Takes less than 10 seconds to signup