All Exams >

Mechanical Engineering >

Manufacturing Engineering >

All Questions

All questions of Metal Casting for Mechanical Engineering Exam

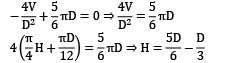

The size of a cylindrical side riser, whose height and diameter are equal, to feed a steel slab casting 30cm 30cm

30cm  30cm is ____________(Use modulus method)

30cm is ____________(Use modulus method)- a) 2872

- b) 2873

Correct answer is between ' 2872, 2873'. Can you explain this answer?

The size of a cylindrical side riser, whose height and diameter are equal, to feed a steel slab casting 30cm 30cm

30cm  30cm is ____________(Use modulus method)

30cm is ____________(Use modulus method)

30cm

30cm  30cm is ____________(Use modulus method)

30cm is ____________(Use modulus method)a)

2872

b)

2873

|

Telecom Tuners answered |

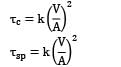

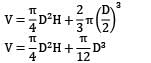

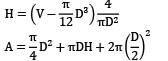

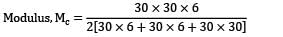

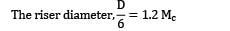

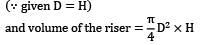

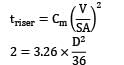

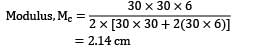

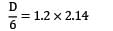

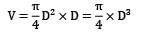

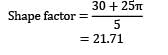

The dimensions of the slab

= 30 cm x 30 cm x 6 cm

This can be considered as a long bar with a cross-section of (30 x 6)cm2

= 2.14

D = 6 x 1.2 x 2.14 = 15.408 cm = H

The riser height, H = D = 15.408 cm

Chills are used in casting moulds to- a)achieve directional solidification

- b)reduce possibility of blow holes

- c)reduce the freezing time

- d)increase the smoothness of cost surface

Correct answer is option 'A'. Can you explain this answer?

Chills are used in casting moulds to

a)

achieve directional solidification

b)

reduce possibility of blow holes

c)

reduce the freezing time

d)

increase the smoothness of cost surface

|

|

Jyoti Deshpande answered |

Chills are placed around the core and it is used to achieve directional solidification.

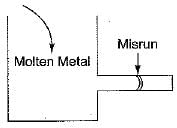

An improper riser may give rise to a defect called- a)Shift

- b)Shrinkage cavity

- c)Penetration

- d)Misrun

Correct answer is option 'B'. Can you explain this answer?

An improper riser may give rise to a defect called

a)

Shift

b)

Shrinkage cavity

c)

Penetration

d)

Misrun

|

|

Zoya Sharma answered |

An improper riser may give rise to a defect called shrinkage cavity

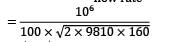

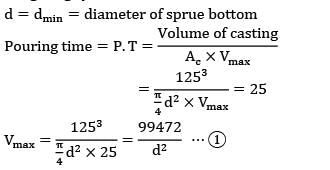

In pressurized gating system with a gating ratio 2:1.5:1. The sprue area is 200mm2 . The time taken (in sec) to fill the cavity of volume 106mm3 with a 20% metal head of 200 mm assuming a 20% loss of head in gating system is __________- a) 5

- b) 6

Correct answer is between ' 5, 6'. Can you explain this answer?

In pressurized gating system with a gating ratio 2:1.5:1. The sprue area is 200mm2 . The time taken (in sec) to fill the cavity of volume 106mm3 with a 20% metal head of 200 mm assuming a 20% loss of head in gating system is __________

a)

5

b)

6

|

Naroj Boda answered |

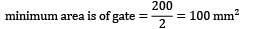

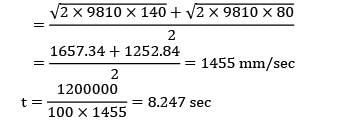

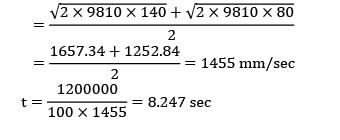

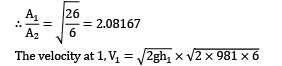

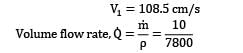

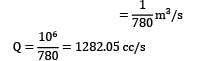

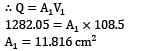

Given Gating Ratio = 2 : 1.5 : 1

Head of metal = 200 mm

loss of head of metal = 20%

net available head = 0.8 x 200

= 160mm

Flow rate of metal = V x A

= 5.645 sec

Which of the following gating ratio represents pressurised gating systems?- a)1 : 1 : 2

- b)1 : 2 : 1

- c)1 : 2 : 3

- d)1 : 3 : 3

Correct answer is option 'B'. Can you explain this answer?

Which of the following gating ratio represents pressurised gating systems?

a)

1 : 1 : 2

b)

1 : 2 : 1

c)

1 : 2 : 3

d)

1 : 3 : 3

|

|

Avinash Sharma answered |

Gating ratio = Sprue area: Runner area: Ingate area

If total ingate area is not greater than the area of sprue, gating systems are known as pressurised gating system.

Option (a), (c) and (d) represents unpressurized gating system.

If total ingate area is not greater than the area of sprue, gating systems are known as pressurised gating system.

Option (a), (c) and (d) represents unpressurized gating system.

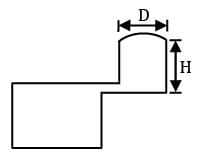

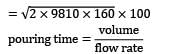

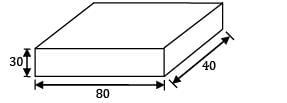

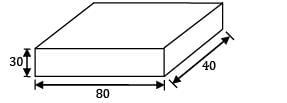

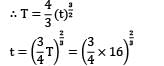

A job shown in the figure is to be made from steel by casting process. The mould for this job is made from wooden pattern. Dimensions of the wooden pattern assuming machining allowance of 3 mm on each side, shaking allowance of 1 mm on length & width & shrinkage allowance of 3%.

- a) 86 x 46 x 36

- b) 88.58 x 47.38 x 37.08

- c) 87.58 x 46.38 x 36.08

- d) 87.58 x 46.38 x 37.08

Correct answer is option 'D'. Can you explain this answer?

A job shown in the figure is to be made from steel by casting process. The mould for this job is made from wooden pattern. Dimensions of the wooden pattern assuming machining allowance of 3 mm on each side, shaking allowance of 1 mm on length & width & shrinkage allowance of 3%.

a)

86 x 46 x 36

b)

88.58 x 47.38 x 37.08

c)

87.58 x 46.38 x 36.08

d)

87.58 x 46.38 x 37.08

|

Telecom Tuners answered |

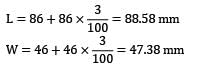

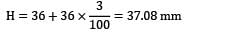

Since given machining allowance is 3 mm on each side, add 3 mm on each side of the part shown in figure. The dimensions of pattern after machining will be

L = 80 + 2 x 3 = 86 mm

W = 40 + 2 x 3 =46 mm

H = 30 + 2 x 3 = 36 mm

The shrinkage allowance of 3% is added to all the dimensions of pattern. Dimension of pattern after providing shrinkage allowance of 3% will be

Given shaking allowance is 1 mm on length and width. Recall that shaking allowance is a negative allowance. Hence 1 mm has to be reduced from the calculated values of length and width side.

L = 88.58 - 1 = 87.58 mm

W = 47.38 - 1 = 46.38 mm

H = 37.08 mm

Sprue in casting refers to.......

- a)Gate

- b)Runner

- c)Riser

- d)Vertical passage

Correct answer is option 'D'. Can you explain this answer?

Sprue in casting refers to.......

a)

Gate

b)

Runner

c)

Riser

d)

Vertical passage

|

Vertex Academy answered |

Concept:

A sprue feeds metal to the runner which in turn reaches the casting through gates.

A sprue is tapered with its bigger end at the top to receive the liquid metal. The smaller end is connected to the runner.

In many cases, it controls the flow of material into the mould. During casting or moulding, the material in the sprue will solidify and need to be removed from the finished part.

Which of the following materials requires highest shrinkage allowance?- a)Aluminium

- b)Gray cast iron

- c)Steel

- d)Brass

Correct answer is option 'C'. Can you explain this answer?

Which of the following materials requires highest shrinkage allowance?

a)

Aluminium

b)

Gray cast iron

c)

Steel

d)

Brass

|

|

Kalyan Chakraborty answered |

Shrinkage allowance is the difference in dimensions between the pattern and the final casting due to the shrinkage of the metal during solidification. The amount of shrinkage allowance required is dependent on the material being used for casting.

Explanation:

Steel has the highest shrinkage allowance among the given materials. This is due to the following reasons:

1. High melting point: Steel has a high melting point compared to other materials. This means that it takes longer for the metal to cool and solidify, resulting in more shrinkage.

2. High carbon content: Steel has a higher carbon content than other materials. Carbon is a strong carbide former, which can lead to a reduction in the solidification range of steel, resulting in more shrinkage.

3. Low thermal conductivity: Steel has a lower thermal conductivity than other materials. This means that heat is retained for a longer time, resulting in a longer solidification time and more shrinkage.

4. High density: Steel has a higher density than other materials. This means that it will shrink more during solidification.

Therefore, steel requires the highest shrinkage allowance among the given materials.

Explanation:

Steel has the highest shrinkage allowance among the given materials. This is due to the following reasons:

1. High melting point: Steel has a high melting point compared to other materials. This means that it takes longer for the metal to cool and solidify, resulting in more shrinkage.

2. High carbon content: Steel has a higher carbon content than other materials. Carbon is a strong carbide former, which can lead to a reduction in the solidification range of steel, resulting in more shrinkage.

3. Low thermal conductivity: Steel has a lower thermal conductivity than other materials. This means that heat is retained for a longer time, resulting in a longer solidification time and more shrinkage.

4. High density: Steel has a higher density than other materials. This means that it will shrink more during solidification.

Therefore, steel requires the highest shrinkage allowance among the given materials.

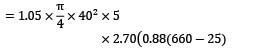

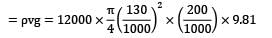

A disk of diameter 40 cm and 5 cm thick is to be casted out of pure aluminium is an open mold operation. Melting temperature of Al , pouring temperature 800

, pouring temperature 800 . Assume that the amount of aluminium heated will be 5% more than that needed to fill the mould cavity. The amount of heat (MJ) added to aluminium starting from room temperature of 25

. Assume that the amount of aluminium heated will be 5% more than that needed to fill the mould cavity. The amount of heat (MJ) added to aluminium starting from room temperature of 25 is__________. (Specific heat of Al (both cold and heated)= 0.88 J/g

is__________. (Specific heat of Al (both cold and heated)= 0.88 J/g . Heat of fusion= 389 J/g. Density Al = 2.70 g/cm3 ).

. Heat of fusion= 389 J/g. Density Al = 2.70 g/cm3 ).- a) 18.5

- b) 19.5

Correct answer is between ' 18.5, 19.5'. Can you explain this answer?

A disk of diameter 40 cm and 5 cm thick is to be casted out of pure aluminium is an open mold operation. Melting temperature of Al , pouring temperature 800

, pouring temperature 800 . Assume that the amount of aluminium heated will be 5% more than that needed to fill the mould cavity. The amount of heat (MJ) added to aluminium starting from room temperature of 25

. Assume that the amount of aluminium heated will be 5% more than that needed to fill the mould cavity. The amount of heat (MJ) added to aluminium starting from room temperature of 25 is__________. (Specific heat of Al (both cold and heated)= 0.88 J/g

is__________. (Specific heat of Al (both cold and heated)= 0.88 J/g . Heat of fusion= 389 J/g. Density Al = 2.70 g/cm3 ).

. Heat of fusion= 389 J/g. Density Al = 2.70 g/cm3 ).

, pouring temperature 800

, pouring temperature 800 . Assume that the amount of aluminium heated will be 5% more than that needed to fill the mould cavity. The amount of heat (MJ) added to aluminium starting from room temperature of 25

. Assume that the amount of aluminium heated will be 5% more than that needed to fill the mould cavity. The amount of heat (MJ) added to aluminium starting from room temperature of 25 is__________. (Specific heat of Al (both cold and heated)= 0.88 J/g

is__________. (Specific heat of Al (both cold and heated)= 0.88 J/g . Heat of fusion= 389 J/g. Density Al = 2.70 g/cm3 ).

. Heat of fusion= 389 J/g. Density Al = 2.70 g/cm3 ).a)

18.5

b)

19.5

|

Pathways Academy answered |

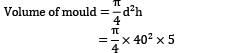

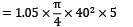

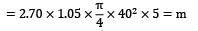

Volume of molten metal = 5% more than volume of mould

⇒ Volume of molten metal

Mass of molten metal

heat supplied = m(cp(Tm - TR) +L.H + Cp(TP -Tm))

Tm = melting temperature

TR = room temperature

Tp = pouring temperature

= 19 MJ

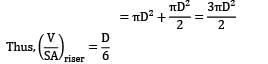

The ratio of surface area to volume for a unit volume of riser is minimum in case of:- a) cylindrical riser

- b) spherical riser

- c) hemispherical riser

- d) cuboidal riser

Correct answer is option 'B'. Can you explain this answer?

The ratio of surface area to volume for a unit volume of riser is minimum in case of:

a)

cylindrical riser

b)

spherical riser

c)

hemispherical riser

d)

cuboidal riser

|

|

Lavanya Menon answered |

For same volume the ratio of surface areas of sphere : cylinder : cube: is 4.84 : 5.54 : 6

While pouring molten metal in the mould of the molten metal does not appear in the riser. It indicates- a)a sound casting will be produced

- b)an obstruction between sprue and riser

- c)insufficient molten metal to fill the cavity

- d)either insufficient molten metal to fill the cavity or an obstruction between sprue and riser

Correct answer is option 'A'. Can you explain this answer?

While pouring molten metal in the mould of the molten metal does not appear in the riser. It indicates

a)

a sound casting will be produced

b)

an obstruction between sprue and riser

c)

insufficient molten metal to fill the cavity

d)

either insufficient molten metal to fill the cavity or an obstruction between sprue and riser

|

|

Anmol Saini answered |

Explanation:

When pouring molten metal into a mould, it is important to ensure that the metal fills the entire cavity without any defects or voids. The use of risers is a common technique to prevent shrinkage defects in castings. A riser is an additional volume of molten metal that is connected to the casting through a channel, and it serves as a reservoir of molten metal that can compensate for the shrinkage during solidification.

If the molten metal does not appear in the riser during pouring, it indicates that a sound casting will be produced. This is because the molten metal has completely filled the cavity without any defects or voids, and there is no need for additional molten metal from the riser. This is a desirable situation, as it indicates that the casting will have good dimensional accuracy and mechanical properties.

If the molten metal does not appear in the riser, it rules out the possibility of the other three options:

- An obstruction between sprue and riser: If there was an obstruction, the molten metal would not have been able to flow freely into the cavity, and there would be defects or voids in the casting.

- Insufficient molten metal to fill the cavity: If there was insufficient molten metal, the cavity would not have been completely filled, and there would be defects or voids in the casting.

- Either insufficient molten metal to fill the cavity or an obstruction between sprue and riser: This is a combination of the previous two options, and it is also ruled out by the absence of molten metal in the riser.

Thus, the absence of molten metal in the riser during pouring is a good sign that a sound casting will be produced.

When pouring molten metal into a mould, it is important to ensure that the metal fills the entire cavity without any defects or voids. The use of risers is a common technique to prevent shrinkage defects in castings. A riser is an additional volume of molten metal that is connected to the casting through a channel, and it serves as a reservoir of molten metal that can compensate for the shrinkage during solidification.

If the molten metal does not appear in the riser during pouring, it indicates that a sound casting will be produced. This is because the molten metal has completely filled the cavity without any defects or voids, and there is no need for additional molten metal from the riser. This is a desirable situation, as it indicates that the casting will have good dimensional accuracy and mechanical properties.

If the molten metal does not appear in the riser, it rules out the possibility of the other three options:

- An obstruction between sprue and riser: If there was an obstruction, the molten metal would not have been able to flow freely into the cavity, and there would be defects or voids in the casting.

- Insufficient molten metal to fill the cavity: If there was insufficient molten metal, the cavity would not have been completely filled, and there would be defects or voids in the casting.

- Either insufficient molten metal to fill the cavity or an obstruction between sprue and riser: This is a combination of the previous two options, and it is also ruled out by the absence of molten metal in the riser.

Thus, the absence of molten metal in the riser during pouring is a good sign that a sound casting will be produced.

The purpose of riser is to- a)deliver molten metal into the mould cavity

- b)act as a reservoir for the molten metal

- c)feed the molten metal to the casting in order to compensate for the shrinkage

- d)deliver the molten metal from pouring basin to gate

Correct answer is option 'B'. Can you explain this answer?

The purpose of riser is to

a)

deliver molten metal into the mould cavity

b)

act as a reservoir for the molten metal

c)

feed the molten metal to the casting in order to compensate for the shrinkage

d)

deliver the molten metal from pouring basin to gate

|

|

Dipika Bose answered |

Riser in Casting Processes

Riser is an integral part of casting processes. It is a reservoir of molten metal that compensates for the shrinkage that occurs during solidification. This shrinkage can lead to various casting defects, such as porosity, shrinkage cavities, and cracks.

Purpose of Riser

The primary purpose of the riser is to feed the molten metal to the casting in order to compensate for the shrinkage. When the molten metal is poured into the mould cavity, it begins to solidify from the surface towards the centre. As the metal solidifies, it shrinks and creates a void or a cavity in the casting.

The riser compensates for this shrinkage by providing additional molten metal to the casting. The molten metal in the riser solidifies after the metal in the casting has solidified. This solidification of the riser provides an additional source of metal to compensate for the shrinkage in the casting.

Other Purposes of Riser

Apart from compensating for the shrinkage, the riser also serves other purposes in the casting processes. These include:

1. Acting as a reservoir for the molten metal: The riser acts as a reservoir for the molten metal and ensures that there is enough metal available to fill the mould cavity.

2. Providing a source of feeding: The riser provides a source of feeding to the casting by supplying additional molten metal.

3. Reducing the risk of defects: The riser reduces the risk of defects in the casting by compensating for the shrinkage and ensuring that the casting is filled with metal.

Conclusion

In summary, the primary purpose of the riser in casting processes is to compensate for the shrinkage that occurs during solidification. It provides additional molten metal to the casting to ensure that the casting is filled with metal and reduce the risk of defects.

Riser is an integral part of casting processes. It is a reservoir of molten metal that compensates for the shrinkage that occurs during solidification. This shrinkage can lead to various casting defects, such as porosity, shrinkage cavities, and cracks.

Purpose of Riser

The primary purpose of the riser is to feed the molten metal to the casting in order to compensate for the shrinkage. When the molten metal is poured into the mould cavity, it begins to solidify from the surface towards the centre. As the metal solidifies, it shrinks and creates a void or a cavity in the casting.

The riser compensates for this shrinkage by providing additional molten metal to the casting. The molten metal in the riser solidifies after the metal in the casting has solidified. This solidification of the riser provides an additional source of metal to compensate for the shrinkage in the casting.

Other Purposes of Riser

Apart from compensating for the shrinkage, the riser also serves other purposes in the casting processes. These include:

1. Acting as a reservoir for the molten metal: The riser acts as a reservoir for the molten metal and ensures that there is enough metal available to fill the mould cavity.

2. Providing a source of feeding: The riser provides a source of feeding to the casting by supplying additional molten metal.

3. Reducing the risk of defects: The riser reduces the risk of defects in the casting by compensating for the shrinkage and ensuring that the casting is filled with metal.

Conclusion

In summary, the primary purpose of the riser in casting processes is to compensate for the shrinkage that occurs during solidification. It provides additional molten metal to the casting to ensure that the casting is filled with metal and reduce the risk of defects.

The impurities in true centrifugal casting- a)get collected at outer surface

- b)mix up thoroughly throughout

- c)get collected at the inner surface

- d)get collected in the middle portion in between inner and outer surface

Correct answer is option 'C'. Can you explain this answer?

The impurities in true centrifugal casting

a)

get collected at outer surface

b)

mix up thoroughly throughout

c)

get collected at the inner surface

d)

get collected in the middle portion in between inner and outer surface

|

|

Gaurav Kapoor answered |

The impurities in true centrifugal casting get collected in the middle portion in between the inner and outer surface. This is because of the unique nature of the centrifugal casting process, which involves the use of centrifugal force to distribute the molten metal and impurities.

Explanation:

1. The Centrifugal Casting Process:

- Centrifugal casting is a casting process that uses the principle of centrifugal force to distribute the molten metal and impurities.

- In this process, a mold is rotated at high speeds while the molten metal is poured into it.

- The centrifugal force generated by the rotation of the mold pushes the molten metal towards the outer surface of the mold, while the impurities tend to move towards the inner surface.

2. Movement of Impurities:

- As the molten metal is poured into the rotating mold, the centrifugal force acts on it, causing it to move towards the outer surface of the mold.

- At the same time, the impurities present in the molten metal also experience the centrifugal force and tend to move towards the inner surface.

- However, due to their higher density compared to the molten metal, the impurities are not able to move as easily as the molten metal.

- As a result, the impurities get trapped in the middle portion of the casting, which is in between the inner and outer surface.

3. Collection of Impurities:

- The impurities that get collected in the middle portion of the casting are typically in the form of slag, oxides, or other non-metallic contaminants.

- These impurities are undesirable in the final casting as they can weaken the material and affect its mechanical properties.

- To minimize the presence of impurities, various techniques can be used, such as the use of proper gating systems, filtering the molten metal, and controlling the pouring temperature.

In conclusion, in true centrifugal casting, the impurities get collected in the middle portion in between the inner and outer surface. This is due to the movement of the molten metal towards the outer surface under the influence of centrifugal force, while the impurities, being denser, tend to remain in the middle portion. Proper control and techniques can be employed to minimize the impurities and ensure a high-quality casting.

Explanation:

1. The Centrifugal Casting Process:

- Centrifugal casting is a casting process that uses the principle of centrifugal force to distribute the molten metal and impurities.

- In this process, a mold is rotated at high speeds while the molten metal is poured into it.

- The centrifugal force generated by the rotation of the mold pushes the molten metal towards the outer surface of the mold, while the impurities tend to move towards the inner surface.

2. Movement of Impurities:

- As the molten metal is poured into the rotating mold, the centrifugal force acts on it, causing it to move towards the outer surface of the mold.

- At the same time, the impurities present in the molten metal also experience the centrifugal force and tend to move towards the inner surface.

- However, due to their higher density compared to the molten metal, the impurities are not able to move as easily as the molten metal.

- As a result, the impurities get trapped in the middle portion of the casting, which is in between the inner and outer surface.

3. Collection of Impurities:

- The impurities that get collected in the middle portion of the casting are typically in the form of slag, oxides, or other non-metallic contaminants.

- These impurities are undesirable in the final casting as they can weaken the material and affect its mechanical properties.

- To minimize the presence of impurities, various techniques can be used, such as the use of proper gating systems, filtering the molten metal, and controlling the pouring temperature.

In conclusion, in true centrifugal casting, the impurities get collected in the middle portion in between the inner and outer surface. This is due to the movement of the molten metal towards the outer surface under the influence of centrifugal force, while the impurities, being denser, tend to remain in the middle portion. Proper control and techniques can be employed to minimize the impurities and ensure a high-quality casting.

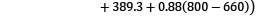

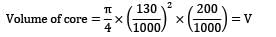

In sand casting of hollow part of zinc, a cylindrical core of diameter 130 mm and height 200 mm is placed inside the mould cavity. The densities of core material and zinc are 1500 kg/m3 and 1200 kg/m3 respectively. The net force that tends to lift the core during pouring of molten metal will be __________ N.- a) 273

- b) 274

Correct answer is between ' 273, 274'. Can you explain this answer?

In sand casting of hollow part of zinc, a cylindrical core of diameter 130 mm and height 200 mm is placed inside the mould cavity. The densities of core material and zinc are 1500 kg/m3 and 1200 kg/m3 respectively. The net force that tends to lift the core during pouring of molten metal will be __________ N.

a)

273

b)

274

|

|

Mira Sharma answered |

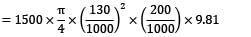

Upward force buoyancy force weight of molten metal displaced

Downward force weight of core

D = density of core

= dvg

Net force upward force – downward force

= 273.441 N

A cylinder of 150 mm diameter and 200 mm height is to be cast without any riser. The cylinder is moulded entirely in the drag of a green sand flask and top gated. The cope of the flask has 200 mm height and the height of metal during pouring is 50 mm above the cope. A tapered sprue is employed and the gating ratio is . The time taken (in seconds) to fill the casting cavity neglecting energy losses, if the in-gate area is , is- a) 2

- b) 4

- c) 8

- d) 15

Correct answer is option 'C'. Can you explain this answer?

A cylinder of 150 mm diameter and 200 mm height is to be cast without any riser. The cylinder is moulded entirely in the drag of a green sand flask and top gated. The cope of the flask has 200 mm height and the height of metal during pouring is 50 mm above the cope. A tapered sprue is employed and the gating ratio is . The time taken (in seconds) to fill the casting cavity neglecting energy losses, if the in-gate area is , is

a)

2

b)

4

c)

8

d)

15

|

Diya Patel answered |

To determine the time taken to fill the casting cavity, we need to consider the volume of the cavity and the flow rate of the metal.

1. Calculating the volume of the casting cavity:

The volume of a cylinder is given by the formula V = πr^2h, where r is the radius and h is the height. In this case, the diameter is given as 150 mm, so the radius is 75 mm (or 0.075 m). The height of the cylinder is 200 mm (or 0.2 m). Therefore, the volume of the casting cavity is:

V_cavity = π(0.075)^2(0.2) = 0.00707 m^3

2. Calculating the flow rate of the metal:

The flow rate of the metal depends on the gating ratio and the in-gate area. The gating ratio is not provided in the question, so let's assume it to be 2.

The in-gate area is given as 10 cm^2 (or 0.001 m^2). Therefore, the total gating area is:

A_gating = gating ratio * in-gate area = 2 * 0.001 = 0.002 m^2

3. Calculating the flow rate:

The flow rate of the metal can be calculated using the formula Q = A_gating * V_flow, where Q is the flow rate and V_flow is the velocity of the metal.

Since the height of the metal during pouring is 50 mm above the cope, the total height of the metal column is 200 mm + 50 mm = 250 mm (or 0.25 m).

Using Bernoulli's equation for incompressible flow, the velocity of the metal can be calculated as:

V_flow = √(2gH), where g is the acceleration due to gravity (9.81 m/s^2) and H is the height of the metal column.

V_flow = √(2 * 9.81 * 0.25) = 2.21 m/s

Now, we can calculate the flow rate:

Q = 0.002 * 2.21 = 0.00442 m^3/s

4. Calculating the time taken:

The time taken to fill the casting cavity can be calculated using the formula t = V_cavity / Q, where t is the time taken.

t = 0.00707 / 0.00442 ≈ 1.6 seconds

Since the time needs to be rounded to the nearest whole number, the correct answer is option 'C' - 8 seconds.

1. Calculating the volume of the casting cavity:

The volume of a cylinder is given by the formula V = πr^2h, where r is the radius and h is the height. In this case, the diameter is given as 150 mm, so the radius is 75 mm (or 0.075 m). The height of the cylinder is 200 mm (or 0.2 m). Therefore, the volume of the casting cavity is:

V_cavity = π(0.075)^2(0.2) = 0.00707 m^3

2. Calculating the flow rate of the metal:

The flow rate of the metal depends on the gating ratio and the in-gate area. The gating ratio is not provided in the question, so let's assume it to be 2.

The in-gate area is given as 10 cm^2 (or 0.001 m^2). Therefore, the total gating area is:

A_gating = gating ratio * in-gate area = 2 * 0.001 = 0.002 m^2

3. Calculating the flow rate:

The flow rate of the metal can be calculated using the formula Q = A_gating * V_flow, where Q is the flow rate and V_flow is the velocity of the metal.

Since the height of the metal during pouring is 50 mm above the cope, the total height of the metal column is 200 mm + 50 mm = 250 mm (or 0.25 m).

Using Bernoulli's equation for incompressible flow, the velocity of the metal can be calculated as:

V_flow = √(2gH), where g is the acceleration due to gravity (9.81 m/s^2) and H is the height of the metal column.

V_flow = √(2 * 9.81 * 0.25) = 2.21 m/s

Now, we can calculate the flow rate:

Q = 0.002 * 2.21 = 0.00442 m^3/s

4. Calculating the time taken:

The time taken to fill the casting cavity can be calculated using the formula t = V_cavity / Q, where t is the time taken.

t = 0.00707 / 0.00442 ≈ 1.6 seconds

Since the time needs to be rounded to the nearest whole number, the correct answer is option 'C' - 8 seconds.

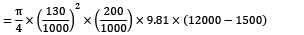

The following data is observed for a casting process:Mass of casting = 5000 kgDensity of metal = 8000 kg/m3Pouring time = 10 secEfficiency factor = 0.9Effective had = 2 mThe chock area of the casting is ___________mm2- a) 11050

- b) 11120

Correct answer is between ' 11050, 11120'. Can you explain this answer?

The following data is observed for a casting process:

Mass of casting = 5000 kg

Density of metal = 8000 kg/m3

Pouring time = 10 sec

Efficiency factor = 0.9

Effective had = 2 m

The chock area of the casting is ___________mm2

a)

11050

b)

11120

|

Manish Aggarwal answered |

= 0.01108595 m2

= 11085.95 mm2

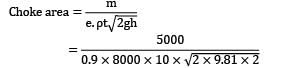

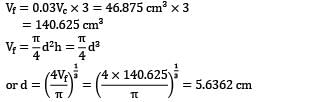

A cylindrical riser is attached to the side of a steel plate casting having dimensions 25cm x 12.5cm x 5cm. The volume shrinkage of steel during solidification is 3% and the volume of riser is 3 times that of dictated by the shrinkage consideration alone. The dimension of the riser in optimum conditions is ____________.- a) 5

- b) 6

Correct answer is between ' 5, 6'. Can you explain this answer?

A cylindrical riser is attached to the side of a steel plate casting having dimensions 25cm x 12.5cm x 5cm. The volume shrinkage of steel during solidification is 3% and the volume of riser is 3 times that of dictated by the shrinkage consideration alone. The dimension of the riser in optimum conditions is ____________.

a)

5

b)

6

|

|

Zoya Sharma answered |

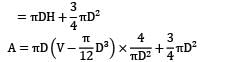

For optimum cylindrical side riser,h = d

Volume of casting, Vc = 25 x 12.5 x 5

Shrinkage of steel during solidification = 3%

Minimum volume of the riser necessary is,

Consider the following ingredients used in moulding

1. Dry silica sand

2. Clay

3. Phenol formaldehyde

4. Sodium silicate

Q. These used for shell moulding include- a)1, 2 and 4

- b)2, 3 and 4

- c)1 and 3

- d)1, 2, 3 and 4

Correct answer is option 'C'. Can you explain this answer?

Consider the following ingredients used in moulding

1. Dry silica sand

2. Clay

3. Phenol formaldehyde

4. Sodium silicate

Q. These used for shell moulding include

1. Dry silica sand

2. Clay

3. Phenol formaldehyde

4. Sodium silicate

Q. These used for shell moulding include

a)

1, 2 and 4

b)

2, 3 and 4

c)

1 and 3

d)

1, 2, 3 and 4

|

Telecom Tuners answered |

- Dry silica sand: This is the primary base material in shell molding. It provides the structure and strength to the mold.

- Phenol formaldehyde: This is a thermosetting resin binder used in shell molding. When mixed with a catalyst, it reacts and cures to form a strong bond between the sand grains, creating the shell.

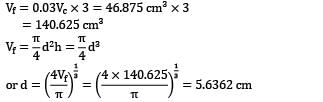

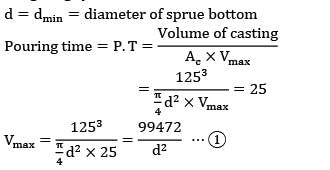

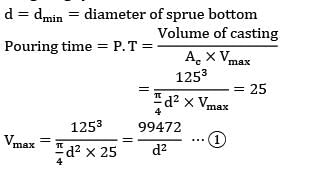

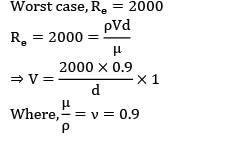

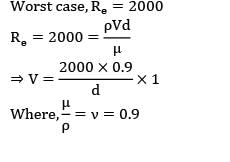

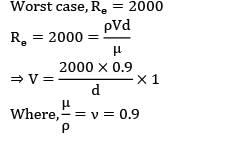

The pouring basin in a sand mould is 200 mm diameter & 100 mm height. The mould cavity is a cube of 125 mm side and must be filled in 25 second. The maximum velocity must ensure laminar flow into the mould cavity and in the gates of circular cross section.Assume:(A) Constant temperature,(B) No loss in the velocity head and(C) Diameter of gate 8 times diameter of the sprue base. Properties of the molten metal are v=0.9mm2 per second,p= 700kg/m3 and cp=33.6 J/mol-k.The diameter of sprue to avoid aspiration effect is ____________.- a) 55

- b) 56

Correct answer is between ' 55, 56'. Can you explain this answer?

The pouring basin in a sand mould is 200 mm diameter & 100 mm height. The mould cavity is a cube of 125 mm side and must be filled in 25 second. The maximum velocity must ensure laminar flow into the mould cavity and in the gates of circular cross section.

Assume:

(A) Constant temperature,

(B) No loss in the velocity head and

(C) Diameter of gate 8 times diameter of the sprue base. Properties of the molten metal are v=0.9mm2 per second,p= 700kg/m3 and cp=33.6 J/mol-k.

The diameter of sprue to avoid aspiration effect is ____________.

a)

55

b)

56

|

|

Neha Joshi answered |

The dimension of pouring basin will not affect the pouring time

Let V = maximum velocity of molten metal in the gating system

To ensure the laminar flow in the gating system Re 2000

2000

2000

2000Worst case, Re = 2000

Which of the following materials has more shrinkage allowances- a)Cl

- b)Lead

- c)Brass

- d)Aluminium alloy

Correct answer is option 'C'. Can you explain this answer?

Which of the following materials has more shrinkage allowances

a)

Cl

b)

Lead

c)

Brass

d)

Aluminium alloy

|

|

Amrita Chauhan answered |

Shrinkage Allowance in Materials

Introduction

Shrinkage allowance is the amount of additional material that needs to be added to a casting pattern to compensate for the shrinkage that occurs during the solidification and cooling process. The shrinkage allowance ensures that the final casting dimensions are accurate and match the desired specifications. Different materials have different shrinkage rates, which is why different shrinkage allowances are required for different materials.

Explanation

Among the materials mentioned in the options (Cl, Lead, Brass, and Aluminium alloy), the material with the highest shrinkage allowance is Brass.

Shrinkage Allowance Factors

Several factors influence the shrinkage allowance in a material, including:

1. Cooling rate: Faster cooling rates tend to increase shrinkage.

2. Solidification time: Longer solidification times lead to higher shrinkage.

3. Alloy composition: Different alloy compositions can result in varying shrinkage rates.

Shrinkage Allowance Comparison

Let's analyze the shrinkage allowances for each material:

1. Cl (Chlorine)

Chlorine is not a casting material but a chemical element. Therefore, it does not have a shrinkage allowance.

2. Lead

Lead is a soft and malleable material with a relatively low melting point. It exhibits minimal shrinkage during the cooling process. Therefore, the shrinkage allowance for lead is relatively low compared to other materials.

3. Brass

Brass is an alloy composed of copper and zinc. It has a higher melting point compared to lead. Due to the different thermal properties of copper and zinc, brass experiences a significant amount of shrinkage during cooling. Consequently, a larger shrinkage allowance is required for brass castings.

4. Aluminium Alloy

Aluminium alloys are widely used in various industries due to their lightweight and excellent mechanical properties. They have a relatively low shrinkage rate compared to materials like brass. Therefore, the shrinkage allowance for aluminium alloy castings is lower compared to brass.

Conclusion

Among the materials mentioned in the options, brass has the highest shrinkage allowance. This is because brass, being an alloy of copper and zinc, experiences significant shrinkage during the cooling process. It is important to consider the shrinkage allowance when designing casting patterns to ensure accurate final dimensions in the castings.

Introduction

Shrinkage allowance is the amount of additional material that needs to be added to a casting pattern to compensate for the shrinkage that occurs during the solidification and cooling process. The shrinkage allowance ensures that the final casting dimensions are accurate and match the desired specifications. Different materials have different shrinkage rates, which is why different shrinkage allowances are required for different materials.

Explanation

Among the materials mentioned in the options (Cl, Lead, Brass, and Aluminium alloy), the material with the highest shrinkage allowance is Brass.

Shrinkage Allowance Factors

Several factors influence the shrinkage allowance in a material, including:

1. Cooling rate: Faster cooling rates tend to increase shrinkage.

2. Solidification time: Longer solidification times lead to higher shrinkage.

3. Alloy composition: Different alloy compositions can result in varying shrinkage rates.

Shrinkage Allowance Comparison

Let's analyze the shrinkage allowances for each material:

1. Cl (Chlorine)

Chlorine is not a casting material but a chemical element. Therefore, it does not have a shrinkage allowance.

2. Lead

Lead is a soft and malleable material with a relatively low melting point. It exhibits minimal shrinkage during the cooling process. Therefore, the shrinkage allowance for lead is relatively low compared to other materials.

3. Brass

Brass is an alloy composed of copper and zinc. It has a higher melting point compared to lead. Due to the different thermal properties of copper and zinc, brass experiences a significant amount of shrinkage during cooling. Consequently, a larger shrinkage allowance is required for brass castings.

4. Aluminium Alloy

Aluminium alloys are widely used in various industries due to their lightweight and excellent mechanical properties. They have a relatively low shrinkage rate compared to materials like brass. Therefore, the shrinkage allowance for aluminium alloy castings is lower compared to brass.

Conclusion

Among the materials mentioned in the options, brass has the highest shrinkage allowance. This is because brass, being an alloy of copper and zinc, experiences significant shrinkage during the cooling process. It is important to consider the shrinkage allowance when designing casting patterns to ensure accurate final dimensions in the castings.

In which of the following are metal moulds are used?- a) Greensand mould

- b) Dry sand mould

- c) Die casting process

- d) Loam moulding

Correct answer is option 'C'. Can you explain this answer?

In which of the following are metal moulds are used?

a)

Greensand mould

b)

Dry sand mould

c)

Die casting process

d)

Loam moulding

|

|

Neha Joshi answered |

Metallic moulds are used in die casting process.

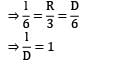

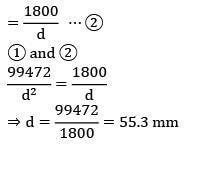

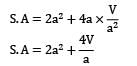

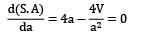

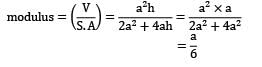

What is the modulus of a optimum side riser in the shape of square parallelopiped with side a:- a) a/4

- b) a/5

- c) a/6

- d) a/3

Correct answer is option 'C'. Can you explain this answer?

What is the modulus of a optimum side riser in the shape of square parallelopiped with side a:

a)

a/4

b)

a/5

c)

a/6

d)

a/3

|

|

Lavanya Menon answered |

Optimum riser ⇒ heat transfer is minimum ⇒

S.A is minimum

Surface area = 2a2 + 4ah = S.A

V = a2 x h

⇒ 4V = 4a3

⇒ V = a3

⇒ a2h =a3 ⇒ a = h

Consider the following advantages of shell mould casting:1. Close dimensional tolerance2. Good surface finish3. Low cost4. EasierWhich of these are correct?- a) 1, 2 and 3 only

- b) 2, 3 and 4 only

- c) 1, 2 and 4 only

- d) 1, 2, 3 and 4

Correct answer is option 'C'. Can you explain this answer?

Consider the following advantages of shell mould casting:

1. Close dimensional tolerance

2. Good surface finish

3. Low cost

4. Easier

Which of these are correct?

a)

1, 2 and 3 only

b)

2, 3 and 4 only

c)

1, 2 and 4 only

d)

1, 2, 3 and 4

|

|

Sinjini Bose answered |

The correct answer is option C: 1, 2, and 4 only.

Shell mould casting, also known as shell molding or shell molding casting, is a casting process that uses a resin-coated sand shell to form the mold. This process offers several advantages over other casting methods. Let's discuss each advantage in detail:

1. Close dimensional tolerance: Shell mould casting provides close dimensional tolerances, meaning that the cast parts can be manufactured with high precision and accuracy. The use of a shell mold allows for greater control over the final dimensions of the cast part, resulting in minimal dimensional variations. This advantage is particularly important in industries where tight tolerances are required, such as aerospace or automotive.

2. Good surface finish: Shell mould casting produces castings with a smooth and consistent surface finish. The resin-coated sand shell used in this process helps to create a mold cavity with excellent surface quality. As a result, the cast parts have a clean and polished appearance, requiring minimal post-processing or finishing operations.

3. Low cost: Shell mould casting is a cost-effective casting method. The process uses readily available materials, such as sand and resin, which are relatively inexpensive compared to other mold materials. Additionally, the use of reusable shell molds reduces the overall production costs as compared to traditional sand casting, where a new mold is required for each casting. The low cost of shell mould casting makes it an attractive option for large-scale production runs.

4. Easier: Shell mould casting is relatively easier compared to other casting methods. The process involves fewer steps and requires less equipment and manpower. The use of pre-coated sand shells simplifies the mold-making process, reducing the time and effort required to produce molds. This advantage makes shell mould casting more efficient and less labor-intensive than some other casting techniques.

In conclusion, shell mould casting offers advantages such as close dimensional tolerance, good surface finish, and ease of use. These advantages make it a preferred choice for many applications where precision, aesthetics, and cost-effectiveness are important factors. Therefore, option C: 1, 2, and 4 only is the correct answer.

Shell mould casting, also known as shell molding or shell molding casting, is a casting process that uses a resin-coated sand shell to form the mold. This process offers several advantages over other casting methods. Let's discuss each advantage in detail:

1. Close dimensional tolerance: Shell mould casting provides close dimensional tolerances, meaning that the cast parts can be manufactured with high precision and accuracy. The use of a shell mold allows for greater control over the final dimensions of the cast part, resulting in minimal dimensional variations. This advantage is particularly important in industries where tight tolerances are required, such as aerospace or automotive.

2. Good surface finish: Shell mould casting produces castings with a smooth and consistent surface finish. The resin-coated sand shell used in this process helps to create a mold cavity with excellent surface quality. As a result, the cast parts have a clean and polished appearance, requiring minimal post-processing or finishing operations.

3. Low cost: Shell mould casting is a cost-effective casting method. The process uses readily available materials, such as sand and resin, which are relatively inexpensive compared to other mold materials. Additionally, the use of reusable shell molds reduces the overall production costs as compared to traditional sand casting, where a new mold is required for each casting. The low cost of shell mould casting makes it an attractive option for large-scale production runs.

4. Easier: Shell mould casting is relatively easier compared to other casting methods. The process involves fewer steps and requires less equipment and manpower. The use of pre-coated sand shells simplifies the mold-making process, reducing the time and effort required to produce molds. This advantage makes shell mould casting more efficient and less labor-intensive than some other casting techniques.

In conclusion, shell mould casting offers advantages such as close dimensional tolerance, good surface finish, and ease of use. These advantages make it a preferred choice for many applications where precision, aesthetics, and cost-effectiveness are important factors. Therefore, option C: 1, 2, and 4 only is the correct answer.

The purpose of gate is to- a)feed the casting at a rate consistent with the rate of solidification

- b)act as reservoir for molten metal

- c)help feed the casting until all solidification takes place

- d)feed molten metal from the pouring basin to gate

Correct answer is option 'A'. Can you explain this answer?

The purpose of gate is to

a)

feed the casting at a rate consistent with the rate of solidification

b)

act as reservoir for molten metal

c)

help feed the casting until all solidification takes place

d)

feed molten metal from the pouring basin to gate

|

|

Shreya Kulkarni answered |

Gate is the opening through which the molten metal enters the mould cavity. The shape and the cross section of the ingot should be such that it can readily be broken off after casting solidification and also allow the molten metal to enter quietly into the mould cavity.

In a centrifugal casting method~:- a) no core is used

- b) core may be made of any metal

- c) core is made of sand

- d) core is made of ferrous metal

Correct answer is option 'A'. Can you explain this answer?

In a centrifugal casting method~:

a)

no core is used

b)

core may be made of any metal

c)

core is made of sand

d)

core is made of ferrous metal

|

|

Avinash Sharma answered |

No core is used in centrifugal casting method.

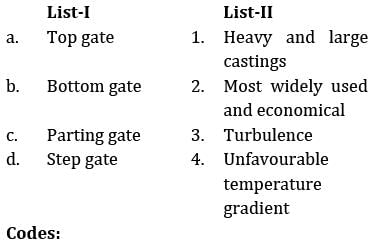

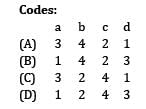

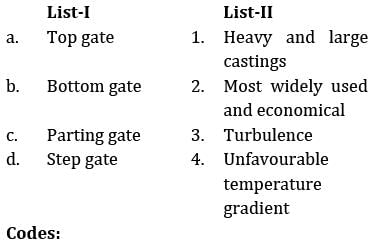

Match List-I with List-II and select the correct answer using the code given below the lists:

- a) A

- b) B

- c) C

- d) D

Correct answer is option 'A'. Can you explain this answer?

Match List-I with List-II and select the correct answer using the code given below the lists:

a)

A

b)

B

c)

C

d)

D

|

Pioneer Academy answered |

Top gate  causes turbulence due to high head and velocity

causes turbulence due to high head and velocity

causes turbulence due to high head and velocity

causes turbulence due to high head and velocityBottom gate unfavourable temperature gradient

unfavourable temperature gradient

unfavourable temperature gradient

unfavourable temperature gradientParting gate most widely used and economical

most widely used and economical

most widely used and economical

most widely used and economicalStep gate multiple gates are used for heavy and large castings

multiple gates are used for heavy and large castings

multiple gates are used for heavy and large castings

multiple gates are used for heavy and large castingsThe success of a casting process depends mainly on the following properties of the moulding sand:

1. Permeability

2. Strength.

3. Deformation

4. Flowability

5. Refractoriness

Which of the these are valid?- a)1,2, 3 and 4

- b)all of these

- c)1, 2, 4 and 5

- d)1 and 2

Correct answer is option 'B'. Can you explain this answer?

The success of a casting process depends mainly on the following properties of the moulding sand:

1. Permeability

2. Strength.

3. Deformation

4. Flowability

5. Refractoriness

Which of the these are valid?

1. Permeability

2. Strength.

3. Deformation

4. Flowability

5. Refractoriness

Which of the these are valid?

a)

1,2, 3 and 4

b)

all of these

c)

1, 2, 4 and 5

d)

1 and 2

|

Sarthak Kulkarni answered |

Permeability: It is expressed as the gas flow rate through the specimen under a specified pressure difference across it.

Strength: It refers to compressive strength.

Deformation: It indicates the change in length of a standard specimen at the point of failure.

Flowability: it refers to the ability of the sand to flow around and over the pattern when the mould is rammed.

Refractioness: It measures the ability of the sand to remain solid as a function of temperature.

Strength: It refers to compressive strength.

Deformation: It indicates the change in length of a standard specimen at the point of failure.

Flowability: it refers to the ability of the sand to flow around and over the pattern when the mould is rammed.

Refractioness: It measures the ability of the sand to remain solid as a function of temperature.

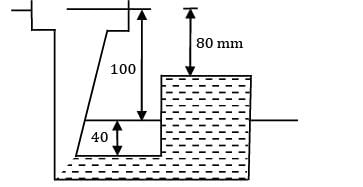

A casting of dimension 200 x 100 x 60mm is casted in such a way that 60 mm dimension is vertical and 2/3 rd of it is in drag. If the height of cope is 100 mm and cavity is fed by a bottom gate with a cross-sectional area 100mm2 , the time (seconds) taken to fill the cavity is _____________.- a) 8

- b) 9

Correct answer is between ' 8, 9'. Can you explain this answer?

A casting of dimension 200 x 100 x 60mm is casted in such a way that 60 mm dimension is vertical and 2/3 rd of it is in drag. If the height of cope is 100 mm and cavity is fed by a bottom gate with a cross-sectional area 100mm2 , the time (seconds) taken to fill the cavity is _____________.

a)

8

b)

9

|

|

Avinash Sharma answered |

Consider the following ingredients used in moulding:1. Dry silica sand2. Clay3. Phenol formaldehyde4. Sodium silicate Those used for shell mould casting include- a) 1, 2 and 4

- b) 2, 3 and 4

- c) 1 and 3

- d) 1, 2, 3 and 4

Correct answer is option 'C'. Can you explain this answer?

Consider the following ingredients used in moulding:

1. Dry silica sand

2. Clay

3. Phenol formaldehyde

4. Sodium silicate Those used for shell mould casting include

a)

1, 2 and 4

b)

2, 3 and 4

c)

1 and 3

d)

1, 2, 3 and 4

|

|

Zoya Sharma answered |

Shell mould casting uses silica sand and phenal formaldehyde.

Fluidity is greatly influenced by- a)Carbon content in molten metal

- b)Pouring temperature of molten metal

- c)Inoculation added

- d)None of these

Correct answer is option 'B'. Can you explain this answer?

Fluidity is greatly influenced by

a)

Carbon content in molten metal

b)

Pouring temperature of molten metal

c)

Inoculation added

d)

None of these

|

|

Anshu Patel answered |

Fluidity can be defined as the length of spiral covered by the molten metal before it get solidifies.

Fluidity is the function of temperature, higher the temperature, more will be the fluidity.

Fluidity is the function of temperature, higher the temperature, more will be the fluidity.

The two parts of a sand casting mould are called- a)Gate and sprue

- b)Upper and drag

- c)Cope and drag

- d)Cope and bottom

Correct answer is option 'C'. Can you explain this answer?

The two parts of a sand casting mould are called

a)

Gate and sprue

b)

Upper and drag

c)

Cope and drag

d)

Cope and bottom

|

|

Ashutosh Sharma answered |

Cope and drag are two parts of the casting mould.

Upper part is called cope and lower part is called drag.

Upper part is called cope and lower part is called drag.

What is the purpose of inoculation- a)to improve the finish of the casting

- b)to alter the chemical composition of a cast metal

- c)to modify the structure and properties of a cast metal

- d)to clean the casting

Correct answer is option 'C'. Can you explain this answer?

What is the purpose of inoculation

a)

to improve the finish of the casting

b)

to alter the chemical composition of a cast metal

c)

to modify the structure and properties of a cast metal

d)

to clean the casting

|

|

Sandeep Sengupta answered |

Purpose of Inoculation in Casting

Inoculation is a crucial process in metal casting that primarily aims to enhance the structure and properties of the cast metal. Here’s a detailed overview of its significance:

1. Structural Modification

- Inoculation introduces specific alloying elements or inoculants during the solidification of molten metal.

- These inoculants promote the formation of a refined microstructure, which can significantly enhance the mechanical properties of the metal.

2. Improvement in Properties

- The inoculation process helps in controlling grain size and distribution in the cast metal.

- A finer grain structure leads to improved strength, ductility, and toughness of the final product.

3. Reduction of Defects

- By modifying the solidification process, inoculation can minimize casting defects such as porosity and segregation.

- This results in a more homogeneous material with consistent properties throughout.

4. Enhanced Performance

- The tailored microstructure achieved through inoculation often results in better performance characteristics under operational conditions.

- This is particularly important in applications where mechanical properties are critical, such as in automotive and aerospace components.

5. Cost-Effectiveness

- Inoculation can lead to a reduction in the amount of expensive alloying elements needed to achieve desired properties, making the casting process more economical.

In summary, the primary purpose of inoculation in casting is to modify the structure and properties of cast metals, ensuring that they meet specific performance standards and operational requirements. This process is essential for producing high-quality cast components in various industries.

Inoculation is a crucial process in metal casting that primarily aims to enhance the structure and properties of the cast metal. Here’s a detailed overview of its significance:

1. Structural Modification

- Inoculation introduces specific alloying elements or inoculants during the solidification of molten metal.

- These inoculants promote the formation of a refined microstructure, which can significantly enhance the mechanical properties of the metal.

2. Improvement in Properties

- The inoculation process helps in controlling grain size and distribution in the cast metal.

- A finer grain structure leads to improved strength, ductility, and toughness of the final product.

3. Reduction of Defects

- By modifying the solidification process, inoculation can minimize casting defects such as porosity and segregation.

- This results in a more homogeneous material with consistent properties throughout.

4. Enhanced Performance

- The tailored microstructure achieved through inoculation often results in better performance characteristics under operational conditions.

- This is particularly important in applications where mechanical properties are critical, such as in automotive and aerospace components.

5. Cost-Effectiveness

- Inoculation can lead to a reduction in the amount of expensive alloying elements needed to achieve desired properties, making the casting process more economical.

In summary, the primary purpose of inoculation in casting is to modify the structure and properties of cast metals, ensuring that they meet specific performance standards and operational requirements. This process is essential for producing high-quality cast components in various industries.

Which of the following sand ramming methods result into hardest layer at parting plane and around the pattern and less dense in top layers?- a) Jolting

- b) Squeezing

- c) Jolting and Squeezing

- d) Slinging

Correct answer is option 'A'. Can you explain this answer?

Which of the following sand ramming methods result into hardest layer at parting plane and around the pattern and less dense in top layers?

a)

Jolting

b)

Squeezing

c)

Jolting and Squeezing

d)

Slinging

|

|

Janhavi Choudhary answered |

Introduction:

The sand ramming method is used in foundry processes to pack sand around a pattern in order to create a mold cavity. There are various sand ramming methods, and each method produces different results in terms of hardness and density of the mold. The question asks which method results in the hardest layer at the parting plane and around the pattern, while being less dense in the top layers.

Jolting:

Jolting is a sand ramming method where the flask containing the pattern is subjected to a jolting action. This action helps in compacting the sand around the pattern. The jolting action causes the sand particles to rearrange and settle more tightly, resulting in a denser mold. However, this method does not provide uniform compaction throughout the entire mold.

Squeezing:

Squeezing is another sand ramming method where the flask containing the pattern is squeezed by applying pressure. This pressure helps in packing the sand around the pattern. Squeezing provides better uniform compaction compared to jolting and results in a denser mold. However, the hardness of the mold may not be as high as in the case of jolting.

Jolting and Squeezing:

Jolting and squeezing are both used in combination in some sand ramming methods. This combination helps in achieving better compaction and density of the mold. However, the hardness of the mold may still not be as high as in the case of jolting alone.

Slinging:

Slinging is not a sand ramming method. It involves the process of throwing or slinging sand particles onto the pattern to create a mold. This method does not provide proper compaction or density and is not suitable for creating molds with a hard layer at the parting plane and around the pattern.

Conclusion:

Based on the explanations above, it can be concluded that the sand ramming method that results in the hardest layer at the parting plane and around the pattern, while being less dense in the top layers, is jolting (option A). Jolting provides better compaction and hardness compared to squeezing, jolting and squeezing, and slinging.

The sand ramming method is used in foundry processes to pack sand around a pattern in order to create a mold cavity. There are various sand ramming methods, and each method produces different results in terms of hardness and density of the mold. The question asks which method results in the hardest layer at the parting plane and around the pattern, while being less dense in the top layers.

Jolting:

Jolting is a sand ramming method where the flask containing the pattern is subjected to a jolting action. This action helps in compacting the sand around the pattern. The jolting action causes the sand particles to rearrange and settle more tightly, resulting in a denser mold. However, this method does not provide uniform compaction throughout the entire mold.

Squeezing:

Squeezing is another sand ramming method where the flask containing the pattern is squeezed by applying pressure. This pressure helps in packing the sand around the pattern. Squeezing provides better uniform compaction compared to jolting and results in a denser mold. However, the hardness of the mold may not be as high as in the case of jolting.

Jolting and Squeezing:

Jolting and squeezing are both used in combination in some sand ramming methods. This combination helps in achieving better compaction and density of the mold. However, the hardness of the mold may still not be as high as in the case of jolting alone.

Slinging:

Slinging is not a sand ramming method. It involves the process of throwing or slinging sand particles onto the pattern to create a mold. This method does not provide proper compaction or density and is not suitable for creating molds with a hard layer at the parting plane and around the pattern.

Conclusion:

Based on the explanations above, it can be concluded that the sand ramming method that results in the hardest layer at the parting plane and around the pattern, while being less dense in the top layers, is jolting (option A). Jolting provides better compaction and hardness compared to squeezing, jolting and squeezing, and slinging.

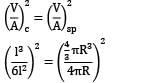

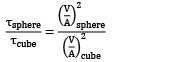

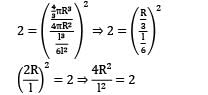

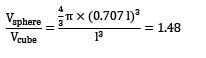

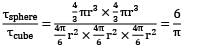

Two castings of the same metal have the same surface area. One casting is in form of a sphere and the other is a cube. The ratio of the solidification time for the sphere to that of the cube is____________.- a) 3/4

- b) 6

- c) 5/4

- d) 3

Correct answer is option 'B'. Can you explain this answer?

Two castings of the same metal have the same surface area. One casting is in form of a sphere and the other is a cube. The ratio of the solidification time for the sphere to that of the cube is____________.

a)

3/4

b)

6

c)

5/4

d)

3

|

|

Neha Joshi answered |

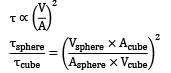

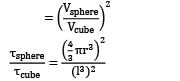

Let τ = Solidification time

According to Chvorinov’s rule

But since Acube = Asphere

Which of the following are the requirements of an ideal gating system?1. The molten metal should enter the mould cavity with as high velocity as possible.2. It should facilitate complete filling of the mould cavity.3. It should be able to prevent the absorption of air or gases from the surroundings in the molten metal while flowing through it.Select the correct answer using the codes given below- a) 1, 2 and 3

- b) 1 and 2

- c) 2 and 3

- d) 1 and 3

Correct answer is option 'C'. Can you explain this answer?

Which of the following are the requirements of an ideal gating system?

1. The molten metal should enter the mould cavity with as high velocity as possible.

2. It should facilitate complete filling of the mould cavity.

3. It should be able to prevent the absorption of air or gases from the surroundings in the molten metal while flowing through it.

Select the correct answer using the codes given below

a)

1, 2 and 3

b)

1 and 2

c)

2 and 3

d)

1 and 3

|

|

Avinash Sharma answered |

Statement 1 is wrong because if the velocity is as high as possible the flow will become turbulent which results in sand erosion, respiration effects etc.

Mechanical properties of the cast parts are superior in- a)shell-mould casting

- b)centrifugal casting

- c)investment casting

- d)permanent mould casting

Correct answer is option 'B'. Can you explain this answer?

Mechanical properties of the cast parts are superior in

a)

shell-mould casting

b)

centrifugal casting

c)

investment casting

d)

permanent mould casting

|

|

Dipika Bose answered |

Mechanical properties of cast parts refer to the physical and mechanical characteristics of the materials used in the casting process. These properties determine the strength, durability, and performance of the cast parts. Different casting methods have varying effects on the mechanical properties of the cast parts. Among the given options, centrifugal casting is known to provide superior mechanical properties compared to the other casting methods.

1. Shell-Mould Casting:

- Shell-mould casting is a precision casting process that uses a shell made of a resin-bonded sand mixture to produce complex and accurate castings.

- The process involves creating a hollow shell by curing the sand mixture coated on a pattern, which is then removed to leave a cavity.

- Molten metal is poured into the shell, and after solidification, the shell is broken to retrieve the casting.

- While shell-mould casting allows for high dimensional accuracy and good surface finish, the mechanical properties of the cast parts may not be as superior as in centrifugal casting.

2. Investment Casting:

- Investment casting, also known as lost-wax casting, is a process that uses wax patterns to create molds for casting.

- The wax patterns are coated with a ceramic shell, which is then heated to remove the wax and harden the ceramic.

- Molten metal is poured into the ceramic shell, and after solidification, the shell is broken to retrieve the casting.

- Investment casting offers excellent dimensional accuracy and surface finish but may not provide the same level of mechanical properties as centrifugal casting.

3. Permanent Mould Casting:

- Permanent mould casting, also known as gravity die casting, is a process that uses a reusable metal mold to produce castings.

- Molten metal is poured into the metal mold, and after solidification, the mold is opened to retrieve the casting.

- Permanent mould casting can provide good dimensional accuracy and surface finish, but the mechanical properties may not be as superior as in centrifugal casting.

4. Centrifugal Casting:

- Centrifugal casting is a process that utilizes centrifugal force to distribute molten metal in a mold.

- The mold is rotated at high speed, causing the molten metal to be forced against the mold walls.

- This process ensures a dense and uniform structure, resulting in superior mechanical properties.

- The centrifugal force helps to eliminate gas and impurities, leading to improved strength and integrity of the cast parts.

- Centrifugal casting is particularly suitable for producing cylindrical and symmetrical parts, such as pipes, cylinders, and rings.

In conclusion, centrifugal casting is known to provide superior mechanical properties compared to shell-mould casting, investment casting, and permanent mould casting. The centrifugal force and uniform distribution of molten metal in the mold result in dense and strong cast parts with excellent strength, durability, and performance.

1. Shell-Mould Casting:

- Shell-mould casting is a precision casting process that uses a shell made of a resin-bonded sand mixture to produce complex and accurate castings.

- The process involves creating a hollow shell by curing the sand mixture coated on a pattern, which is then removed to leave a cavity.

- Molten metal is poured into the shell, and after solidification, the shell is broken to retrieve the casting.

- While shell-mould casting allows for high dimensional accuracy and good surface finish, the mechanical properties of the cast parts may not be as superior as in centrifugal casting.

2. Investment Casting:

- Investment casting, also known as lost-wax casting, is a process that uses wax patterns to create molds for casting.

- The wax patterns are coated with a ceramic shell, which is then heated to remove the wax and harden the ceramic.

- Molten metal is poured into the ceramic shell, and after solidification, the shell is broken to retrieve the casting.

- Investment casting offers excellent dimensional accuracy and surface finish but may not provide the same level of mechanical properties as centrifugal casting.

3. Permanent Mould Casting:

- Permanent mould casting, also known as gravity die casting, is a process that uses a reusable metal mold to produce castings.

- Molten metal is poured into the metal mold, and after solidification, the mold is opened to retrieve the casting.

- Permanent mould casting can provide good dimensional accuracy and surface finish, but the mechanical properties may not be as superior as in centrifugal casting.

4. Centrifugal Casting:

- Centrifugal casting is a process that utilizes centrifugal force to distribute molten metal in a mold.

- The mold is rotated at high speed, causing the molten metal to be forced against the mold walls.

- This process ensures a dense and uniform structure, resulting in superior mechanical properties.

- The centrifugal force helps to eliminate gas and impurities, leading to improved strength and integrity of the cast parts.

- Centrifugal casting is particularly suitable for producing cylindrical and symmetrical parts, such as pipes, cylinders, and rings.

In conclusion, centrifugal casting is known to provide superior mechanical properties compared to shell-mould casting, investment casting, and permanent mould casting. The centrifugal force and uniform distribution of molten metal in the mold result in dense and strong cast parts with excellent strength, durability, and performance.

Consider the following materials:

1. Sand

2. Plaster and Ceramic

3. Metal

A mould can be made of - a)1 only

- b)1 and 3

- c)1 and 2

- d)1, 2 and 3

Correct answer is option 'D'. Can you explain this answer?

Consider the following materials:

1. Sand

2. Plaster and Ceramic

3. Metal

A mould can be made of

1. Sand

2. Plaster and Ceramic

3. Metal

A mould can be made of

a)

1 only

b)

1 and 3

c)

1 and 2

d)

1, 2 and 3

|

Aarav Chauhan answered |

Moulds can be classified on the basis of material i.e. green sand mould, plastic mould and metal mould.

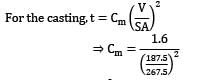

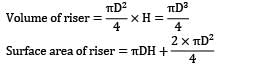

A cylindrical side riser is used for a sand casting mold. The casting itself is a rectangular plate with dimensions 7.5 x 12.5 x 2 cm3 . The solidification time for this casting is 1.6 min. The cylinder for the riser has a diameter to height ratio equal to 1. If the riser and casting are in same mold, then for a riser solidification time of 2 min, its dimension is __________ cm- a) 4.6

- b) 4.8

Correct answer is between ' 4.6, 4.8'. Can you explain this answer?

A cylindrical side riser is used for a sand casting mold. The casting itself is a rectangular plate with dimensions 7.5 x 12.5 x 2 cm3 . The solidification time for this casting is 1.6 min. The cylinder for the riser has a diameter to height ratio equal to 1. If the riser and casting are in same mold, then for a riser solidification time of 2 min, its dimension is __________ cm

a)

4.6

b)

4.8

|

|

Neha Joshi answered |

Volume of plate = 7.5 x 12.5 x 2 = 187.5 cm3

Surface area of plate

= 2 x (7.5 x 12.5 + 7.5 x 2 + 12.5 x 2)

=267.5 cm2

Cm = 3.26 min/cm2

Now, we design the riser so that its solidification time is 2 min, using the same value of mold constant as they both are in the same mold.

Now, triser = 2 min (Given)

D = 4.699 cm

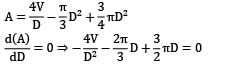

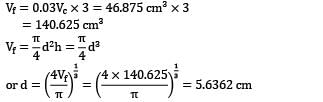

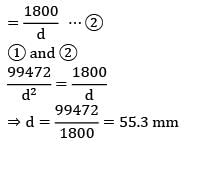

A steel slab casting of dimensions 30 cm x 30 cm x 6 cm with a side riser is to be casted horizontally into the mould. Using modulus method, the volume of the cylindrical riser is __________cm3- a) 2850

- b) 2900

Correct answer is between ' 2850, 2900'. Can you explain this answer?

A steel slab casting of dimensions 30 cm x 30 cm x 6 cm with a side riser is to be casted horizontally into the mould. Using modulus method, the volume of the cylindrical riser is __________cm3

a)

2850

b)

2900

|

|

Zoya Sharma answered |

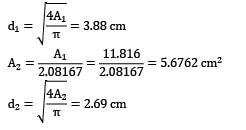

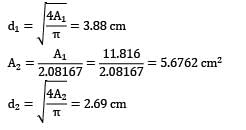

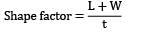

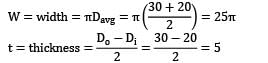

The dimensions of the slab = 30 cm x 30 cm x 6 cm

This can be considered as a long bar with a cross section of (30 x 6)cm2

MR = 1.2 Mc

D = 15.4 cm

= 2872.95 cm3

In solidification of metal during casting, compensation for solid contraction is- a)provided by the oversize pattern

- b)achieved by property placed risers

- c)obtained by promoting directional solidification

- d)made by providing chills

Correct answer is option 'A'. Can you explain this answer?

In solidification of metal during casting, compensation for solid contraction is

a)

provided by the oversize pattern

b)

achieved by property placed risers

c)

obtained by promoting directional solidification

d)

made by providing chills

|

|

Sagarika Mukherjee answered |

Liquid shrinkage and shrinkage during phase change is provided by riser and solid shrinkage can be compensated by providing allowances over the pattern.

Sprue in casting refers to- a)Gate

- b)Runner

- c)Riser

- d)Vertical passage

Correct answer is option 'D'. Can you explain this answer?

Sprue in casting refers to

a)

Gate

b)

Runner

c)

Riser

d)

Vertical passage

|

|

Nisha Singh answered |

- Sprues and runners are some of the largest pieces of excess material that we remove from moulded parts. They are created deliberately during the moulding process as the method in which the molten material enters the mould cavity.

- A sprue is a large diameter channel through which the material enters the mould. A runner is a smaller diameter channel that directs the molten metal is directed towards the individual part (particularly common when casting multiple parts at once).

- The part where the metal reaches its destination and begins to flow into the mould cavity is called the ‘gate’.

- Metal castings, when solid, need to have this extra material removed, however manufacturers of small plastic models most notably use these as a packaging method.

Hence, the correct answer is Option D

To get more insights about metal casting in manufacturing, go through the link:

Metal is to be poured in a cubical cavity of 100 cm side made entirely in drag. The crosssection of the cope box is 200x 150 cm and height is 100 cm. If the densities of metal and sand are 7900 kg/m3 and 1600 kg/m3 respectively. The minimum weight required to be placed on cope in kN to prevent lifting of cope box is __________.- a) 72

- b) 73

Correct answer is between ' 72, 73'. Can you explain this answer?

Metal is to be poured in a cubical cavity of 100 cm side made entirely in drag. The crosssection of the cope box is 200x 150 cm and height is 100 cm. If the densities of metal and sand are 7900 kg/m3 and 1600 kg/m3 respectively. The minimum weight required to be placed on cope in kN to prevent lifting of cope box is __________.

a)

72

b)

73

|

|

Mira Sharma answered |

Metallastatic pressure on the mould = pgh

= 7900 x 9.81 x 1

= 77499 N/m2

Upward force exerted by molten metal on cope = 77499 x 1 x 1

= 77.499 kN

So, minimum weight to keep in cope box

= 77.499 - 4.8

= 72.699 kN

The rate of formation of thickness (in mm) of the metal skin frozen during solidification of pure zinc casting is found to be 2 times of square root of solidification time (in s). What will be the solidification time if thickness of the solid zinc casting is 16 mm?- a) 4.48 sec

- b) 5.24 sec

- c) 3.2 sec

- d) 7.24 sec

Correct answer is option 'B'. Can you explain this answer?

The rate of formation of thickness (in mm) of the metal skin frozen during solidification of pure zinc casting is found to be 2 times of square root of solidification time (in s). What will be the solidification time if thickness of the solid zinc casting is 16 mm?

a)

4.48 sec

b)

5.24 sec

c)

3.2 sec

d)

7.24 sec

|

|

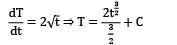

Avinash Sharma answered |

Where T is thickness

At t = 0, T = 0 ⇒ C = 0