SSC Exam > SSC Questions > Facing operation isa)machining the ends of a...

Start Learning for Free

Facing operation is

- a)machining the ends of a workpiece to produce a flat surface square with the axis

- b)reducing the diameter of a workpiece over a very narrow surface

- c)embossing a diamond-shaped pattern on the surface of a workpiece

- d)beveling the extreme end of a workpiece

Correct answer is option 'A'. Can you explain this answer?

| FREE This question is part of | Download PDF Attempt this Test |

Verified Answer

Facing operation isa)machining the ends of a workpiece to produce a f...

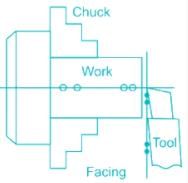

Facing is a machining operation by which the end surface of the workpiece is made flat by removing metal from it.

View all questions of this test

Undercutting/Grooving is the process of reducing the diameter of a workpiece over a narrow surface.

Knurling is an operation of embossing a diamond-shaped pattern on the surface of a workpiece.

Chamfering is the operation of bevelling the extreme end of a workpiece. It is used to remove the sharp edge of the workpiece surface.

Most Upvoted Answer

Facing operation isa)machining the ends of a workpiece to produce a f...

Facing Operation Explanation:

Facing operation involves machining the ends of a workpiece to produce a flat surface square with the axis. Here's a detailed explanation of this process:

Definition:

Facing is a machining operation where the tool is perpendicular to the workpiece's surface, creating a flat surface at the end of the workpiece.

Process:

1. The workpiece is mounted securely in the machine tool.

2. A cutting tool is brought into contact with the end of the workpiece.

3. The tool removes material from the end of the workpiece, creating a flat surface that is square with the axis of the workpiece.

Purpose:

The main purpose of facing operation is to create a smooth and flat surface at the end of the workpiece. This is essential for ensuring that the workpiece can be accurately positioned and measured for further machining operations.

Applications:

Facing operation is commonly used in various industries such as automotive, aerospace, and manufacturing. It is often the first step in the machining process to prepare the workpiece for subsequent operations.

Importance:

Facing operation is critical for achieving precision and accuracy in machined parts. It helps ensure that the workpiece meets the required specifications and dimensions for the final product.

Conclusion:

In conclusion, facing operation is a fundamental machining process that involves machining the ends of a workpiece to produce a flat surface square with the axis. It is essential for creating high-quality machined parts in various industries.

Facing operation involves machining the ends of a workpiece to produce a flat surface square with the axis. Here's a detailed explanation of this process:

Definition:

Facing is a machining operation where the tool is perpendicular to the workpiece's surface, creating a flat surface at the end of the workpiece.

Process:

1. The workpiece is mounted securely in the machine tool.

2. A cutting tool is brought into contact with the end of the workpiece.

3. The tool removes material from the end of the workpiece, creating a flat surface that is square with the axis of the workpiece.

Purpose:

The main purpose of facing operation is to create a smooth and flat surface at the end of the workpiece. This is essential for ensuring that the workpiece can be accurately positioned and measured for further machining operations.

Applications:

Facing operation is commonly used in various industries such as automotive, aerospace, and manufacturing. It is often the first step in the machining process to prepare the workpiece for subsequent operations.

Importance:

Facing operation is critical for achieving precision and accuracy in machined parts. It helps ensure that the workpiece meets the required specifications and dimensions for the final product.

Conclusion:

In conclusion, facing operation is a fundamental machining process that involves machining the ends of a workpiece to produce a flat surface square with the axis. It is essential for creating high-quality machined parts in various industries.

|

Explore Courses for SSC exam

|

|

Similar SSC Doubts

Facing operation isa)machining the ends of a workpiece to produce a flat surface square with the axisb)reducing the diameter of a workpiece over a very narrow surfacec)embossing a diamond-shaped pattern on the surface of a workpieced)beveling the extreme end of a workpieceCorrect answer is option 'A'. Can you explain this answer?

Question Description

Facing operation isa)machining the ends of a workpiece to produce a flat surface square with the axisb)reducing the diameter of a workpiece over a very narrow surfacec)embossing a diamond-shaped pattern on the surface of a workpieced)beveling the extreme end of a workpieceCorrect answer is option 'A'. Can you explain this answer? for SSC 2024 is part of SSC preparation. The Question and answers have been prepared according to the SSC exam syllabus. Information about Facing operation isa)machining the ends of a workpiece to produce a flat surface square with the axisb)reducing the diameter of a workpiece over a very narrow surfacec)embossing a diamond-shaped pattern on the surface of a workpieced)beveling the extreme end of a workpieceCorrect answer is option 'A'. Can you explain this answer? covers all topics & solutions for SSC 2024 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for Facing operation isa)machining the ends of a workpiece to produce a flat surface square with the axisb)reducing the diameter of a workpiece over a very narrow surfacec)embossing a diamond-shaped pattern on the surface of a workpieced)beveling the extreme end of a workpieceCorrect answer is option 'A'. Can you explain this answer?.

Facing operation isa)machining the ends of a workpiece to produce a flat surface square with the axisb)reducing the diameter of a workpiece over a very narrow surfacec)embossing a diamond-shaped pattern on the surface of a workpieced)beveling the extreme end of a workpieceCorrect answer is option 'A'. Can you explain this answer? for SSC 2024 is part of SSC preparation. The Question and answers have been prepared according to the SSC exam syllabus. Information about Facing operation isa)machining the ends of a workpiece to produce a flat surface square with the axisb)reducing the diameter of a workpiece over a very narrow surfacec)embossing a diamond-shaped pattern on the surface of a workpieced)beveling the extreme end of a workpieceCorrect answer is option 'A'. Can you explain this answer? covers all topics & solutions for SSC 2024 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for Facing operation isa)machining the ends of a workpiece to produce a flat surface square with the axisb)reducing the diameter of a workpiece over a very narrow surfacec)embossing a diamond-shaped pattern on the surface of a workpieced)beveling the extreme end of a workpieceCorrect answer is option 'A'. Can you explain this answer?.

Solutions for Facing operation isa)machining the ends of a workpiece to produce a flat surface square with the axisb)reducing the diameter of a workpiece over a very narrow surfacec)embossing a diamond-shaped pattern on the surface of a workpieced)beveling the extreme end of a workpieceCorrect answer is option 'A'. Can you explain this answer? in English & in Hindi are available as part of our courses for SSC.

Download more important topics, notes, lectures and mock test series for SSC Exam by signing up for free.

Here you can find the meaning of Facing operation isa)machining the ends of a workpiece to produce a flat surface square with the axisb)reducing the diameter of a workpiece over a very narrow surfacec)embossing a diamond-shaped pattern on the surface of a workpieced)beveling the extreme end of a workpieceCorrect answer is option 'A'. Can you explain this answer? defined & explained in the simplest way possible. Besides giving the explanation of

Facing operation isa)machining the ends of a workpiece to produce a flat surface square with the axisb)reducing the diameter of a workpiece over a very narrow surfacec)embossing a diamond-shaped pattern on the surface of a workpieced)beveling the extreme end of a workpieceCorrect answer is option 'A'. Can you explain this answer?, a detailed solution for Facing operation isa)machining the ends of a workpiece to produce a flat surface square with the axisb)reducing the diameter of a workpiece over a very narrow surfacec)embossing a diamond-shaped pattern on the surface of a workpieced)beveling the extreme end of a workpieceCorrect answer is option 'A'. Can you explain this answer? has been provided alongside types of Facing operation isa)machining the ends of a workpiece to produce a flat surface square with the axisb)reducing the diameter of a workpiece over a very narrow surfacec)embossing a diamond-shaped pattern on the surface of a workpieced)beveling the extreme end of a workpieceCorrect answer is option 'A'. Can you explain this answer? theory, EduRev gives you an

ample number of questions to practice Facing operation isa)machining the ends of a workpiece to produce a flat surface square with the axisb)reducing the diameter of a workpiece over a very narrow surfacec)embossing a diamond-shaped pattern on the surface of a workpieced)beveling the extreme end of a workpieceCorrect answer is option 'A'. Can you explain this answer? tests, examples and also practice SSC tests.

|

Explore Courses for SSC exam

|

|

Signup for Free!

Signup to see your scores go up within 7 days! Learn & Practice with 1000+ FREE Notes, Videos & Tests.