SSC Exam > SSC Questions > ______ is the total area under the stress-st...

Start Learning for Free

______ is the total area under the stress-strain curve in a tension test.

- a)Modulus of elasticity

- b)Modulus of toughness

- c)Modulus of Resilience

- d)Resilience

Correct answer is option 'B'. Can you explain this answer?

Most Upvoted Answer

______ is the total area under the stress-strain curve in a tension t...

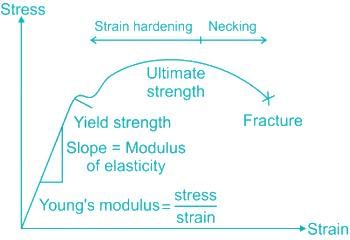

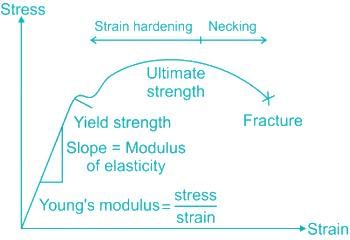

Modulus of elasticity is defined as the slope of its stress-strain curve in the elastic deformation region.

Strain Energy of the member is defined as the internal work done in deforming the body by the action of externally applied forces.

Resilience is defined as the capacity of a strained body for doing work on the removal of the straining force.

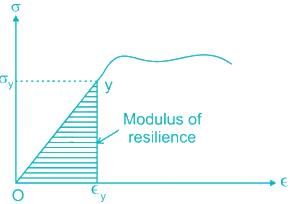

Proof resilience is defined as the maximum strain energy stored in a body. So, it is the quantity of strain energy stored in a body when strained up to the elastic limit (ability to store or absorb energy without permanent deformation).

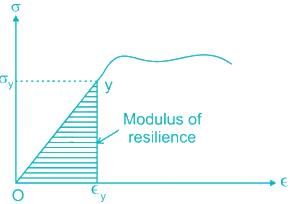

Modulus of resilience is defined as proof resilience per unit volume. It is the area under the stress-strain curve up to the elastic limit.

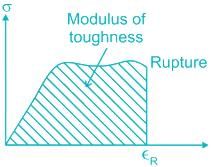

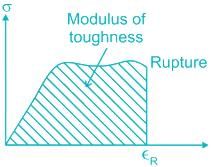

The modulus of toughness is the ability to absorb energy up to fracture. From the stress-strain diagram, the area under the complete curve gives the measure of modulus of toughness.

Free Test

FREE

| Start Free Test |

Community Answer

______ is the total area under the stress-strain curve in a tension t...

Modulus of toughness is the correct answer.

The stress-strain curve is a graphical representation of the relationship between stress (force per unit area) and strain (deformation) during a tension test. This test is used to determine the mechanical properties of a material, including its strength and ductility.

The total area under the stress-strain curve represents the energy absorbed by the material during the test. This energy is a measure of the material's toughness, which is its ability to absorb energy before fracture. The modulus of toughness is therefore defined as the total area under the stress-strain curve.

To understand this concept better, let's break down the stress-strain curve and its different regions:

1. Elastic Region: In the initial linear portion of the curve, the material behaves elastically and returns to its original shape after the applied load is removed. The modulus of elasticity (Young's modulus) represents the slope of this linear region and is a measure of the material's stiffness.

2. Yield Point: Beyond the elastic region, the material starts to deform plastically, and a yield point is observed. The stress at this point is known as the yield stress, which is an indication of the material's strength.

3. Plastic Region: After the yield point, the material undergoes significant plastic deformation without a substantial increase in stress. This region is characterized by strain hardening, where the material becomes stronger as it deforms. The modulus of resilience represents the area under the elastic region of the stress-strain curve and is a measure of the material's ability to store energy.

4. Ultimate Tensile Strength: The maximum stress the material can withstand before failure is known as the ultimate tensile strength. This point marks the end of the plastic deformation and the beginning of fracture.

5. Fracture Point: The material fractures when the stress exceeds its ultimate tensile strength. The area under the stress-strain curve beyond this point represents the energy absorbed by the material during fracture and is a measure of its toughness.

In conclusion, the total area under the stress-strain curve in a tension test represents the energy absorbed by the material and is defined as the modulus of toughness.

The stress-strain curve is a graphical representation of the relationship between stress (force per unit area) and strain (deformation) during a tension test. This test is used to determine the mechanical properties of a material, including its strength and ductility.

The total area under the stress-strain curve represents the energy absorbed by the material during the test. This energy is a measure of the material's toughness, which is its ability to absorb energy before fracture. The modulus of toughness is therefore defined as the total area under the stress-strain curve.

To understand this concept better, let's break down the stress-strain curve and its different regions:

1. Elastic Region: In the initial linear portion of the curve, the material behaves elastically and returns to its original shape after the applied load is removed. The modulus of elasticity (Young's modulus) represents the slope of this linear region and is a measure of the material's stiffness.

2. Yield Point: Beyond the elastic region, the material starts to deform plastically, and a yield point is observed. The stress at this point is known as the yield stress, which is an indication of the material's strength.

3. Plastic Region: After the yield point, the material undergoes significant plastic deformation without a substantial increase in stress. This region is characterized by strain hardening, where the material becomes stronger as it deforms. The modulus of resilience represents the area under the elastic region of the stress-strain curve and is a measure of the material's ability to store energy.

4. Ultimate Tensile Strength: The maximum stress the material can withstand before failure is known as the ultimate tensile strength. This point marks the end of the plastic deformation and the beginning of fracture.

5. Fracture Point: The material fractures when the stress exceeds its ultimate tensile strength. The area under the stress-strain curve beyond this point represents the energy absorbed by the material during fracture and is a measure of its toughness.

In conclusion, the total area under the stress-strain curve in a tension test represents the energy absorbed by the material and is defined as the modulus of toughness.

|

Explore Courses for SSC exam

|

|

Similar SSC Doubts

______ is the total area under the stress-strain curve in a tension test.a)Modulus of elasticityb)Modulus of toughnessc)Modulus of Resilienced)ResilienceCorrect answer is option 'B'. Can you explain this answer?

Question Description

______ is the total area under the stress-strain curve in a tension test.a)Modulus of elasticityb)Modulus of toughnessc)Modulus of Resilienced)ResilienceCorrect answer is option 'B'. Can you explain this answer? for SSC 2025 is part of SSC preparation. The Question and answers have been prepared according to the SSC exam syllabus. Information about ______ is the total area under the stress-strain curve in a tension test.a)Modulus of elasticityb)Modulus of toughnessc)Modulus of Resilienced)ResilienceCorrect answer is option 'B'. Can you explain this answer? covers all topics & solutions for SSC 2025 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for ______ is the total area under the stress-strain curve in a tension test.a)Modulus of elasticityb)Modulus of toughnessc)Modulus of Resilienced)ResilienceCorrect answer is option 'B'. Can you explain this answer?.

______ is the total area under the stress-strain curve in a tension test.a)Modulus of elasticityb)Modulus of toughnessc)Modulus of Resilienced)ResilienceCorrect answer is option 'B'. Can you explain this answer? for SSC 2025 is part of SSC preparation. The Question and answers have been prepared according to the SSC exam syllabus. Information about ______ is the total area under the stress-strain curve in a tension test.a)Modulus of elasticityb)Modulus of toughnessc)Modulus of Resilienced)ResilienceCorrect answer is option 'B'. Can you explain this answer? covers all topics & solutions for SSC 2025 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for ______ is the total area under the stress-strain curve in a tension test.a)Modulus of elasticityb)Modulus of toughnessc)Modulus of Resilienced)ResilienceCorrect answer is option 'B'. Can you explain this answer?.

Solutions for ______ is the total area under the stress-strain curve in a tension test.a)Modulus of elasticityb)Modulus of toughnessc)Modulus of Resilienced)ResilienceCorrect answer is option 'B'. Can you explain this answer? in English & in Hindi are available as part of our courses for SSC.

Download more important topics, notes, lectures and mock test series for SSC Exam by signing up for free.

Here you can find the meaning of ______ is the total area under the stress-strain curve in a tension test.a)Modulus of elasticityb)Modulus of toughnessc)Modulus of Resilienced)ResilienceCorrect answer is option 'B'. Can you explain this answer? defined & explained in the simplest way possible. Besides giving the explanation of

______ is the total area under the stress-strain curve in a tension test.a)Modulus of elasticityb)Modulus of toughnessc)Modulus of Resilienced)ResilienceCorrect answer is option 'B'. Can you explain this answer?, a detailed solution for ______ is the total area under the stress-strain curve in a tension test.a)Modulus of elasticityb)Modulus of toughnessc)Modulus of Resilienced)ResilienceCorrect answer is option 'B'. Can you explain this answer? has been provided alongside types of ______ is the total area under the stress-strain curve in a tension test.a)Modulus of elasticityb)Modulus of toughnessc)Modulus of Resilienced)ResilienceCorrect answer is option 'B'. Can you explain this answer? theory, EduRev gives you an

ample number of questions to practice ______ is the total area under the stress-strain curve in a tension test.a)Modulus of elasticityb)Modulus of toughnessc)Modulus of Resilienced)ResilienceCorrect answer is option 'B'. Can you explain this answer? tests, examples and also practice SSC tests.

|

Explore Courses for SSC exam

|

|

Signup for Free!

Signup to see your scores go up within 7 days! Learn & Practice with 1000+ FREE Notes, Videos & Tests.