GATE Exam > GATE Questions > A machine member is subjected to fluctuating ...

Start Learning for Free

A machine member is subjected to fluctuating stress σ = σ0cos(8πt). The endurance limit of the material is 350 MPa. If the factor of safety used in the design is 3.5 then the maximum allowable value of σ0 is __________ MPa (round off to 2 decimal places).

Correct answer is '100'. Can you explain this answer?

Verified Answer

A machine member is subjected to fluctuating stress σ = σ0...

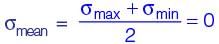

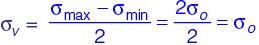

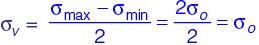

Fluctuating stress,

σ = σocos(8πt)

σmax = σo

σmin =–σo

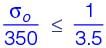

σe = 350 MPa

FOS = 3.5

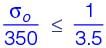

From strength criteria,

σo ≤ 100 MPa

σ = σocos(8πt)

σmax = σo

σmin =–σo

σe = 350 MPa

FOS = 3.5

From strength criteria,

σo ≤ 100 MPa

Most Upvoted Answer

A machine member is subjected to fluctuating stress σ = σ0...

And strain conditions. This can lead to fatigue failure of the machine member over time.

When a machine member is subjected to fluctuating stress and strain conditions, it experiences cyclic loading. This cyclic loading can cause the material to undergo repeated cycles of elastic deformation, plastic deformation, and eventually fatigue failure.

Fatigue failure occurs when the machine member fails under cyclic loading conditions, even though the applied stress levels may be below the material's ultimate strength. This is because the repeated loading and unloading cycles cause microscopic cracks to form and propagate within the material.

These cracks can initiate at stress concentration points or other weak spots in the machine member. As the cyclic loading continues, these cracks grow and eventually lead to catastrophic failure.

To prevent fatigue failure, engineers take several measures. They can design the machine member with appropriate safety factors, ensure a smooth and well-finished surface to reduce stress concentration, and use materials with high fatigue strength.

Additionally, engineers may perform fatigue analysis and testing to estimate the fatigue life of the machine member under specific loading conditions. This helps in determining the expected lifespan of the machine member and allows for necessary maintenance or replacement before failure occurs.

In summary, fluctuating stress and strain conditions can lead to fatigue failure of machine members. Understanding the fatigue behavior of materials and implementing appropriate design and maintenance practices can help prevent such failures and ensure the longevity and reliability of the machine.

When a machine member is subjected to fluctuating stress and strain conditions, it experiences cyclic loading. This cyclic loading can cause the material to undergo repeated cycles of elastic deformation, plastic deformation, and eventually fatigue failure.

Fatigue failure occurs when the machine member fails under cyclic loading conditions, even though the applied stress levels may be below the material's ultimate strength. This is because the repeated loading and unloading cycles cause microscopic cracks to form and propagate within the material.

These cracks can initiate at stress concentration points or other weak spots in the machine member. As the cyclic loading continues, these cracks grow and eventually lead to catastrophic failure.

To prevent fatigue failure, engineers take several measures. They can design the machine member with appropriate safety factors, ensure a smooth and well-finished surface to reduce stress concentration, and use materials with high fatigue strength.

Additionally, engineers may perform fatigue analysis and testing to estimate the fatigue life of the machine member under specific loading conditions. This helps in determining the expected lifespan of the machine member and allows for necessary maintenance or replacement before failure occurs.

In summary, fluctuating stress and strain conditions can lead to fatigue failure of machine members. Understanding the fatigue behavior of materials and implementing appropriate design and maintenance practices can help prevent such failures and ensure the longevity and reliability of the machine.

|

Explore Courses for GATE exam

|

|

Similar GATE Doubts

A machine member is subjected to fluctuating stress σ = σ0cos(8πt). The endurance limit of the material is 350 MPa. If the factor of safety used in the design is 3.5 then the maximum allowable value of σ0 is __________ MPa (round off to 2 decimal places).Correct answer is '100'. Can you explain this answer?

Question Description

A machine member is subjected to fluctuating stress σ = σ0cos(8πt). The endurance limit of the material is 350 MPa. If the factor of safety used in the design is 3.5 then the maximum allowable value of σ0 is __________ MPa (round off to 2 decimal places).Correct answer is '100'. Can you explain this answer? for GATE 2025 is part of GATE preparation. The Question and answers have been prepared according to the GATE exam syllabus. Information about A machine member is subjected to fluctuating stress σ = σ0cos(8πt). The endurance limit of the material is 350 MPa. If the factor of safety used in the design is 3.5 then the maximum allowable value of σ0 is __________ MPa (round off to 2 decimal places).Correct answer is '100'. Can you explain this answer? covers all topics & solutions for GATE 2025 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for A machine member is subjected to fluctuating stress σ = σ0cos(8πt). The endurance limit of the material is 350 MPa. If the factor of safety used in the design is 3.5 then the maximum allowable value of σ0 is __________ MPa (round off to 2 decimal places).Correct answer is '100'. Can you explain this answer?.

A machine member is subjected to fluctuating stress σ = σ0cos(8πt). The endurance limit of the material is 350 MPa. If the factor of safety used in the design is 3.5 then the maximum allowable value of σ0 is __________ MPa (round off to 2 decimal places).Correct answer is '100'. Can you explain this answer? for GATE 2025 is part of GATE preparation. The Question and answers have been prepared according to the GATE exam syllabus. Information about A machine member is subjected to fluctuating stress σ = σ0cos(8πt). The endurance limit of the material is 350 MPa. If the factor of safety used in the design is 3.5 then the maximum allowable value of σ0 is __________ MPa (round off to 2 decimal places).Correct answer is '100'. Can you explain this answer? covers all topics & solutions for GATE 2025 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for A machine member is subjected to fluctuating stress σ = σ0cos(8πt). The endurance limit of the material is 350 MPa. If the factor of safety used in the design is 3.5 then the maximum allowable value of σ0 is __________ MPa (round off to 2 decimal places).Correct answer is '100'. Can you explain this answer?.

Solutions for A machine member is subjected to fluctuating stress σ = σ0cos(8πt). The endurance limit of the material is 350 MPa. If the factor of safety used in the design is 3.5 then the maximum allowable value of σ0 is __________ MPa (round off to 2 decimal places).Correct answer is '100'. Can you explain this answer? in English & in Hindi are available as part of our courses for GATE.

Download more important topics, notes, lectures and mock test series for GATE Exam by signing up for free.

Here you can find the meaning of A machine member is subjected to fluctuating stress σ = σ0cos(8πt). The endurance limit of the material is 350 MPa. If the factor of safety used in the design is 3.5 then the maximum allowable value of σ0 is __________ MPa (round off to 2 decimal places).Correct answer is '100'. Can you explain this answer? defined & explained in the simplest way possible. Besides giving the explanation of

A machine member is subjected to fluctuating stress σ = σ0cos(8πt). The endurance limit of the material is 350 MPa. If the factor of safety used in the design is 3.5 then the maximum allowable value of σ0 is __________ MPa (round off to 2 decimal places).Correct answer is '100'. Can you explain this answer?, a detailed solution for A machine member is subjected to fluctuating stress σ = σ0cos(8πt). The endurance limit of the material is 350 MPa. If the factor of safety used in the design is 3.5 then the maximum allowable value of σ0 is __________ MPa (round off to 2 decimal places).Correct answer is '100'. Can you explain this answer? has been provided alongside types of A machine member is subjected to fluctuating stress σ = σ0cos(8πt). The endurance limit of the material is 350 MPa. If the factor of safety used in the design is 3.5 then the maximum allowable value of σ0 is __________ MPa (round off to 2 decimal places).Correct answer is '100'. Can you explain this answer? theory, EduRev gives you an

ample number of questions to practice A machine member is subjected to fluctuating stress σ = σ0cos(8πt). The endurance limit of the material is 350 MPa. If the factor of safety used in the design is 3.5 then the maximum allowable value of σ0 is __________ MPa (round off to 2 decimal places).Correct answer is '100'. Can you explain this answer? tests, examples and also practice GATE tests.

|

Explore Courses for GATE exam

|

|

Signup for Free!

Signup to see your scores go up within 7 days! Learn & Practice with 1000+ FREE Notes, Videos & Tests.